Pulse laser three-dimensional engraving method

A three-dimensional engraving and pulsed laser technology, applied in the field of fiber laser three-dimensional engraving and laser three-dimensional engraving, can solve the problems of affecting the surface quality, increasing the number of engraving layers, reducing the processing efficiency, etc., to improve the engraving accuracy, strong three-dimensional sense, pattern texture clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The steps of this pulsed laser three-dimensional engraving method include:

[0025] (1) According to the characteristics and precision requirements of the carved object, discretely slice and layer the 3D model of the carved object;

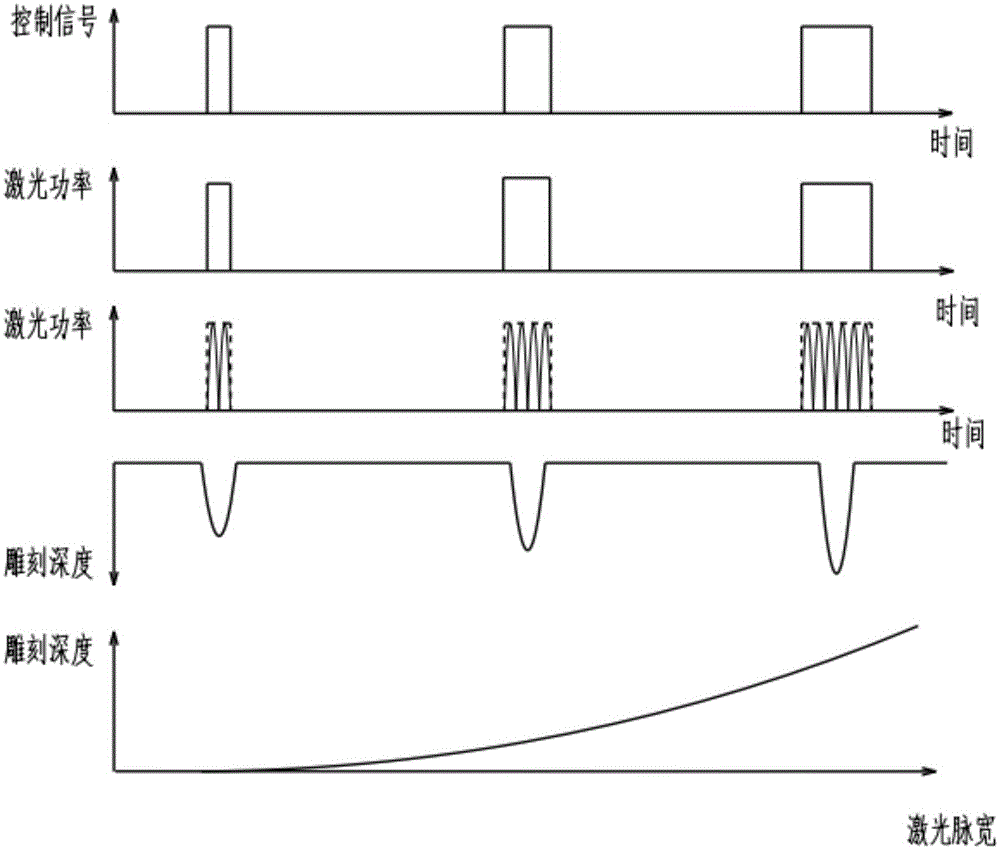

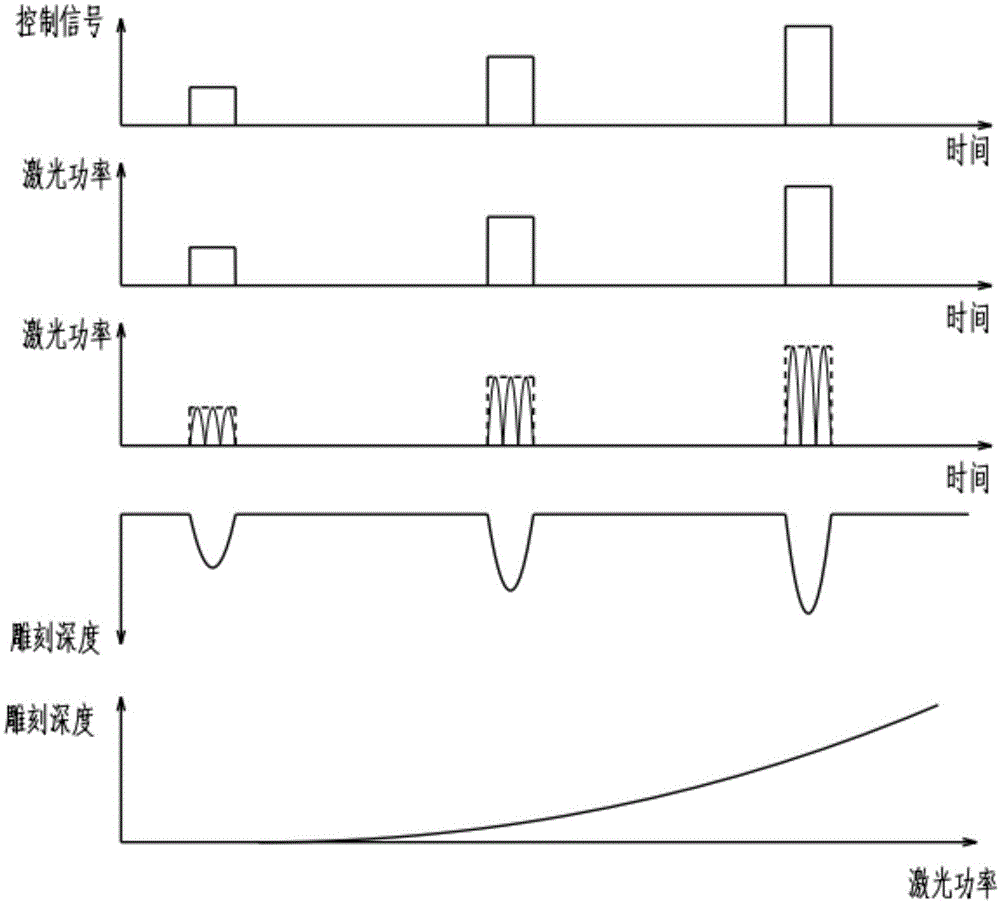

