Patents

Literature

92results about How to "Improve engraving accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

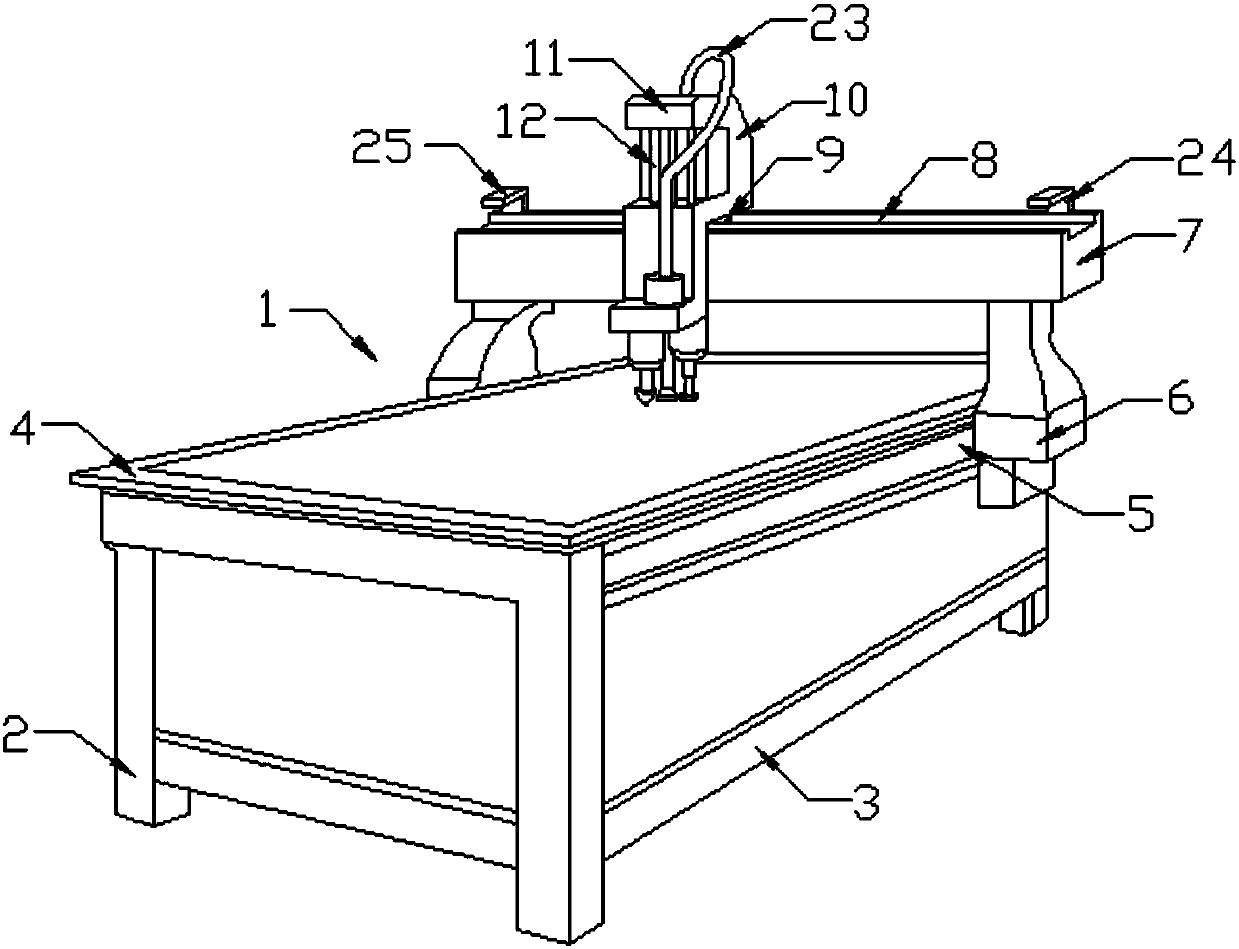

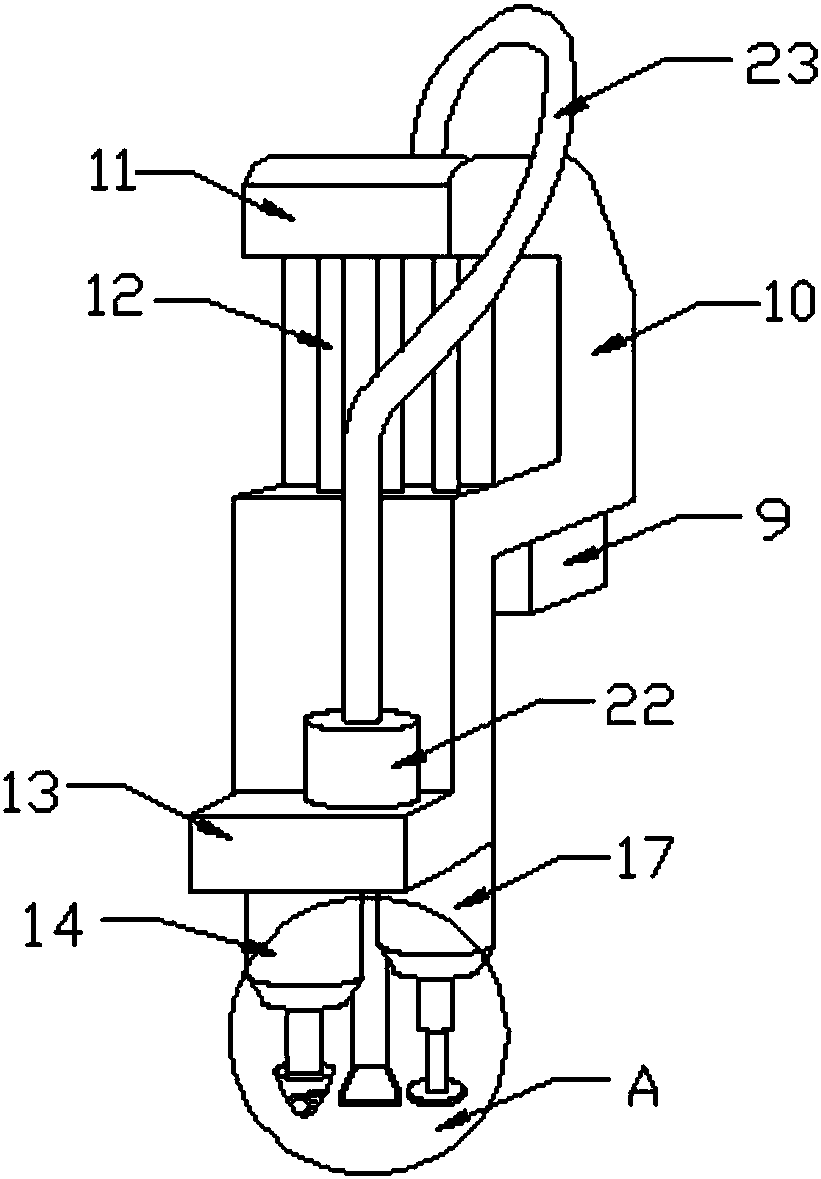

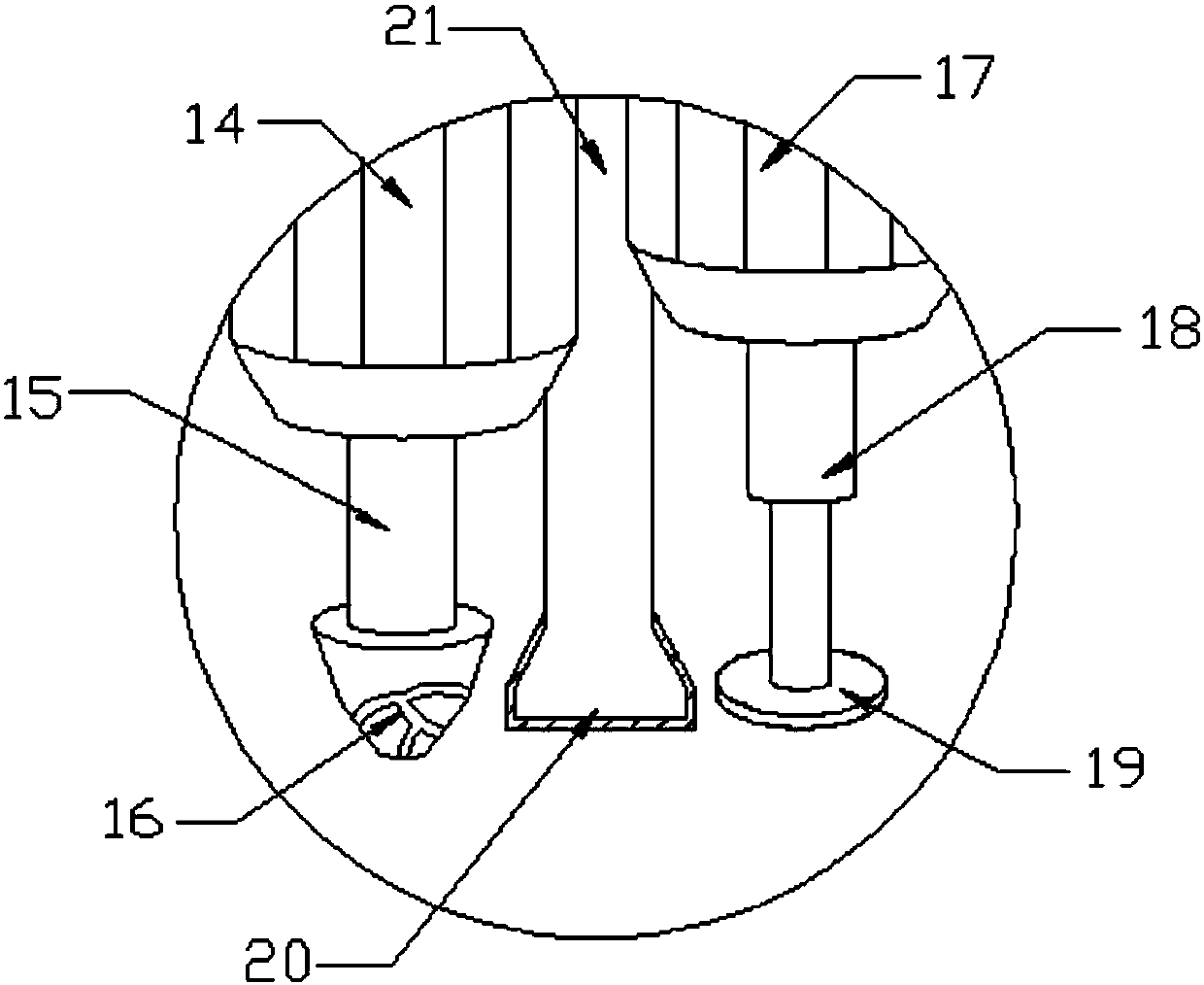

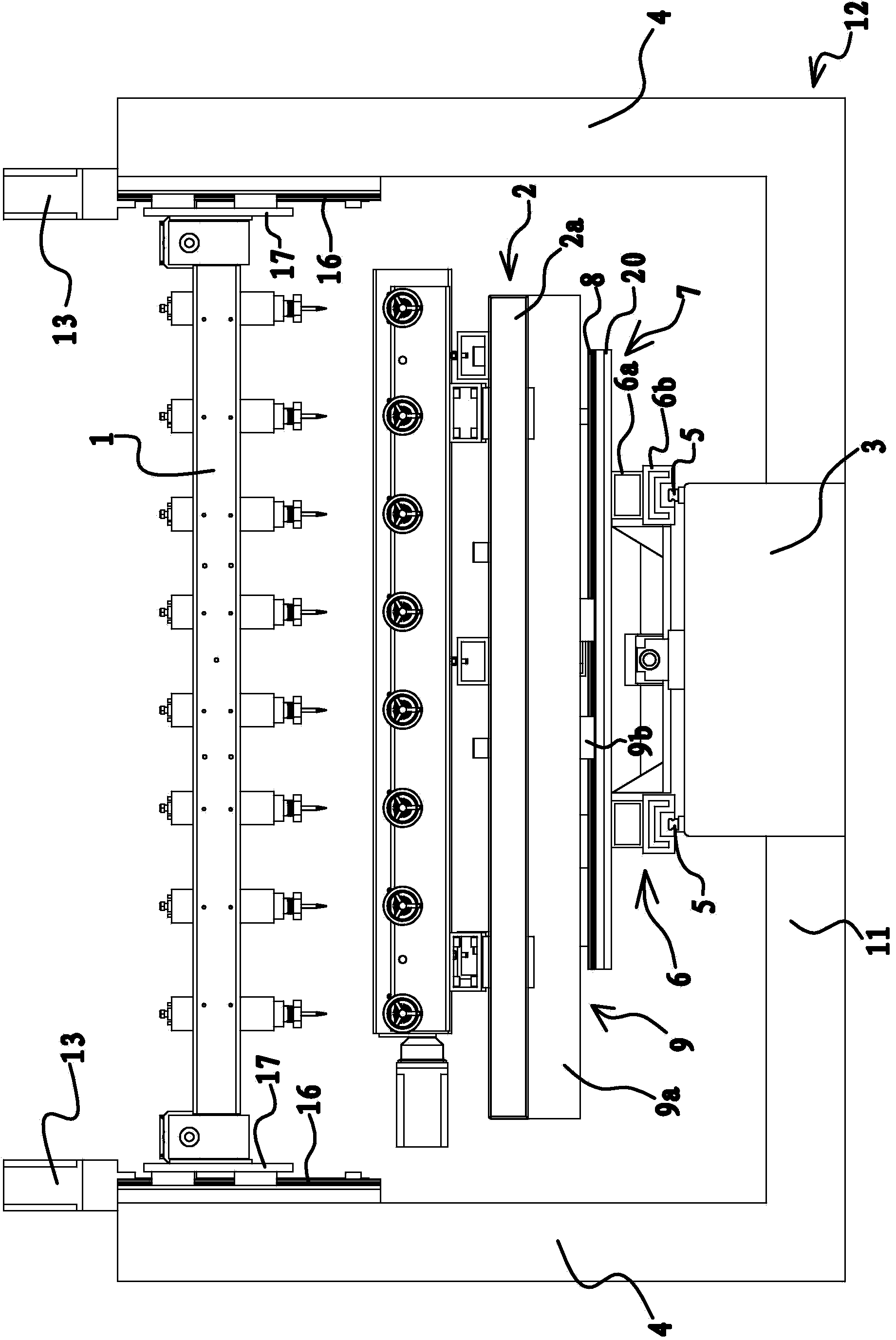

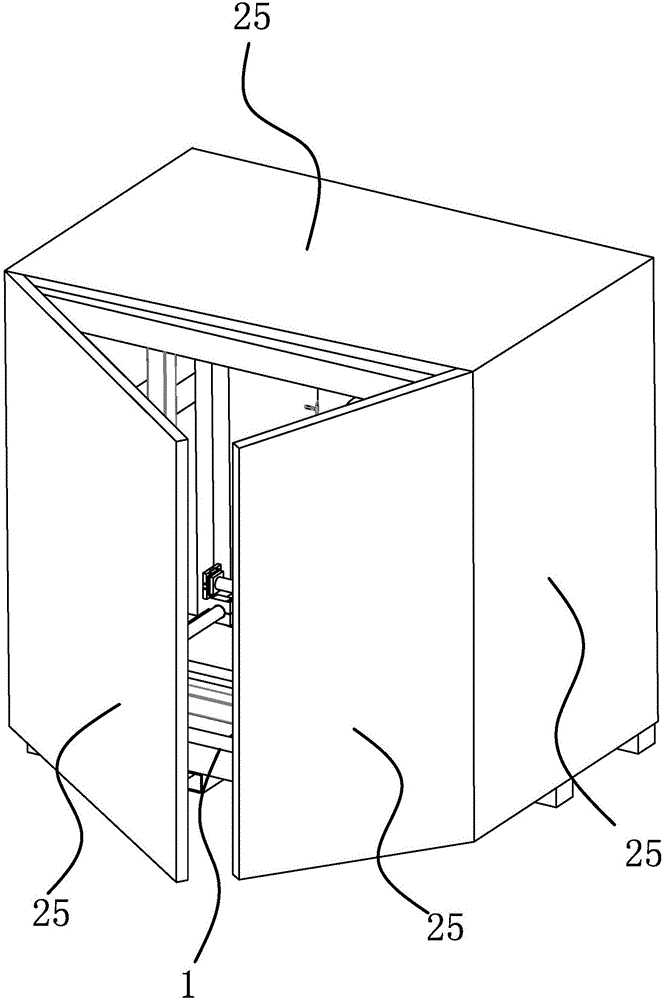

Engraving device for wood board processing

The invention discloses an engraving device for wood board processing. The engraving device for wood board processing comprises an engraver main body and a support, wherein the support is fixedly mounted at the bottom of the engraver main body; the engraving device for wood board processing further comprises a machine base, an engraving workbench, side guide rails, first moving sliding bases, a moving cross beam, a transverse guide rail, a second moving sliding base and a vertical column. The engraving device for wood board processing can polish wood board burrs, formed by engraving, on the surface of an engraved wood board, so that the surface smoothness of the engraved wood board is ensured; a large amount of wood dust and dust, generated in the processes of engraving the wood board by an engraving cutter bit and removing the burrs by a polishing cutter wheel, are sucked from the surface of the wood board through a dust suction fan and a dust suction hood, so that the wood dust generated in the engraving process is prevented from scattering on the surface of the wood board to influence the wood board engraving accuracy of the engraving cutter bit, and the wood dust and the dust are prevented from diffusing into air to cause the environment pollution and endanger the health of people who work in the environment for a long time; an adopted dust suction way helps to clean up thewood dust and the dust in an engraving groove.

Owner:WENZHOU CHUYING TECH CO LTD

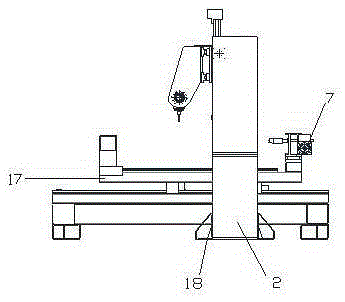

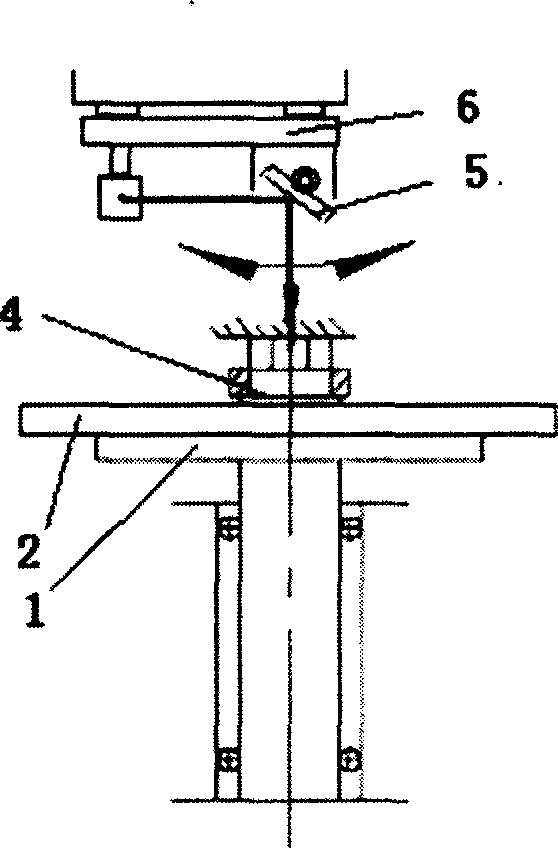

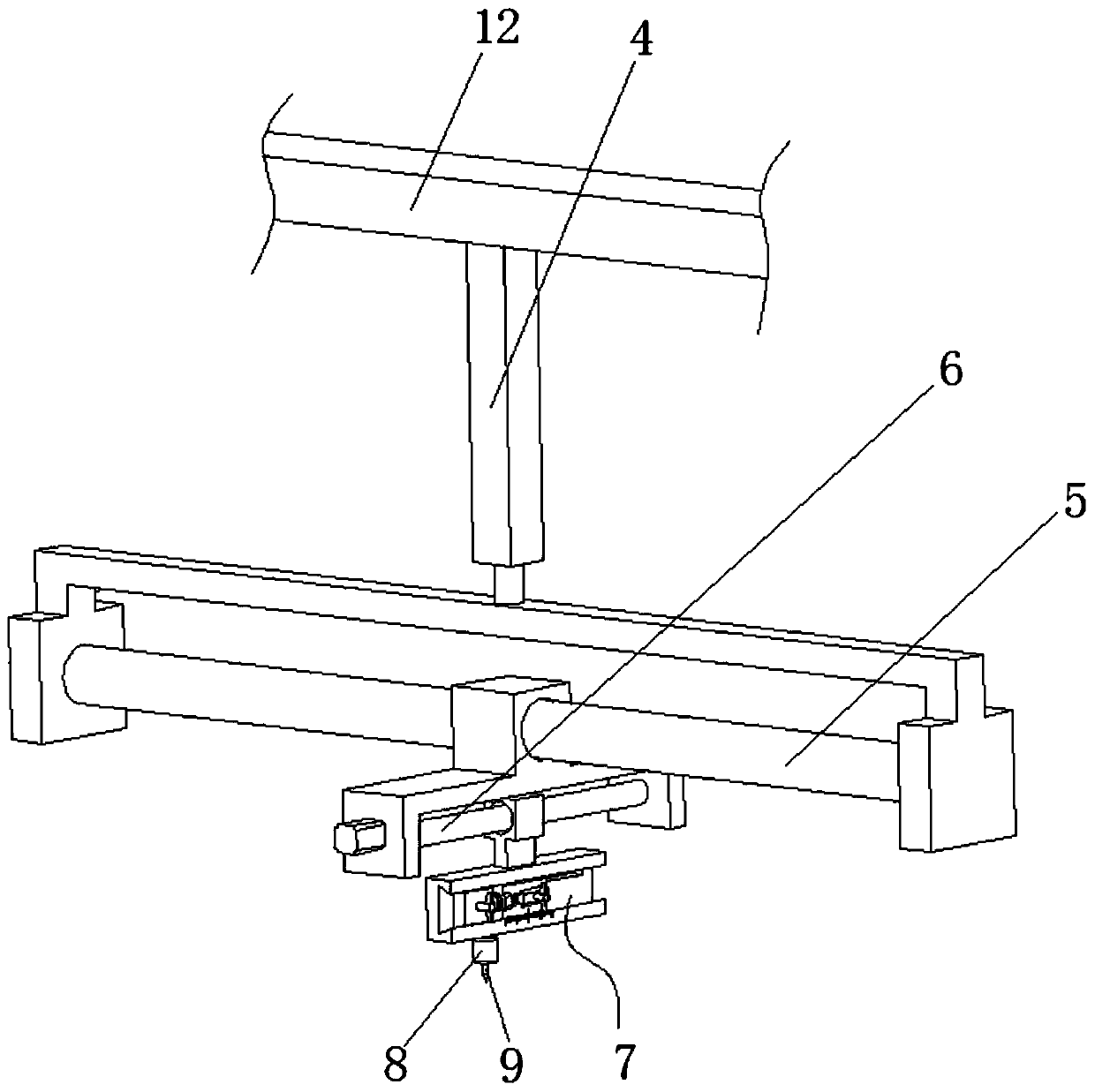

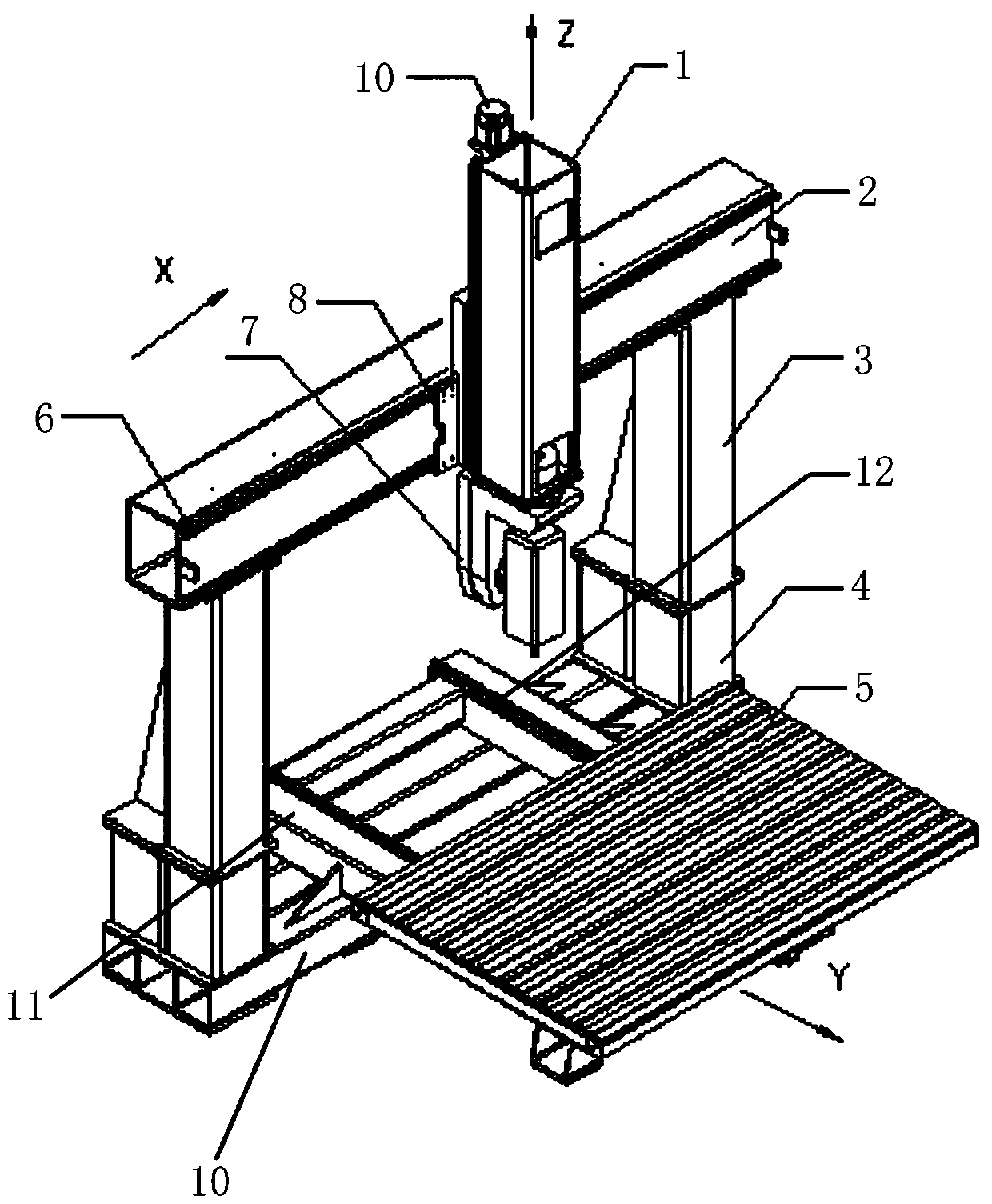

Three-dimensional engraver

ActiveCN104290513AImprove engraving accuracySimple connection and cooperationModel makingMechanical engineeringEngineering

The invention discloses a three-dimensional engraver and belongs to the technical field of the machinery. The three-dimensional engraver solves the problem that the present three-dimensional engraver is low in precision. The three-dimensional engraver comprises a rack and an engraving platform on the rack, wherein the upper part of the engraving platform is provided with a cutter frame for mounting a cutter, the rack comprises a pedestal and an upright arranged on two sides of the pedestal, a lifting motor to move up and down the cutter frame is arranged between the upright and the cutter frame, the pedestal is provided with a longitudinal motor which drives a drive plate to be longitudinally reciprocated along a horizontal direction, and the drive plate is provided with a horizontal motor which drives a working platform to be horizontally reciprocated along the horizontal direction. In the engraver, there is simple connection relation between the cutter frame and the upright and the cutter frame is steadily moved so as to improve the engraving precision.

