Patents

Literature

119results about How to "Improve engraving efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

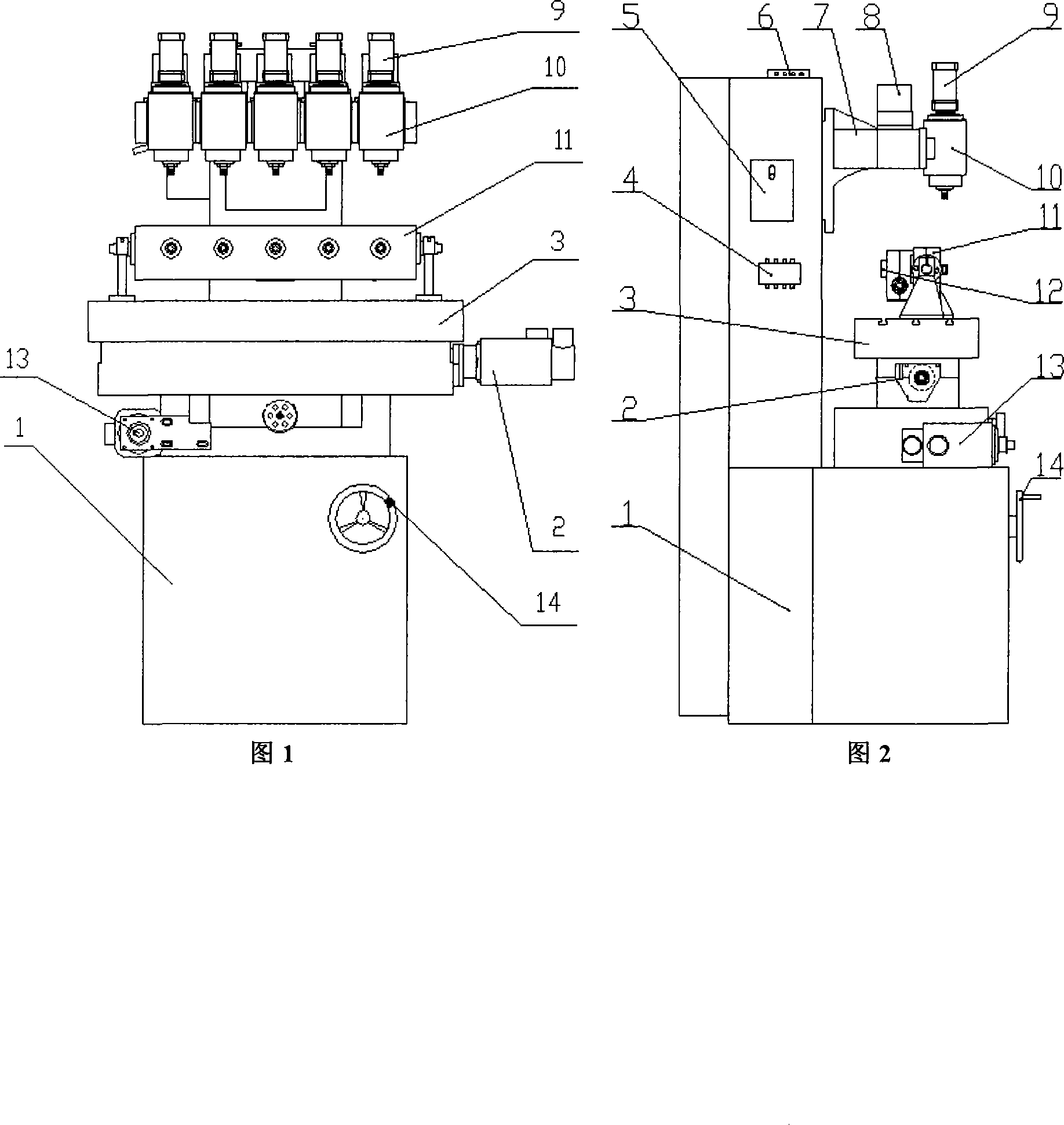

