Numerical control flexible roll bending plate bending machine for small-diameter thin-walled pipe body

A technology of thin-walled tubes and small diameters, which is applied in the field of flexible bending of small-diameter thin-walled tubes in the field of CNC plate rolling machines. It can solve the problems of fewer finished products, the inability of plate rolling machines to roll and shape, and high prices, so as to improve production efficiency. , not easy to be scratched, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

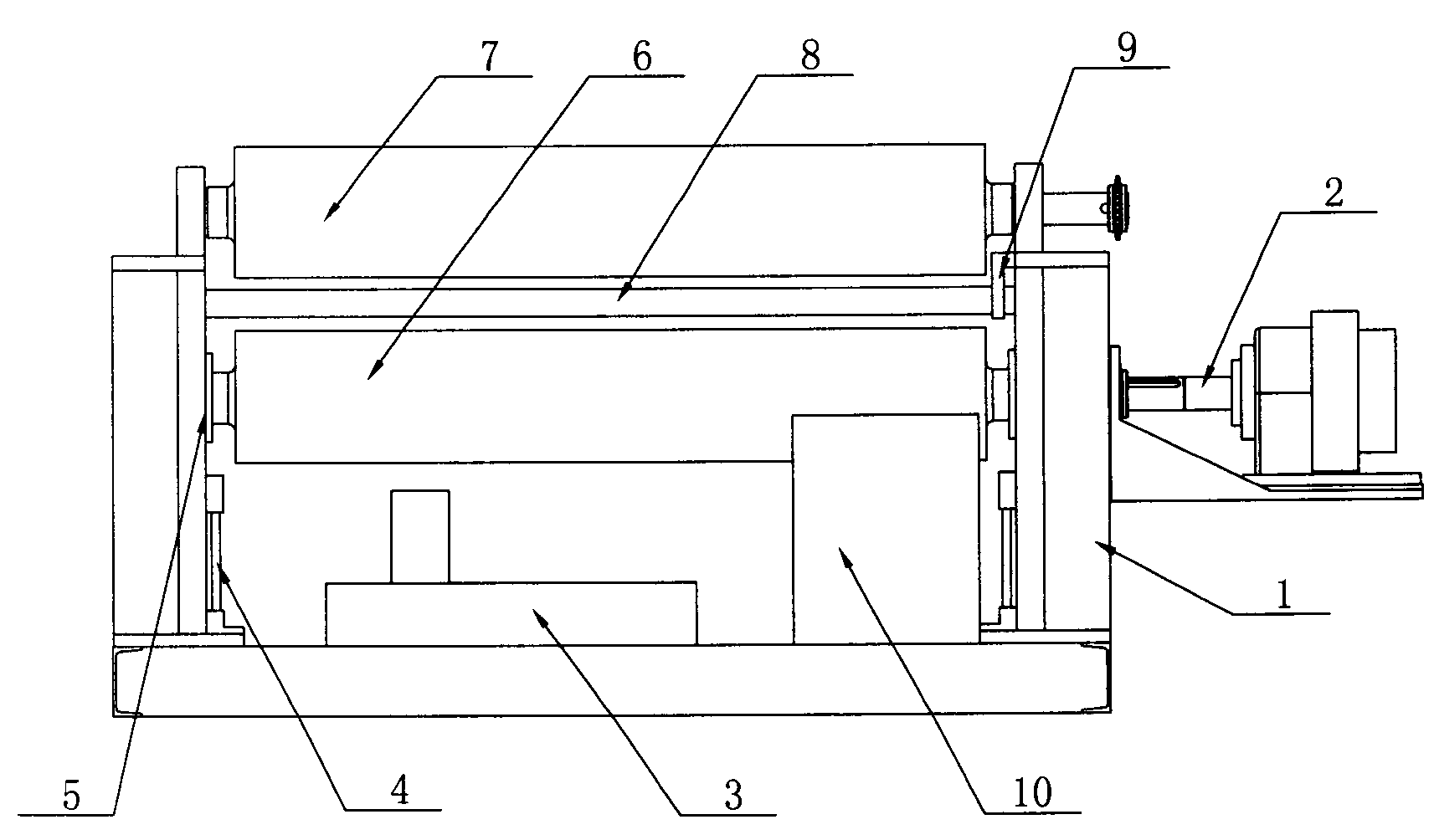

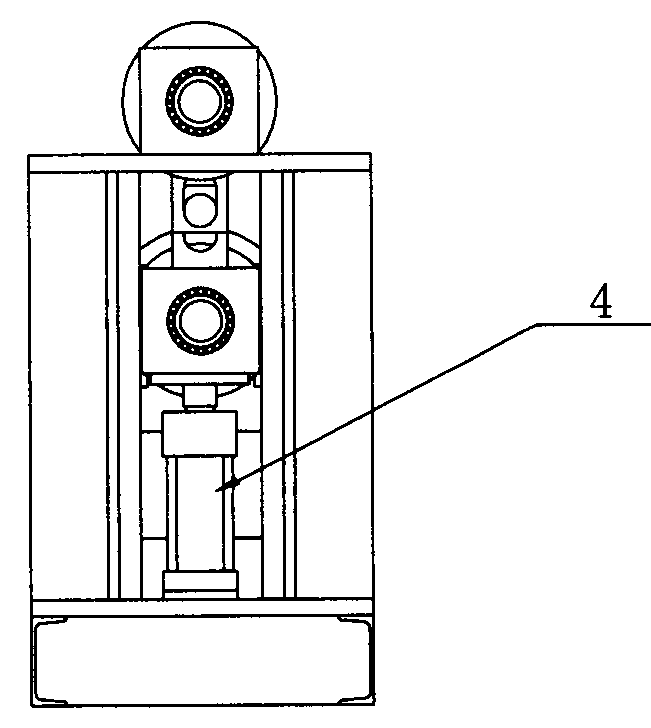

[0018] See Figure 1-Figure 2 , This specific embodiment adopts the following technical solutions: it includes frame 1, transmission device 2, hydraulic station 3, oil cylinder 4, displacement sensor 5, lower rubber roller 6, upper rubber roller 7, mold roller 8, mold follow-up restraint device 9. PLC control cabinet 10, the lower rubber roller 6 is installed on the frame 1, the rotating shaft of the lower rubber roller 6 is connected with the transmission device 2, the displacement sensor 5 is arranged between the lower rubber roller 6 and the upper rubber roller 7, and two oil cylinders 4 The piston rods are respectively connected to the two ends of the lower rubber roller 6, the hydraulic station 3 is arranged at the lower end of the frame 1, one side of the hydraulic station 3 is provided with a PLC control cabinet 10, and the upper side of the lower rubber roller 6 is provided with a mold roller 8 , The upper side of the mold roller 8 is provided with a squeegee roller 7, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com