Owner:台州耐科兴智能装备有限公司

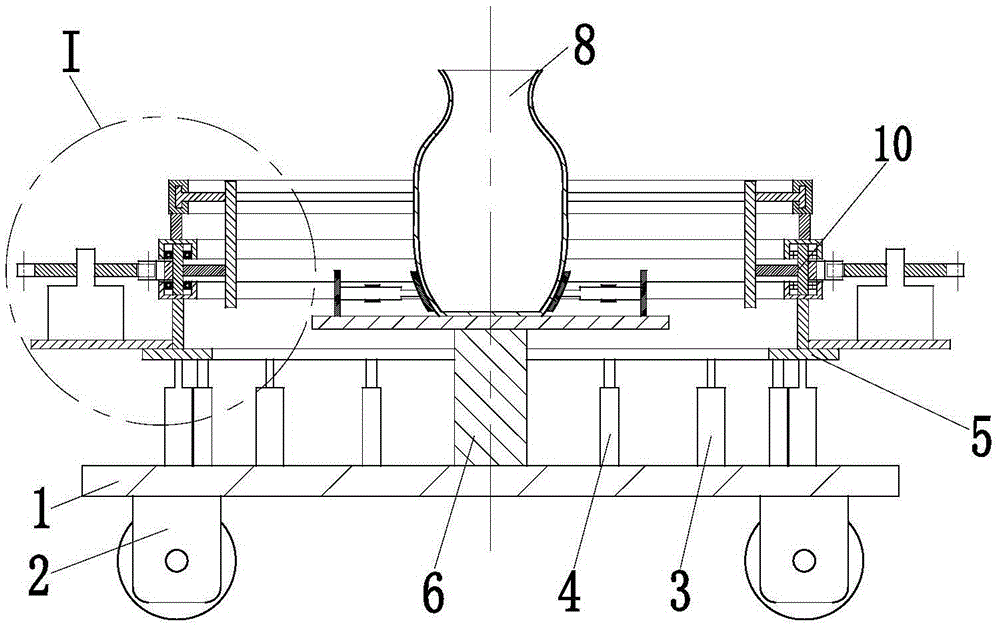

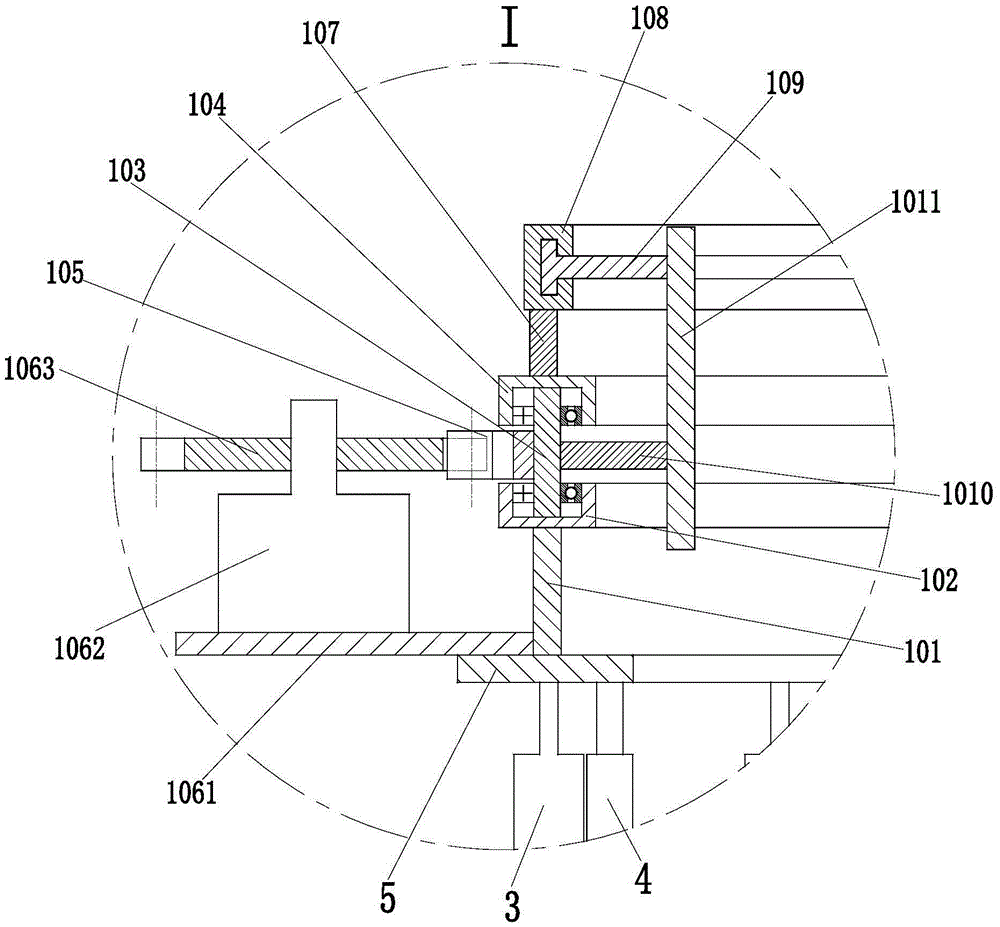

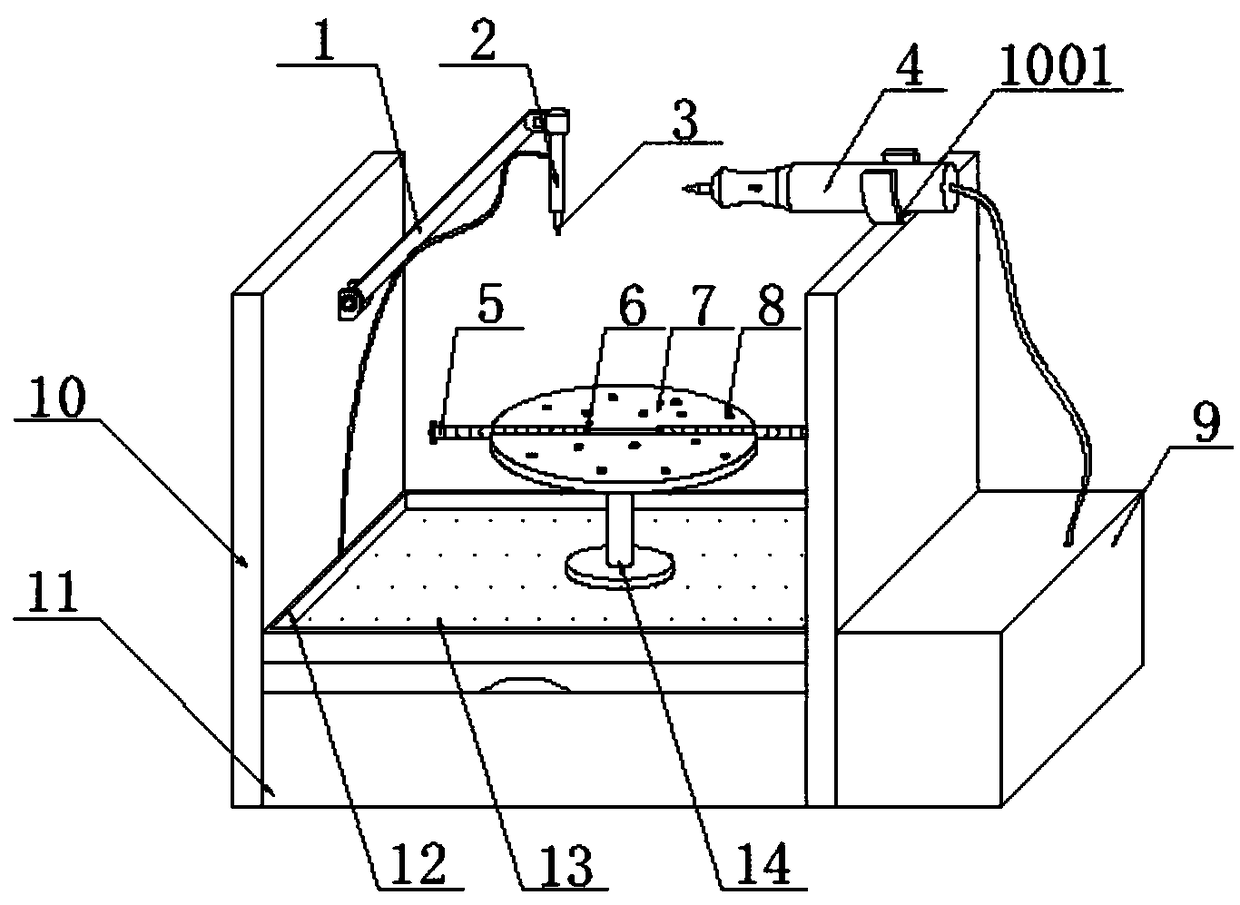

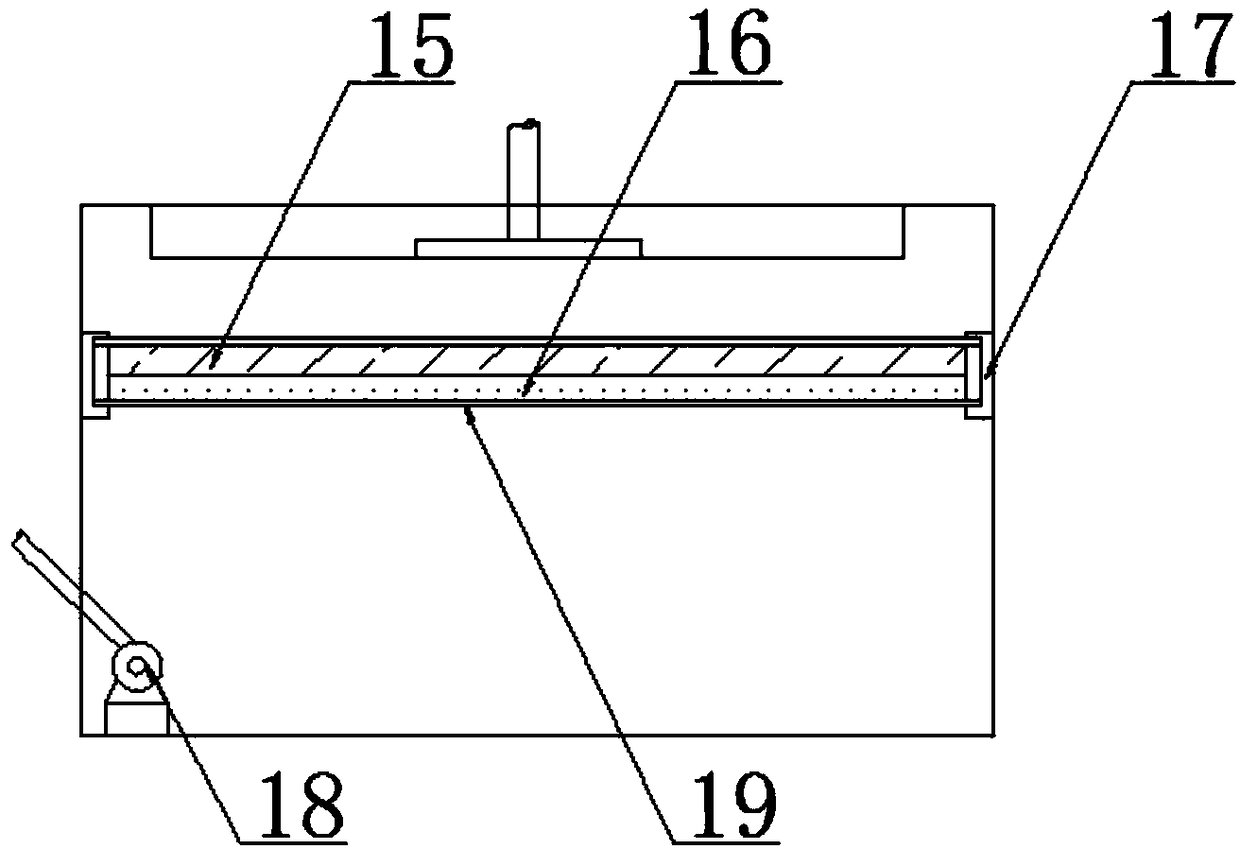

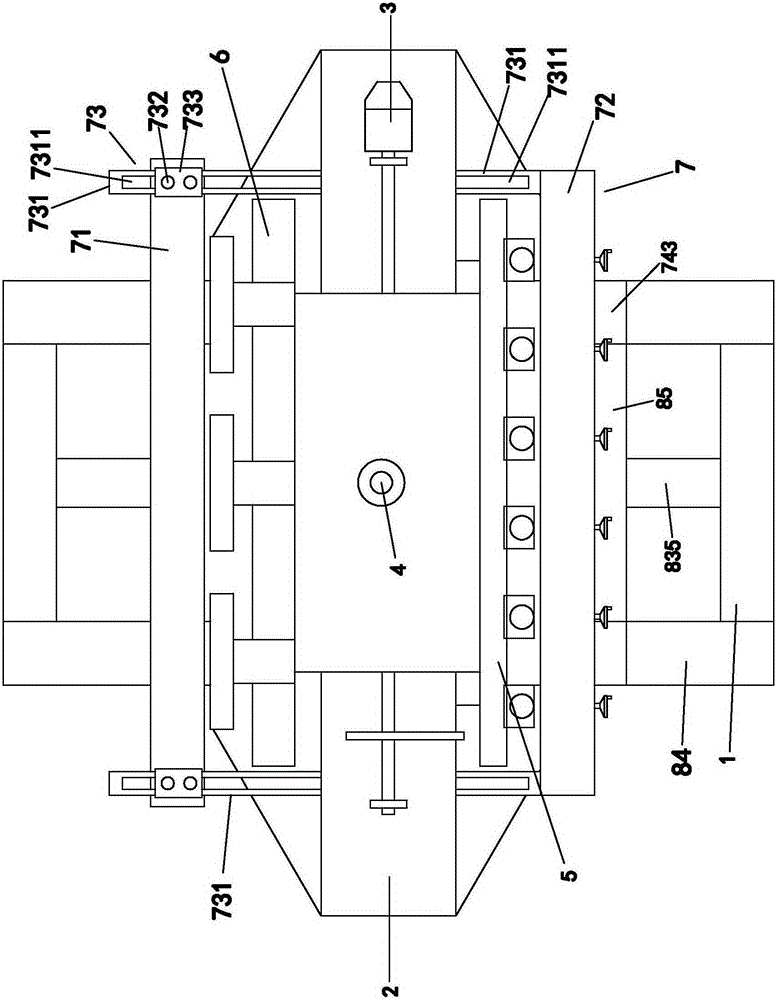

Special engraving equipment for full-automatic ceramic surface processing

InactiveCN105619577ARealize automatic engraving functionShort processing timeCeramic shaping apparatusModel makingHydraulic cylinderEngraving

The invention relates to special engraving equipment for full-automatic ceramic surface processing. The equipment comprises a baseplate; four universal wheels are symmetrically mounted on the lower end surface of the baseplate; a lap of hydraulic cylinders 1 is peripherally mounted at the middle part of the baseplate; extension rods are respectively mounted between every two adjacent hydraulic cylinders 1; mounting pieces are respectively mounted at the top ends of the hydraulic cylinders 1 and the extension rods; the extension rods achieve a function of assisting movement of the hydraulic cylinders 1; the hydraulic cylinders 1 drive the mounting pieces to move up and down under assistance of the extension rods; a fixed column is welded at the middle part of the upper end surface of the baseplate; a mounting circular table is welded on the upper end surface of the fixed column; and a ceramic body is placed at the middle part of the mounting circular table. The equipment can solve such difficulties as long processing time, high labor intensity, high engraving error rate and low engraving efficiency in a traditional manual engraving processing mode, can realize full-automatic ceramic surface engraving function, and has such advantages as short processing time, high engraving precision, no need of manual processing and high engraving efficiency.

Owner:唐山市开平区雅风陶瓷厂

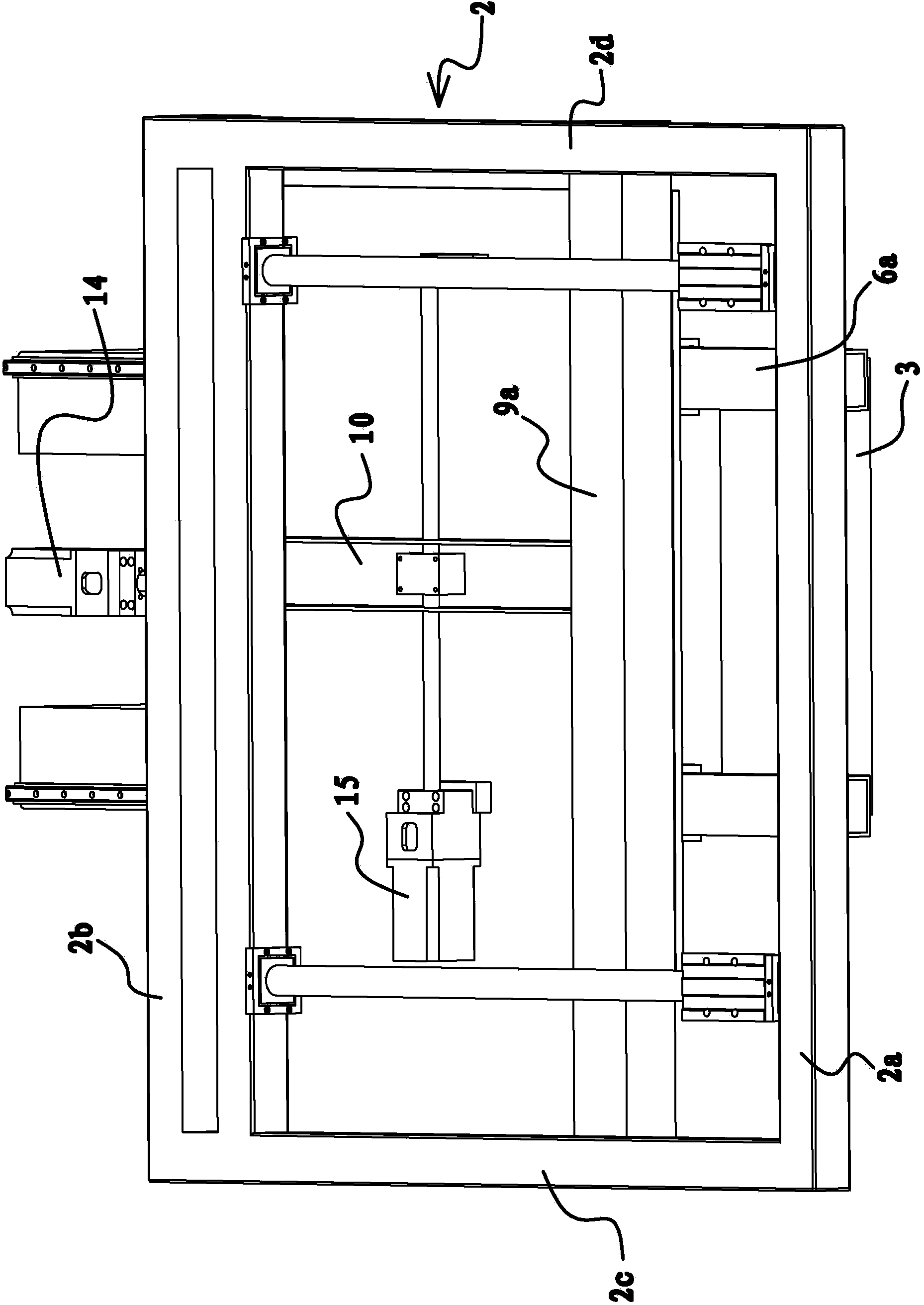

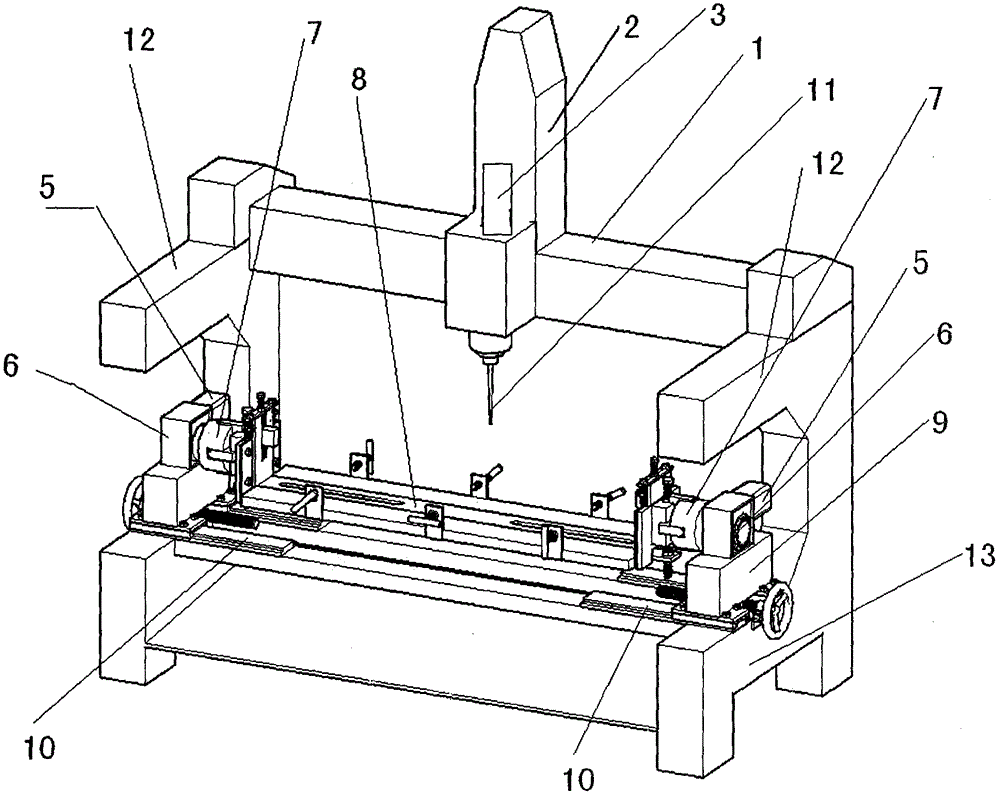

Cylindrical engraving machine

The invention discloses a cylindrical engraving machine, which solves the technical problem that engraving heads of an existing engraving machine have unclear location and low engraving precision, and the like. An X-directional driving device is arranged between a plurality of engraving heads and portal cranes, a Y-directional driving device with two synchronous sides is arranged between a left upright column, a right upright column and a bed body, the engraving heads realize a Z-directional motion; a work-piece is driven by a U-shaft driving device to automatically rotate, a control system controls the engraving heads to locate in the X direction, the Y direction and the Z direction; an engraving motor automatically rotates to implement an engraving operation. As the X direction adopts agear rack transmission mode, and the location is precise, the Y direction adopts a two-side synchronous driving mode, so the location precision is further improved. A plurality of three-jaw chucks are synchronously rotated, work-pieces are fixed on the three-jaw chucks, the circumferential location of the work-pieces are accurate, two ends of the work-pieces are respectively fixed by a top core and a centre of the chucks, and thus the work-pieces cannot generate a displacement deviation in an axial direction; during processing, the work-pieces are firmly fixed, so a higher load can be supported by the work-pieces.

Owner:安庆市宏大涛业精啄数控科技有限公司

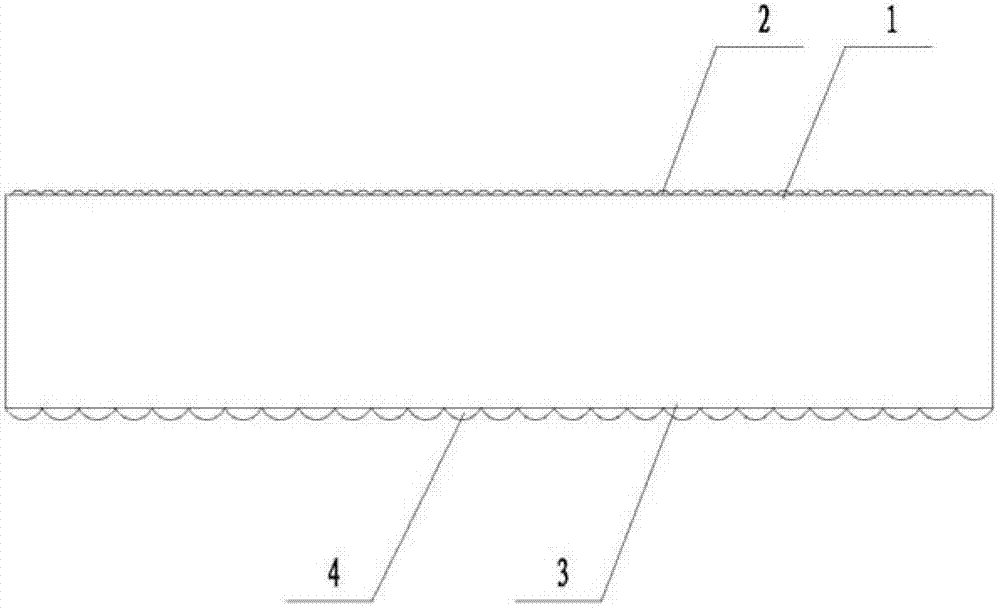

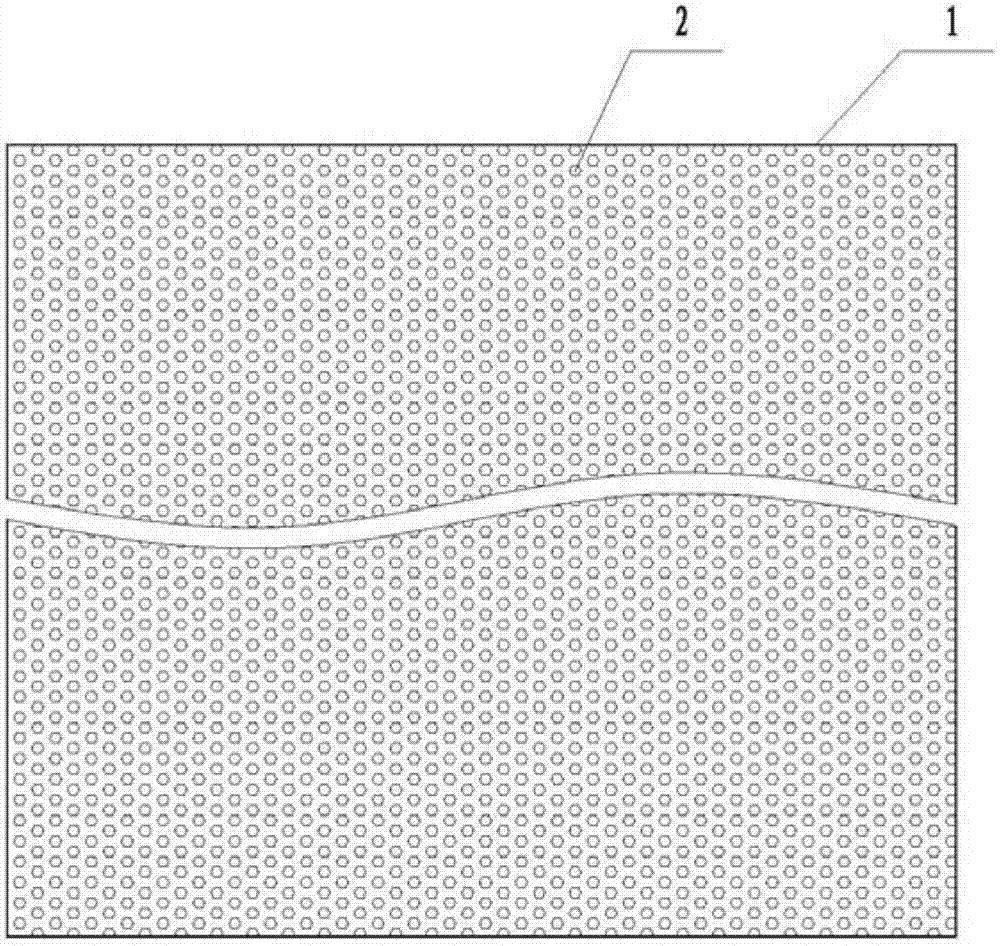

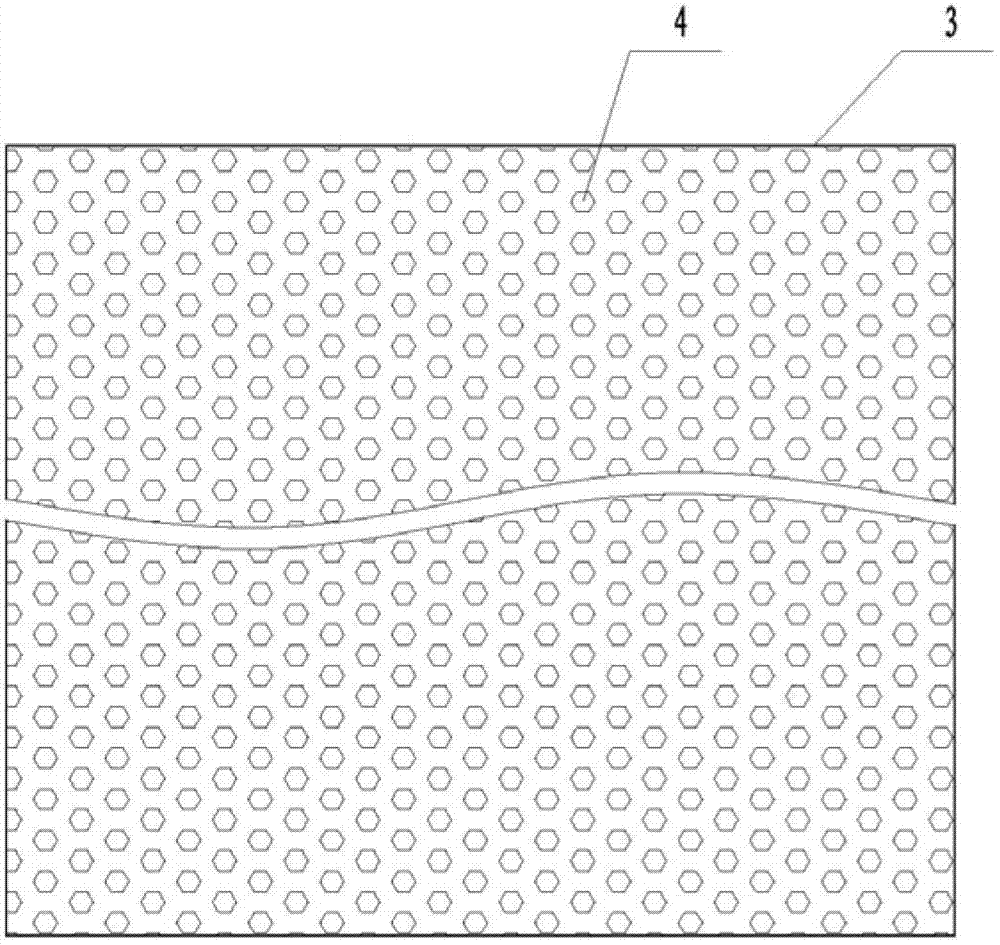

Light guide plate and manufacturing method of light guide plate as well as backlight module and display device

InactiveCN102928911AIncrease display brightnessImprove product qualityPolishing machinesPoint-like light sourceLight guideDisplay device

The invention relates to the technical field of display and particularly relates to a light guide plate capable of utilizing a micro-penetration surface to collect light and a manufacturing method of the light guide plate as well as a backlight module and a display device. An emergent surface of the light guide plate is the micro-penetration surface; the micro-penetration surface comprises a plurality of micro-penetration points and the micro-penetration points are provided with convex surfaces; and the bottom surface of the light guide plate is a net surface and the net surface comprises a plurality of net points and the net points are provided with convex surfaces. The manufacturing method of the light guide plate comprises the steps of: presetting a micro-penetration point distribution pattern by a precision engraving machine; putting a micro-penetration surface die core base plate into a precision engraving machine; engraving the micro-penetration surface die core base plate into a micro-penetration face die core according to the micro-penetration point distribution pattern; assembling the micro-penetration surface die core and a light guide plate die core into a light guide plate die; and injecting and molding into the light guide plate by the light guide plate die. A micro-penetration surface design is adopted and directions of all scattering lights in the light guide plate can be adjusted by using the micro-penetration surface to collect the scattering lights; and the development brightness and the influence definition of a liquid crystal liquid screen are improved and the product quality is improved.

Owner:BOE TECH GRP CO LTD +1

Process for engraving three-dimensional large-sized copper pattern roller by using laser

InactiveCN101695890AProtect environmentImprove engraving accuracyPrinting pre-treatmentLaser beam welding apparatusSurface finishingCopper

The invention relates to a process for engraving a three-dimensional large-sized copper pattern roller by using laser, which comprises the following technological steps of: (A), designing a printed pattern; (B), processing the surface; (C), engraving; (D), detecting; (E), removing pigment on the surface; (F), polishing the surface; and (G), electroplating. The invention has the following advantages that: (1) the environment is protected, and the discharge of the waste liquid of chemicals does not exist in the entire engraving process; (2) the engraving accuracy is high, and the engraving quality is good; and (3) the labor strength is low, the efficiency is high, and time, labour and force are saved.

