Test method for measuring ultimate bearing capacity of ceiling support system

A technology of ultimate bearing capacity and support system, applied in the field of construction, can solve the problems of limited theoretical research of calculation results, undisclosed ultimate bearing capacity, reference value of engineering examples to be verified, etc., to achieve fast and convenient testing methods, strong practicability, and good The effect of mentoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A test method for measuring the ultimate bearing capacity of a suspended ceiling support system, comprising the following method steps:

[0030] (1) Build a ceiling support structure system;

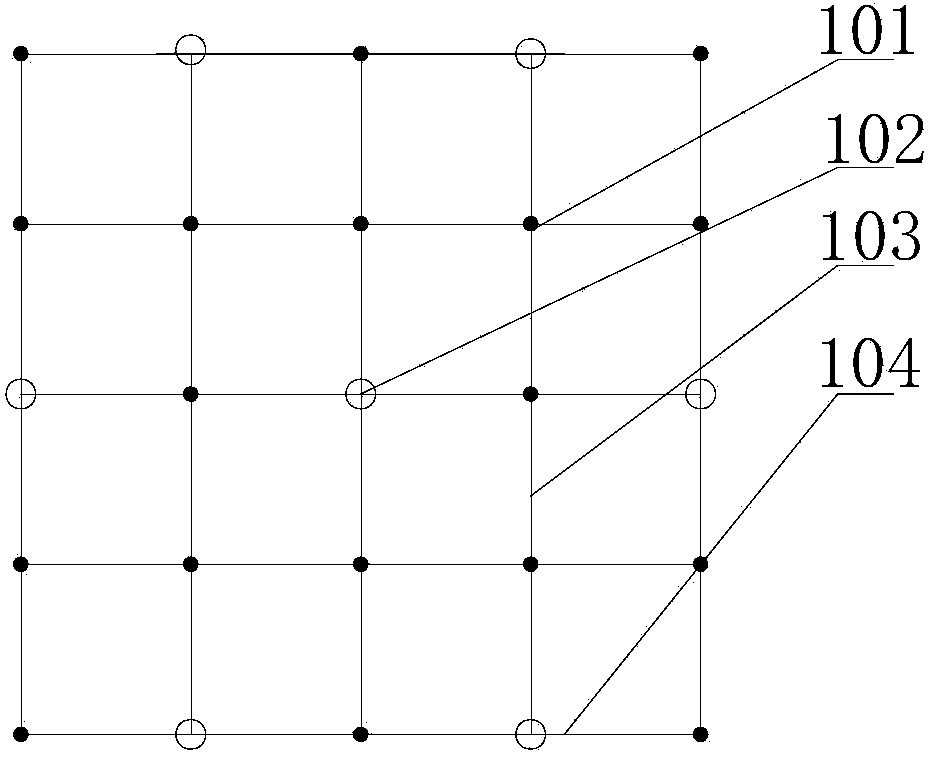

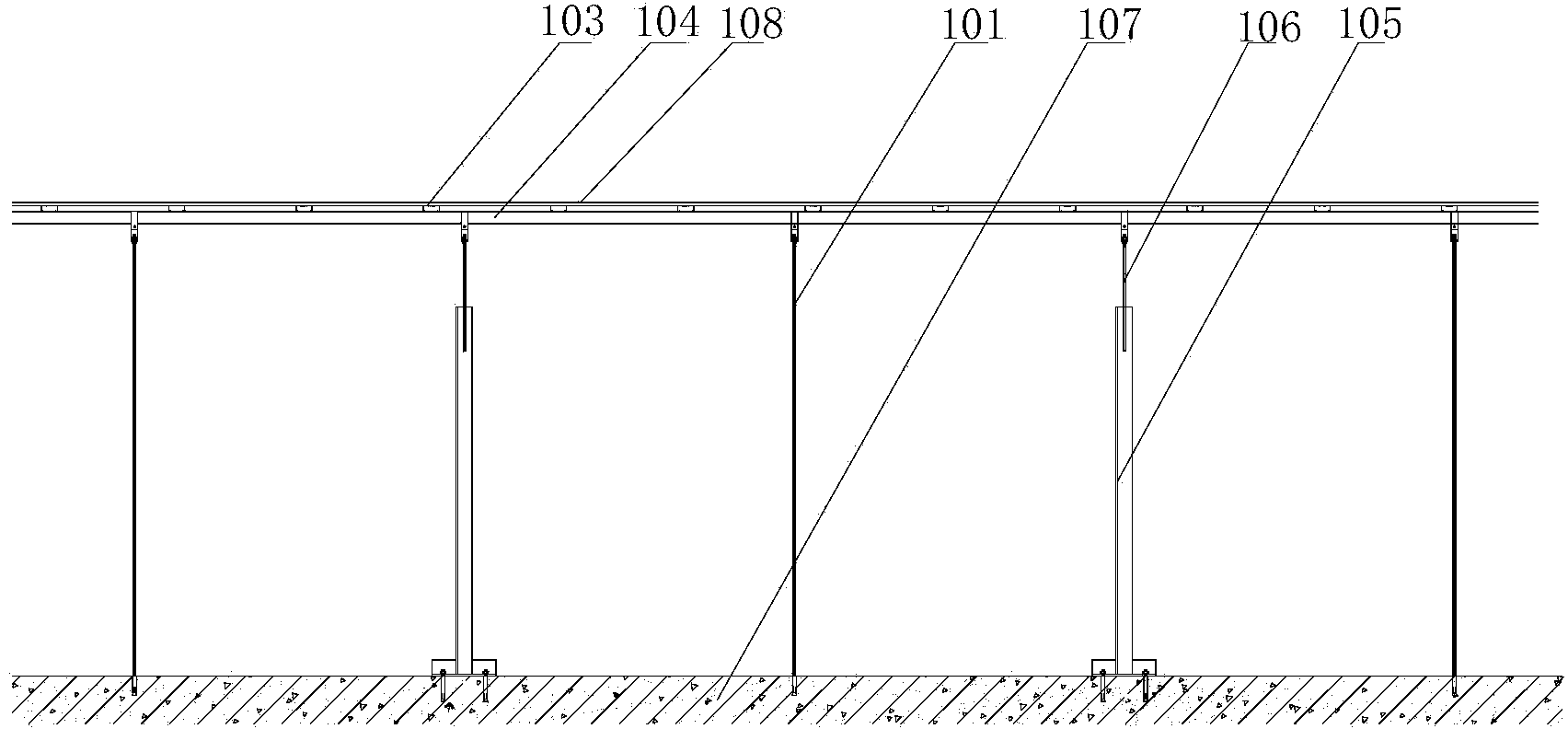

[0031] see figure 1 with figure 2 . The suspended ceiling support structure system is a reinforced anti-support structure system. The reinforced anti-support structure system includes a suspender 101, a reinforced anti-support 102, an auxiliary keel 103 and a main keel 104. The main keel 104 and the auxiliary keel 103 are vertically connected. The lower ends of the suspender 101 and the reinforced counter support 102 are vertically connected to the main keel 104, and the suspender 101 and the reinforced counter support 102 are arranged one by one along the direction of the main keel 104, that is, each suspender A reinforced anti-support 102 is added to the rod 101, and the suspension rod 101 and the reinforced anti-support 102 are arranged in a three-to-one arrangement along t...

Embodiment 2

