Chip laser engraving equipment and using method thereof

A laser engraving and laser engraving technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of high engraving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

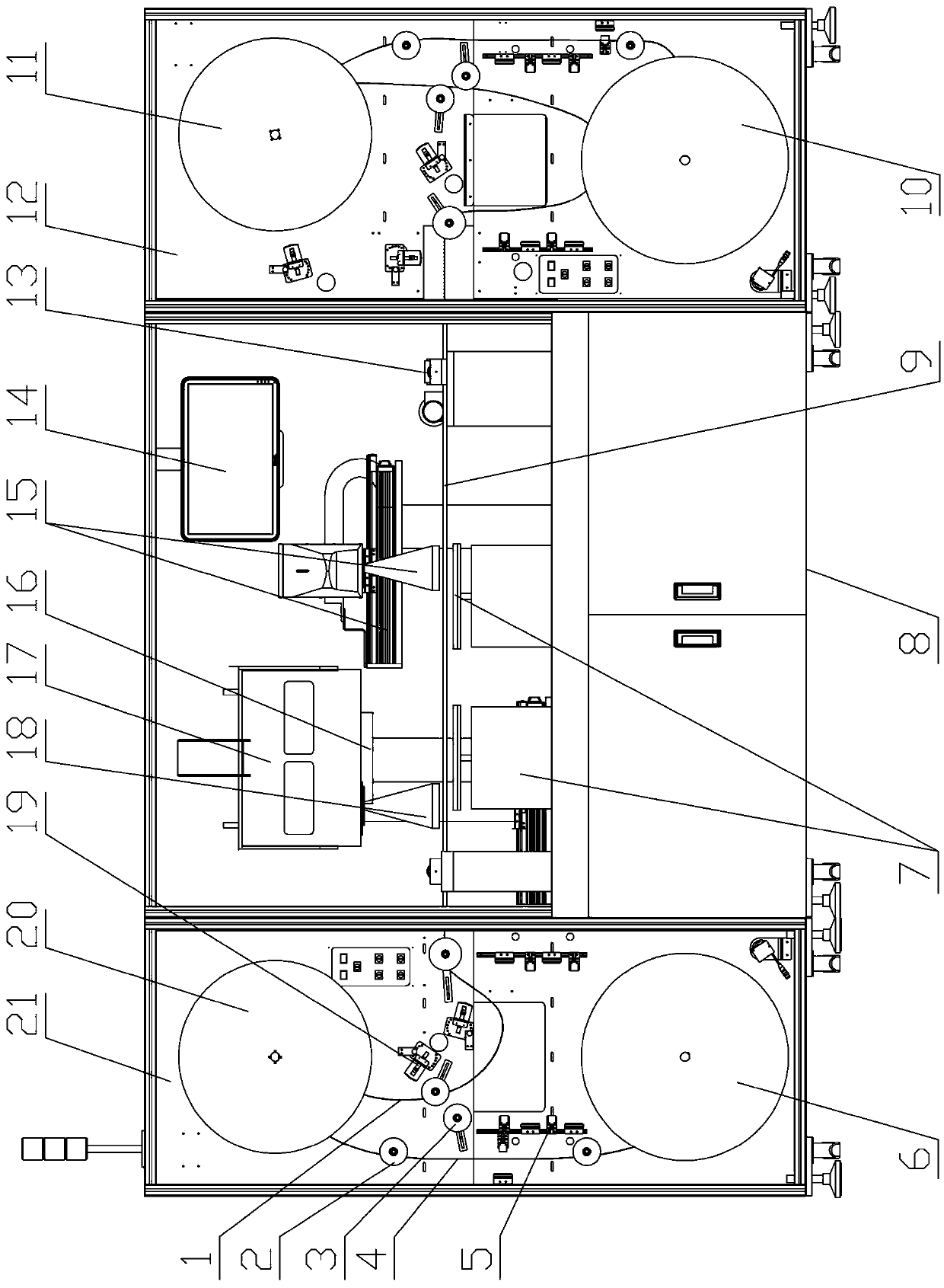

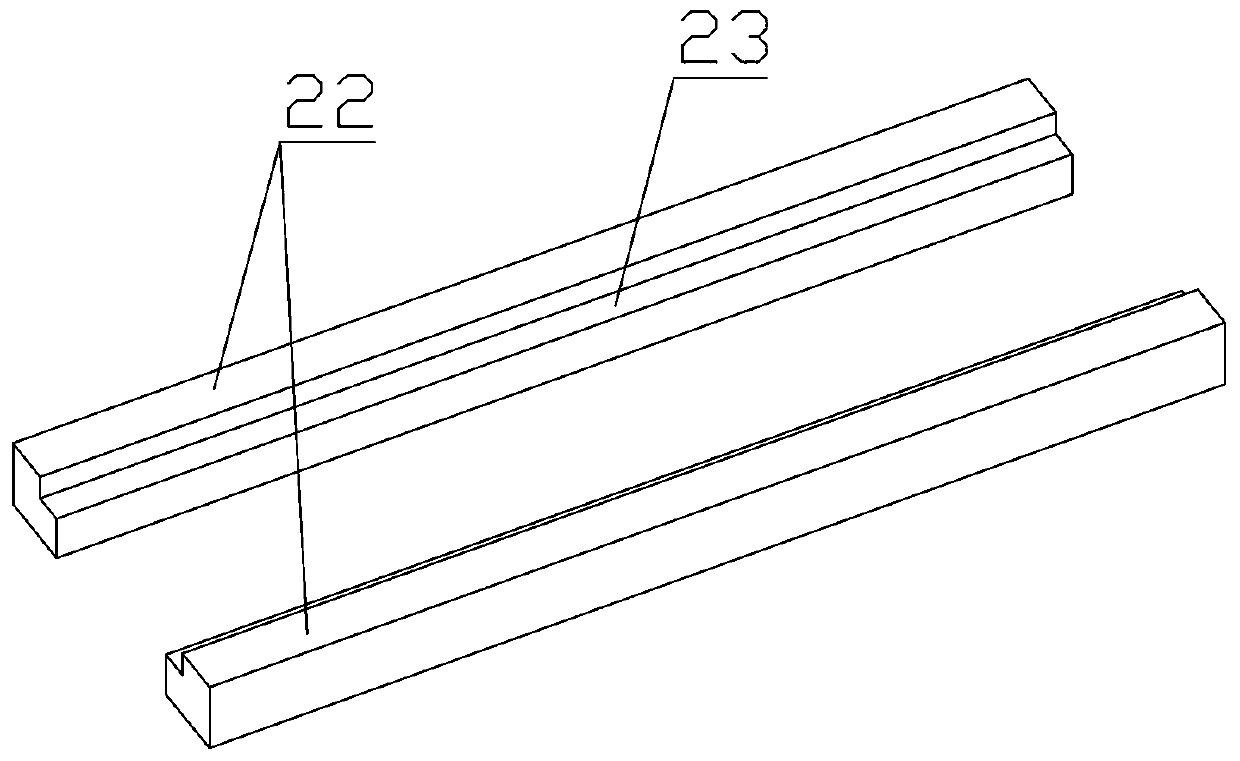

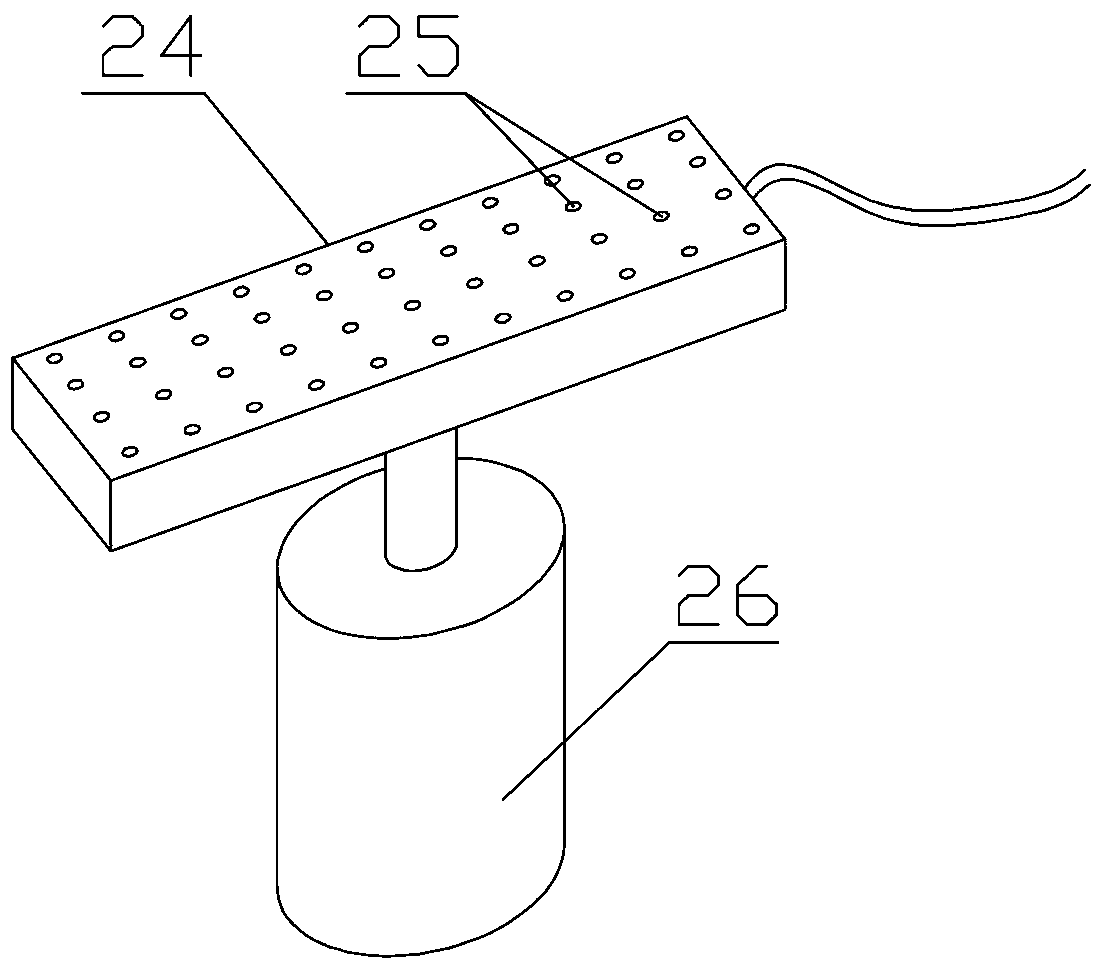

[0024] see Figure 1-Figure 5 , the present invention is a kind of chip laser engraving equipment, comprises feeding room 21, laser engraving room 8 and unloading room 12 successively, is provided with feeding device and static eliminator 19 in the feeding room, is provided with in the unloading room The blanking device and the static eliminator, the left and right ends of the laser engraving room are respectively provided with a chip tape driving device 13, and a chip tape bracket 9 is arranged between the two sets of chip tape driving devices, and the two ends of the chip tape bracket are separated from the two sets of chip tape driving devices. The outer end of the chip tape driving device protrudes; the laser engraving machine 16 and the protective cover 17 are fixedly arranged above the chip tape bracket, and a dust extractor and a dust extraction pipeline are also provided with the inner space of the protective cover, and are connected with the Said laser engraving machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com