Owner:肖云国

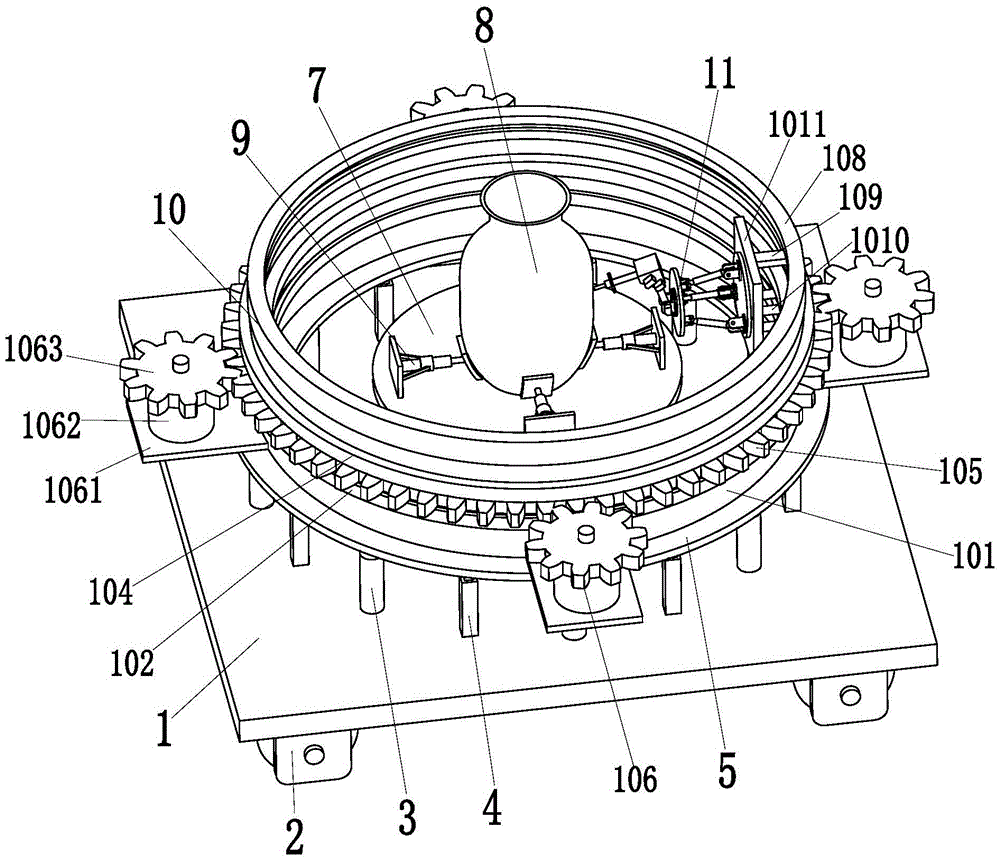

Special full-automatic engraving equipment for machining ceramic surfaces

ActiveCN105644239ARealize automatic engraving functionShort processing timeCeramic shaping apparatusModel makingHydraulic cylinderEngraving

The invention relates to special full-automatic engraving equipment for machining ceramic surfaces. The special full-automatic engraving equipment for machining ceramic surfaces comprises a bottom plate, wherein four universal wheels are symmetrically mounted on the lower end surface of the bottom plate; first hydraulic cylinders are circularly mounted in the middle of the bottom plate in a circumferential manner; an extensible rod is mounted between each two adjacent first hydraulic cylinders; mounting plates are mounted at top ends of the first hydraulic cylinders and top ends of the extensible rods; the extensible rods assist in movement of the first hydraulic cylinders; the first hydraulic cylinders drive the mounting plates to move in the up-down direction under the assisting effect of the extensible rods; a fixed column is welded to the middle of the upper end surface of the bottom plate; a mounting circular table is welded to the upper end surface of the fixed column; and a ceramic body is placed in the middle of the mounting circular table. By the special full-automatic engraving equipment for machining the ceramic surfaces, the problem that an existing manual engraving mode is long in processing time, large in labor intensity, large in engraving error rate, low in engraving efficiency and the like can be solved, and a full-automatic ceramic surface engraving function can be fulfilled. The special full-automatic engraving equipment for machining the ceramic surfaces has the advantages of short processing time, high engraving precision, no manual processing, high engraving efficiency and the like.

Owner:广东金润源陶瓷股份有限公司

Three-dimensional carving machine

The invention relates to a three-dimensional carving machine and belongs to the technical field of machines. The problem that an existing three-dimensional carving machine is not high in carving precision is solved. The three-dimensional carving machine comprises a machine frame and a carving platform arranged on the machine frame; a limiting clamp used for clamping is arranged above the carving platform; the machine frame comprises a base and stand columns arranged on the two sides of the base; a cross beam is connected with the two stand columns; the base is provided with a longitudinal motor for driving the carving platform to move horizontally and longitudinally in a reciprocating mode. The cross beam and the stand columns are fixedly connected, the parallel stand columns are provided and connected with horizontal and transverse guide rails, a tool frame is connected with the guide rails through layer boards, tools are coaxially linked and driven by a motor to swing front and back, multi-angle three-dimensional machining is conducted, the carving precision is improved, and the three-dimensional carving machine is suitable for complex carving processes.

Owner:NANTONG OUKE CNC EQUIP CO LTD

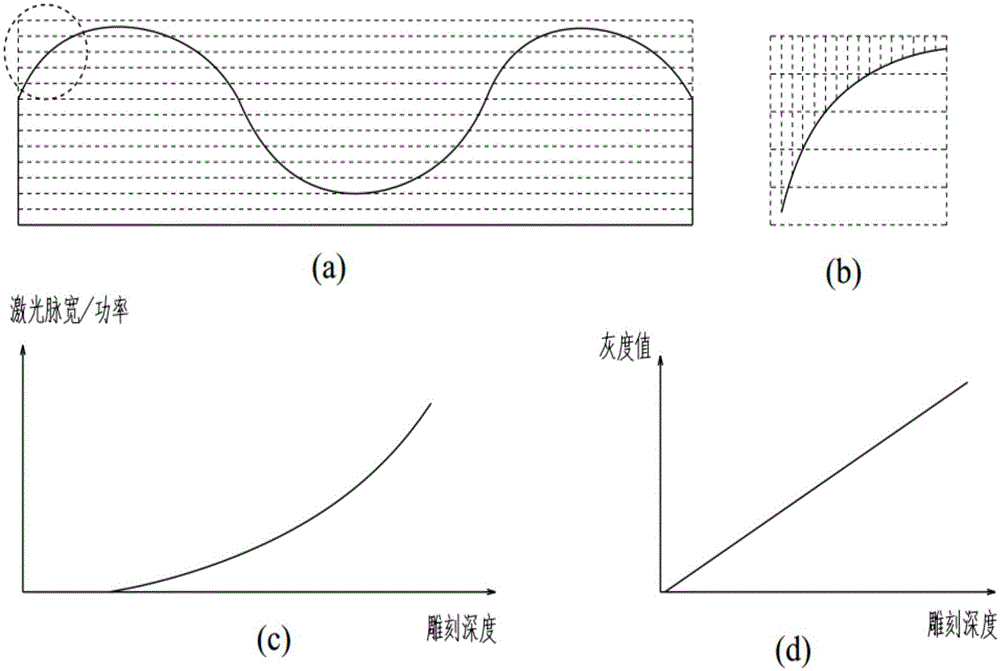

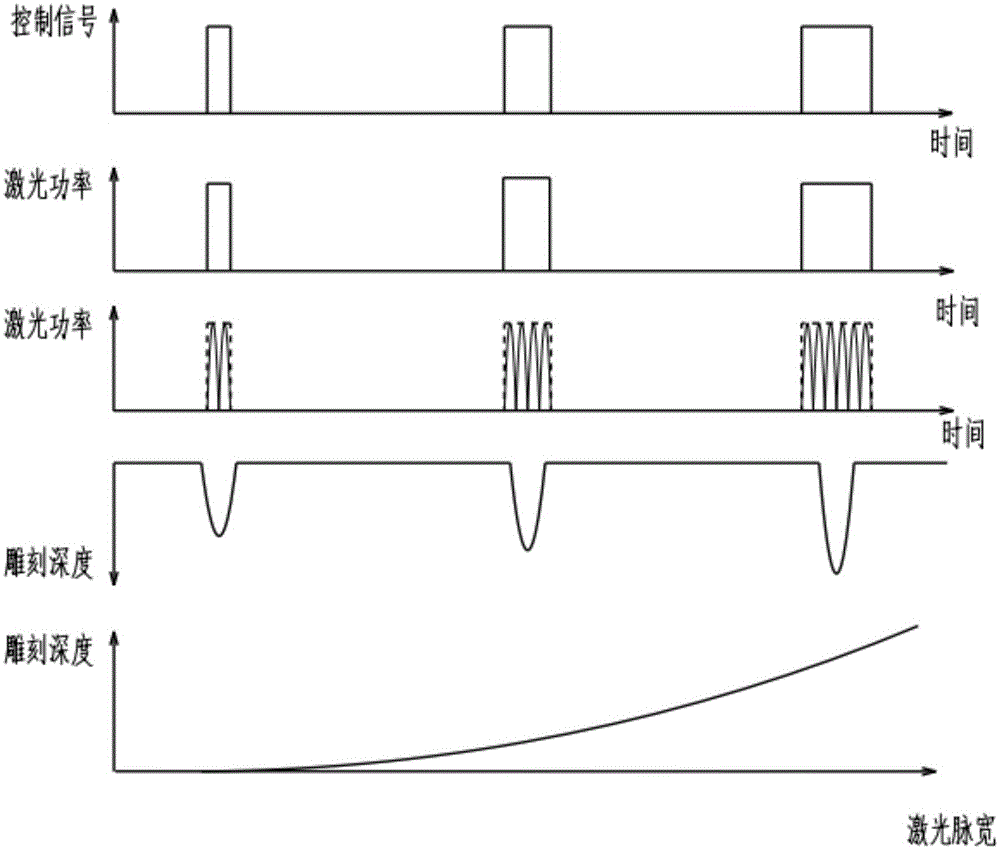

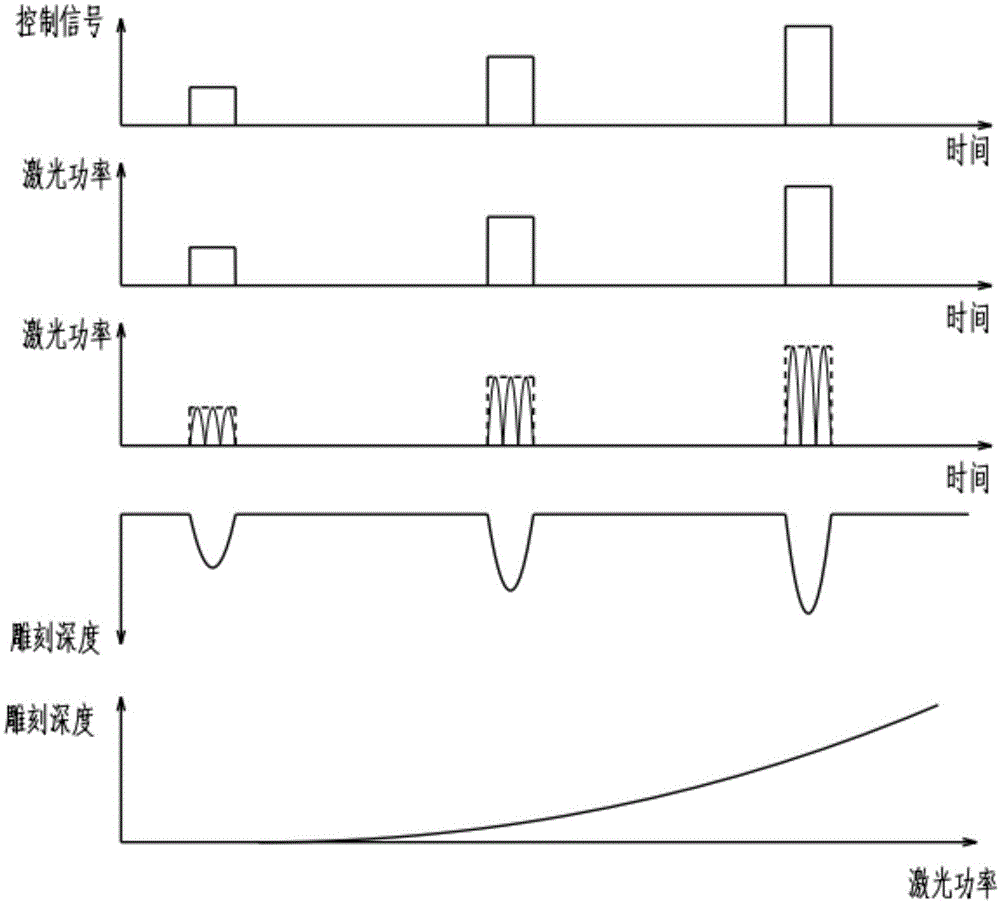

Pulse laser three-dimensional engraving method

InactiveCN105057892AWide range of engraving depthsClear textureLaser beam welding apparatusEngravingOptoelectronics

The invention discloses a pulse laser three-dimensional engraving method. According to the method, the engraving depth range is large, pattern lines are clear, three-dimensional impression is strong, and the engraving time can be substantially shortened or the engraving precision can be substantially improved. The method includes the steps that firstly, according to the characteristic and precision requirement of an engraved object, a three-dimensional model of the engraved object is subjected to disperse slice layering through combination with the characteristics of a laser device in use; secondly, a corresponding method for controlling laser output parameters is selected so that engraving, of different depths, in the same layer can be achieved; thirdly, data in the first step and the second step are converted into electric signals capable of being recognized by the laser device through a computer, and therefore output of the laser device can be controlled, and engraving is completed layer by layer; and in the first step, the engraving depth of the same layer is represented through a gray value after layering is performed, different gray values represent different engraving depths, two-dimensional lattice coordinates are used for representing coordinates of corresponding engraving points in the same layer, the values of the coordinates are the gray values, and the gray values correspond to the engraving depths of the points.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Novel vertical numerical-control engraving machine

The invention discloses a novel vertical numerical-control engraving machine which comprises a base, a gantry, a bottom workpiece clamping frame, a top workpiece clamping frame and a machining tool rest. The gantry is fixed on the base, the bottom workpiece clamping frame is arranged in the gantry, the top workpiece clamping frame is arranged above the bottom workpiece clamping frame and is mounted in the gantry in a vertically movable manner, the machining tool rest is mounted on the gantry in a vertically movable manner, a first tool rest and a second tool rest which are capable of moving in all directions are respectively mounted on two sides of the machining tool rest, a first tool used for rough machining is mounted on the first tool rest, and a second tool used for finish machining is mounted on the second tool rest. The novel vertical numerical-control engraving machine has the advantages that without changing the engraving machine or detaching or changing the tools, workpieces to be engraved can be subjected to finish machining after rough machining, so that labor intensity of workers is reduced greatly, engraving precision is increased, machining errors are reduced, and work efficiency is improved.

Owner:黄泉福

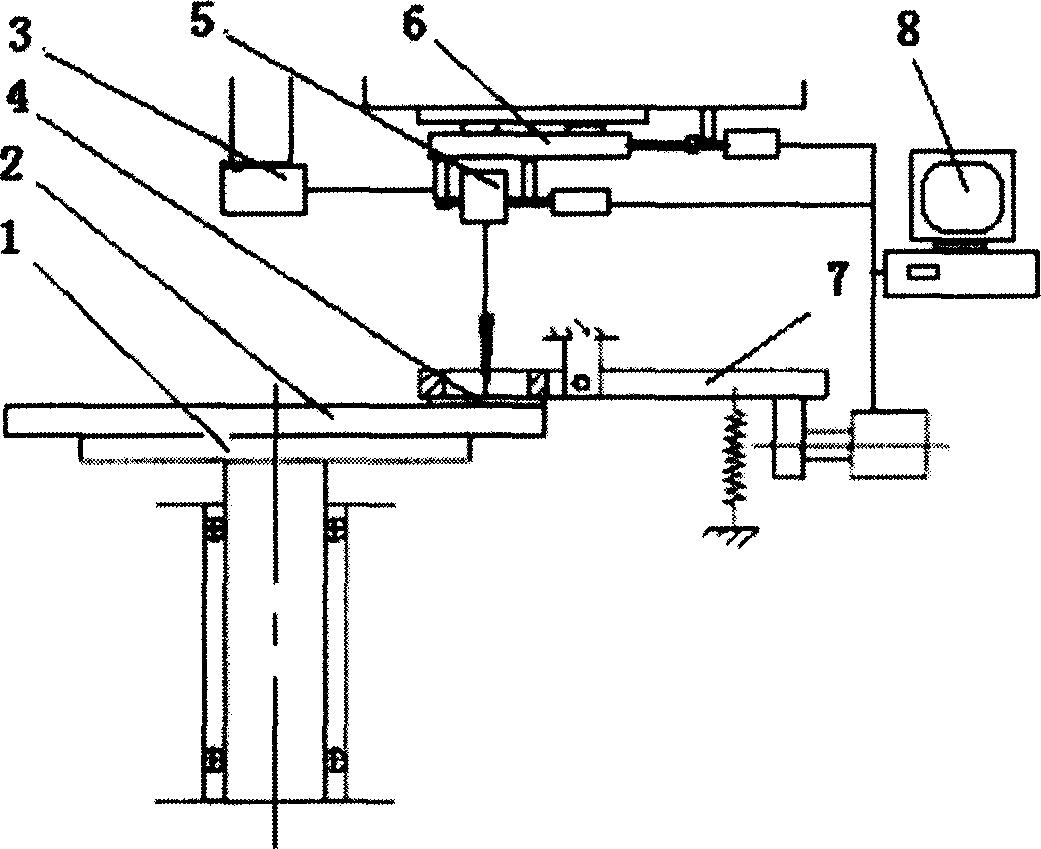

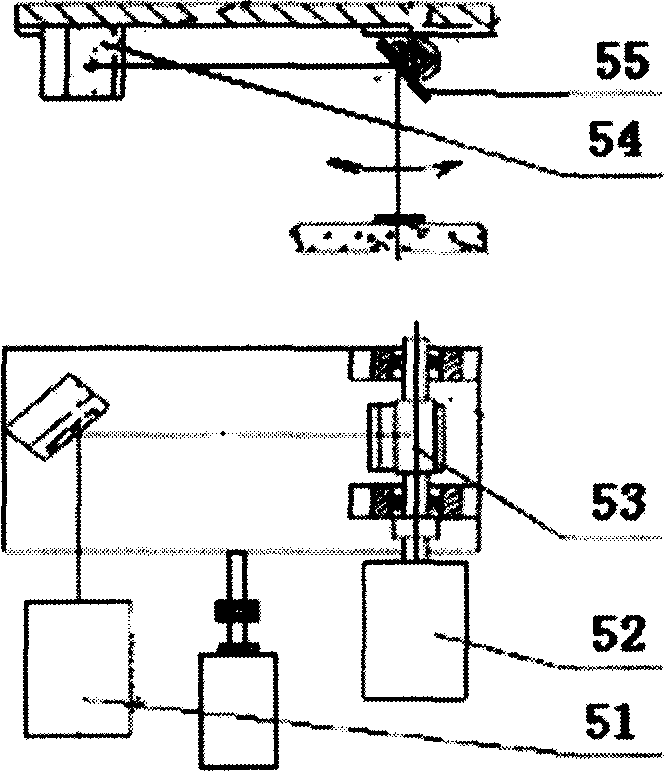

Two-dimensional scanning precision laser exposure system

InactiveCN1851557AEngraving technology breakthroughShorten production timePhotomechanical exposure apparatusMicrolithography exposure apparatusComputer control systemGraphics

A two-dimensional scan two-dimensional scan precision laser exposure system consists of circular dividing machine workbench, divided coded disk, laser, mask, oscillatory scanning system, precision laser stepping platform, mask uplift mechanism and computer control system, wherein said laser as light source, computer control system controlling oscillatory scanning system and precision laser stepping platform movement to complete two-dimensional scan illumination mask, circular dividing machine workbench driving coded disk rotating to select photo etching area, mask uplift mechanism lifting mask when coded disk rotating and downfall in exposure. The present invention has advantages of accurately positioning, easy and simple to handle, convenient installing and adjusting, greatly raising coded disk dividing precision.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Pattern carving process

ActiveCN107364270APrinting environmental protectionImprove qualityDecorative surface effectsScreen printingLaser engraving

The invention provides a pattern carving process. The pattern carving process sequentially comprises the following steps that printing images and texts are input in a laser carving machine; the surface of a water cup is subjected to laser carving; the water cup obtained after laser carving is subjected to pattern cavity depth detection; the surface of the water cup is subjected to electronic carving, and the water cup obtained after electronic carving is subjected to pattern cavity depth detection; the water cup is etched in an etch tank; a net point detector is used for measuring the etch depth and the height of a remaining net wall; the water cup is subjected to manual carving; cleaning liquid is adopted for cleaning the surface of the water cup, and the water cup is packed and put in storage after being checked to be qualified. The carving process is adopted, no ink exists in the whole process, the carving process is more environment-friendly than silk-screen printing, the quality of carved products is higher in grade, and pattern layers are more distinct.

Owner:SHANDONG JIAOTONG UNIV

Carving machine used for industrial equipment

ActiveCN105818592AAccurate engravingReduce consumptionModel makingEngravingIndustrial equipmentCarving

The invention discloses a carving machine used for industrial equipment. The carving machine comprises a base, wherein a carving table is firmly connected to the top of the base; a supporting table is disposed on one side of the carving table; a slideway is formed in one side face of the supporting table; a first slide block is movably connected inside the slideway; a drill bit is firmly connected to one side face of the first slide block; a first carving rod and a second carving rod are disposed on the bottom of the drill bit; one end of the first carving rod passes through the drill bit and extends into the drill bit; one end of the second carving rod is firmly connected to the bottom of the drill bit; one side face of the drill bit is firmly connected to a supporting plate; a water tank is disposed on the top of the supporting plate; a water hose is disposed on the bottom of the water tank; and one end of the water hose communicates with a through hole in the bottom of the water tank. The carving machine used for the industrial equipment has the advantages that accurate carving of a small model is implemented as a whole; consumption of energy sources is reduced; effective processing of chippings is implemented; overall carving precision is increased; and working efficiency is increased.

Owner:建湖县高新投资发展有限公司

Ceramics preparation method

The invention relates to a preparation method for daily ceramic, which comprises: a) preparing mud blank; b) calcining the product from step a) into the hard black semi-finished product with as Moh coefficient 3. 5-5. 2; c) on numerical-controlled machine tool, carving the former semi-finished product with the hard alloy tools; d) adorning and glazing; e) final calcining and forming. This invention can manufacture the hard black with Moh factor 3. 5-5. 2, and improves the product quality with small error and deformation rate.