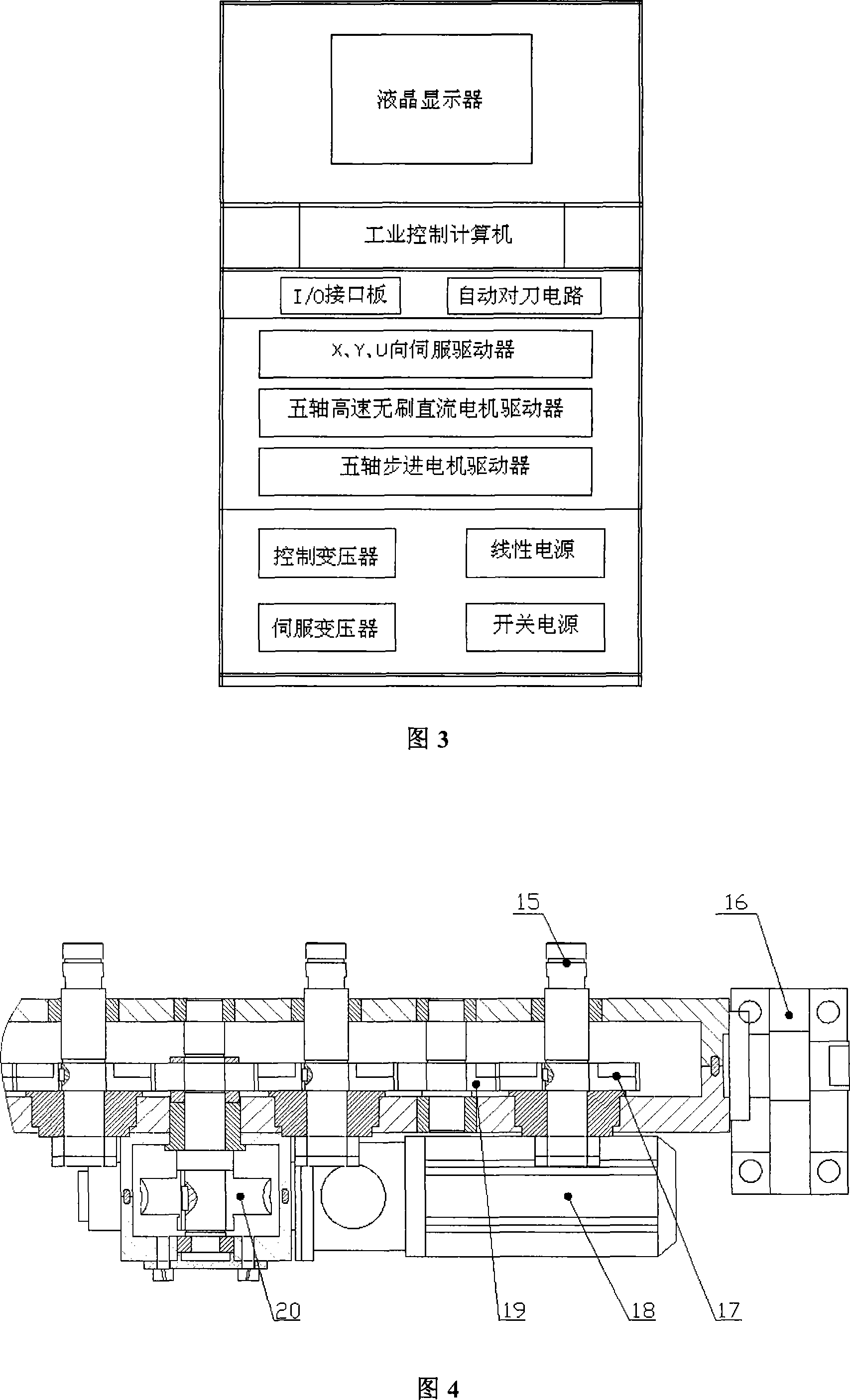

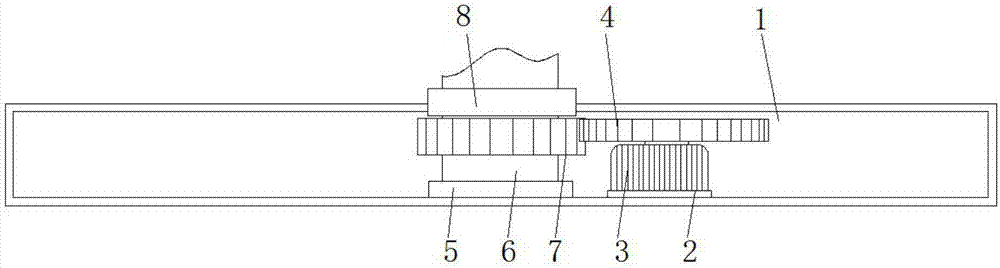

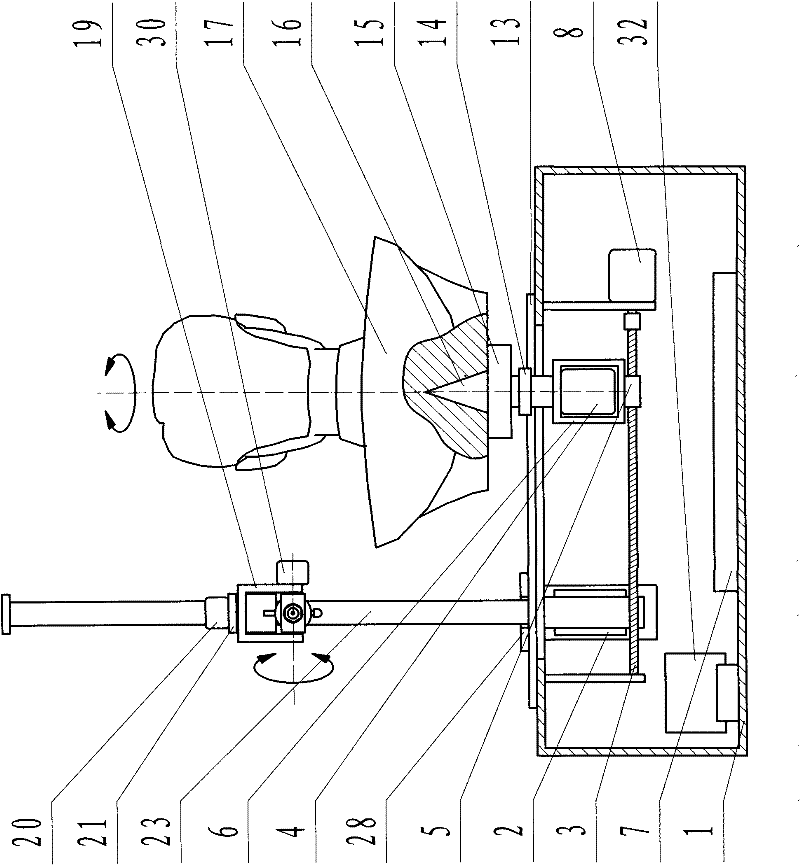

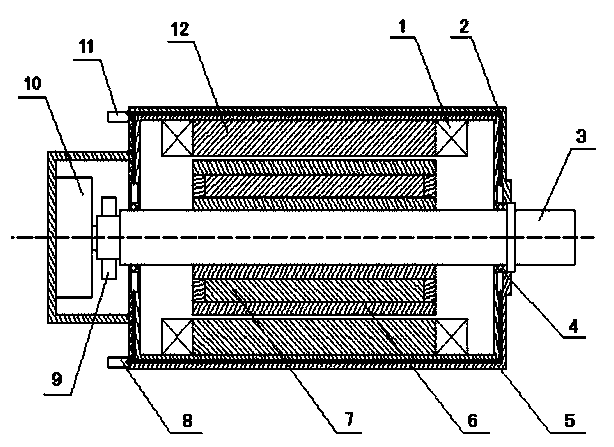

Multi-station digital-controlled carving machine

InactiveCN101195318AGood interface functionGuaranteed radial errorAutomatic control devicesFeeding apparatusNumerical controlDigital control

