Wall carving machine based on negative-pressure adsorption principle and use method thereof

An engraving machine and negative pressure technology, which is applied in the field of engraving machines, can solve the problems of difficulty in guaranteeing the quality of time engraving, inability to realize standardized operations, low work efficiency and waste, and meet low environmental requirements, wide application range and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

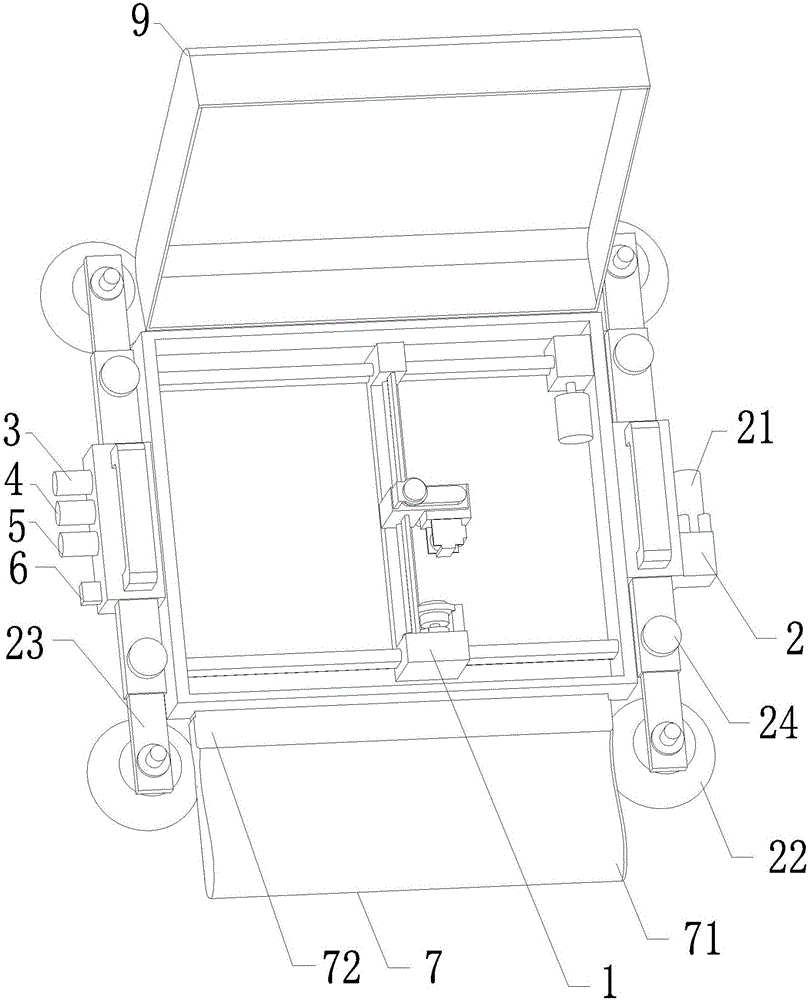

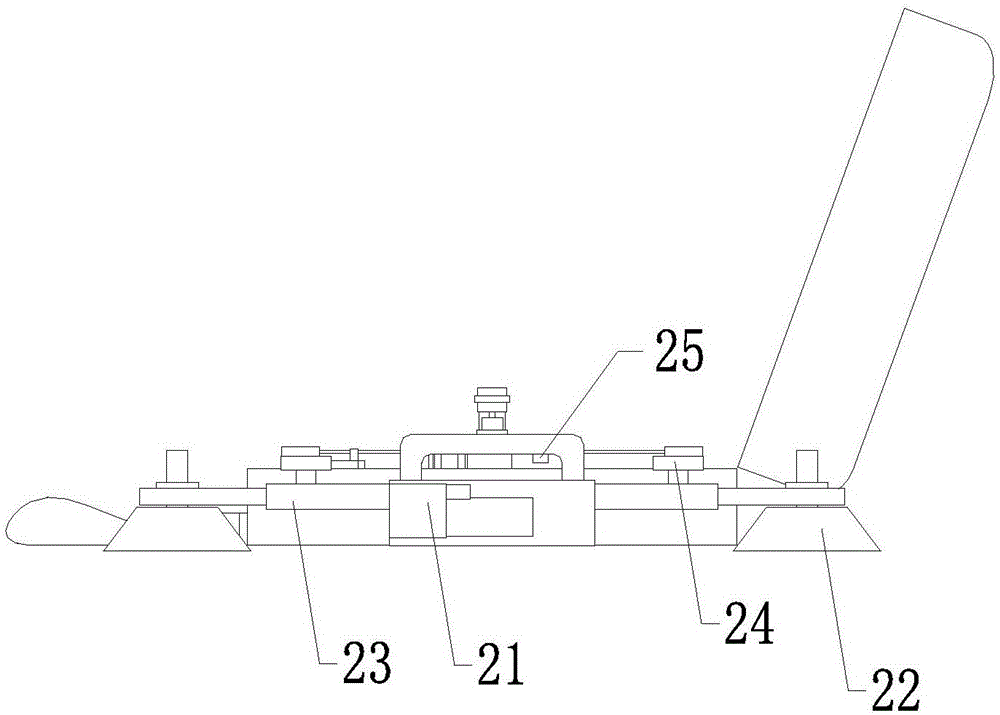

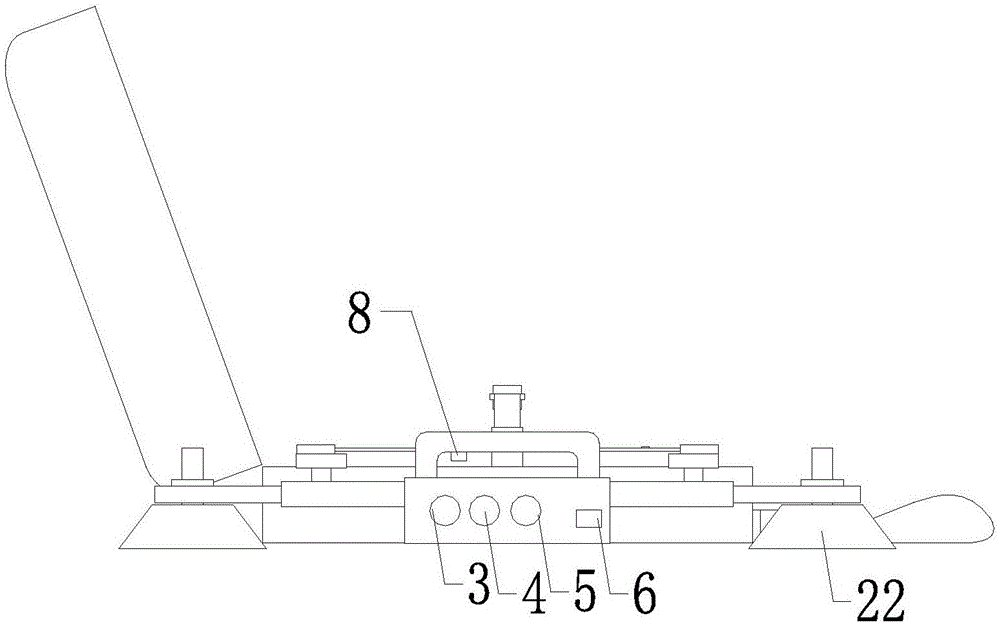

[0040] Such as figure 1 , figure 2 , image 3 As shown, a wall engraving machine based on the principle of negative pressure adsorption in this embodiment includes an engraving assembly 1 for engraving the wall, and a negative pressure adsorption assembly 2 for fixing the device on the wall. The x-axis initial position fine-tuning knob 3 for fine-tuning the initial engraving position in the x-axis direction, the y-axis initial position fine-tuning knob 4 for fine-tuning the initial engraving position in the y-axis direction, and the fine-tuning knob 4 for fine-tuning the initial engraving position in the z-axis direction The z-axis initial position fine-tuning knob 5 of the initial engraving position, the initial position determination button 6 for determining the initial position of engraving, the collection device 7 for collecting the dust, the switch 8 and the housing 9; the engraving assembly 1, The negative pressure adsorption assembly 2, the x-axis initial position fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com