Owner:鄂尔多斯市国礼陶瓷有限公司

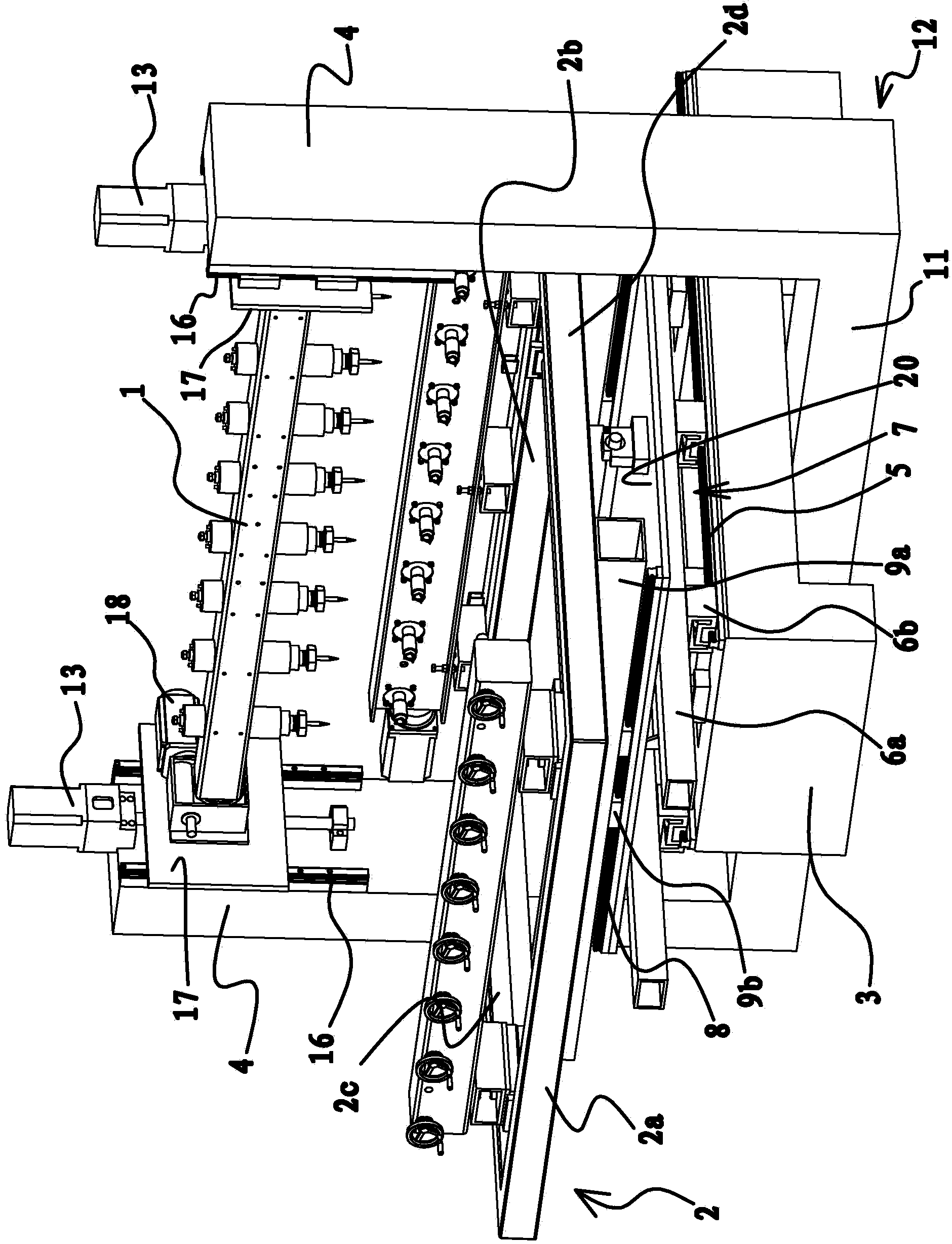

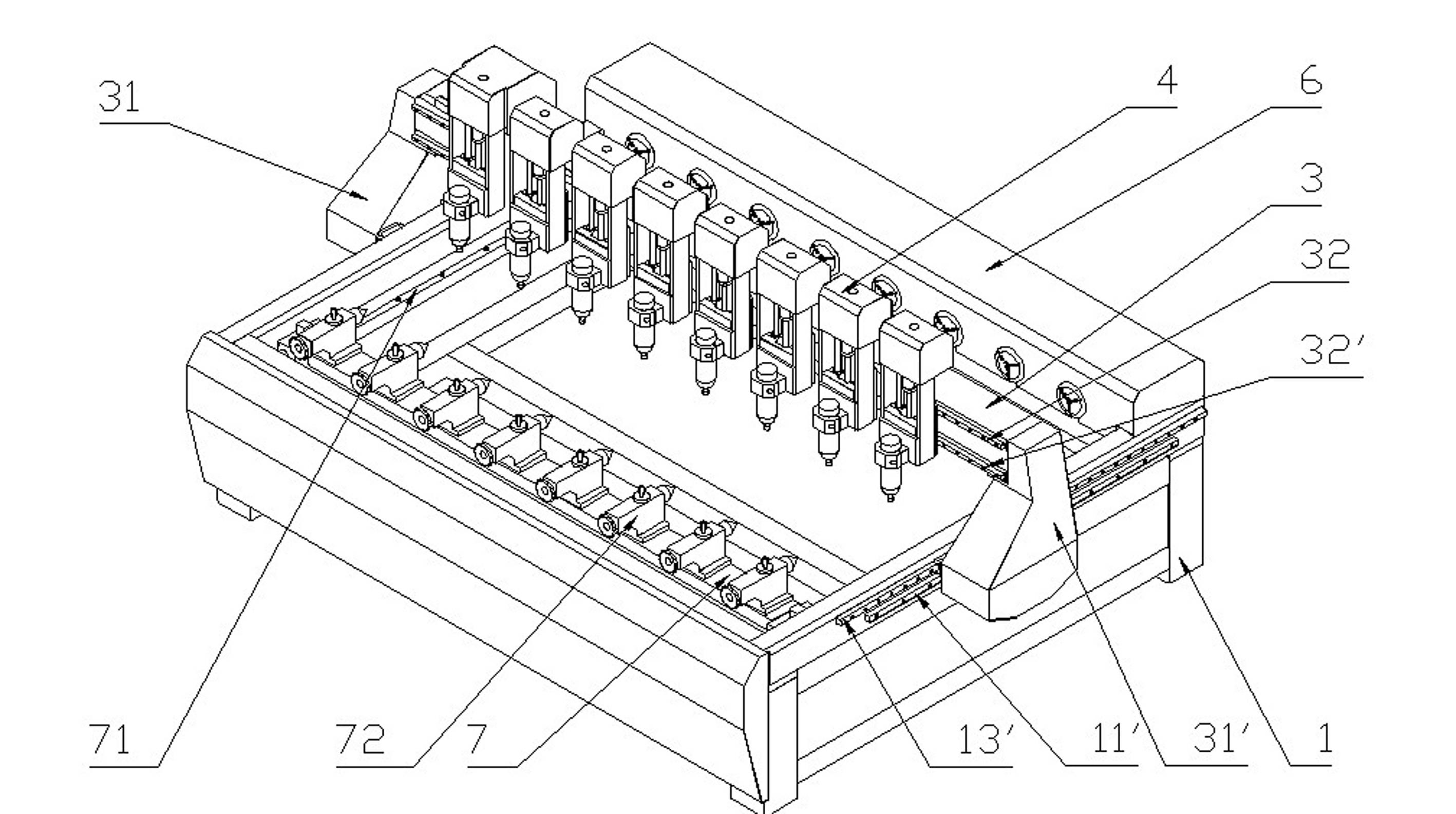

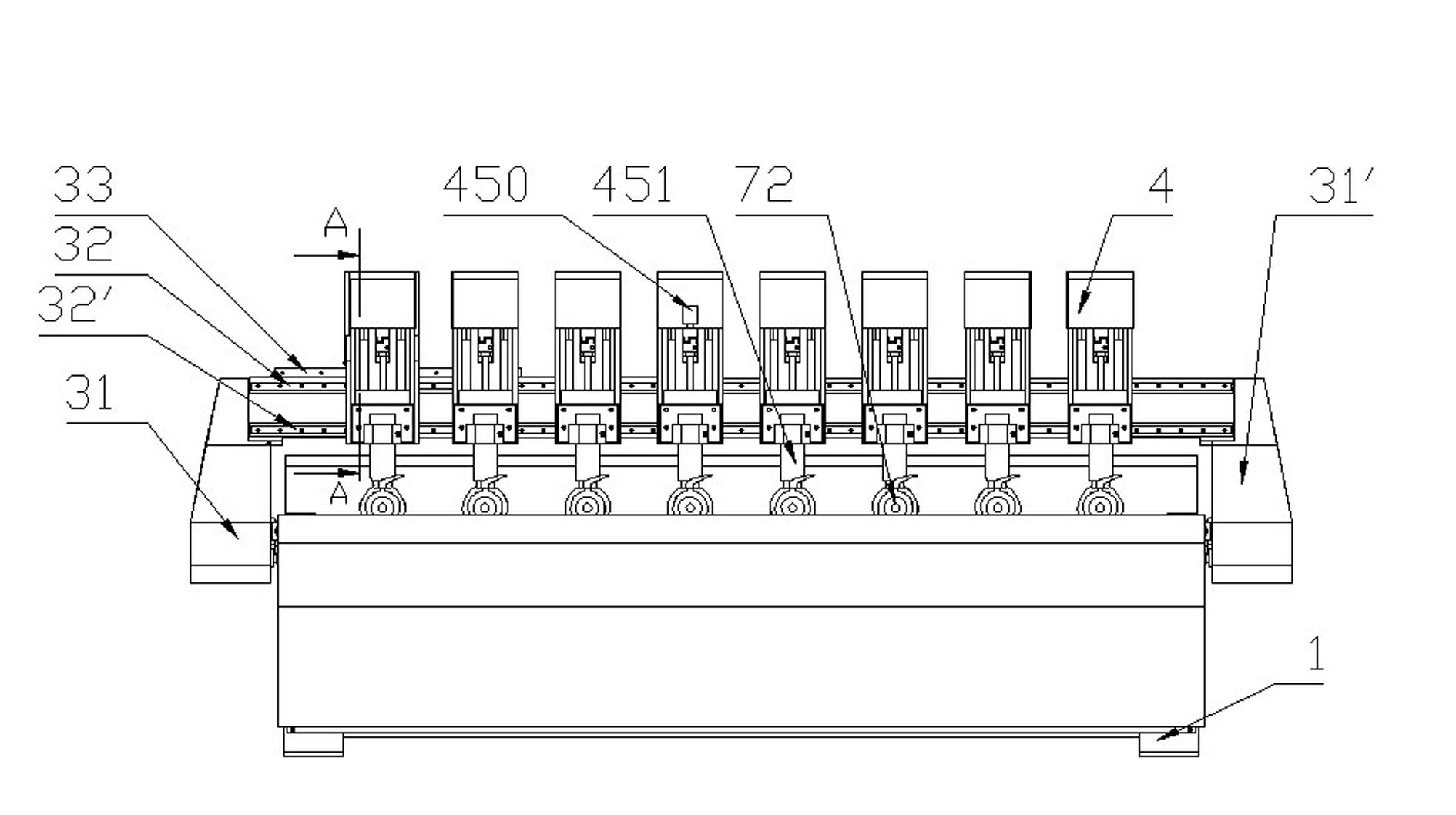

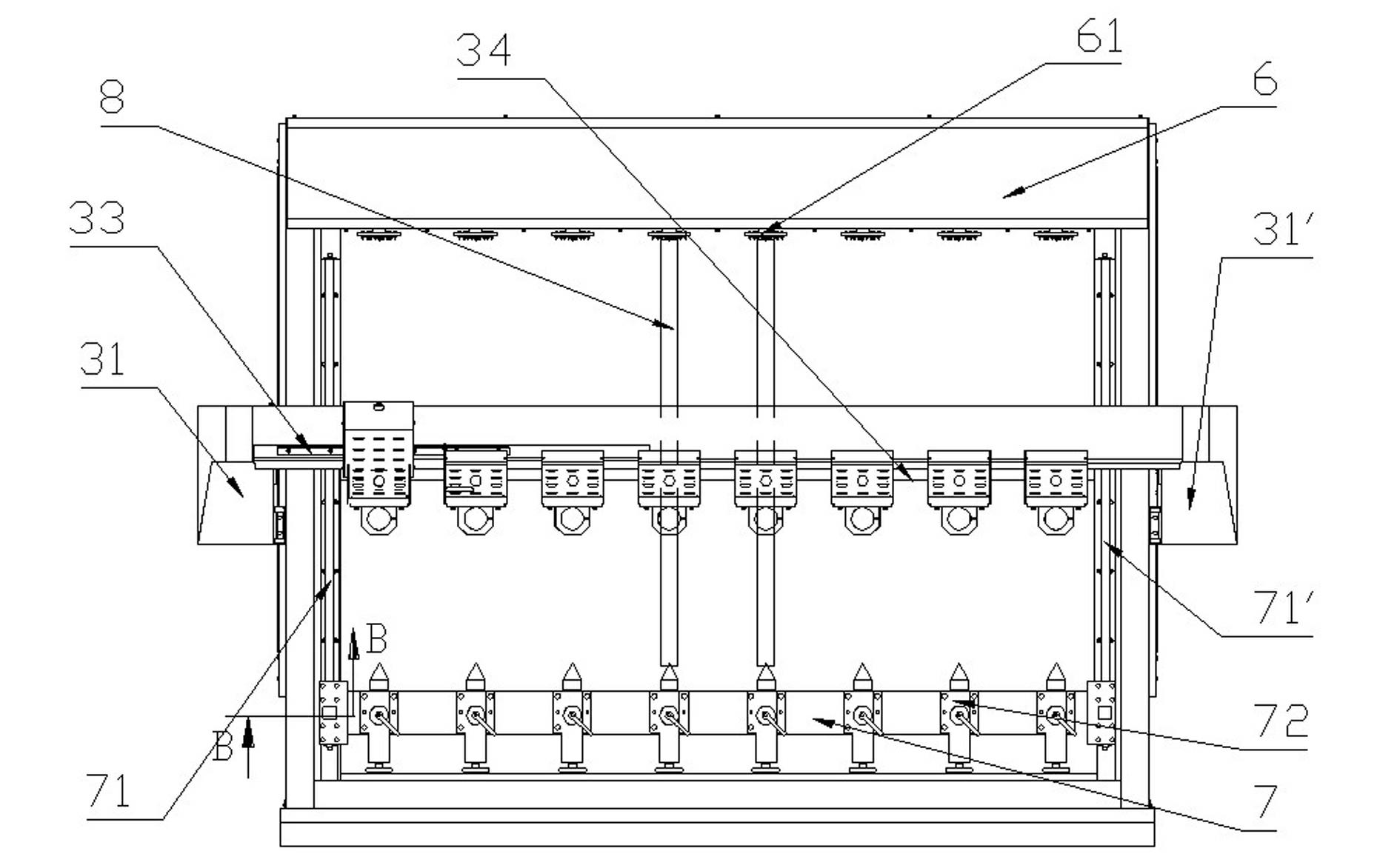

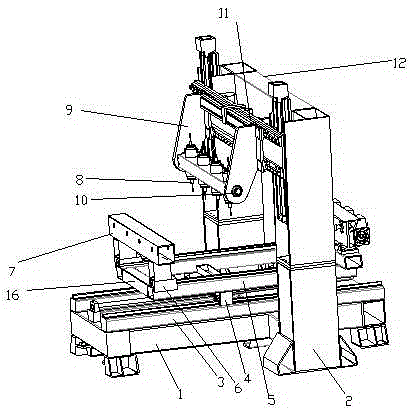

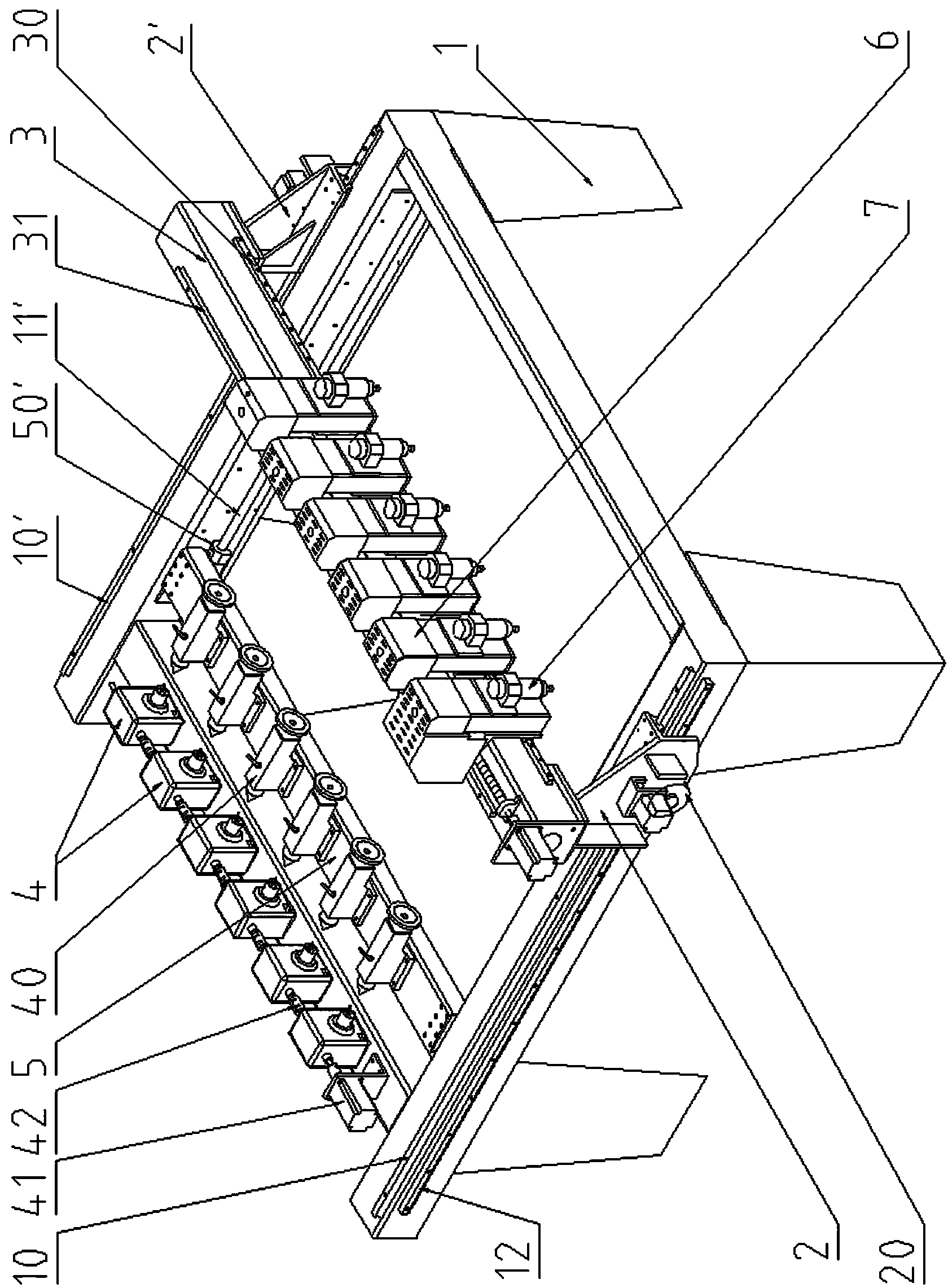

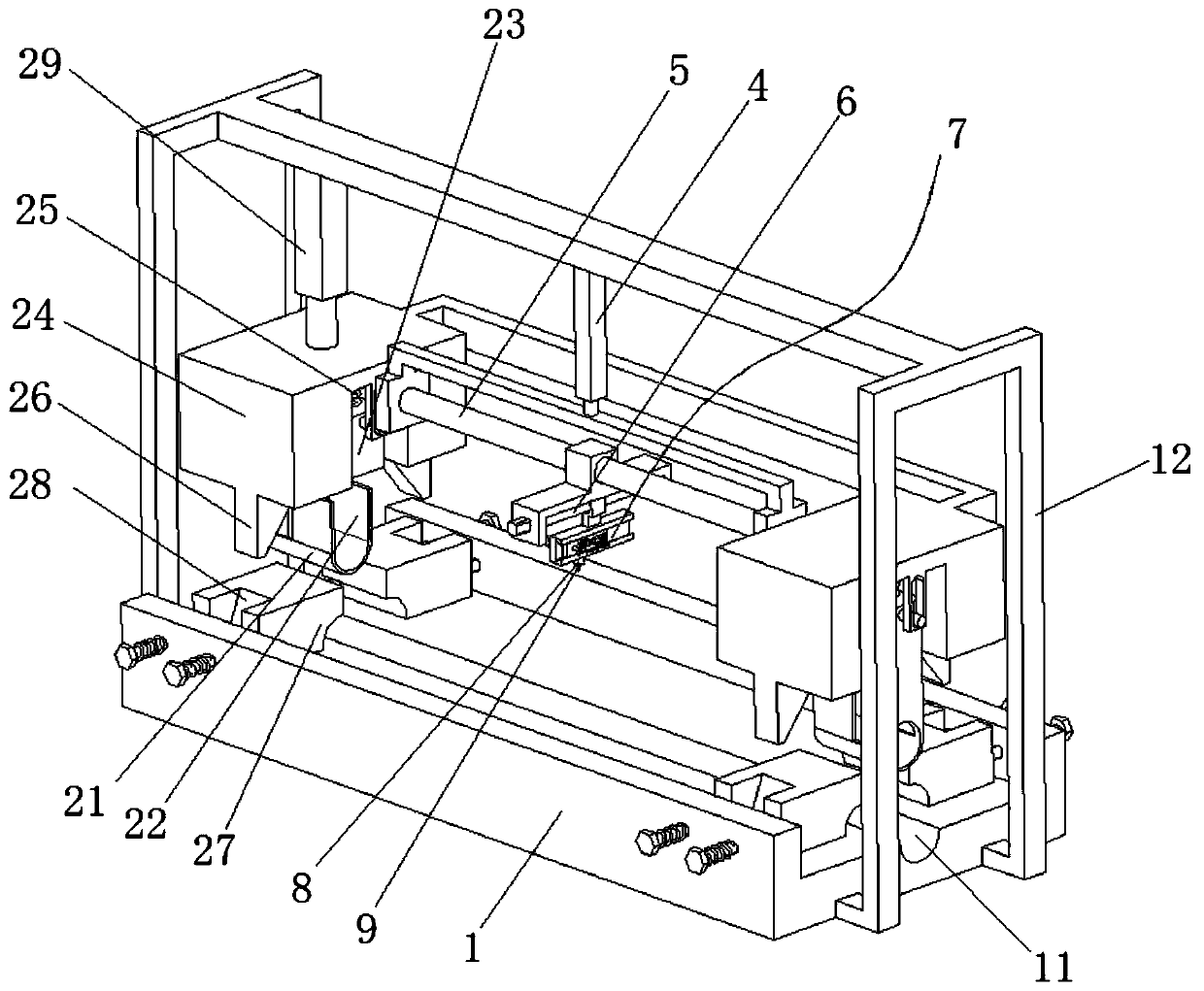

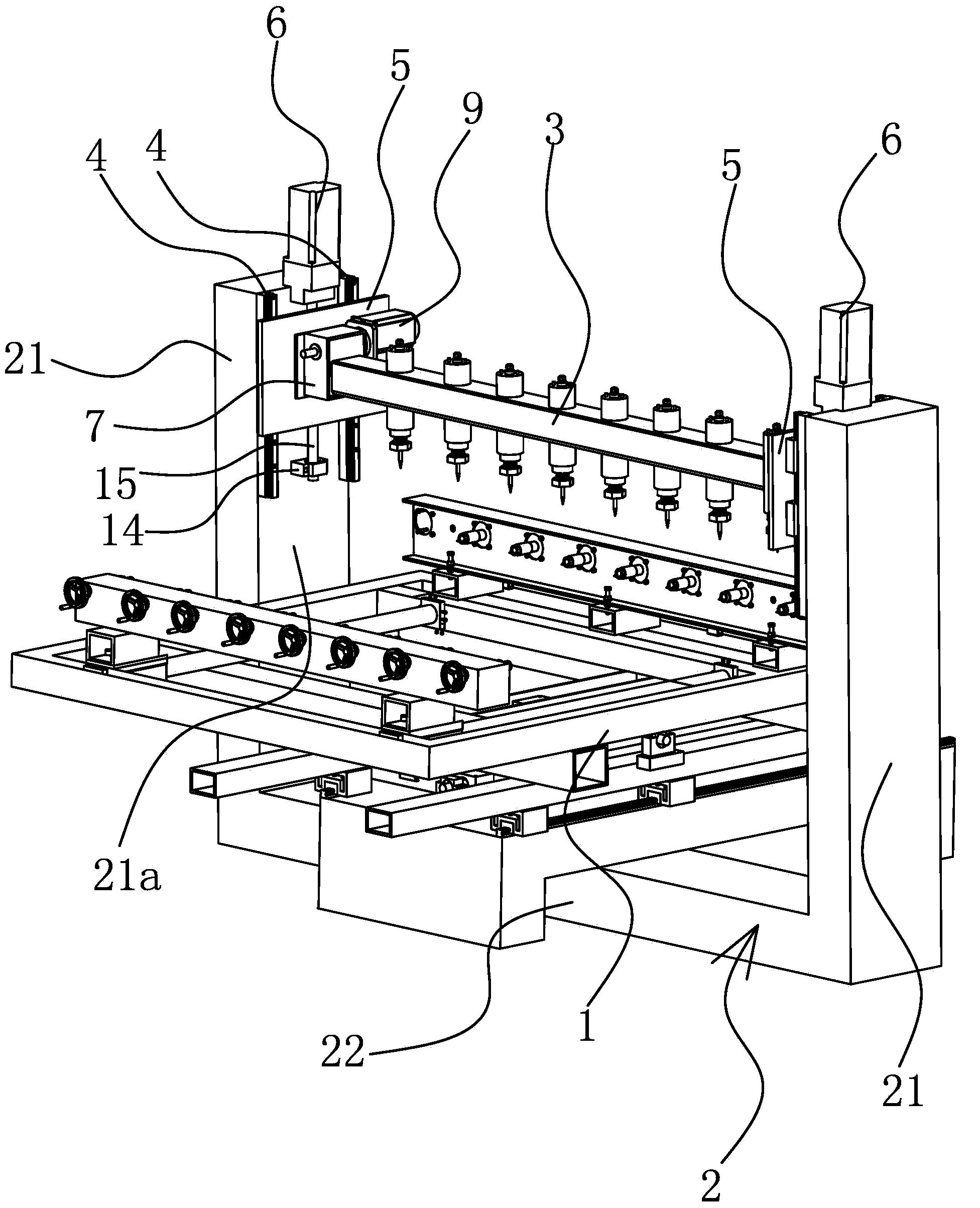

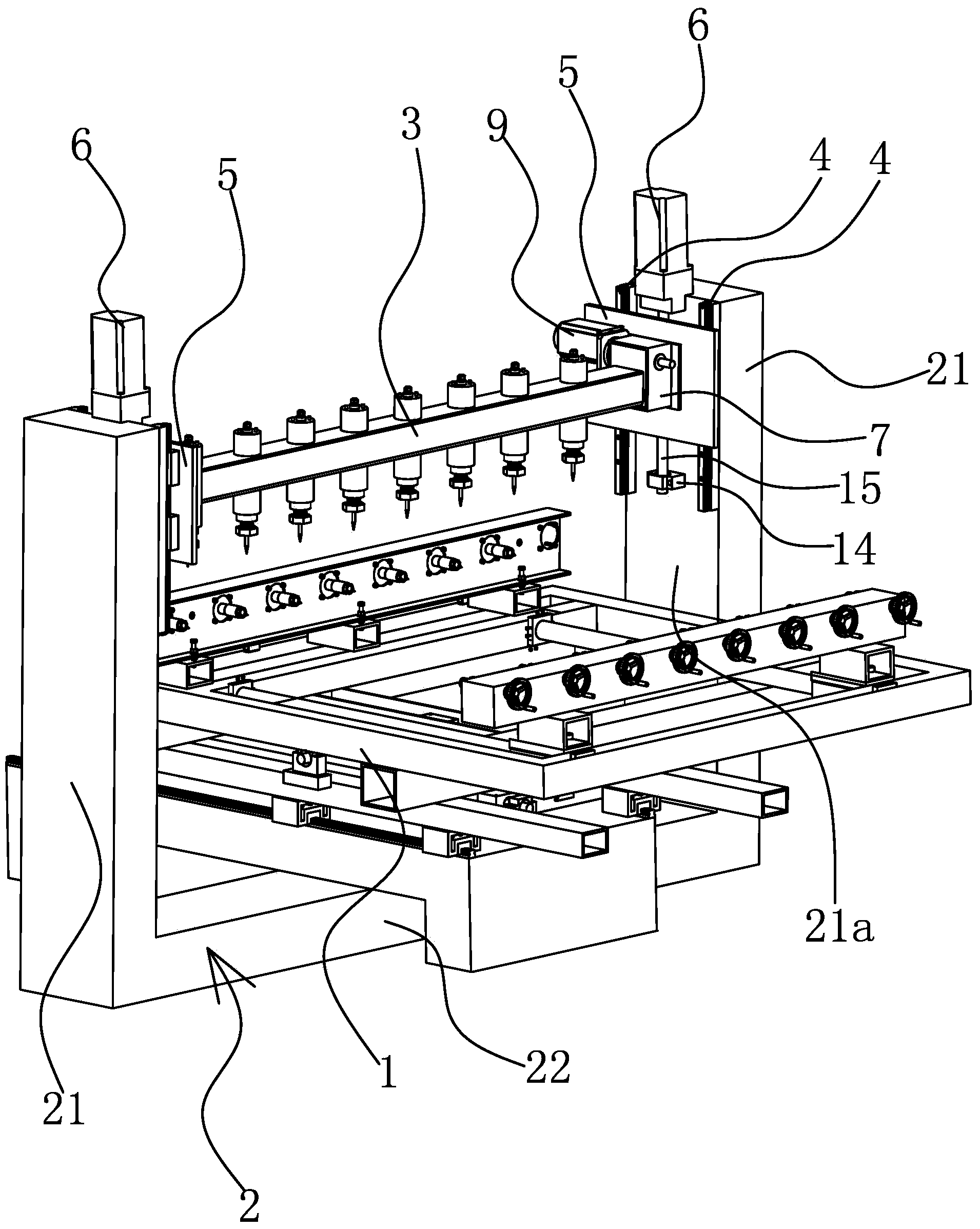

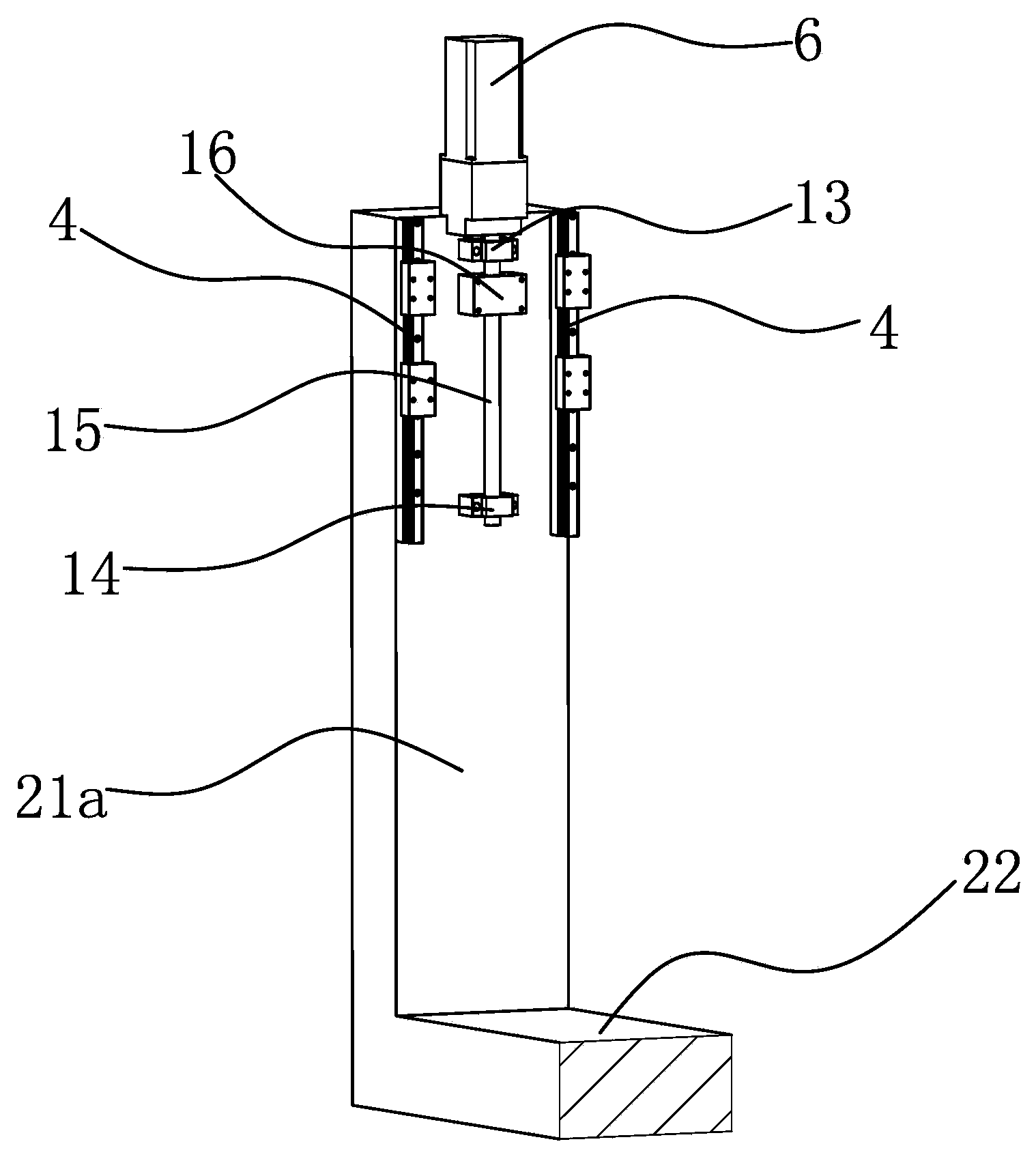

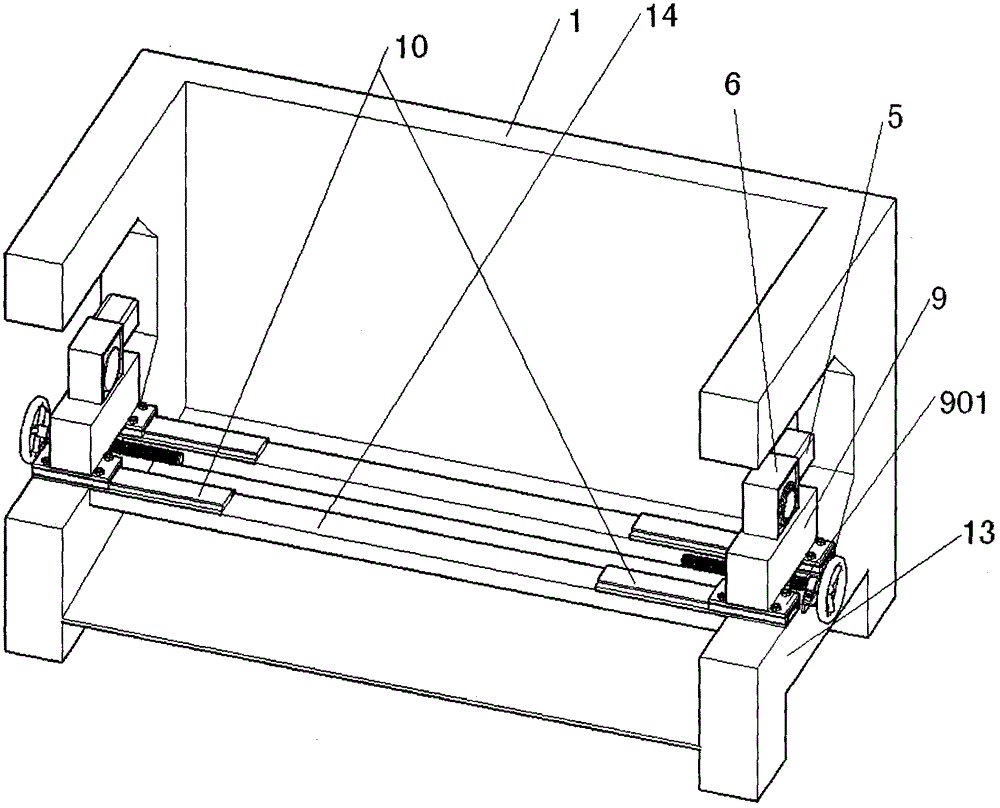

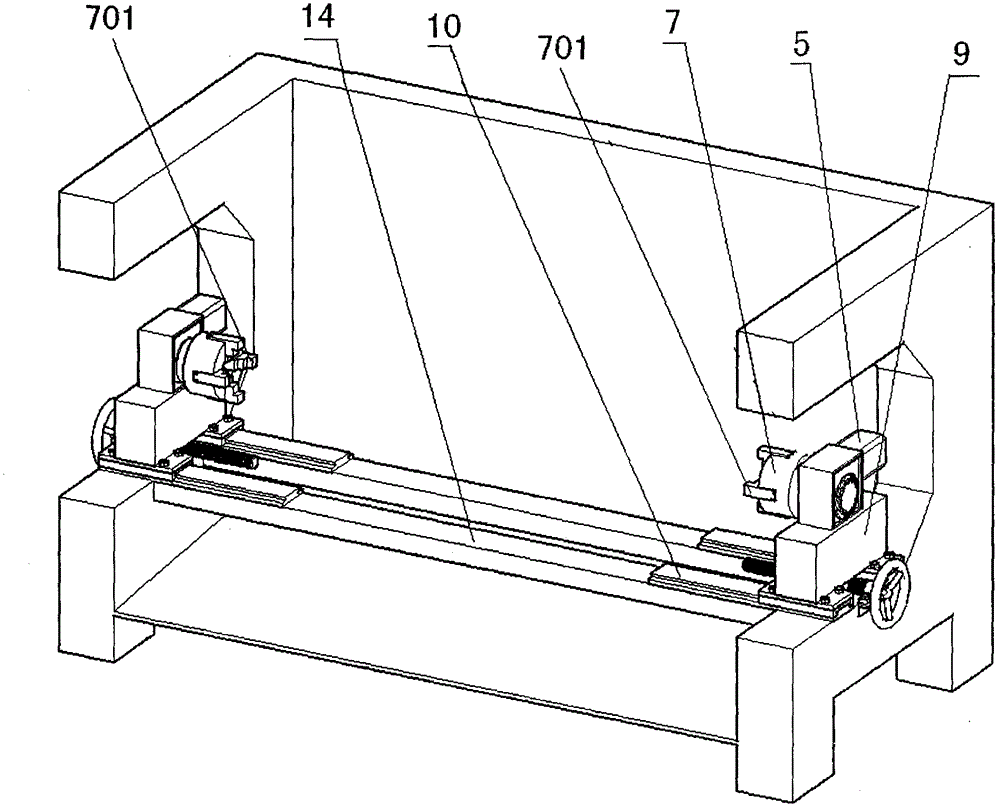

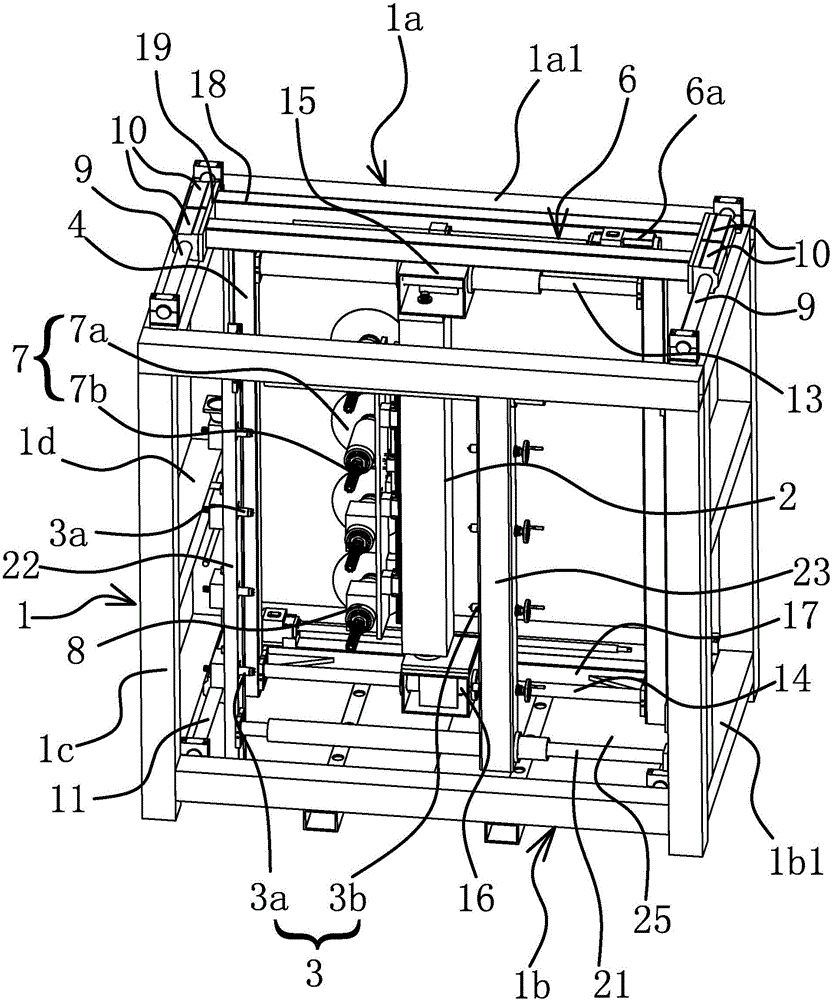

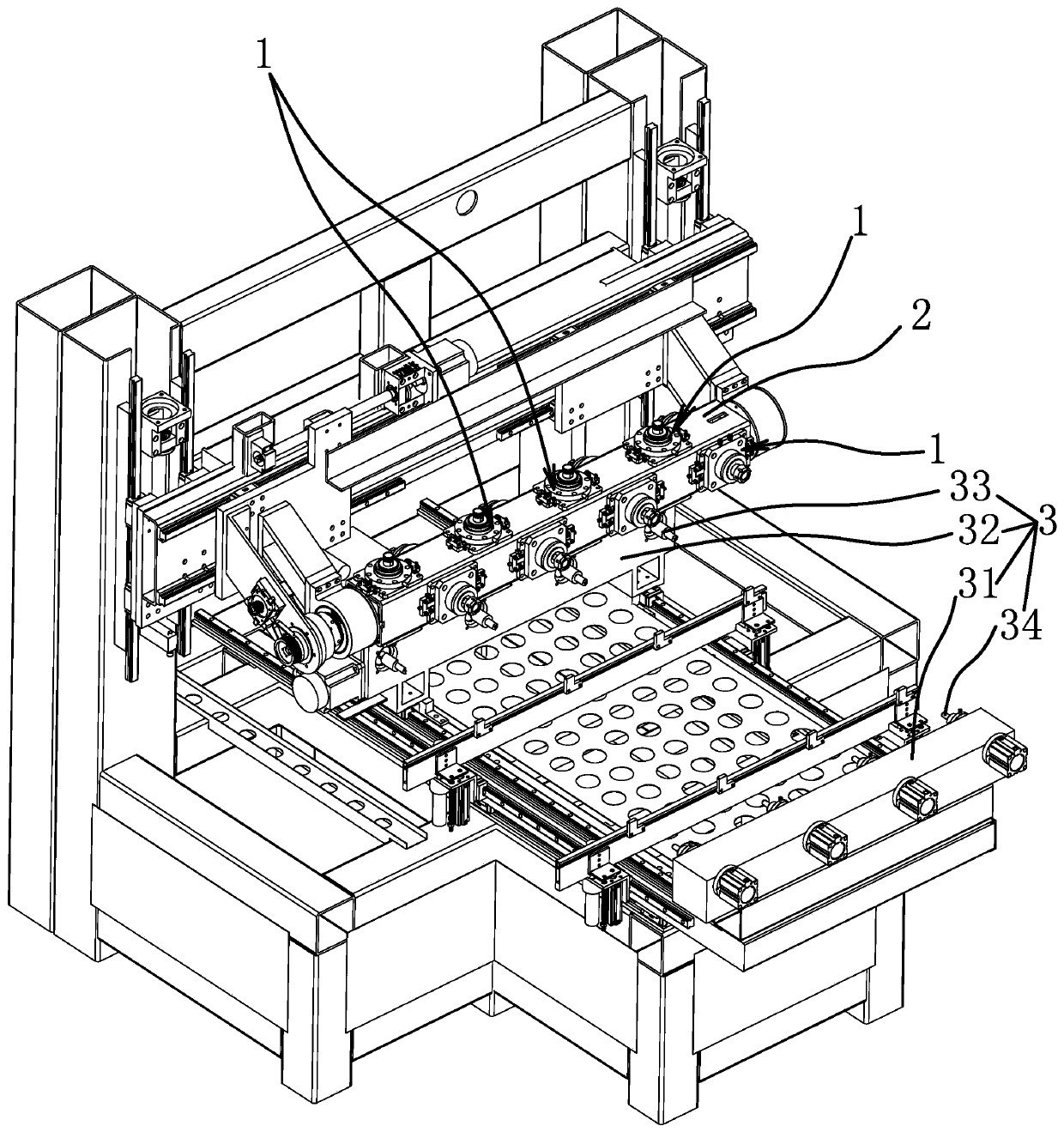

Independent-tool-setting type 3D multi-functional numerical control carving machine

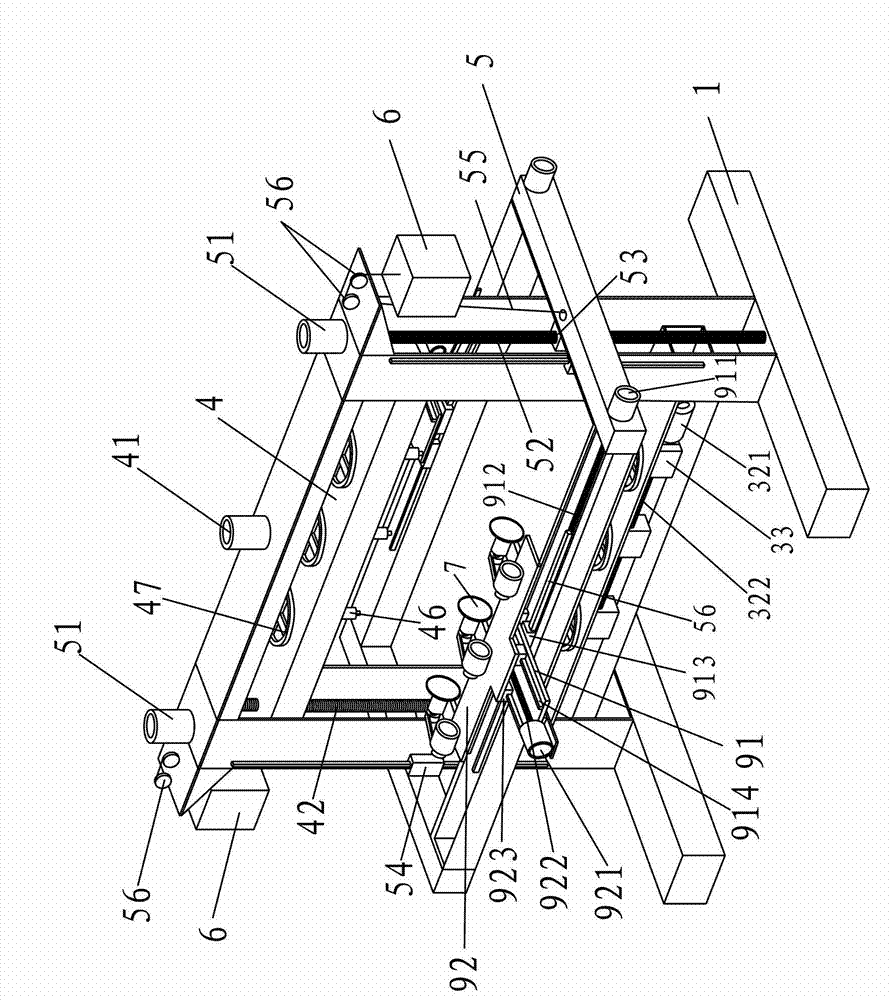

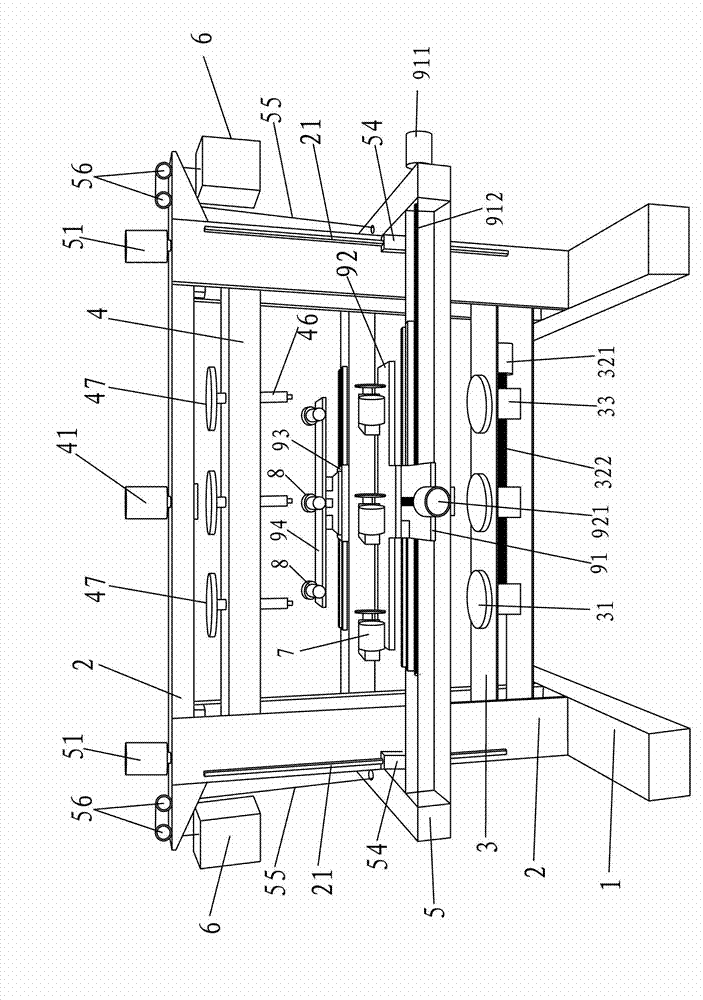

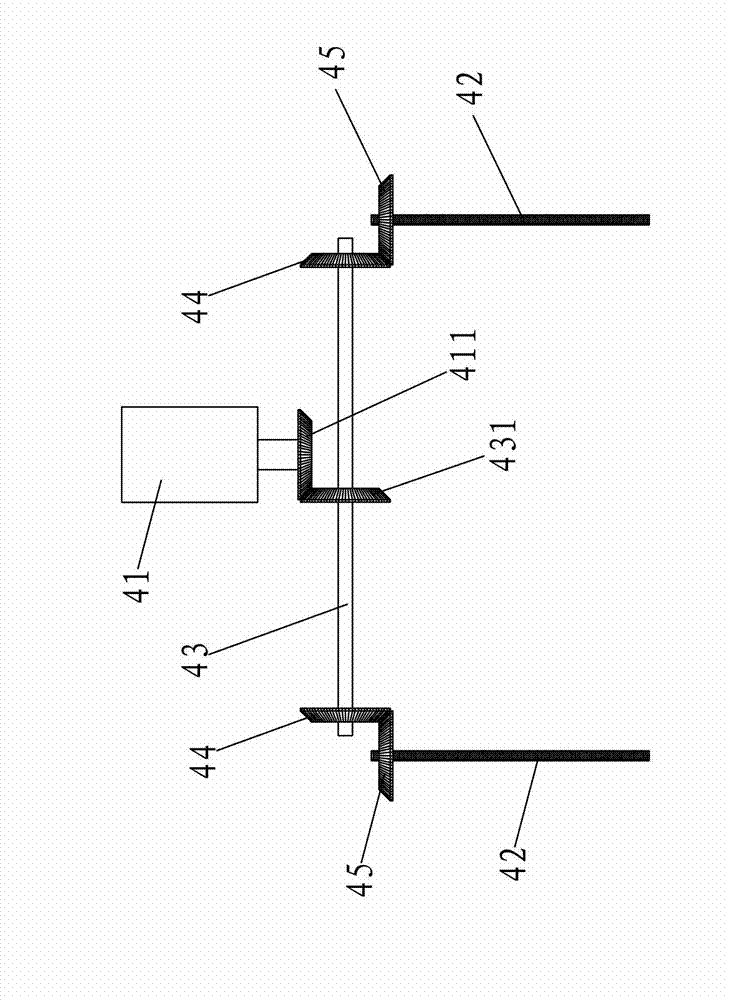

InactiveCN103522813AImprove work efficiencyImprove engraving accuracyModel makingEngravingNumerical controlEngineering

The invention provides an independent-tool-setting type 3D multi-functional numerical control carving machine which has the functions of periphery carving, 3D carving, planar carving and the like, and is high in carving precision and working efficiency. A left stand column and a right stand column are movably connected to a machine tool body through a left guide rail and a right guide rail, a Y-direction drive device is further arranged among the left stand column, the right stand column and the machine tool bed, a gantry is arranged above the left stand column and the right stand column, and multiple U-shaft clamping devices are arranged on the machine tool body below the gantry. A left inner guide rail and a right inner guide rail are arranged on the inner side of the machine tool body, an ejector pin supporting plate is movably arranged between the left inner guide rail and the right inner guide rail, a left locking device and a right locking device are arranged among the ejector pin supporting plate, the left inner guide rail and the right inner guide rail, and multiple ejector pins are arranged on the ejector pin supporting plate. The gantry is provided with multiple carving heads through an X-direction perpendicular guide rail and an X-direction horizontal guide rail, wherein the carving heads are mutually connected through an X-direction connecting rod, and the gantry further comprises an X-direction drive device connected with the carving heads. The carving heads are provided with independent Z-direction vertical structures.

Owner:安庆市宏大涛业精啄数控科技有限公司

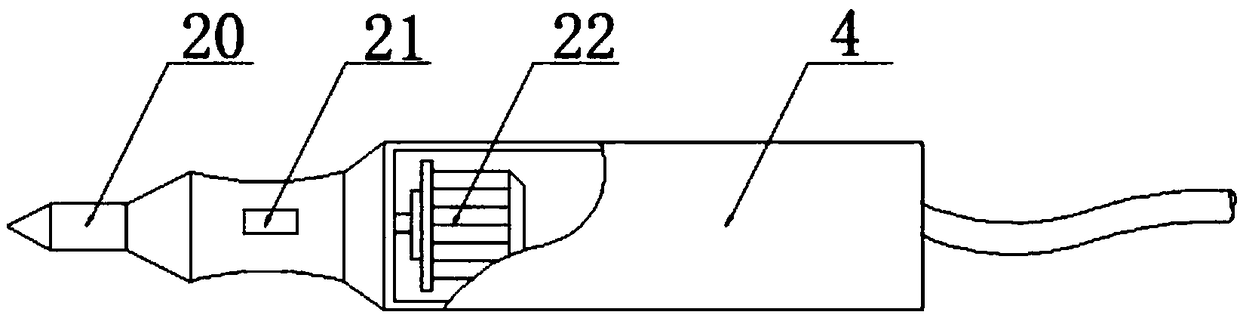

Jade carving processing platform

The invention discloses a jade carving processing platform which comprises a connecting rod, a transmission rod, a spray head, a carving machine shell, a screw, a rubber gasket, a rotating disk, a through hole, a battery box, side baffle plates, a limit clamp, a water tank, a groove, a filter screen, a rotating shaft, a non-woven filter layer, filter paper, a sliding groove, a water pump, an outerframe, a carving head, a push switch and a motor. A jade carving machine supports jades by the aid of the rotating disk, the rotating screw is matched with the rubber gasket to fix the jades, hand holding of operators is omitted, harm to the operators is reduced, the jades with different sizes can be fixed by the rotating screw, and the use range is wide. During carving, the position-adjustable spray head can be used for flushing and cooling the jades, breakage of the jades is avoided, scraps on the surfaces of the jades are washed out, jade carving cannot be affected, and carving precision is improved. In addition, the scraps are filtered and collected, water is recycled, and the jade carving processing platform is economical, environmentally friendly and convenient and rapid to operate.

Owner:东阳市飞诺工贸有限公司

Small stone carving laser carving equipment

ActiveCN110548998AImprove engraving accuracyPrecise positioningLaser beam welding apparatusHydraulic cylinderStone carving

The invention provides small stone carving laser carving equipment. The small stone carving laser carving equipment comprises a base, a supporting beam arranged on the base, a clamping mechanism usedfor clamping a cylindrical stone, an air cylinder, a longitudinal axis sliding rail, a horizontal axis sliding rail, a spindle motor, and a carving knife head connected with the spindle motor, whereinthe air cylinder is arranged on the supporting beam, and the air cylinder, the longitudinal axis sliding rail, the horizontal axis sliding rail and the spindle motor are connected with one another insequence; and the clamping mechanism comprises a semicircular supporting groove, a fixed seat, a concave movable seat, two corresponding clamping blocks and a hydraulic cylinder, and the semicircularsupporting groove is used for containing the cylindrical stone. The small stone carving laser carving equipment is characterized in that the cylindrical stone is placed in the semicircular supportinggroove, the hydraulic cylinder is used for driving the movable seat and a wedge-shaped block to move downwards, and when the wedge-shaped block makes contact with the wedge-shaped surface, the two clamping blocks are driven to move oppositely, and two rubber pieces on the semicircular supporting groove tightly wrap the cylindrical stone, so that the cylindrical stone does not move in the carvingprocess, and the carving accuracy of the cylindrical stone is greatly improved.

