Multifunctional rope cutting and winding machine

A winding machine, versatile technology for conveying filamentous materials, thin material handling, transport and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

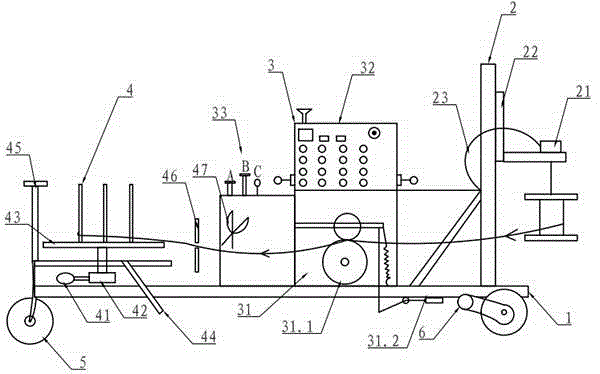

[0026] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, the technical solution of the present invention to achieve the above object is a multifunctional rope splitting and winding machine, the structure of which includes an electro-hydraulic lifting part (2) and a machine control part ( 3) It is composed of a cable storage device (4), and a steering wheel (5) is provided at the bottom of the frame (1) to connect with the traveling motor (6).

[0027] As a preference, the electro-hydraulic lifting part (2) is set on the right side of the frame (1), and the coiled cables are hung on the brake rotating device (21), and the brake rotating device (21) and the electric lifting rod (22) connect.

[0028] Further, the brake rotation device (21) is electrically controlled, and a manual fine-tuning brake device (23) is also provided beside it.

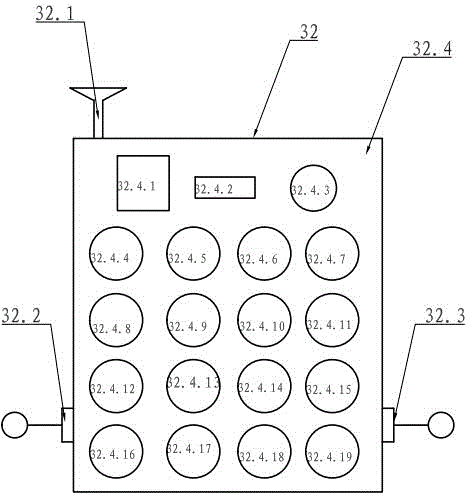

[0029] Preferably, the machine control part (3) is set in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com