Uniform axial force applying device for graphical heterogeneous bonding of silicon-based III-V epitaxial material

A III-V, epitaxial material technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of wafer parallelism deviation, uneven force, crystal orientation shift, etc., to achieve firm bonding , to achieve the effect of automatic leveling and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

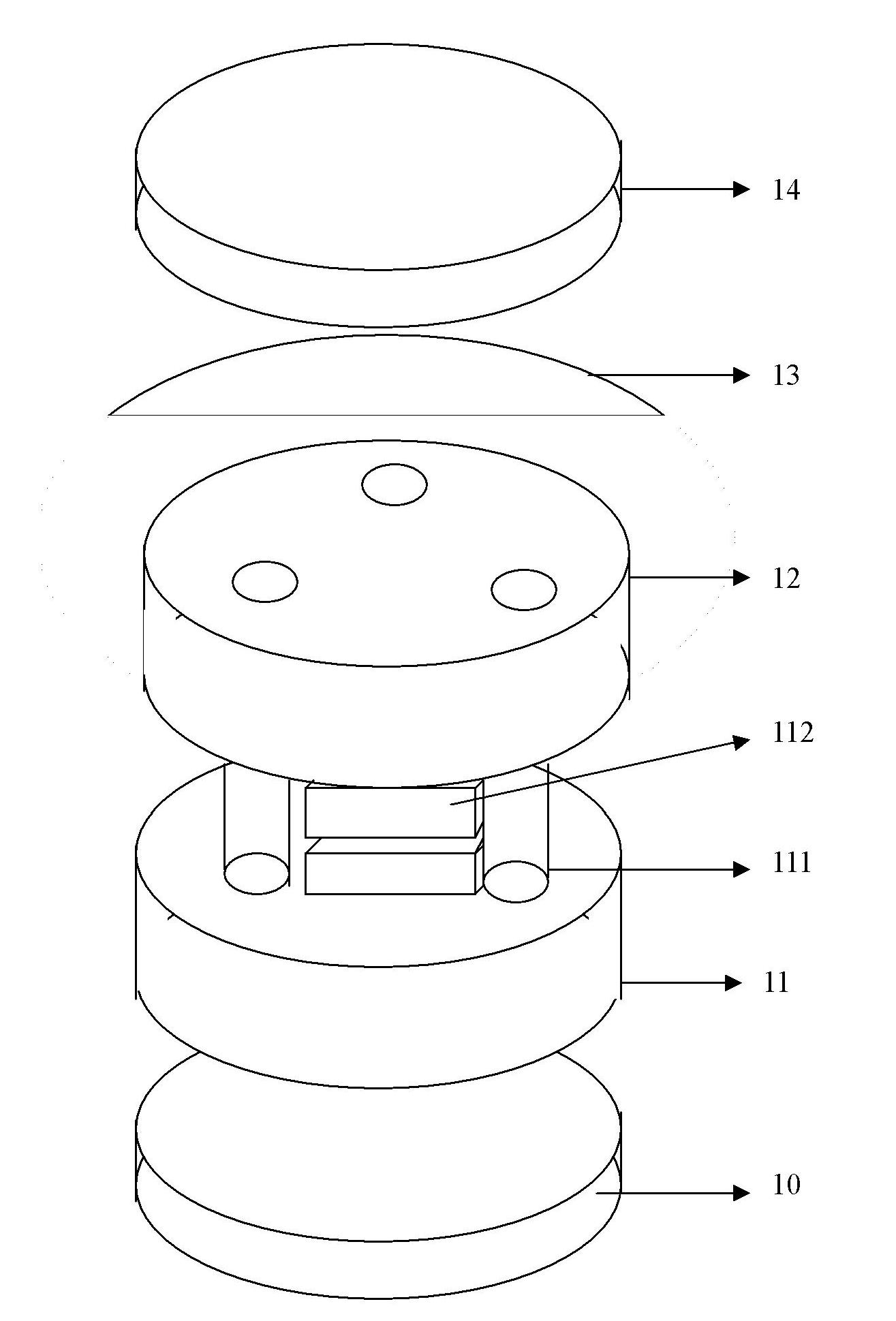

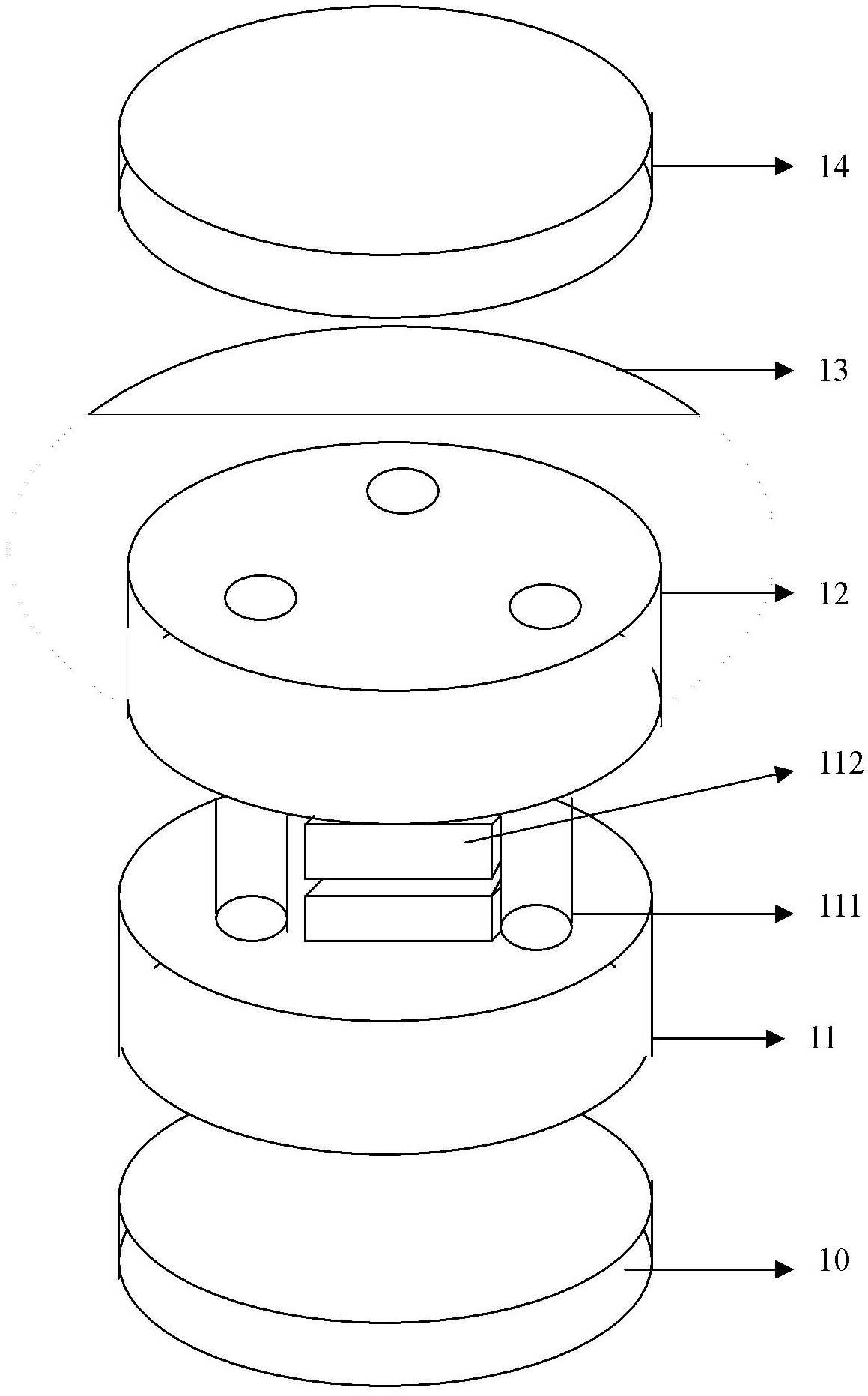

[0020] see figure 1 As shown, the present invention provides a silicon-based III-V epitaxial material pattern heterogeneous bonding uniform axial force applying device, including:

[0021] The lower force application cover plate 10 is in the shape of a disc; the lower force application cover plate 10 will be fixed to the piston end of the upper end cylinder of the bonding equipment through an adjustable connecting part. In the cylinder, the pressure is controlled by the amount of air inflated, and the lower force-applying cover plate 10 is pushed to move or the pressure is changed. The lower force-applying cover plate 10 is made of stainless steel and is polished. It is a pair with the upward force cover plate 14, and the features are the same. The upper and lower force application covers can be adjusted to ensure parallelism.

[0022] Undertake holder 11, this lower accept holder 11 is disc shape, has a plurality of round holes evenly distributed on it (the number of the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com