Owner:任俊 +1

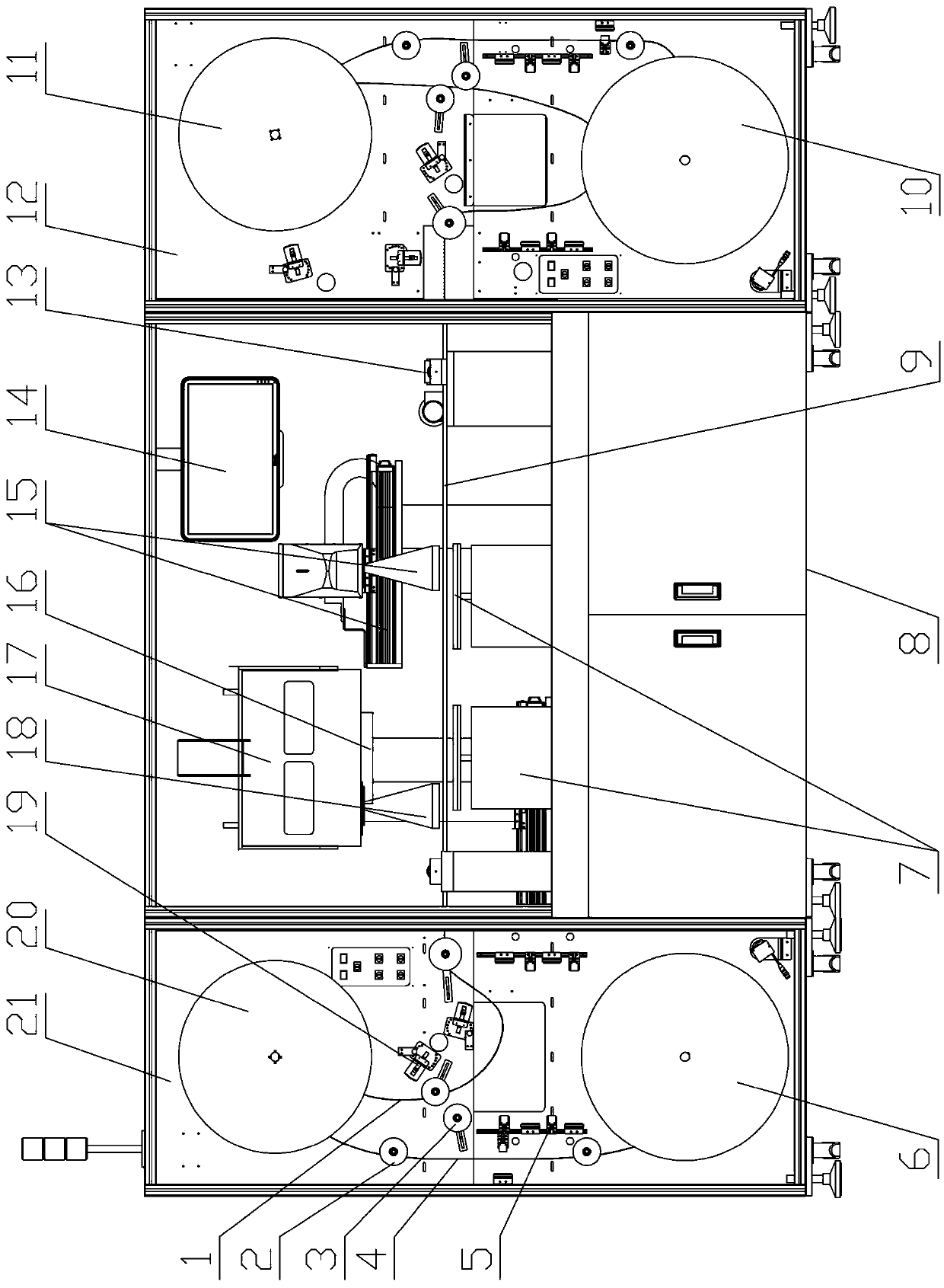

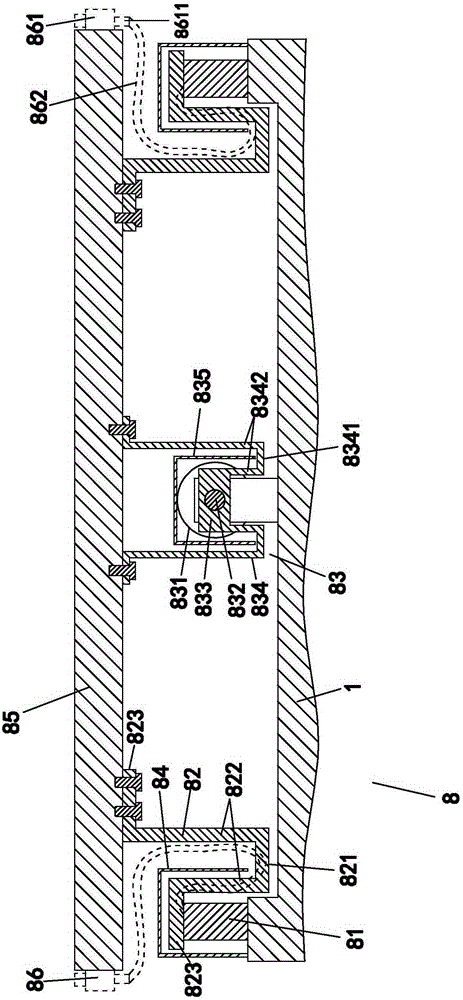

Chip laser engraving equipment and using method thereof

InactiveCN110076461AImprove engraving accuracyNo pollutionLaser beam welding apparatusAdhesiveEngineering

The invention relates to chip laser engraving equipment. The equipment sequentially comprises a feeding room, a laser engraving room and a discharging room, wherein a feeding device and an electrostatic eliminating instrument are arranged in the feeding room, a discharging device and an electrostatic eliminating instrument are arranged in the discharging room, chip adhesive tape driving devices are arranged at the left end and the right end of the laser engraving room correspondingly, and a chip adhesive tape supporting frame is arranged between the two chip adhesive tape driving devices; anda laser engraving machine and a protective cover are fixedly arranged above the chip adhesive tape supporting frame, a visual tracking device is further arranged matched with the laser engraving machine, the feeding device, the discharging device, the chip adhesive tape driving devices, the laser engraving machine and the visual tracking device are all controlled by the same master controller, andthe visual tracking device feeds back tracked and located position information of a chip to the master controller. The equipment has the advantages that the engraving precision is high, the engravedcontent can be customized at any time, physical abrasion on the equipment cannot be generated in the whole process, static electricity can be eliminated through the electrostatic eliminating instruments, and no secondary pollution is caused in the whole process.

Owner:HUBEI HANTAI INTELLIGENT EQUIP

Three-dimensional engraving machine

The invention provides a three-dimensional engraving machine, and belongs to the technical field of an engraving machine. The three-dimensional engraving machine solves the problem of poor stability of a three-dimensional engraving machine in the engraving process in the prior art. The three-dimensional engraving machine comprises a machine frame and a movable engraving platform arranged on the machine frame, wherein a straight strip-shaped cutter frame used for fixing a cutter is arranged above the engraving platform, the machine frame comprises two upright posts, the two upright posts are respectively and vertically arranged at the two sides of the engraving platform, guide rails in vertical arrangement are respectively arranged on each upright post, a support plate capable of vertically moving along the guide rail is arranged on each corresponding guide rail, the two ends of the cutter frame are respectively connected onto the corresponding support plates, and ascending and descending motors driving the support plates to synchronously and vertically move are also arranged on the machine frame. The three-dimensional engraving machine has the advantages that the operation is stable, and the processing precision is high.

Owner:吴善旺

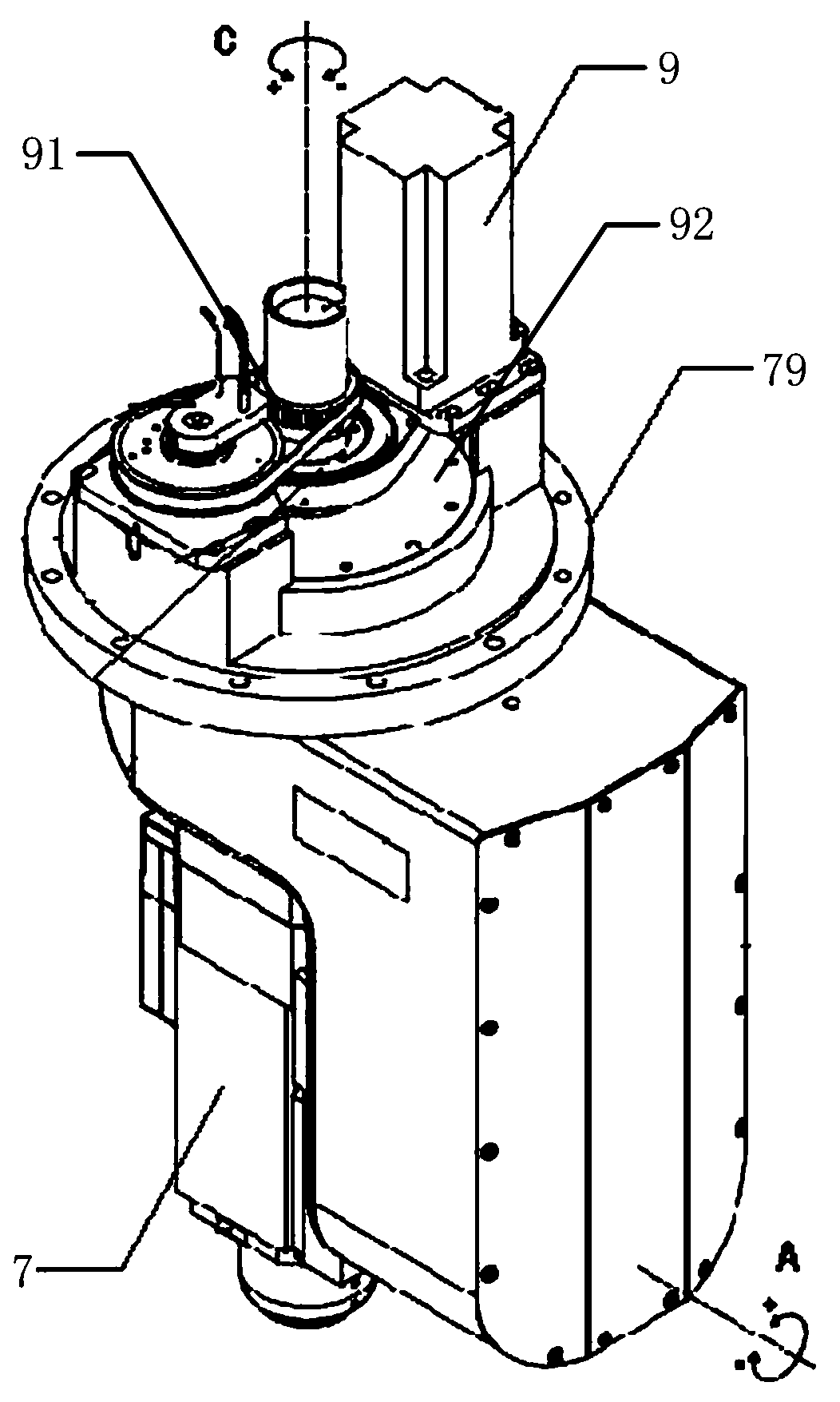

Five-axis linkage carving machine for processing redwood furniture

PendingCN109249734AOptimize the mechanical structureImprove machining accuracyModel makingEngravingCarvingChassis

The invention discloses a five-axis linkage carving machine for processing redwood furniture. The five-axis linkage carving machine for processing redwood furniture comprises a gantry bottom rack, wherein two supports are separately arranged at two ends of the gantry bottom rack; a gantry stand column is supported on the top of each support; the bottom surface of each gantry stand column is weldedto the top surface of the corresponding support; a linear rolling guide track is slidably connected with a ram; a Z-axis box body is fixed on the ram; a double-oscillation electric spindle is arranged on the bottom of the Z-axis box body; a screw is arranged on a side of the Z-axis box body; a cylinder is fixed on the top of the Z-axis box body; the bottom of the cylinder is connected with a cylinder rod; the cylinder rod penetrates in the ram; the cylinder drives the cylinder rod to lift; and the double-oscillation electric spindle is fixed on the bottom of the cylinder rod and lifts along with the cylinder rod.