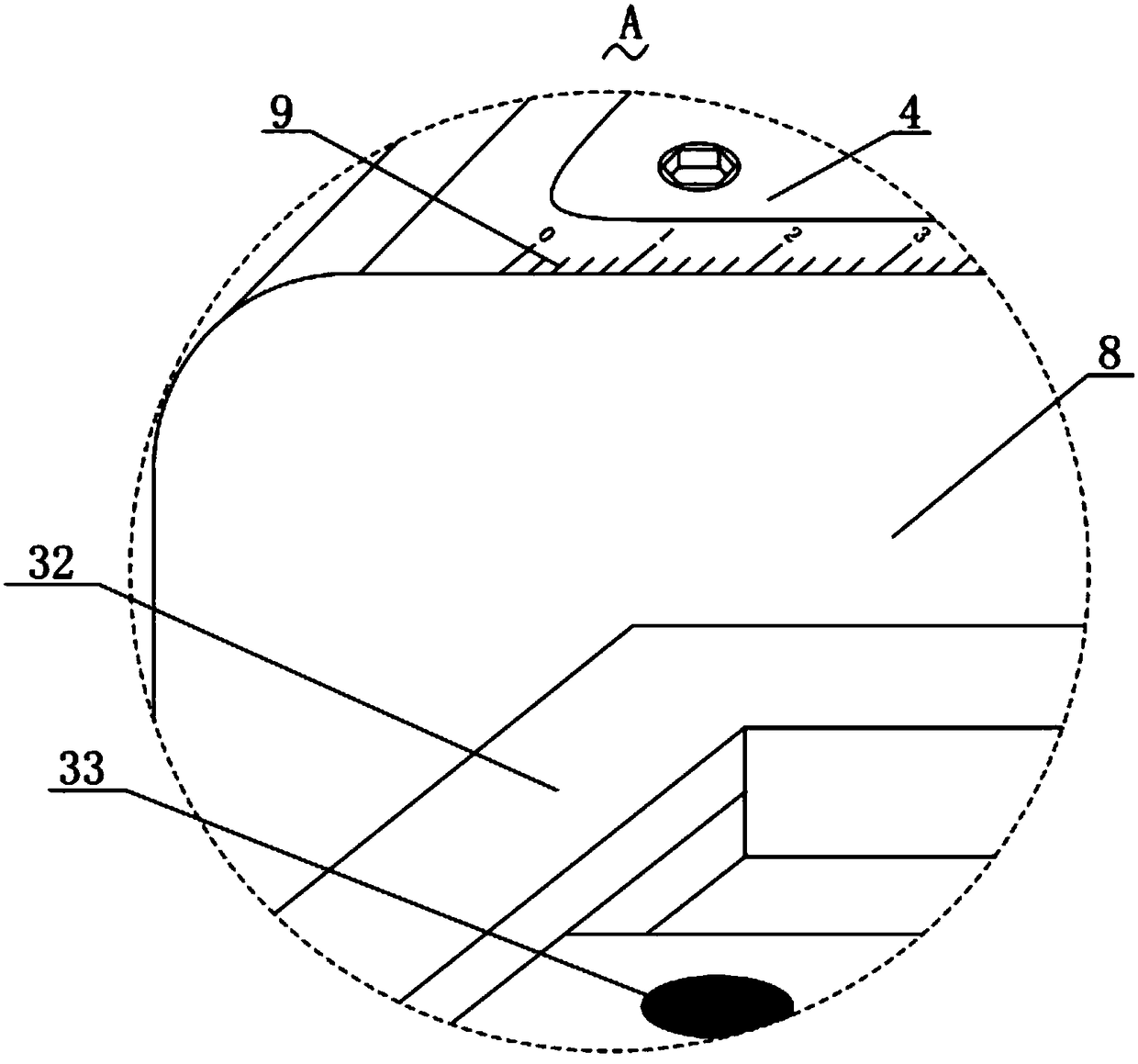

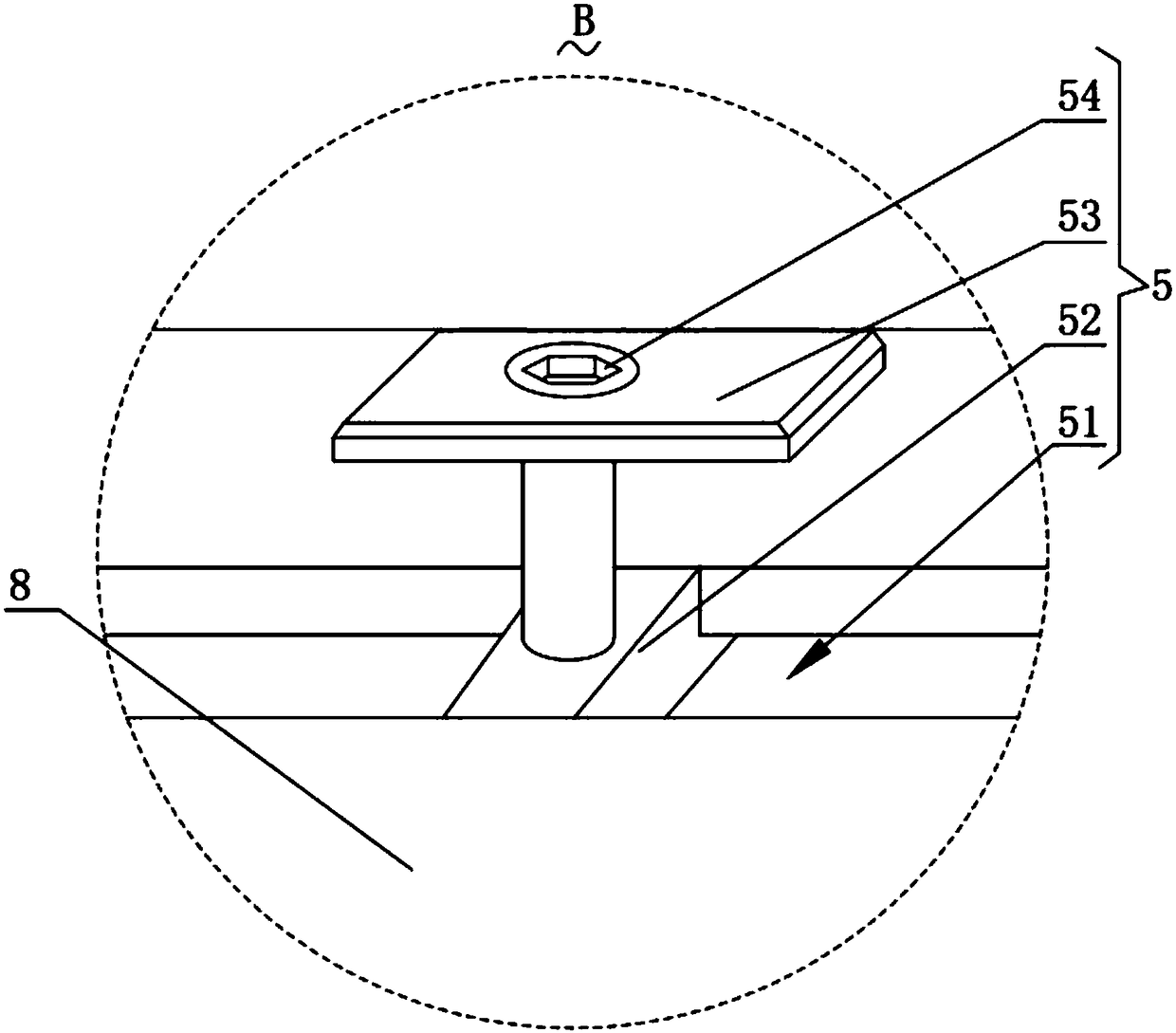

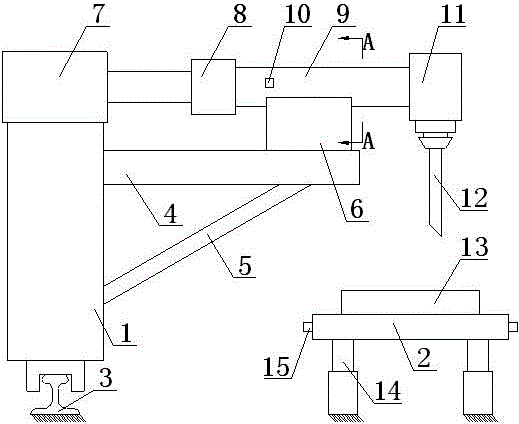

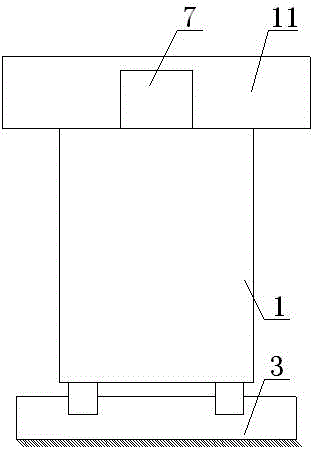

The invention relates to a multi-station numerical control engraving machine comprising a machine body (1), an engraving machine portion and an electric portion, wherein the electric portion comprises a software portion and a hardware portion, the hardware portion employs a control core combined by an industrial control computer and a movement control card, the movement control card is connected with a digital servo-actuator or multi-shaft stepping motor which are controlled by the movement control card by data wire, the software employs an application running under Visual C++ program Windows 2000 XP and an application of 51 single chip computer, the engraving machine portion is mainly composed of an engraving head (10), a multi-station tool device (11) and a tool setting and feeding device, the engraving head uses a brushless direct current motor (9) to drive the central axis. The multi-station numerical control engraving machine can simultaneously engrave various Chinese characters, curves and patterns with single line or double line on cylindrical surfaces, conical surfaces and geometric plane surfaces at multiple stations, and additionally engraving patterns and characters can be edited and designed by users.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

