Vertical engraving machine

A kind of engraving machine, vertical technology, applied in the direction of decorative art, processing models, etc., can solve the problems of engraving accuracy decline, increase machine manufacturing cost, affect engraving accuracy, etc., achieve the effect of improving engraving accuracy and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

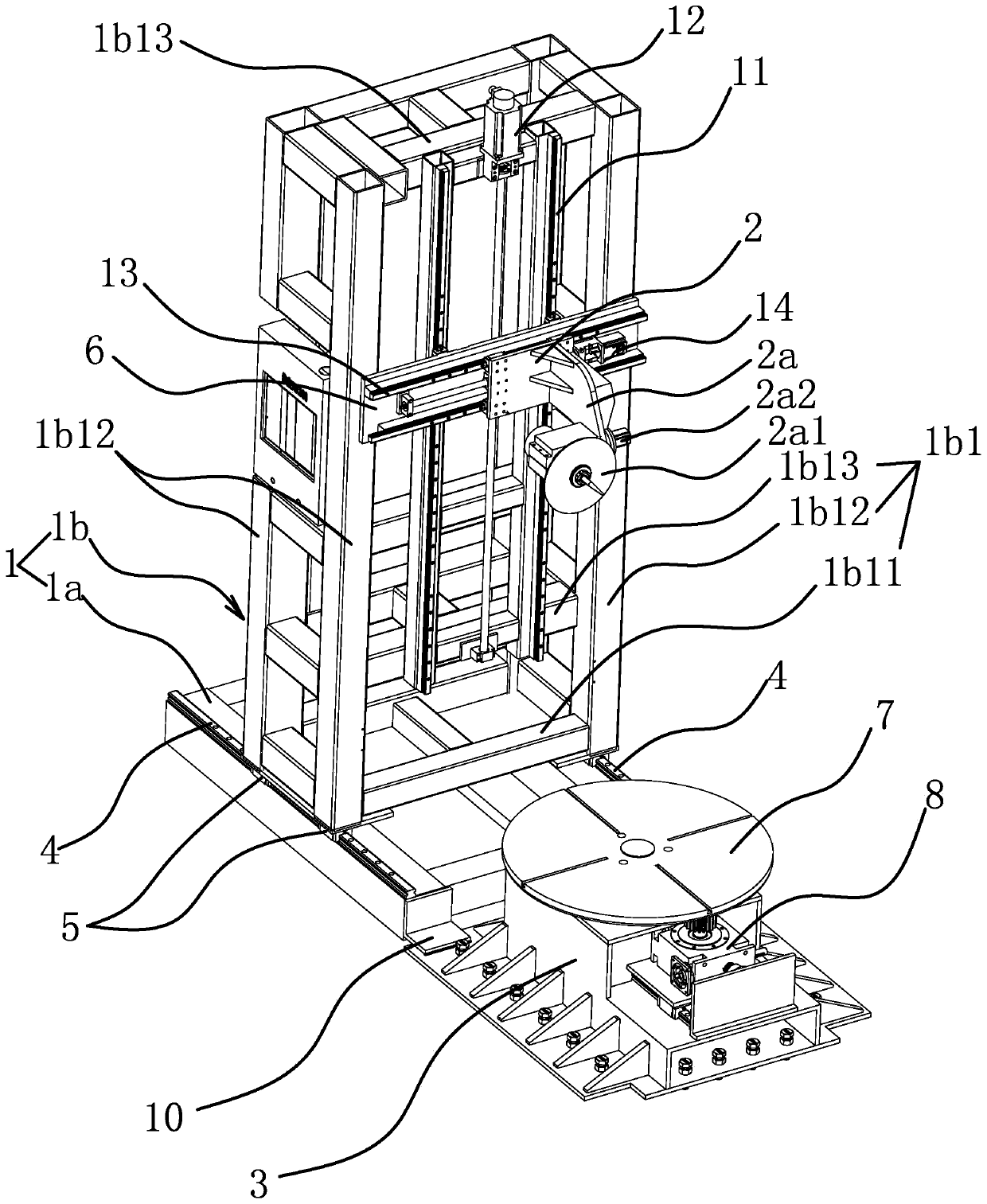

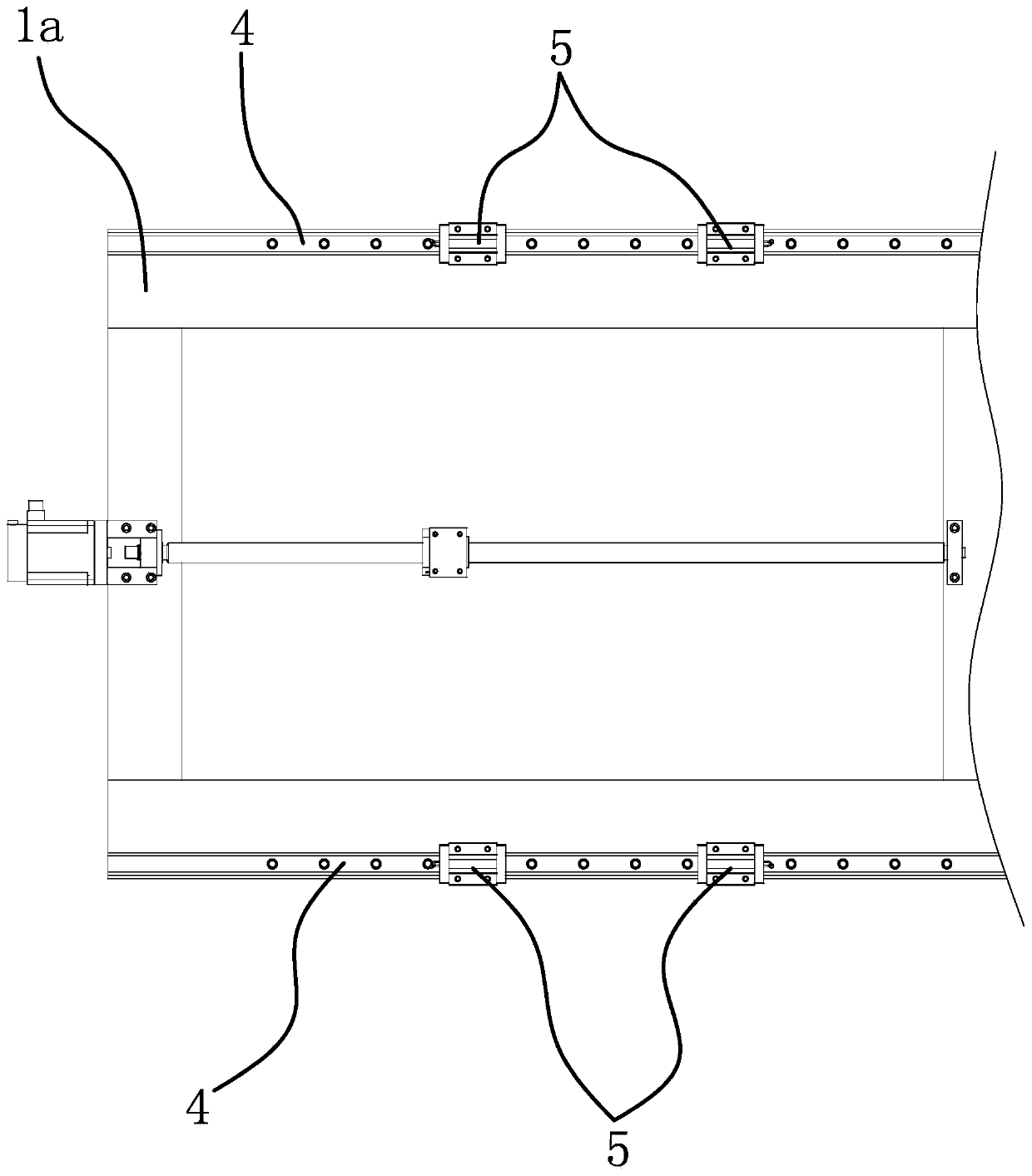

[0034] Specifically, as figure 1 As shown, in this embodiment, the engraving machine is a five-axis vertical engraving machine, including a frame 1, a tool holder 2 and a mounting seat 3 for clamping a vertical workpiece. The mounting seat 3 is provided with a workbench 7, The workbench 7 is a turntable structure, and the workbench 7 is driven by a rotating motor 8 . Wherein, the frame 1 comprises a base 1a and a three-dimensional mobile frame 1b arranged on the top of the base 1a, the base 1a is a flat frame structure, the three-dimensional mobile frame 1b is a columnar and vertically arranged frame structure as a whole, and the three-dimensional mobile frame 1b The length in the horizontal longitudinal direction is smaller than the length of the base 1a in the horizontal longitudinal direction. The mounting bases 3 are arranged side by side at one end of the base 1a and connected by a connecting piece 10, and are fixed relative to the base 1a. The connecting piece 10 can ad...