Owner:东阳甬创智诚家具设计有限公司

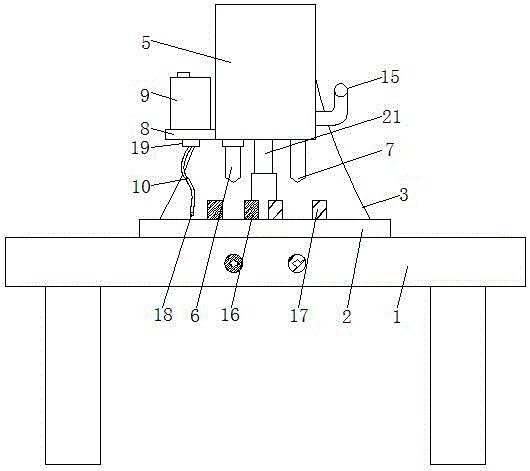

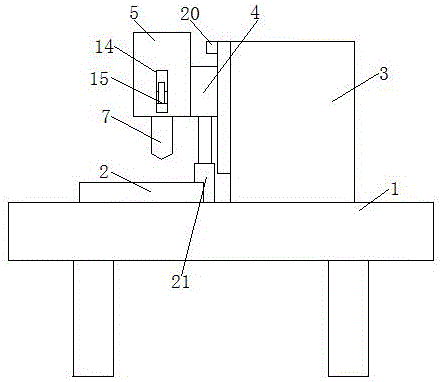

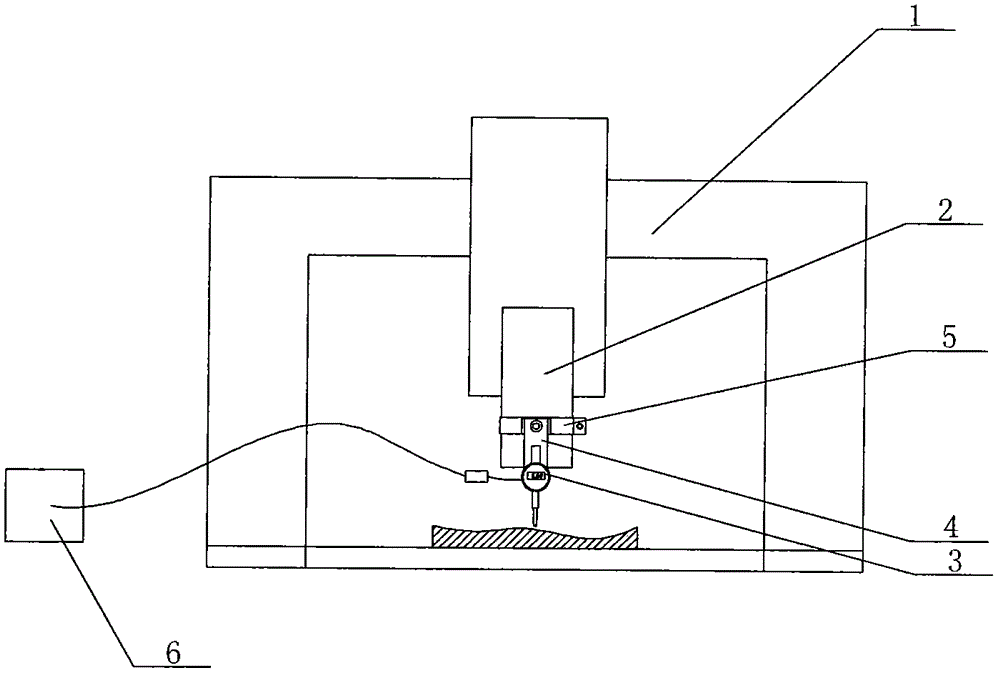

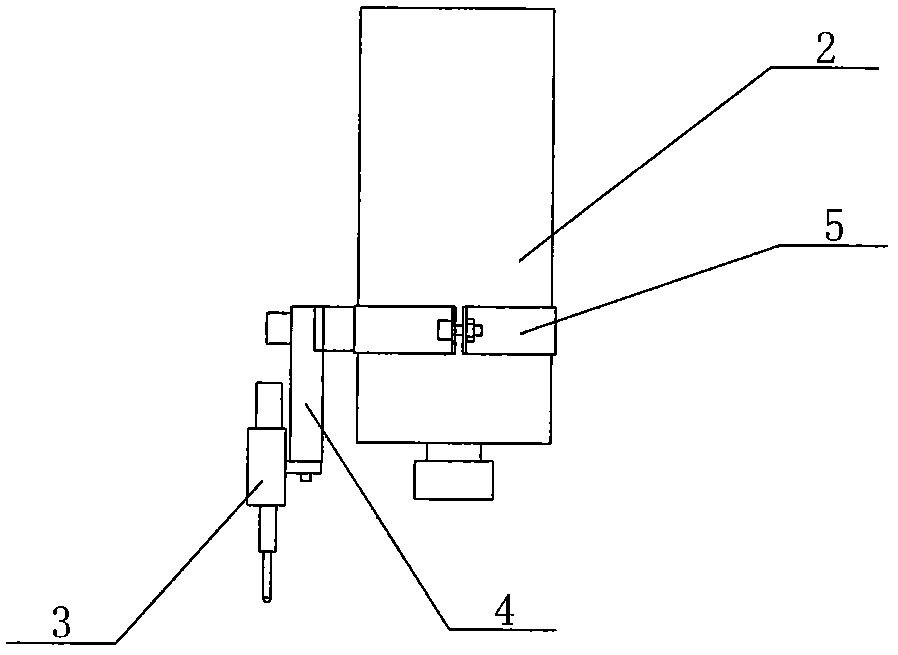

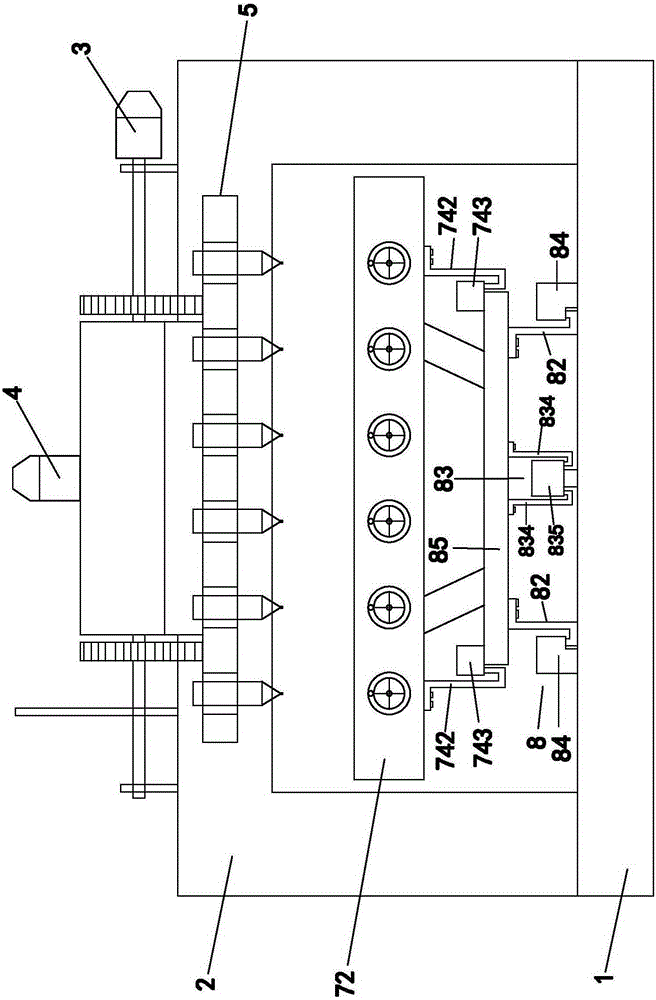

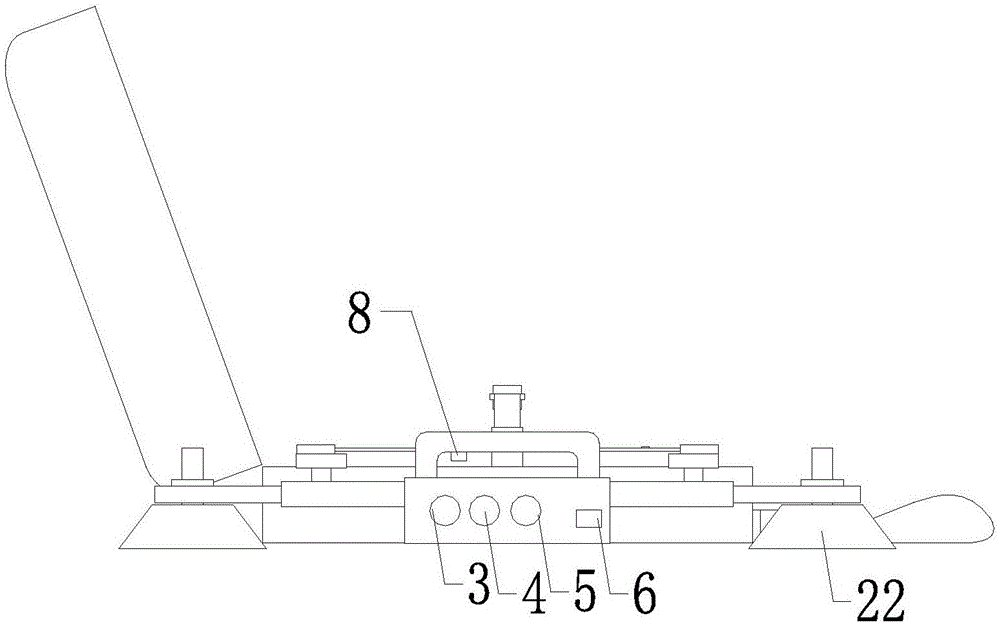

Novel numerical control carving machine

The invention discloses a novel numerical control carving machine and relates to the technical field of mechanical equipment. The novel numerical control carving machine comprises a carving machine body (1) and a main shaft (2). The carving machine body (1) is provided with the main shaft (2). The novel numerical control carving machine further comprises a digital micrometer (3), a connection electric wood block (4) and a stainless steel iron hoop (5). The stainless steel iron hoop (5) is arranged on the lower portion of the main shaft (2) through a fixing bolt, and the front side of the stainless steel iron hoop (5) is connected with the connection electric wood block (4) through a fixing bolt. The lower portion of the connection electric wood block (4) is connected with the digital micrometer (3) through a fixing bolt. The digital micrometer (3) is electrically connected with a computer (6) through a wire. The novel numerical control carving machine is simple in structure, convenient to operate and capable of achieving automatic plate face leveling, and improves carving precision.

Owner:王立果

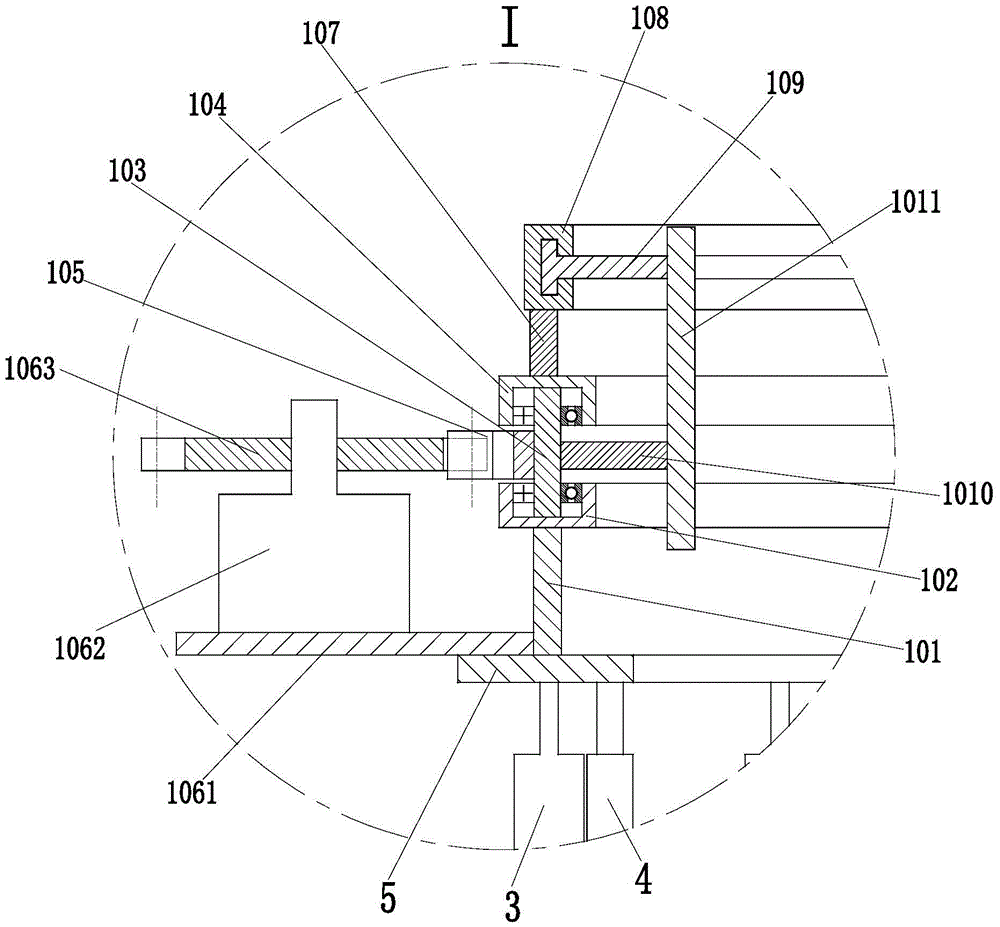

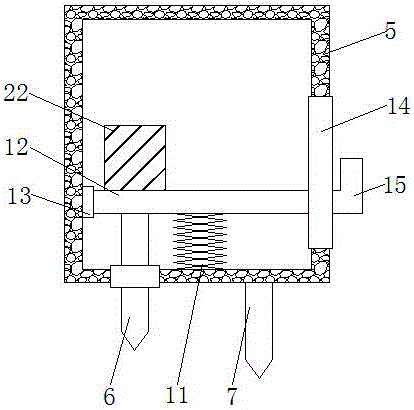

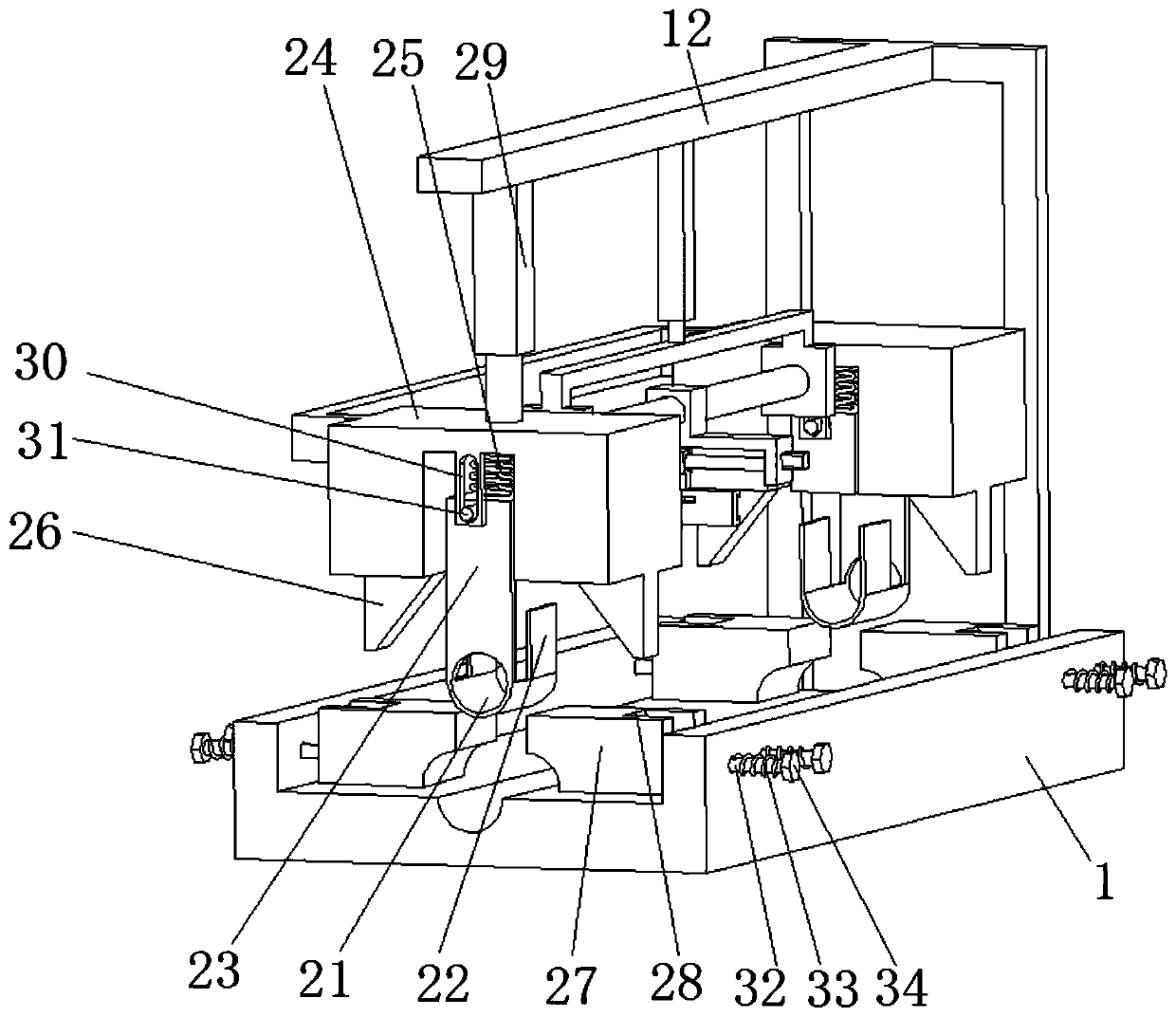

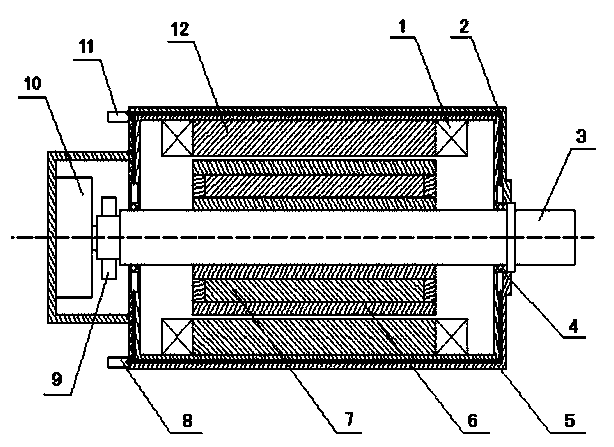

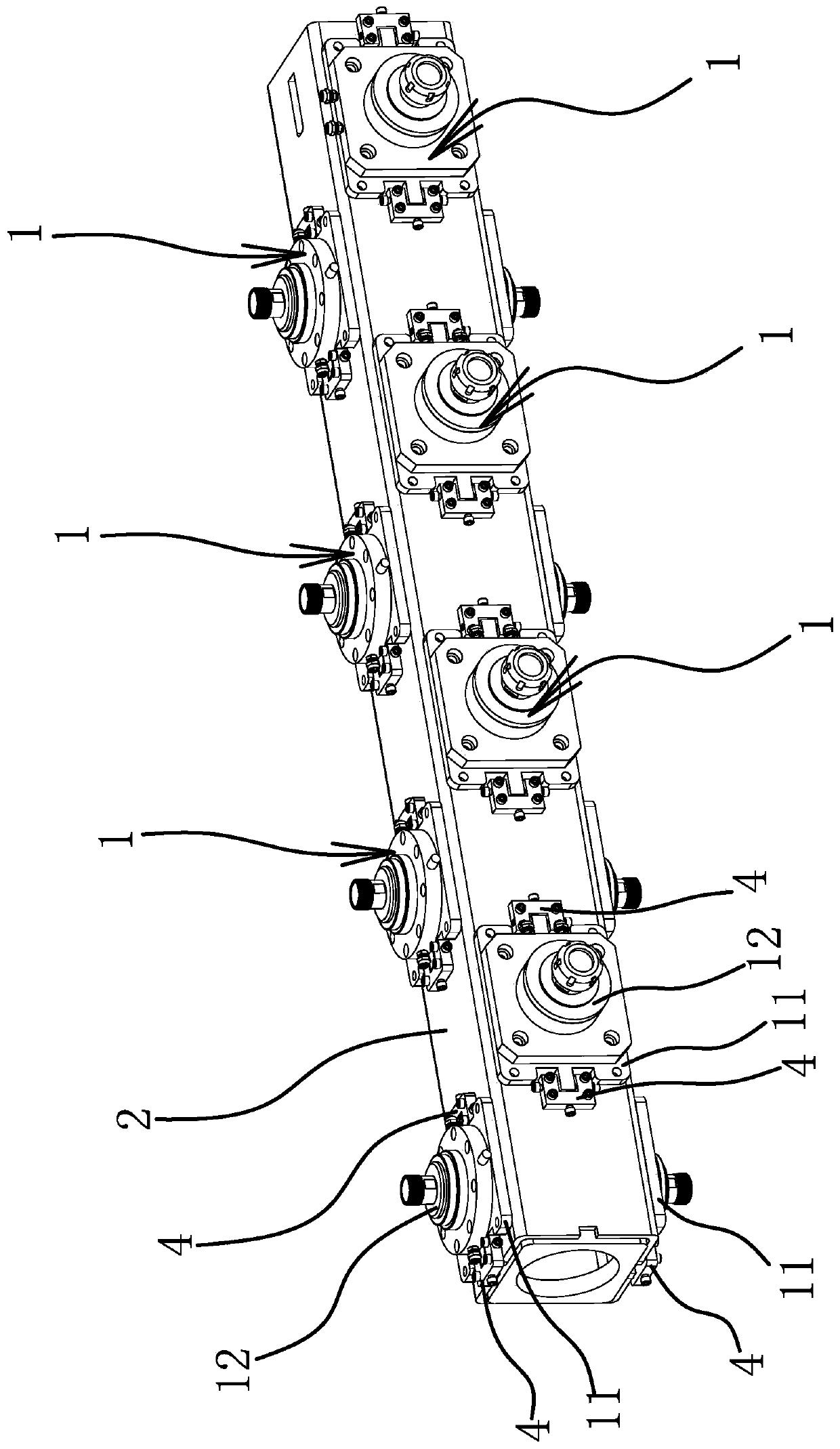

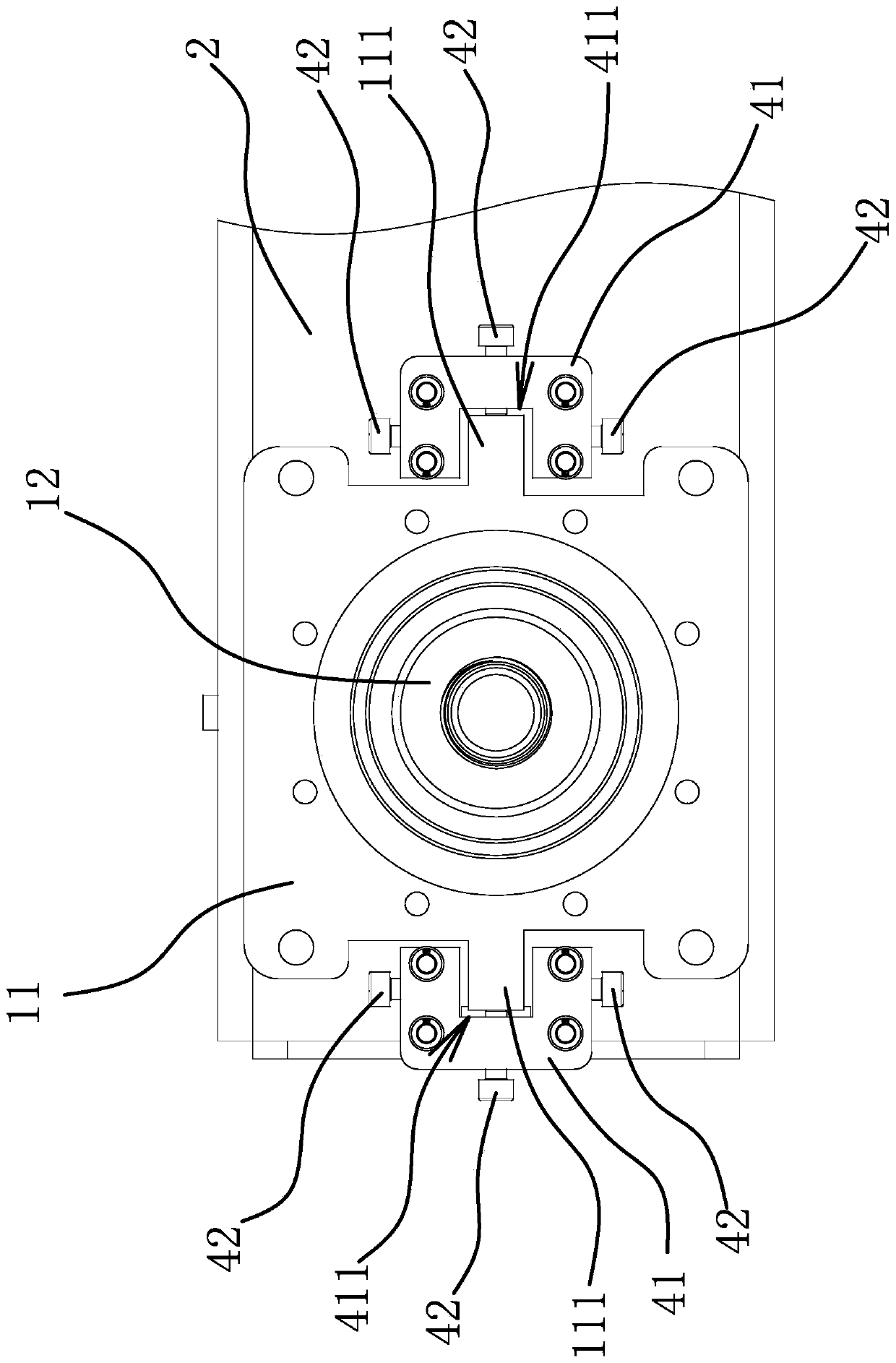

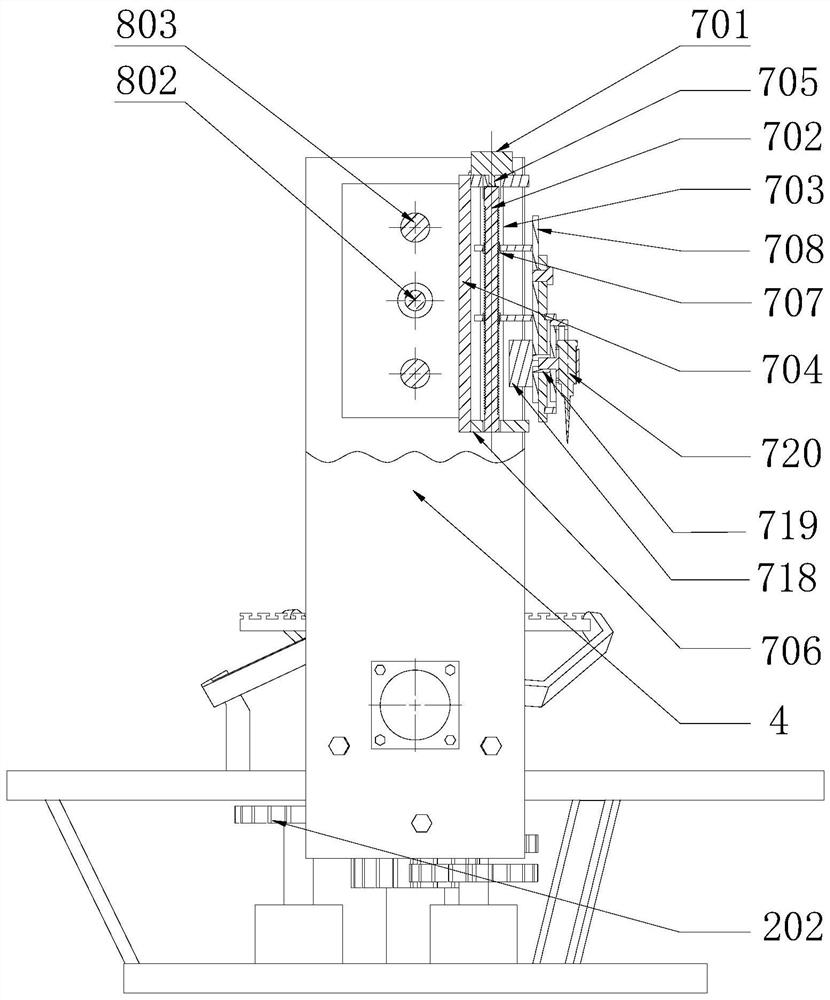

Engraving precision improvement device and axis and table adjustment device for stereo engraving machine

InactiveCN106541764AEasy to adjustEasy loading and unloadingOther artistic work equipmentsModel makingReducer

The invention discloses an engraving precision improvement device and an axis and table adjustment device for a stereo engraving machine and belongs to the technical field of engraving machines. The invention has two topics, wherein the first is the engraving precision improvement device which is characterized in that two sets of independent stepping or servo motors are utilized to drive precision reducers, so that the purposes of reducing and canceling back clearances which exist due to structures of the reducers and improving the engraving precision are achieved; and the second is the axis and table adjustment device which comprises centering chucks, trapezoidal clamping pieces, engine bases, guide rails, an eccentric board and clamping plates. The engraving precision improvement device and the axis and table adjustment device for the stereo engraving machine have the following beneficial effects: by adoption of the engraving machine, engraved objects rotate and revolve accurately, so that the engraving precision is improved; and the axis and table adjustment device can adjust the axis, the height and the length according to object sizes, so that the engraved objects can be conveniently loaded and unloaded.

