Novel numerical control carving machine

A CNC engraving machine and a new type of technology, applied in the field of engraving machines, can solve the problems of too deep engraving, heavy workload, unusable graphics, etc., and achieve the effects of improving engraving accuracy, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

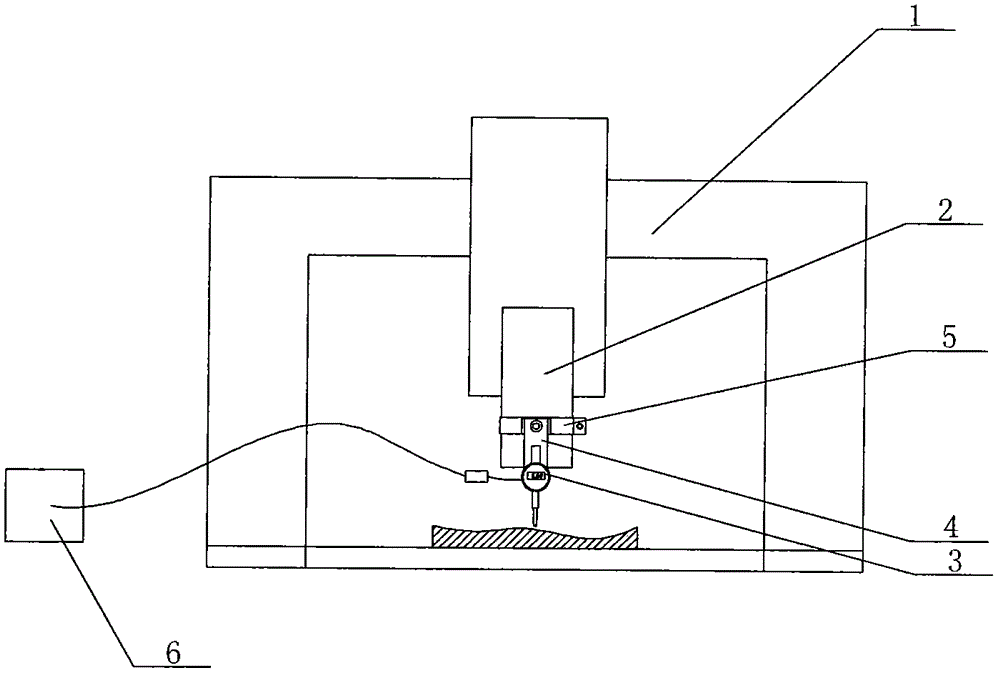

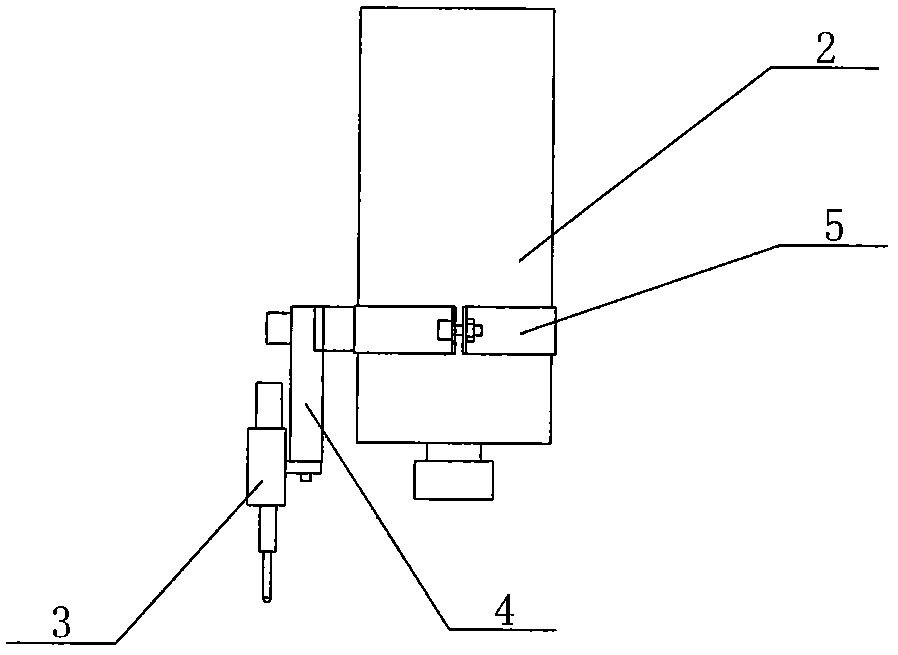

[0013] See figure 1 with figure 2 , This specific embodiment adopts the following technical solutions: it includes the engraving host 1, the spindle 2, the engraving host 1 is provided with the spindle 2, and it also includes the digital display dial indicator 3, the connecting bakelite block 4, and the stainless steel hoop 5. The stainless steel iron hoop 5 is set at the lower part of the main shaft 2 by fixing bolts, and the front side of the stainless steel iron hoop 5 is connected with a connecting bakelite block 4 by fixing bolts, and the lower part of the connecting bakelite block 4 is connected with a digital indicator 3 by fixing bolts. The digital indicator 3 is electrically connected to the computer 6 through a wire.

[0014] The operation steps of this specific implementation are as follows:

[0015] 1. Divide the workpiece into several small areas through the software set in the computer (you can adjust it according to the actual situation during use, the more the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com