Embodiment 2

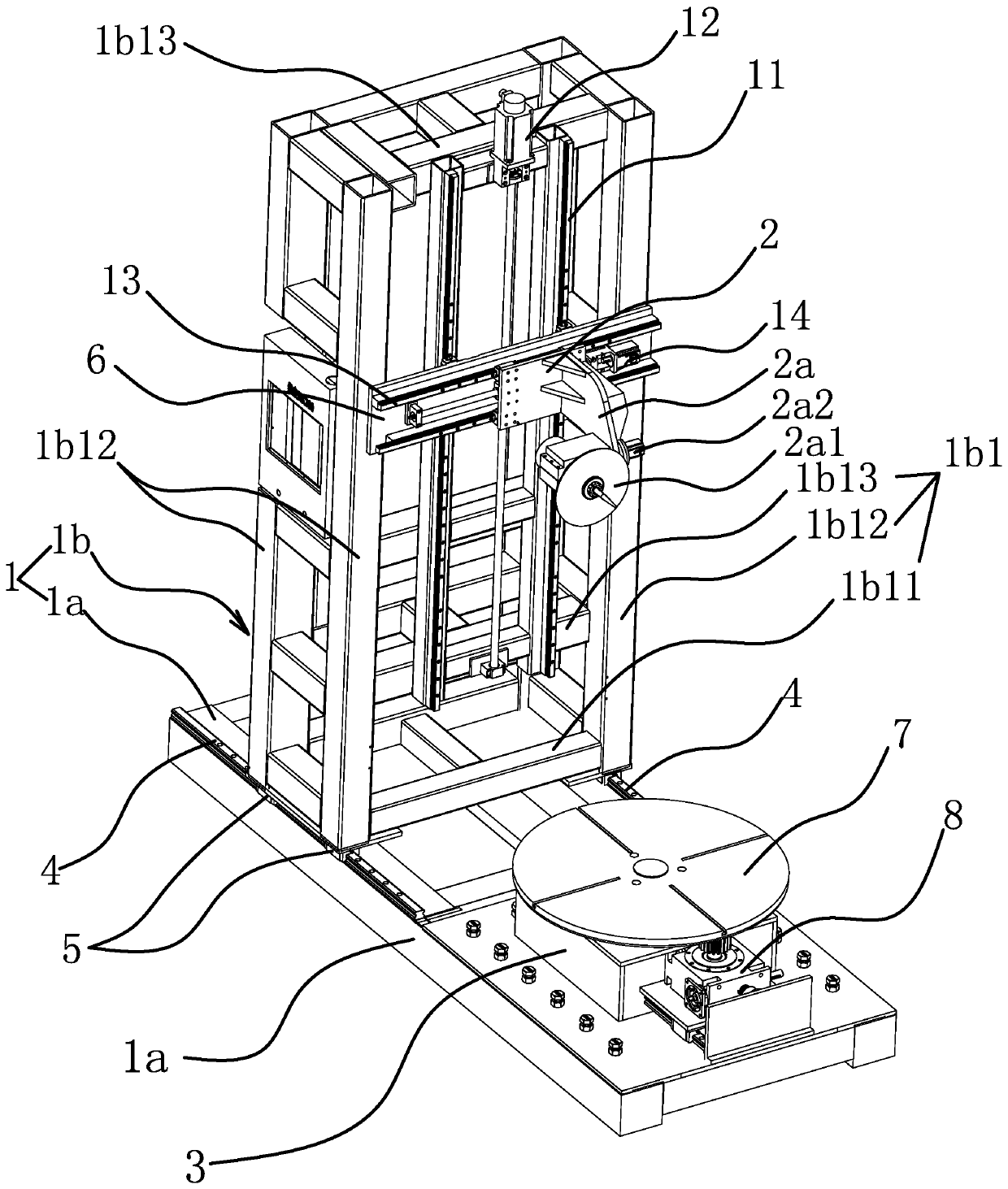

[0039] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, such as image 3 As shown, the mounting base 3 is directly fixed on one end of the base 1a.

Embodiment 3

[0041] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, such as Figure 4 As shown, the mounting seat 3 is arranged separately from the base 1a and is located at one end of the base 1a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com