Owner:蒙建宇

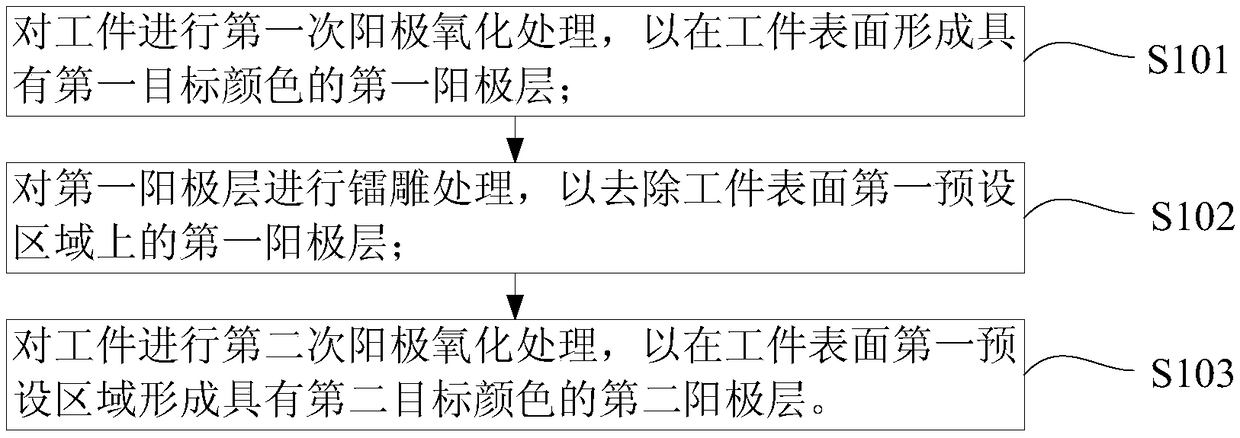

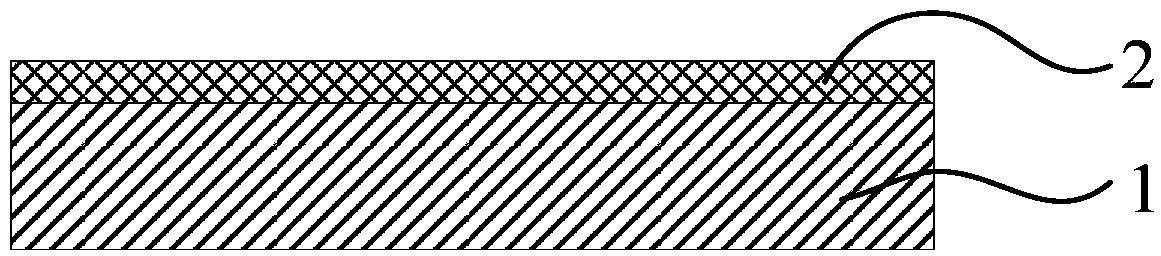

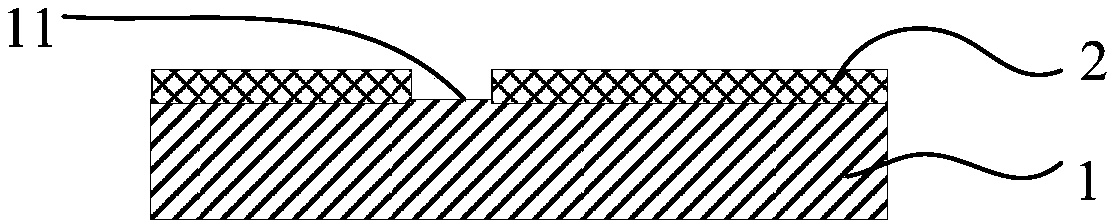

Workpiece surface treatment method and terminal shell

PendingCN108754569AFacilitates a second anodizing treatmentReduce or even avoid knife marksDigital data processing detailsSurface reaction electrolytic coatingUltimate tensile strengthControllability

The invention relates to a workpiece surface treatment method and a terminal shell, and belongs to the technical field of workpiece surface treatment. According to the workpiece surface treatment method and the terminal shell, a first anode layer with a first target color on the surface of a workpiece is subjected to laser carving treatment, so that the first anode layer at a first preset area onthe surface of the workpiece is removed, the first preset area on the surface of the workpiece is exposed out so that the workpiece can be subjected to secondary anodic oxidation treatment, and a second anode layer with a second target color is formed at the first preset area on the surface of the workpiece. Moreover, the controllability of carving strength is good in the laser carving treatment process, carving precision is high, and therefore segment gaps on the surface of the workpiece can be reduced and even avoided, machined traces on the surface of the workpiece are avoided and the visual effect of the workpiece is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

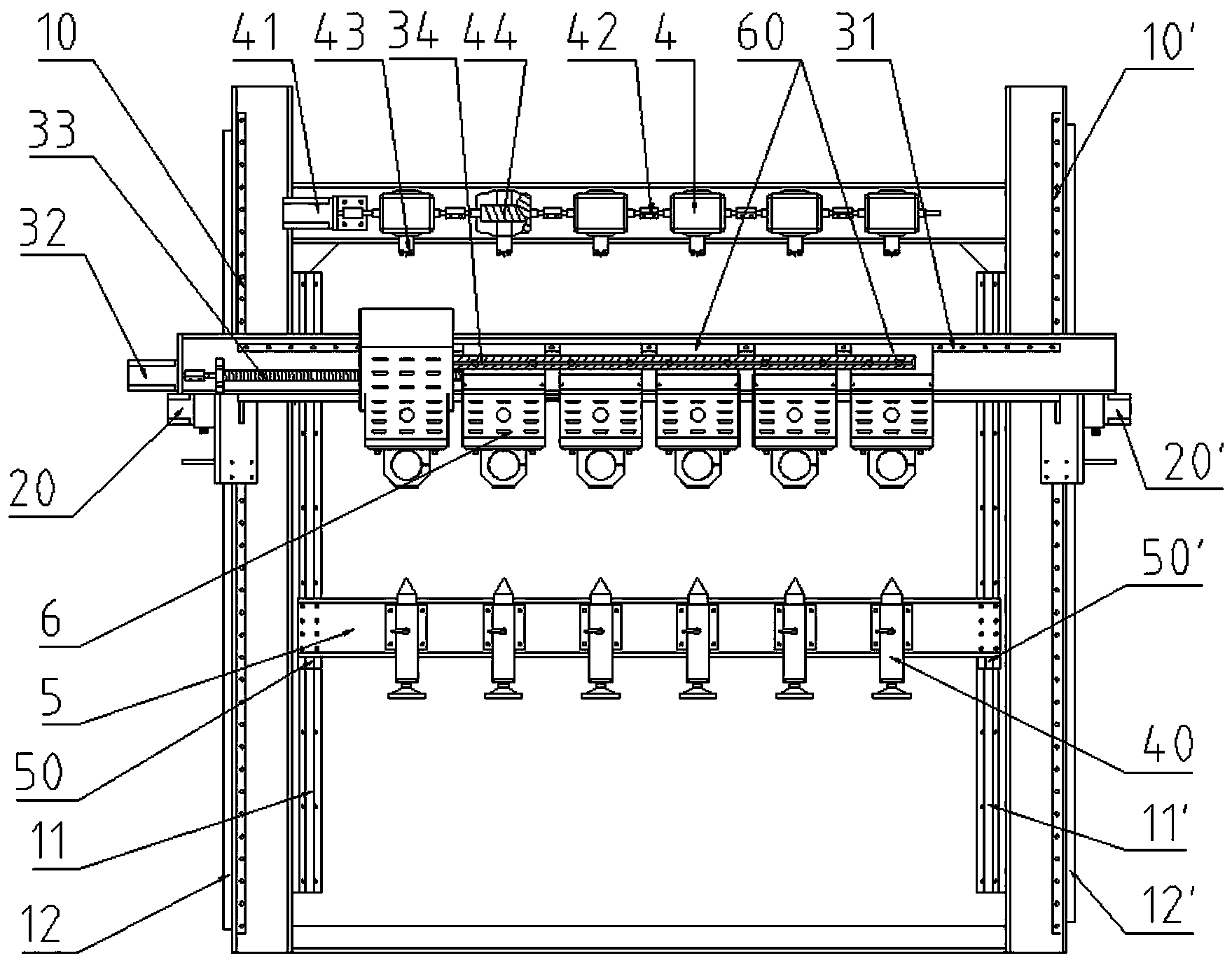

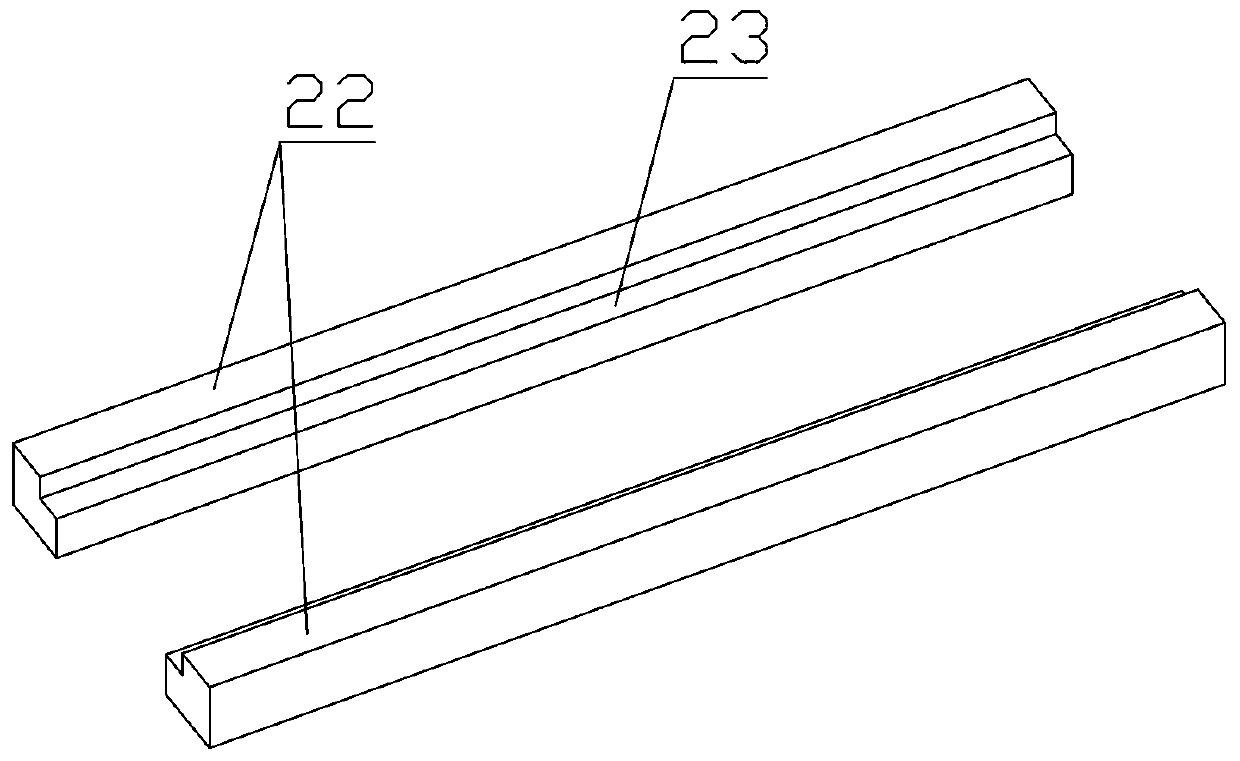

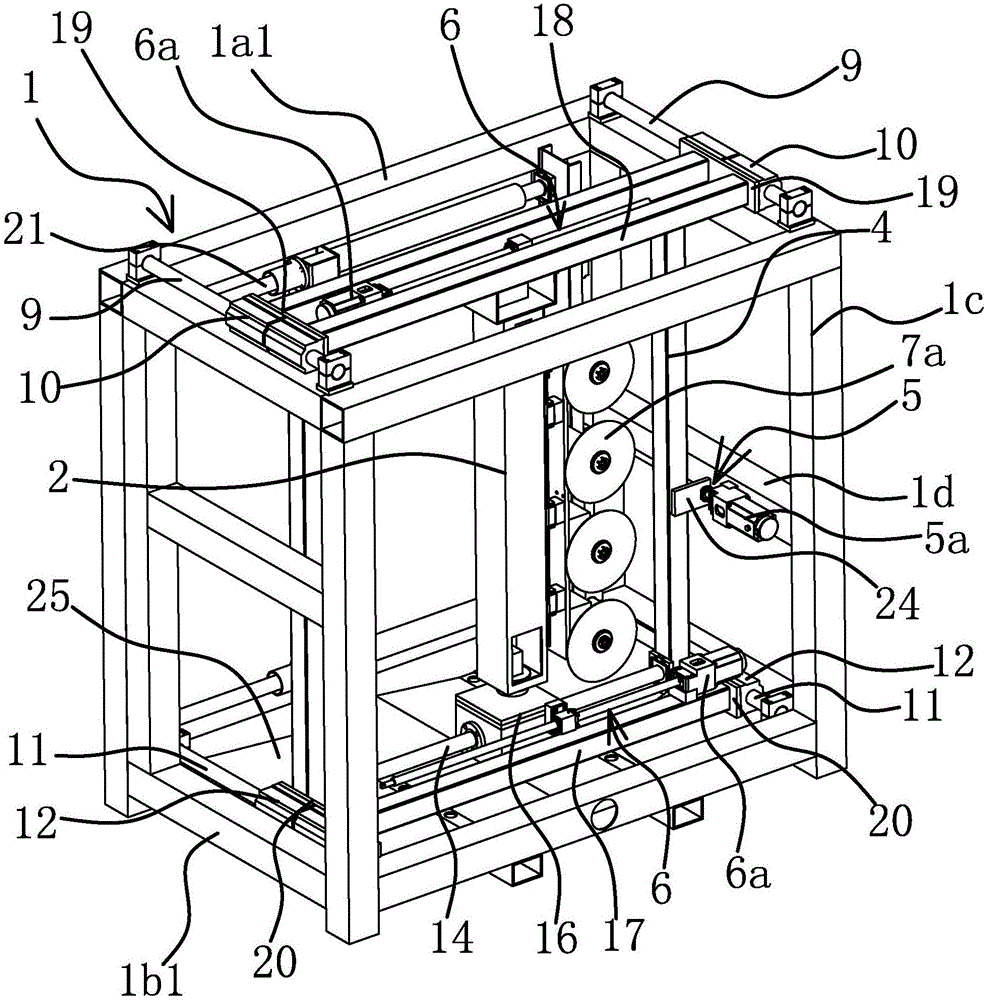

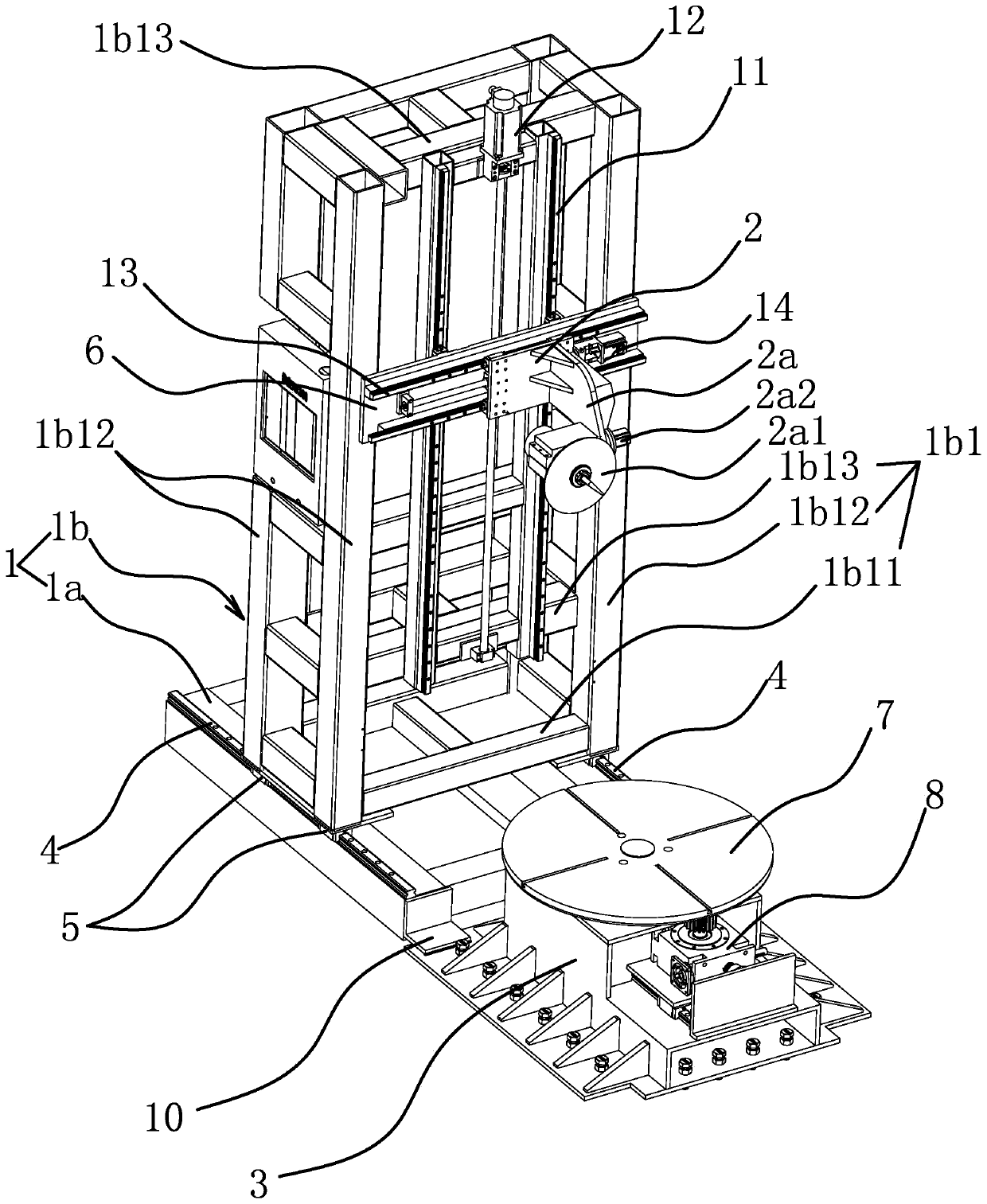

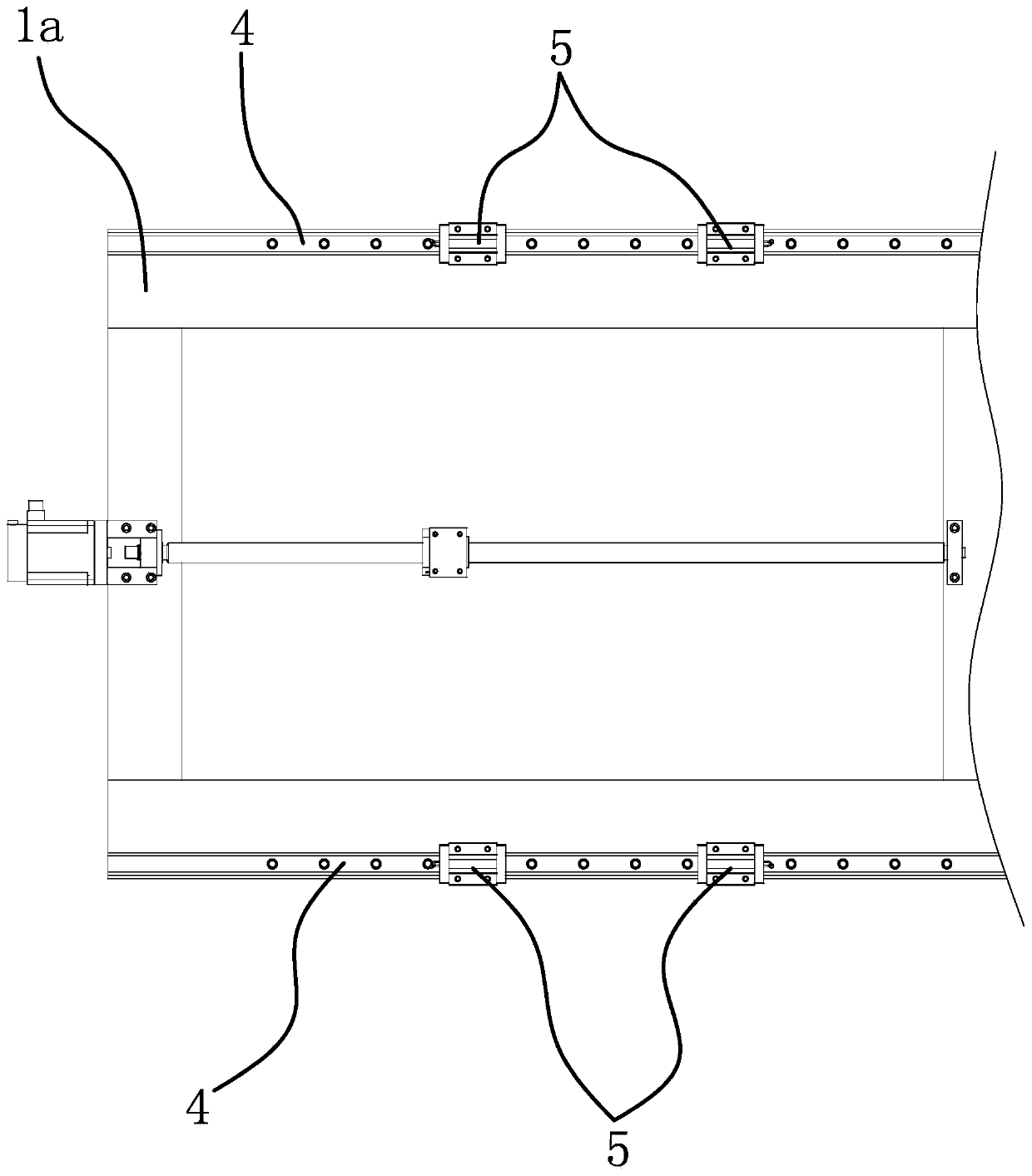

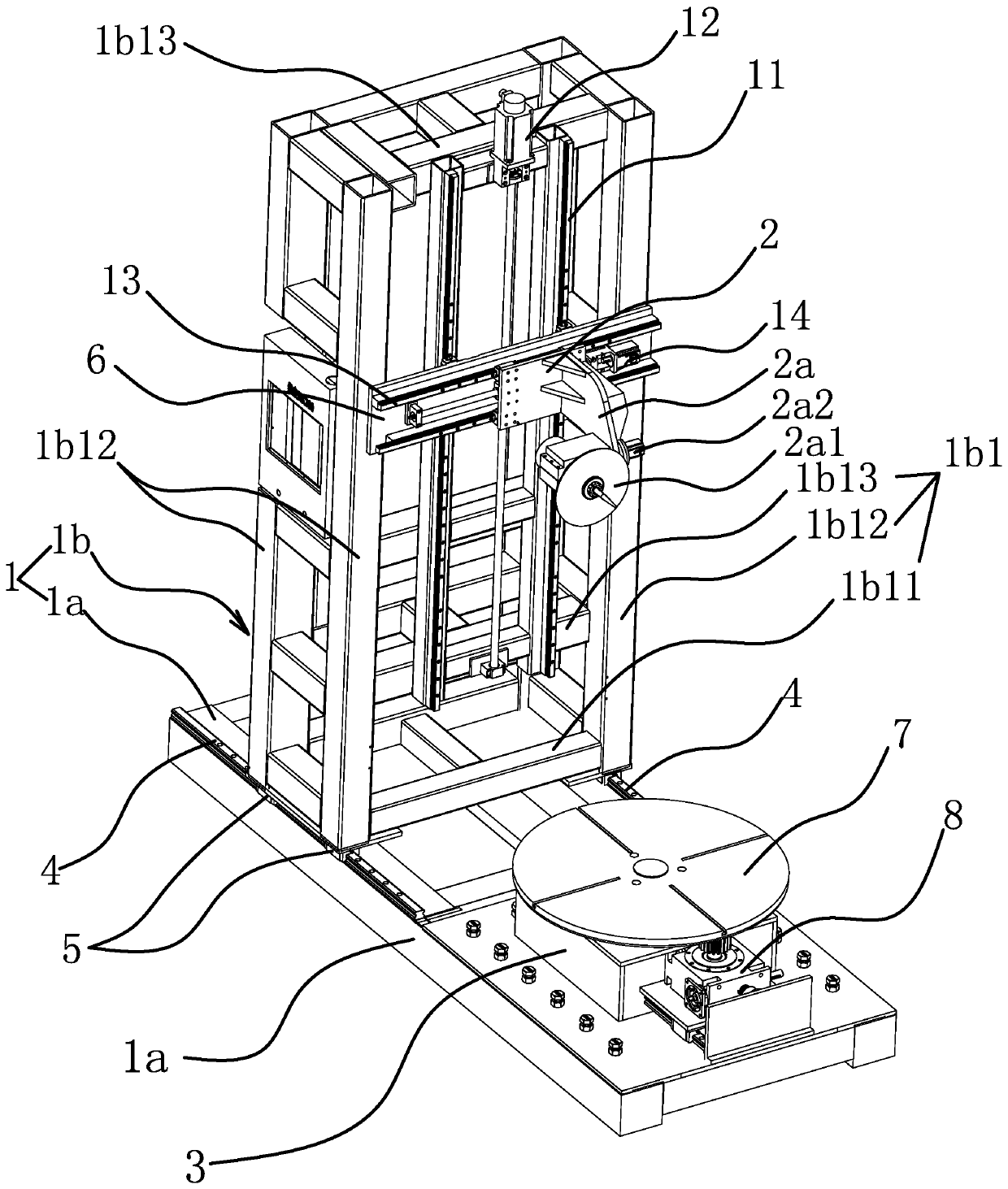

Horizontal numerical control three-dimensional carving machine

ActiveCN105252945AAffects engraving accuracyAffect consistencyModel makingNumerical controlEngineering

The invention discloses a horizontal numerical control three-dimensional carving machine which comprises a base, a portal frame, a workpiece clamping device, a transverse moving mechanism, a vertical moving mechanism and a carving tool frame. The workpiece clamping device comprises a fixed beam, a movable beam and a moving and fixing mechanism. A front-back moving mechanism is arranged between the workpiece clamping device and the base, and comprises two slide rails, slide blocks, a driving structure, slide rail waterproof covers and a movable base plate. The slide rails are fixedly arranged on the base. The driving structure is arranged in the middle. The slide blocks are arranged on the two sides, corresponding to the two slide rails, of the movable base plate respectively. The slide blocks are each of a crank structure. One end of each slide block slides on the corresponding slide rail, and the other end of each slide block is fixedly connected with the movable base plate. The slide water waterproof covers cover the two slide rails and cover the ends, correspondingly sliding on the slide rails, of the slide blocks respectively. The carving machine is high in structural weight capacity, stable in structure and smooth and stable in mechanical actions, and factors influencing carving accuracy and carving consistency can be reduced as much as possible.

