Carving machine

A technology of engraving machine and frame, applied in the field of engraving machines, can solve the problems of inability to achieve rough machining and finishing, difficult to ensure the machining accuracy of the engraving machine, and low engraving accuracy of the engraving machine, so as to reduce personal injury, improve the engraving accuracy, The effect of improving engraving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

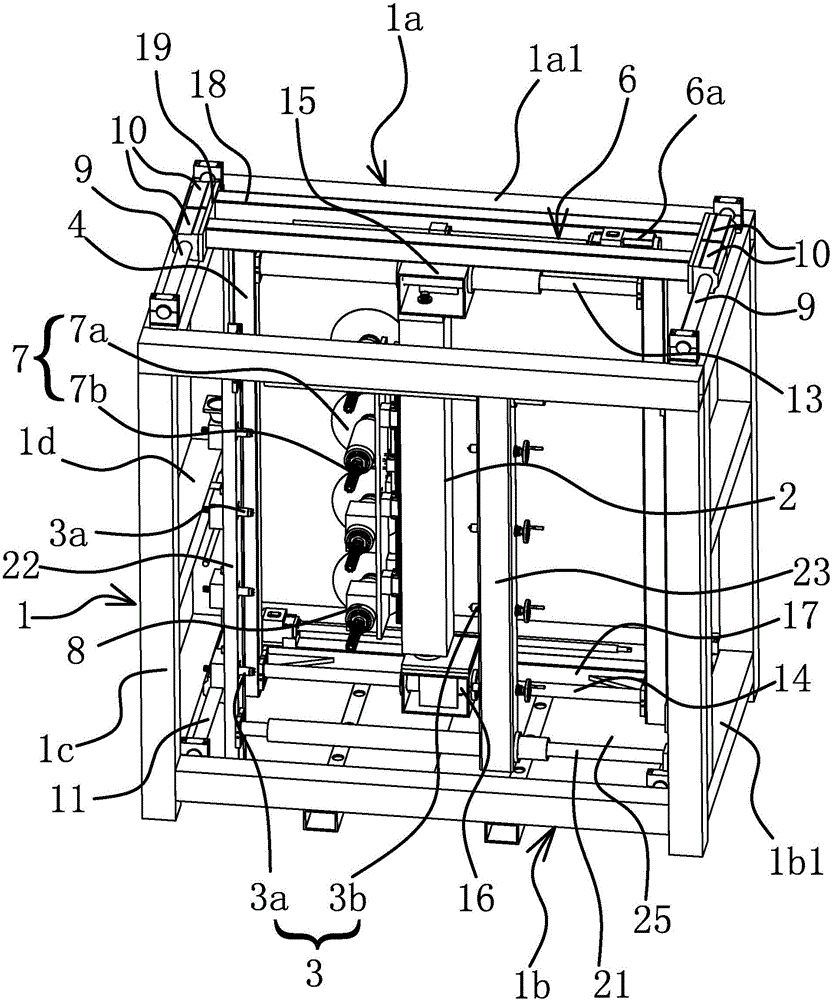

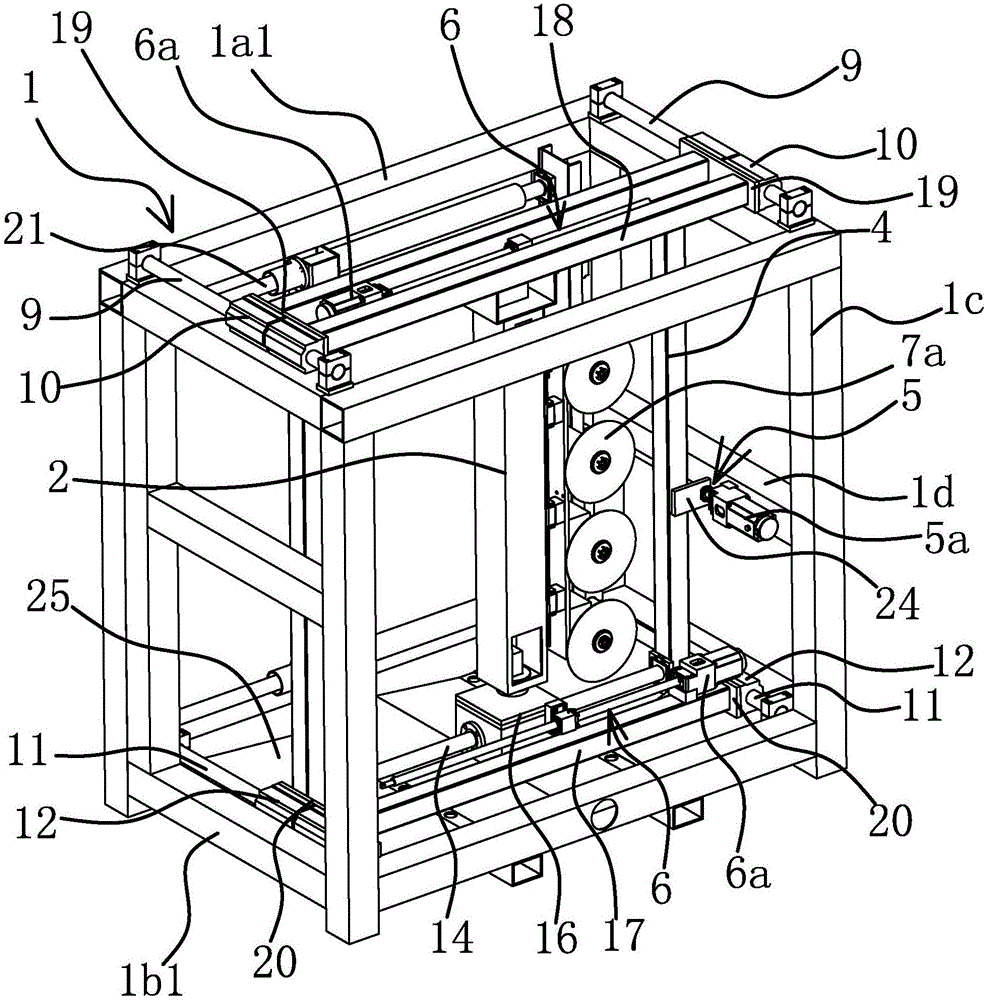

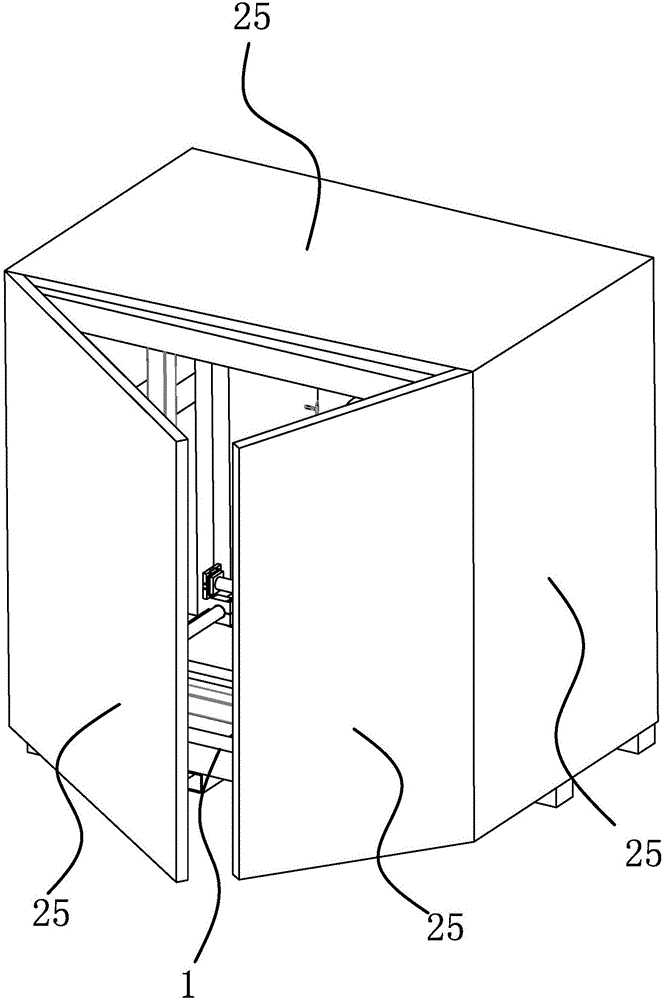

[0031] Such as figure 1 , 2 , 3, the engraving machine includes a frame 1, a workpiece clamping mechanism, a tool frame 2 and other structures, wherein the frame 1 includes an upper rectangular frame 1a formed by four upper beams 1a1, and a lower rectangular frame formed by four lower beams 1b1 1b and four connecting columns 1c between the upper rectangular frame 1a and the lower rectangular frame 1b, constitute a cube structure by the upper rectangular frame 1a, the lower rectangular frame 1b and four connecting columns 1c, on the top of the frame 1 of the cube structure Surface, four sides and bottom surface are provided with the dust-proof plate 25 that cube is closed, and wherein, the dust-proof plate 25 of frame 1 front side can be designed to be door-type structure, thereby facilitates the pick-and-place of workpiece. This engraving machine is mainly used for wood engraving, so it is easy to generate more dust during the engraving process. For this reason, when this en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com