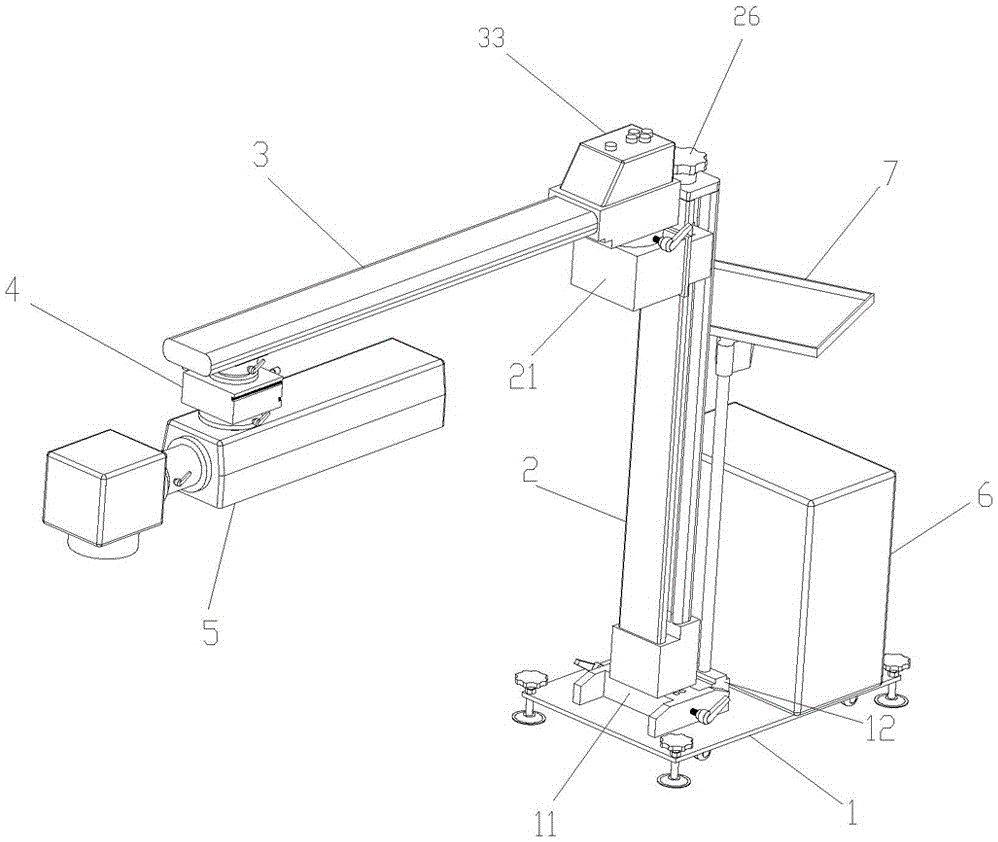

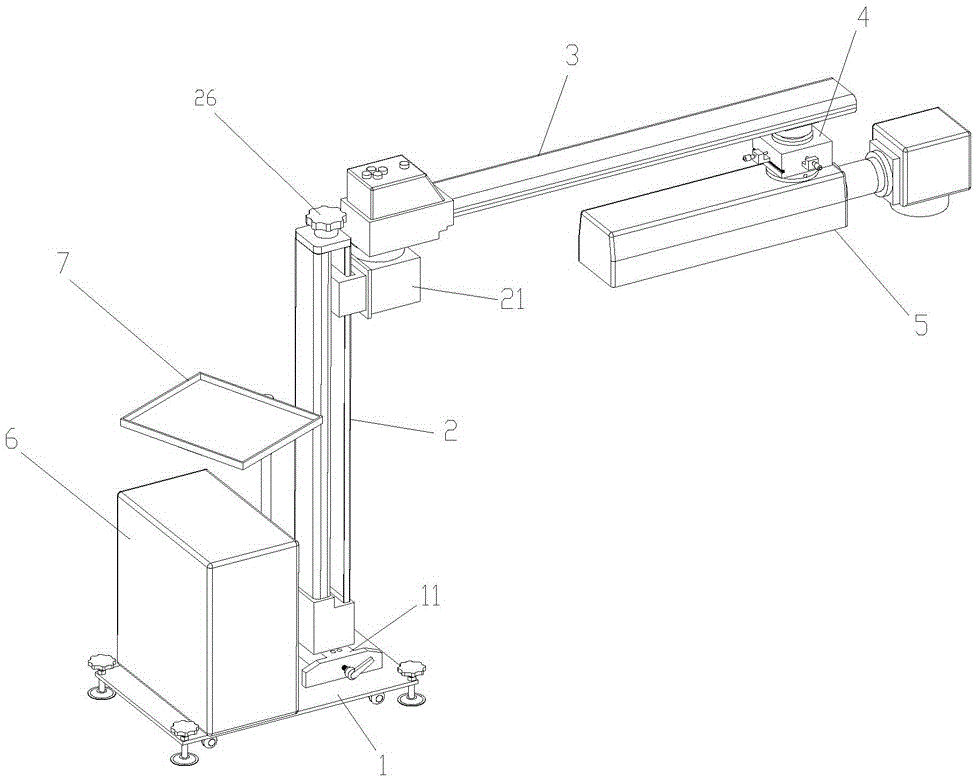