[0026] (2) In combination with the characteristics of the laser used, select the corresponding method of controlling the laser output parameters in order to achieve engraving at different depths in the same layer;

[0027] (3) Convert the data in steps (1) and (2) into electrical signals recognized by the laser through the computer, and then control the output of the laser to complete the engraving layer by layer;

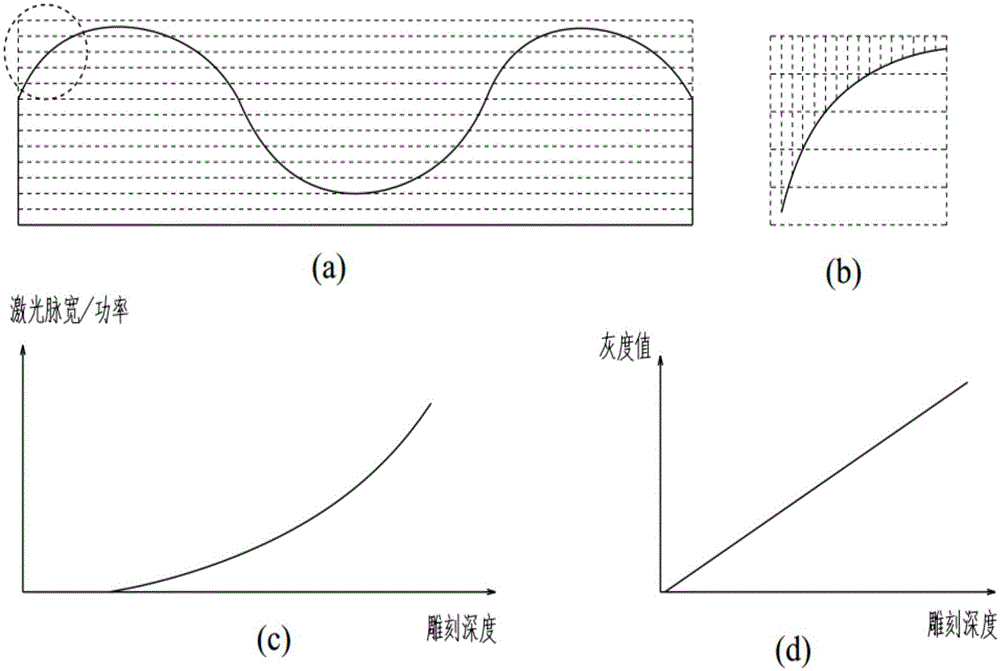

[0028] In the described step (1), the depth of engraving in the same layer after layering is represented by a gray value, and different gray values represent different depths of engraving, and the coordinates of corresponding engraving points in the same layer are represented by two-dimensional lattice coordinates , the value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com