[0051] The test method and steps of measuring the ultimate bearing capacity of the suspended ceiling support system in embodiment 2 are basically the same as in embodiment 1, and the difference is that the loading device in step (4) is a water adding device, and the water adding device is a square leak-proof water injection container. The scale value is marked on the outside of the container. When the pressure is applied, add water quantitatively to the water adding equipment, and ensure that the water adding equipment is placed horizontally.

Embodiment 3

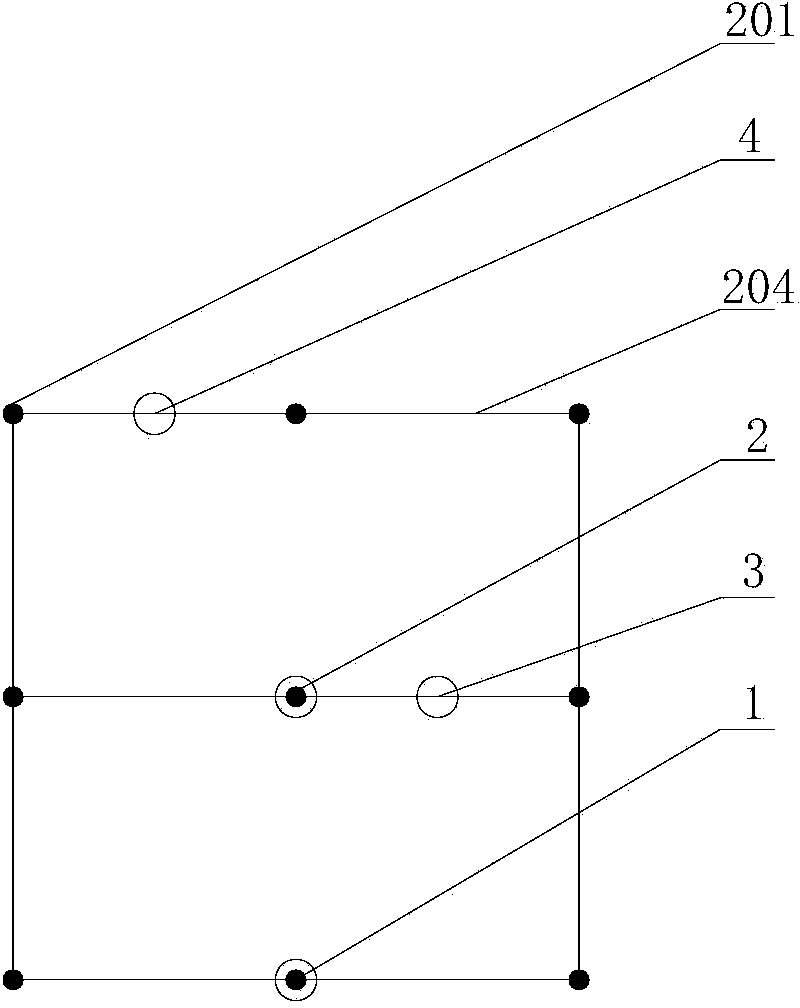

[0053] The test method of measuring the ultimate bearing capacity of the suspended ceiling support system of embodiment 3 is basically the same as that of embodiment 1, and the difference is that the suspended ceiling support structure system in the step (1) is a conversion support structure system, see image 3 with Figure 4 , the conversion support structure system includes a suspender 201, an angle steel 202, an auxiliary keel 203 and a main keel 204, the main keel 204 is vertically connected to the auxiliary keel 203, the upper end of the suspender 201 is fixedly connected to the angle steel 202, and the suspender 201 The lower end is vertically connected with the main keel 204 . According to step (2), when the conversion support structure system is fixed upside down on the floor surface 205, the main keel 204 and the auxiliary keel 203 of the conversion support structure system are placed on top, and the loading equipment is placed and fixed on the main keel and the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com