Annular rotary three-dimensional space carving machine

A three-dimensional, rotary technology, applied in the field of engraving machines, can solve the problems of high-end engraving machines relying on imports, late start of engraving machine technology, and weak independent research and development capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with specific embodiments.

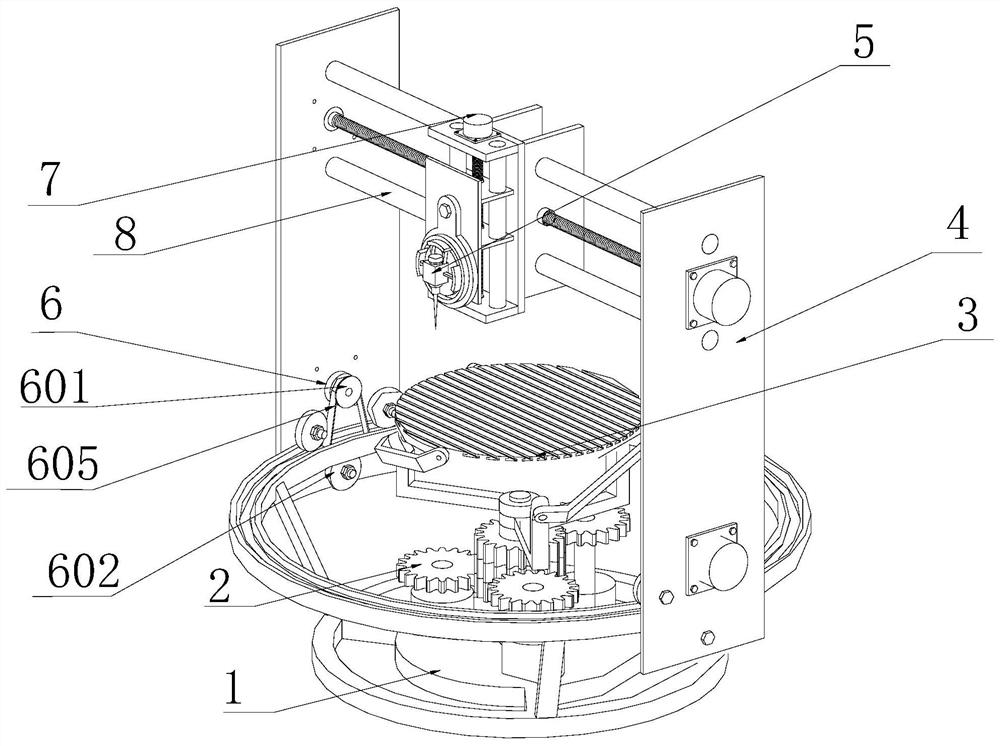

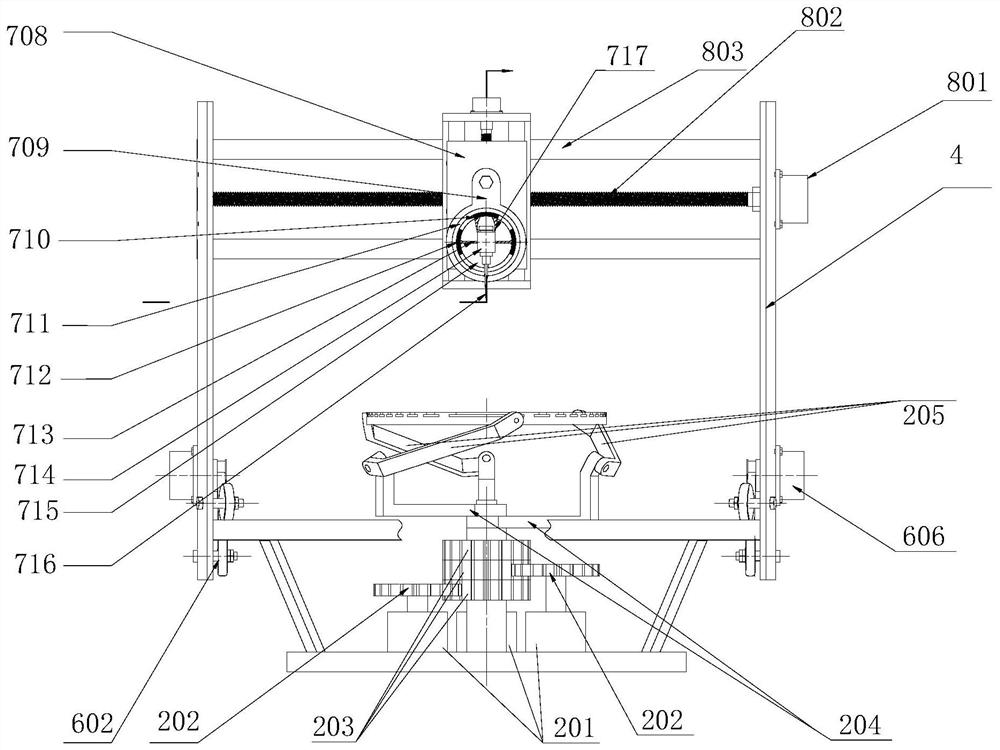

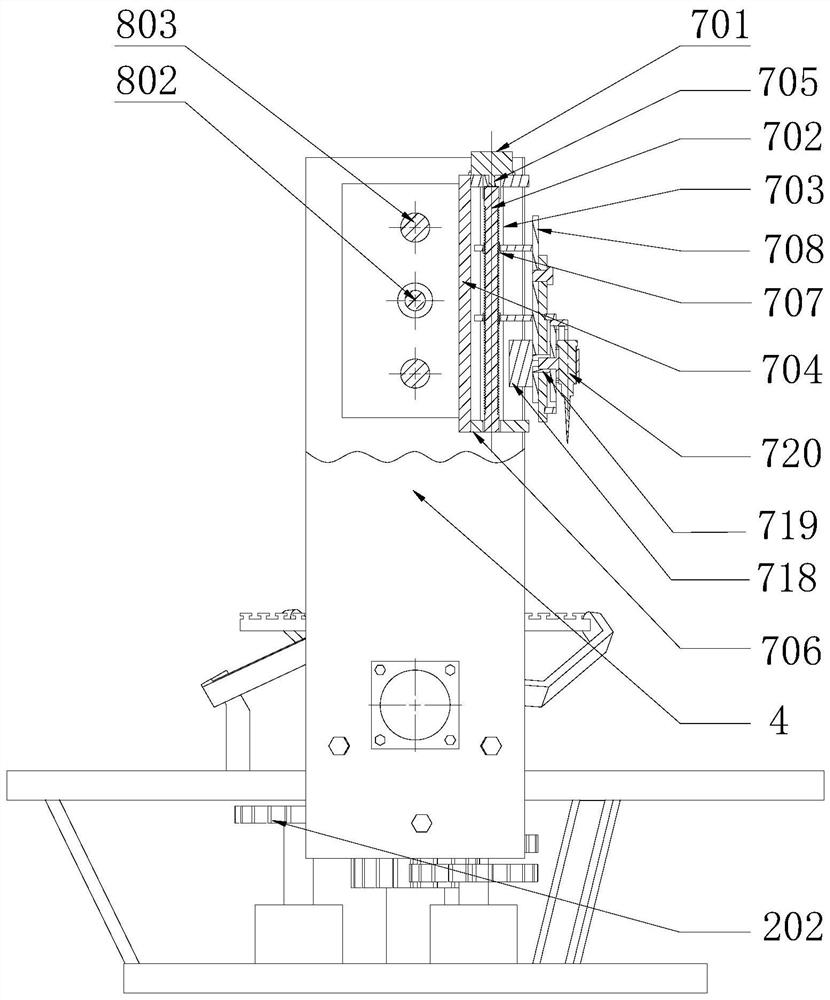

[0042] A circular rotary three-dimensional engraving machine, comprising a base 1, a parallel operation device 2, a workbench 3, an arc-shaped column 4, a cutter head assembly 5, a circular feed mechanism 6 that drives the cutter head assembly to perform circular motion in a horizontal plane, The Y-direction feed mechanism 8 that drives the cutter head assembly to move linearly in the horizontal direction, and the Z-direction feed mechanism 7 that drives the cutter head assembly to make linear motion in the vertical direction.

[0043] The workbench is connected to the base through a parallel operation device. The base is provided with a circular guide rail 101. The arc-shaped column is connected to the guide rail through a circular feed mechanism. The cutter head assembly is connected to the arc-shaped Post connection.

[0044] The circular feed mechanism includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com