Raising Seeding Box Automatic Supply Apparatus

A technology of automatic feeding and seedling boxes, which is applied in the directions of transportation and packaging, unstacking of objects, sowing seeders, etc., can solve the problems of high manufacturing cost and assembly cost, the use of seedling boxes that cannot be of different heights, hooking, etc., and achieve improvement The effect of versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

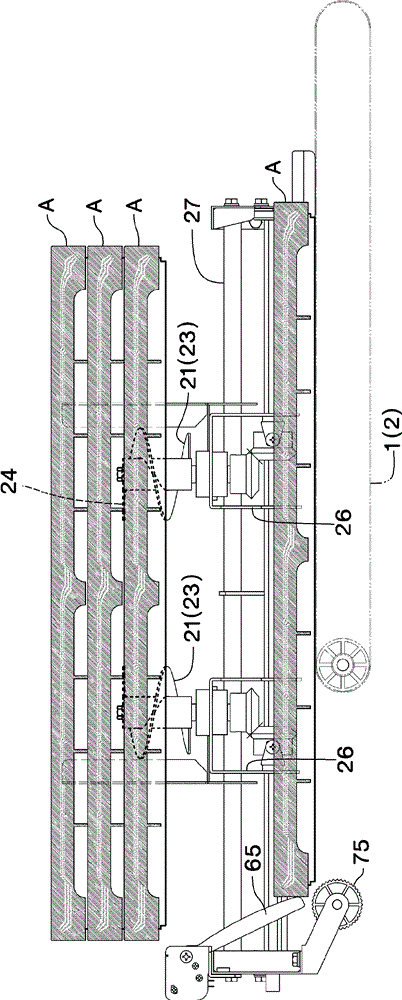

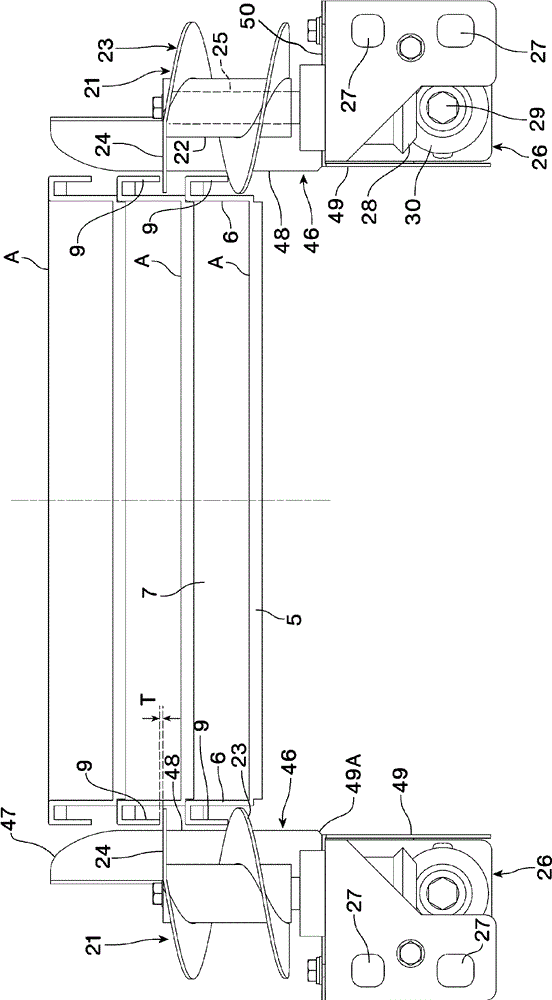

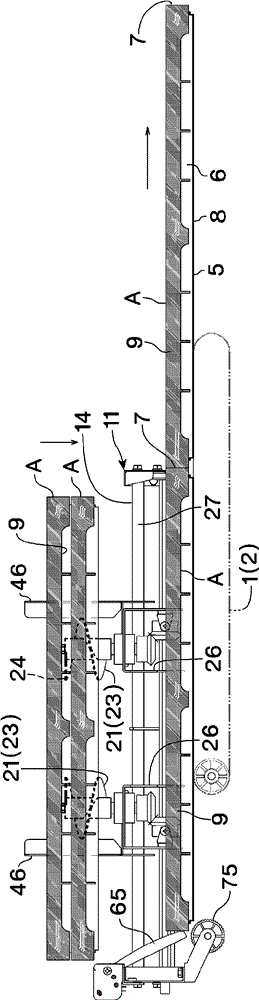

[0049] If an embodiment of the present invention is described according to the accompanying drawings, then 1 is a transfer device for transferring the seedling box A from the beginning end to the terminal end, and a transfer unit 2 is provided, and the transfer unit 2 has supporting legs (illustration omitted) ) The transfer table (illustration omitted) of the transfer roller or transfer belt of the seedling box A constitutes.

[0050] The above-mentioned seedling raising box A is a so-called drawer shape with an open upper surface and a predetermined depth, and has a bottom plate 5, left and right side walls 6, and front and rear walls 7. 8 is the bottom edge of the bottom surface of the bottom plate 5, and 9 is located on the side wall 6 and the front and rear walls. side edge on wall 7.

[0051] In addition, for easy understanding, although the direction or position of front, back, left and right is demonstrated based on the transfer direction which transfers the said seedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com