Owner:福建省农球机械科技有限公司

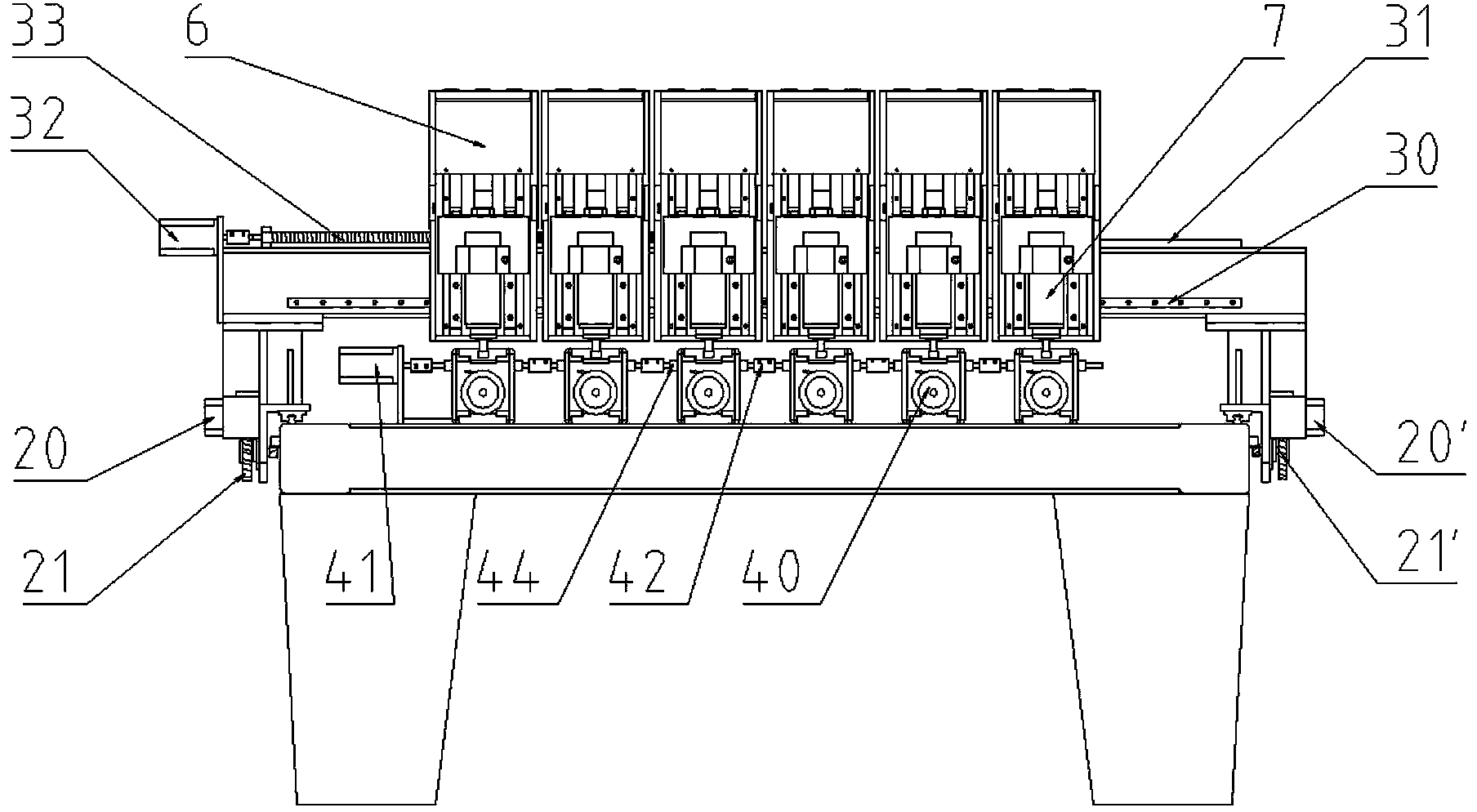

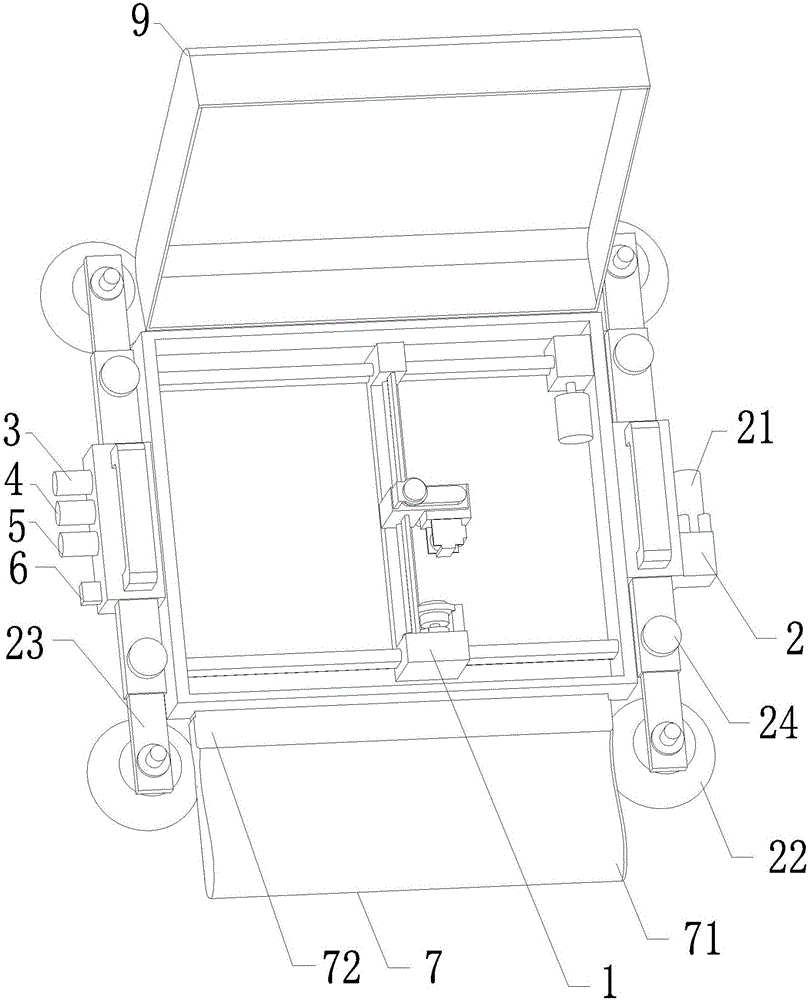

Carving machine

ActiveCN106218289ADoes not affect engraving accuracyImprove engraving accuracyOther artistic work equipmentsModel makingEngineeringCarving

The invention provides a carving machine, and belongs to the technical field of carving devices. The carving machine solves the technical problems that an existing carving machine is complex in structure and high in manufacturing cost. The carving machine comprises a machine frame and a workpiece clamping mechanism arranged in the machine frame. A straight-strip-shaped tool frame located on one side of the workpiece clamping mechanism is further arranged in the machine frame. Clamping assemblies arrayed in the vertical direction are arranged in the workpiece clamping mechanism. A rectangular vertically-arranged movement frame is arranged in the machine frame and is driven by a first lead screw mechanism to move back and forth in the horizontal and longitudinal directions. The tool frame mentioned above is arranged in the vertical direction, connected to the interior of the movement frame and driven by a second lead screw mechanism to move back and forth in the horizontal and transverse directions. Tool assemblies corresponding to the clamping assemblies one to one in number are arranged on the tool frame. Each tool assembly is driven by a corresponding carving motor. The carving machine has the beneficial effects of being high in carving precision and carving efficiency.

Owner:玉环圣弘法数控雕刻设备有限公司

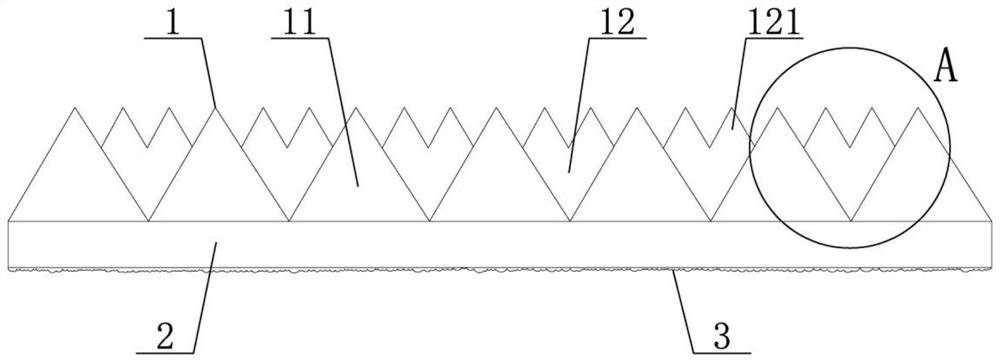

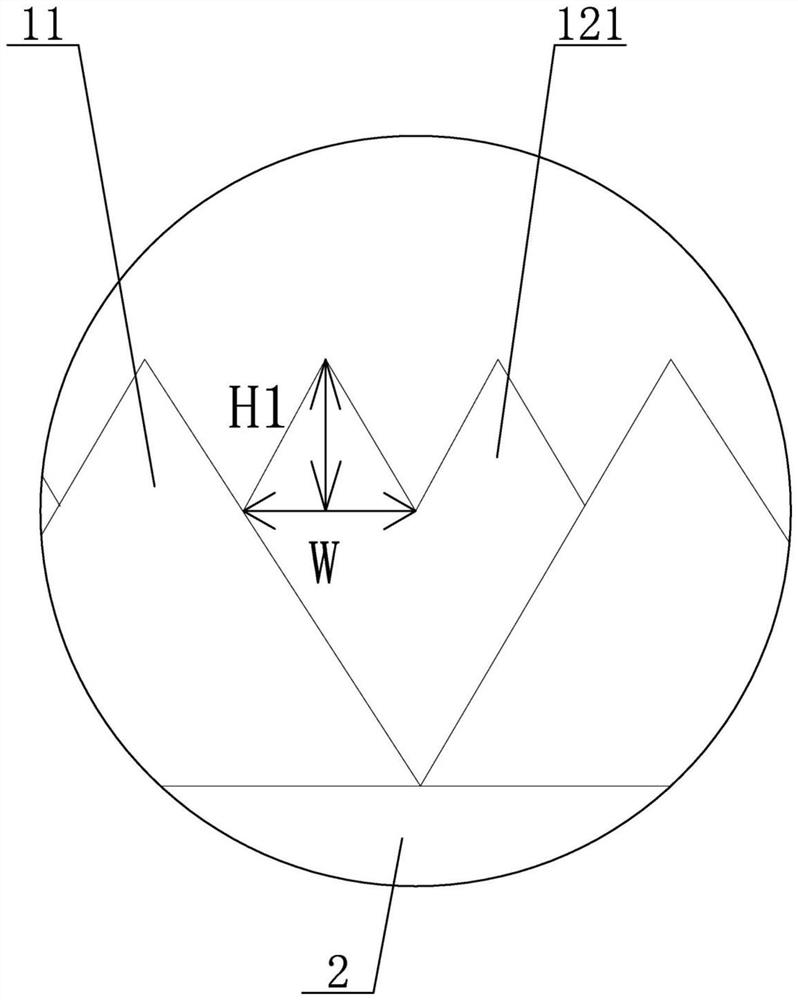

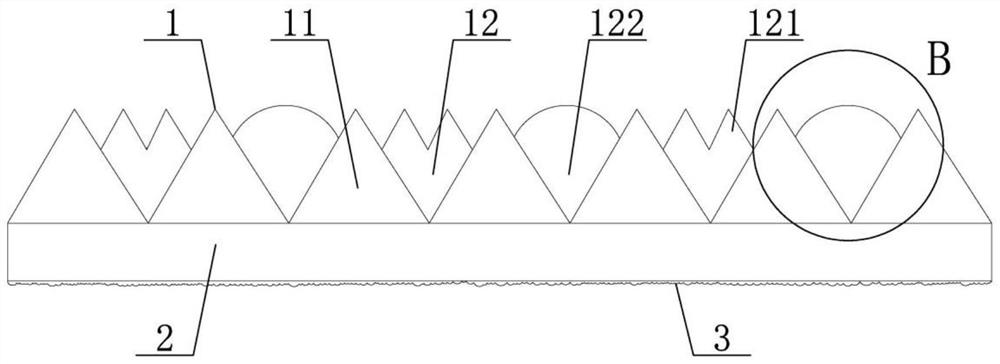

Brightness enhancement film with high resilience and high brightness

The high-resilience and high-brightness brightness brightness enhancement film comprises a prism layer, a base material layer and a back coating structure layer, which are arranged in sequence; the prism layer comprises a first prism structure and a second prism structure, the cross section of a prism of the first prism structure is triangular, and prisms of the second prism structure are evenly arranged between prisms of the first prism structure. The upper portion of each prism of the second prism structure is provided with two upper edges, and the highest position of the first prism structure is flush with the highest positions of the upper edges. Through the design, the brightness enhancement film can rebound faster, the brightness is higher, and the preparation method is simpler and more convenient.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

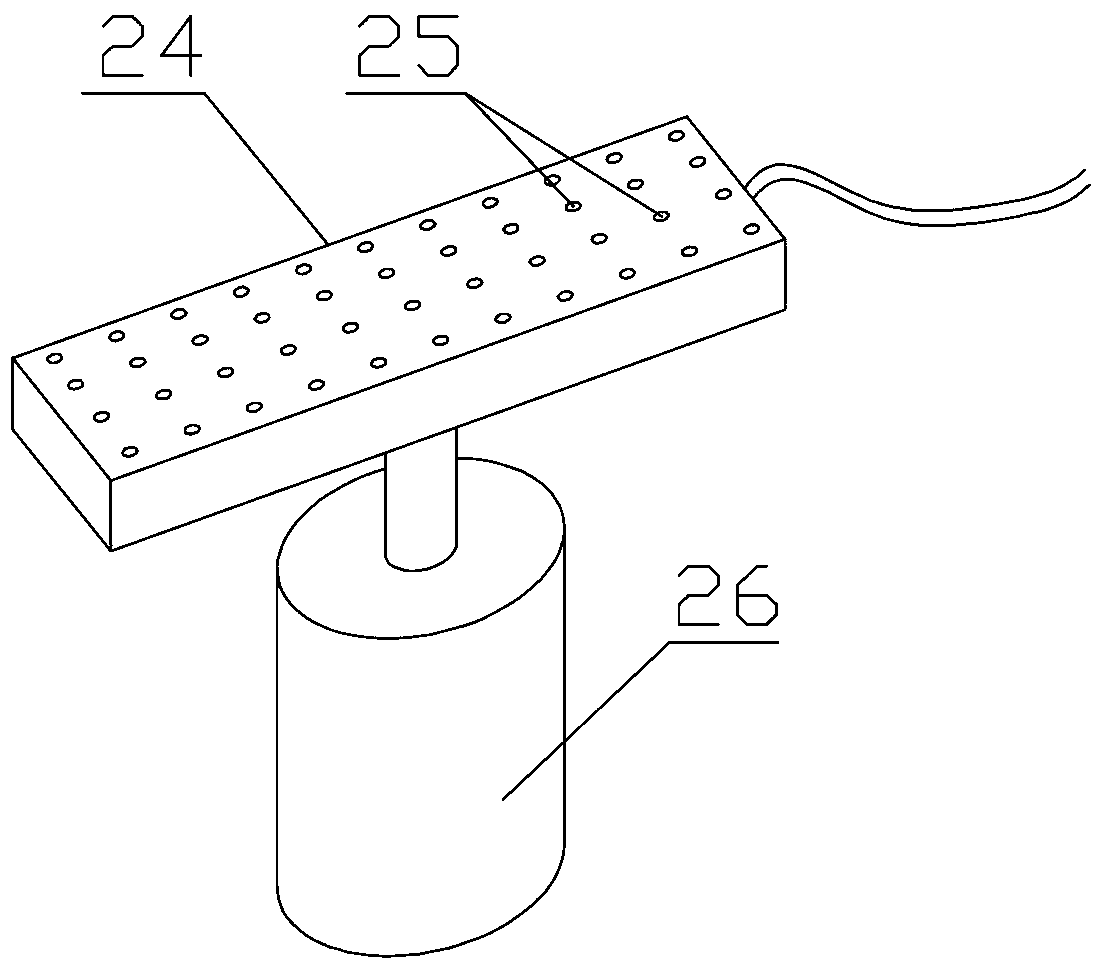

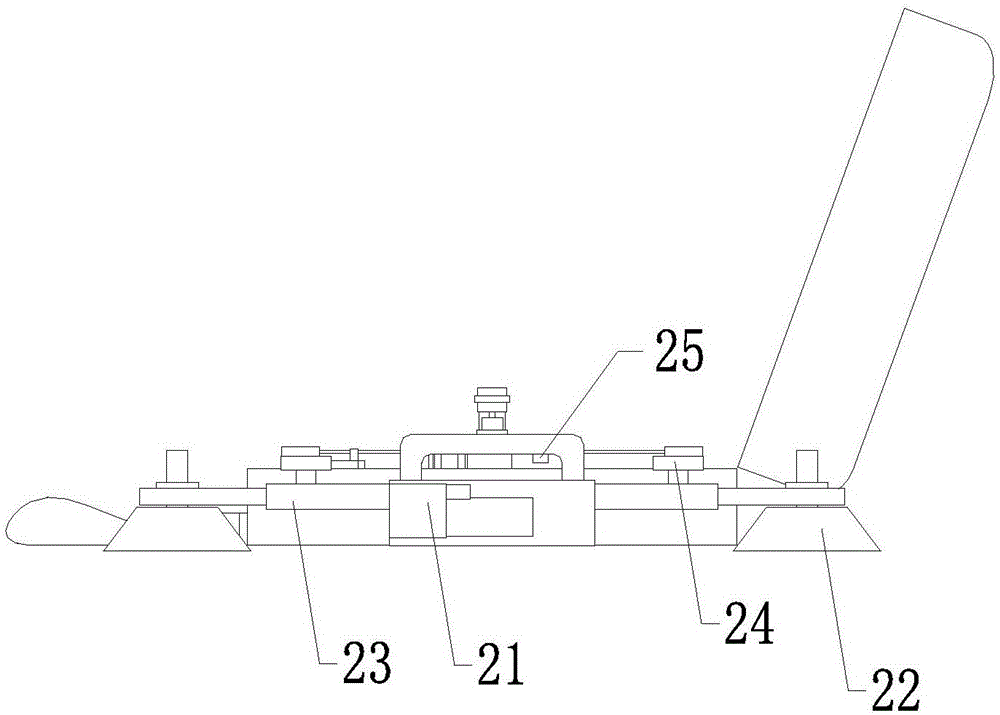

Wall carving machine based on negative-pressure adsorption principle and use method thereof

ActiveCN106585248AWide range of applicationsImprove work efficiencyModel makingLength changeEngineering

The invention relates to the field of carving machines, in particular to a wall carving machine based on the negative-pressure adsorption principle and a use method thereof. The wall carving machine comprises a carving component, a negative-pressure adsorption component used for fixing the wall carving machine on a wall, an x-axis initial position fine-tuning knob used for fine-tuning of an initial carving position in an x-axis direction, a y-axis initial position fine-tuning knob, a z-axis initial position fine-tuning knob, an initial position OK button, a collection device used for collecting debris, a switch and a housing, wherein the negative-pressure adsorption component comprises a mini vacuum pump used for providing negative pressure, suckers used for forming a negative-pressure cavity and providing an upward frictional force for the wall carving machine, telescopic rods used for adjusting the positions of the suckers through length changes according to construction environments to facilitate adsorption, fixing knobs and an adsorption control button. The wall carving machine not only allows a user to perform precise automatic carving on a vertical or inclined working face but also is wide in application range and high in working efficiency.

Owner:安徽金福瑞家具股份有限公司

Three-dimensional carving machine

PendingCN110228320AImprove engraving accuracyPrevent deviationOther artistic work equipmentsModel makingDrive motorEngineering

The invention provides a three-dimensional carving machine, and belongs to the technical field of machines. By adoption of the three-dimensional carving machine, the carving precision can be improved.The three-dimensional carving machine comprises a plurality of carving assemblies, a strip-shaped tool rest connected with the carving assemblies, and a clamping assembly used for clamping workpieces. Each carving assembly comprises a base arranged on the tool rest and a driving motor fixed to the base and used for driving a tool to rotate. The bases are fixed in the axial direction of the driving motors relative to the tool rest and can move in the radial direction of the driving motors relative to the tool rest. Positioners used for adjusting the movement of the bases relative to the tool rest are arranged on the side edges of the bases and can position the bases in the radial direction of the driving motors. According to the three-dimensional carving machine, the positions of tools canbe slightly adjusted, so that positional deviations, caused by manufacturing and assembling errors, of the tools are avoided, it is guaranteed that the tools can be located at machining positions required by the design, and accordingly, the carving precision of the carving machine is improved.

Owner:吴善旺

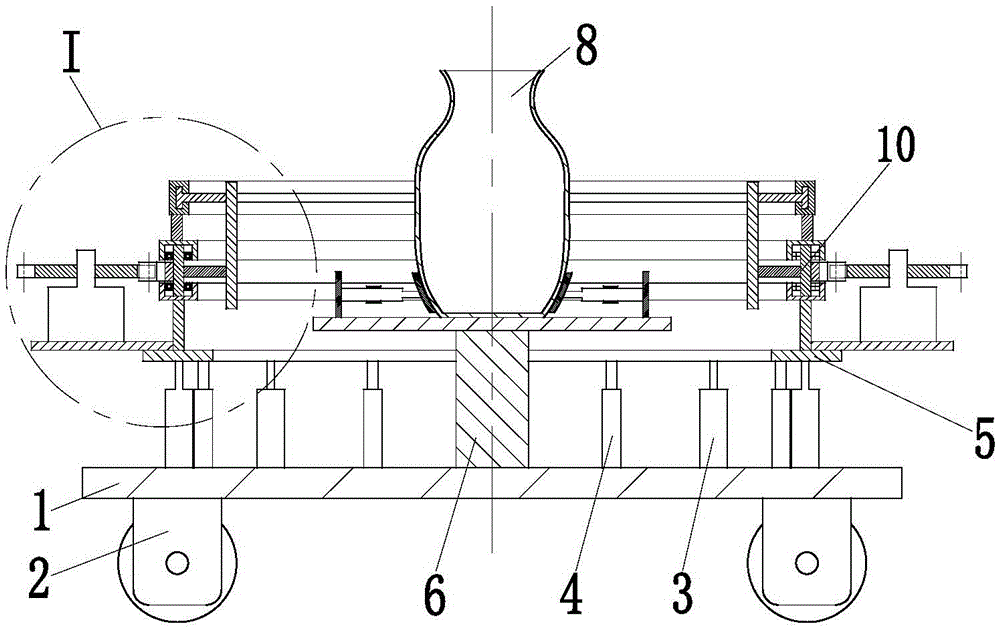

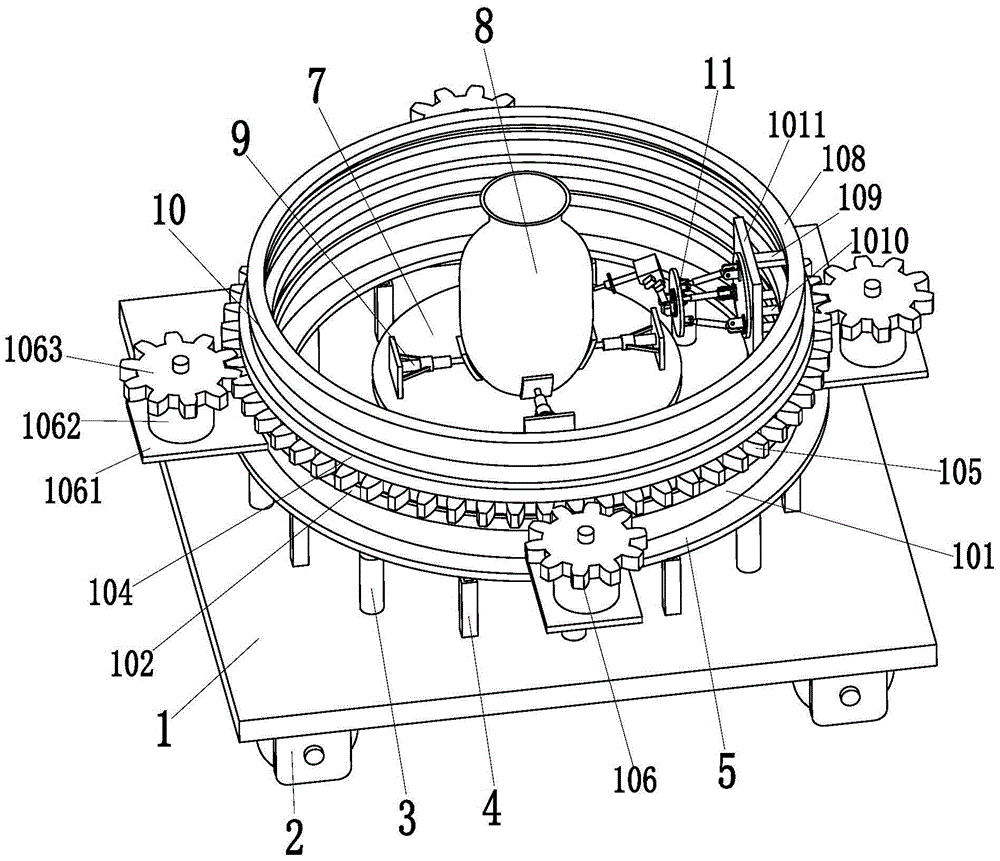

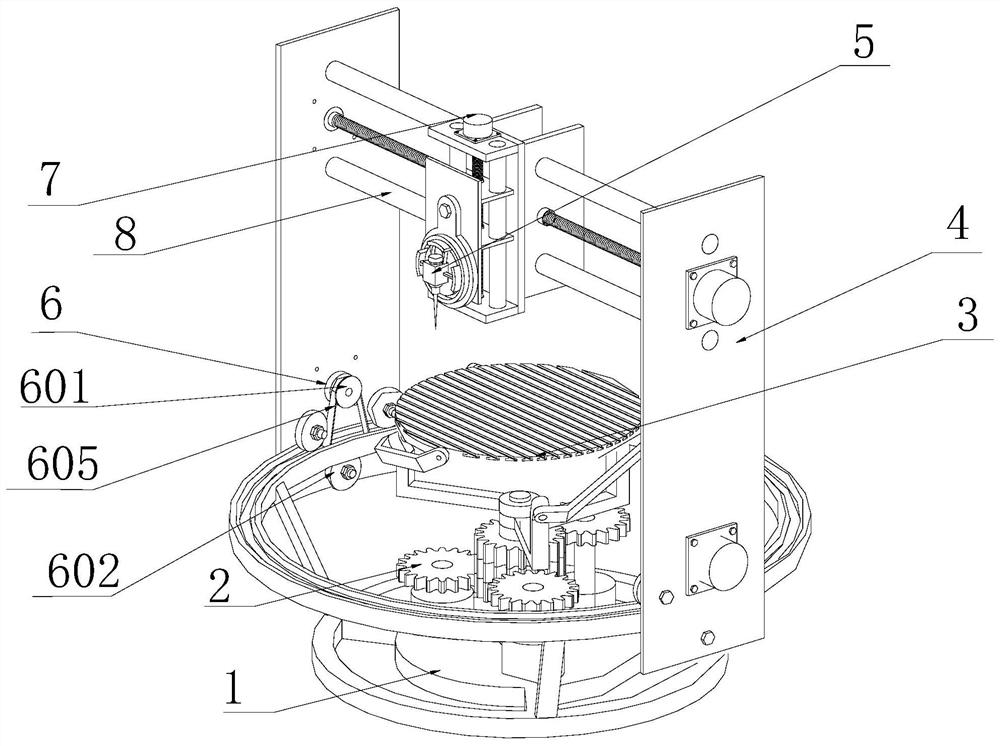

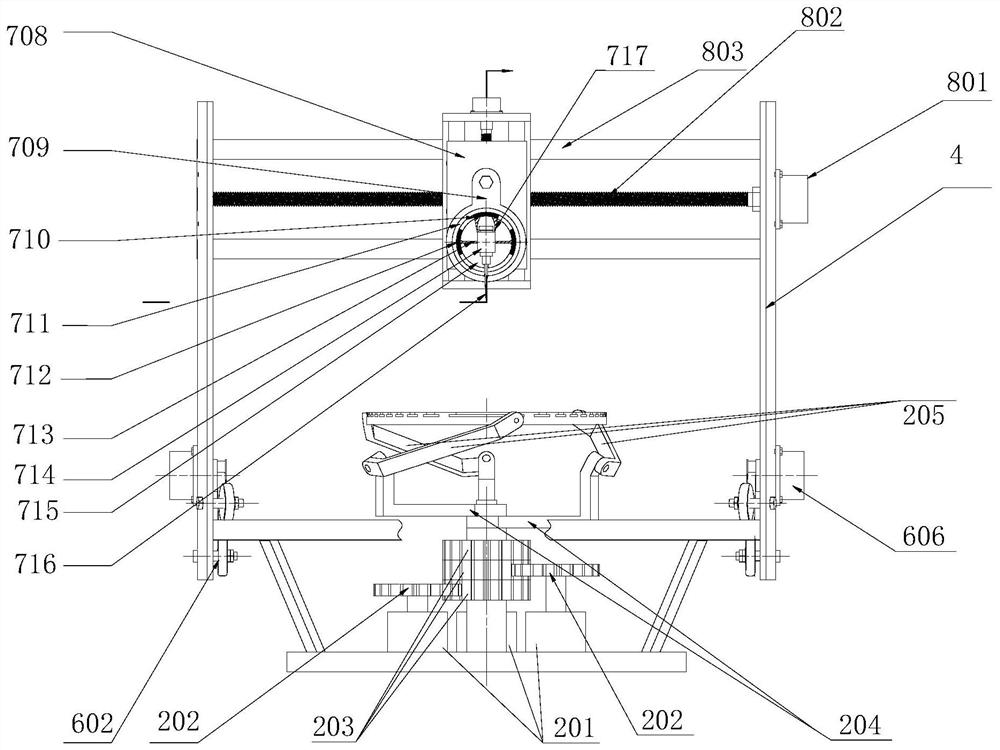

Annular rotary three-dimensional space carving machine

The invention discloses an annular rotary three-dimensional space carving machine. The annular rotary three-dimensional space carving machine comprises a base, a parallel operation device, a workbench, an arc-shaped stand column, a cutterhead assembly, a circumferential feeding mechanism for driving the cutterhead assembly to do circumferential motion in a horizontal plane, a Y-direction feeding mechanism for driving the cutterhead assembly to do linear motion in a horizontal direction, and a Z-direction feeding mechanism for driving the cutterhead assembly to do linear motion in a vertical direction; the workbench is connected to the base through the parallel operation device; an annular guide rail is arranged on the base; the arc-shaped stand column is connected with the guide rail through the circumferential feeding mechanism; the cutterhead assembly is connected with the arc-shaped stand column through the Y-direction feeding mechanism and the Z-direction feeding mechanism; and the circumferential feeding mechanism is a three-roller circumferential feeding mechanism. The annular rotary three-dimensional space carving machine is stable in structure and high in operation precision and belongs to the field of carving machines.

Owner:SOUTH CHINA AGRI UNIV

Vertical engraving machine

PendingCN110228317AImprove engraving accuracyMobile stable and reliableModel makingEngineeringMachining

The invention provides a vertical engraving machine, and belongs to the technical field of machining equipment. The problem about how to improve engraving precision is solved. The vertical engraving machine comprises a machine frame, a tool frame and a mounting base, wherein the machine frame comprises a base and a three-dimensional moving frame arranged above the base and used for mounting the tool frame; at least two sliding rails are fixedly arranged on the base in parallel; the three-dimensional moving frame is of a framework structure which is integrally columnar and vertically arranged,and the width direction of the three-dimensional moving frame is consistent with the direction of the sliding rails; two sliding blocks are respectively fixed on two sides of the bottom of the three-dimensional moving frame, and each sliding block is in sliding connection with the corresponding sliding rail; and the mounting base is immobile relative to the base and is arranged on one end of the sliding rails. Through the design, the three-dimensional moving frame moves horizontally and longitudinally with a tool, and the mounting base does not move during machining, so that the problem that the engraving precision is influenced caused by inaccurate clamping and positioning due to instable movement of the workpiece is avoided, and the engraving precision of the engraving machine is improved.

Owner:吴善旺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com