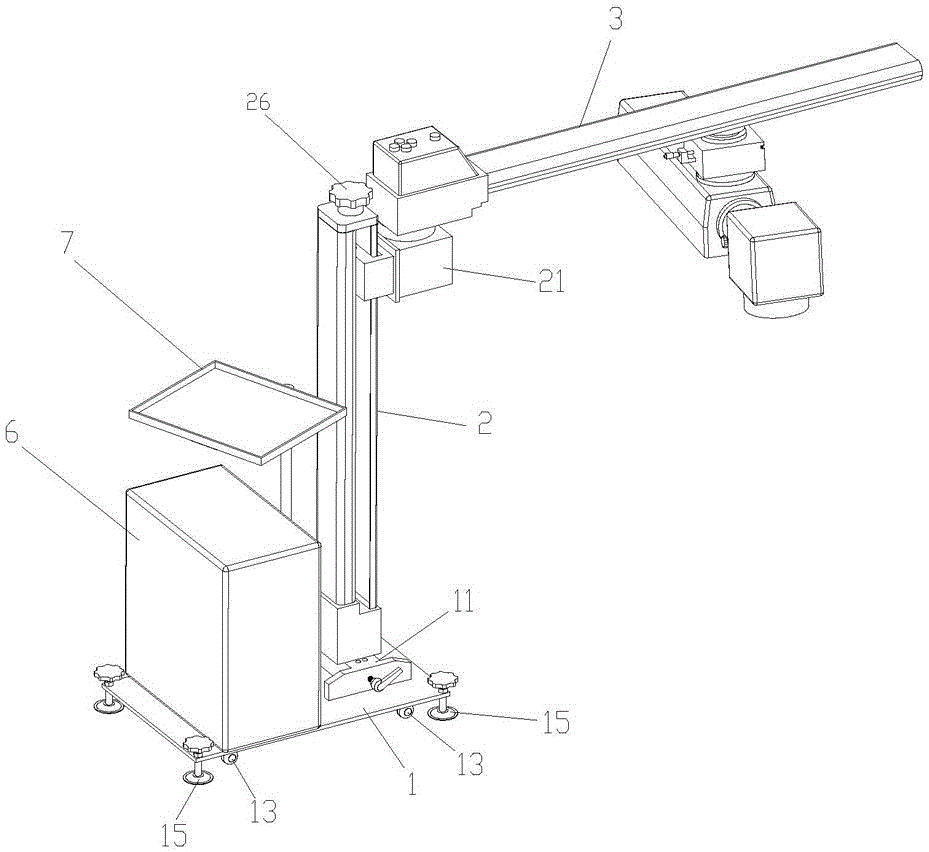

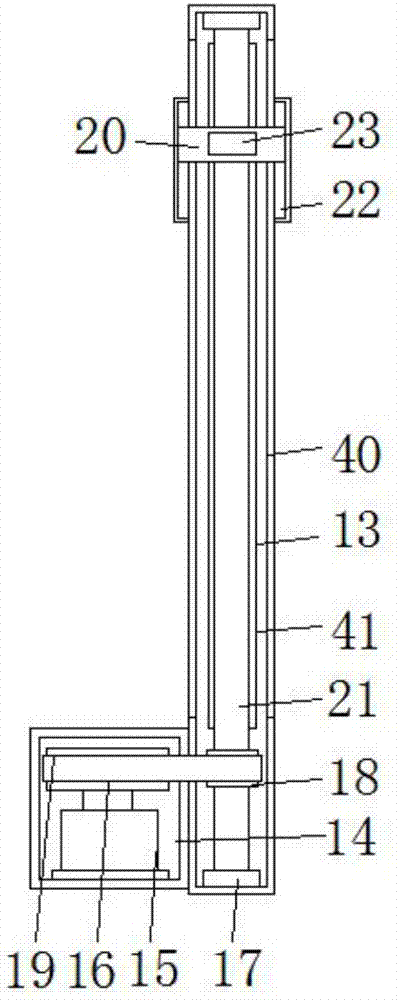

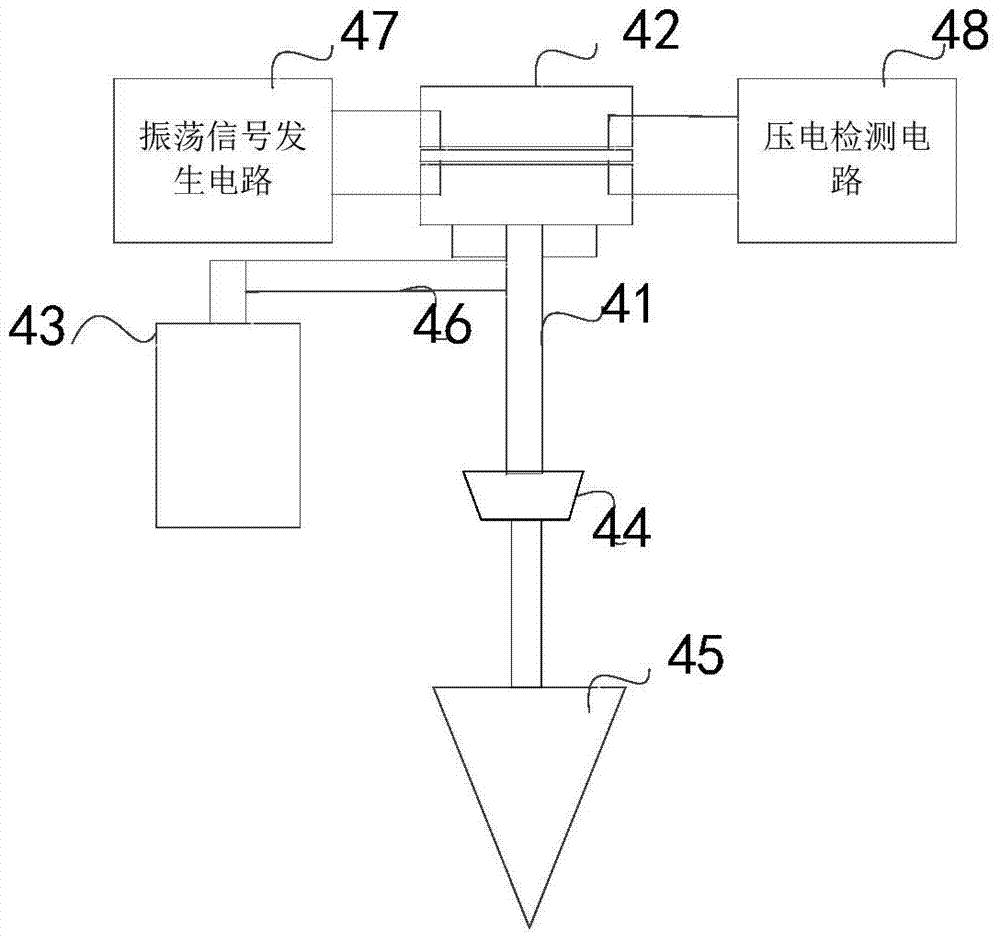

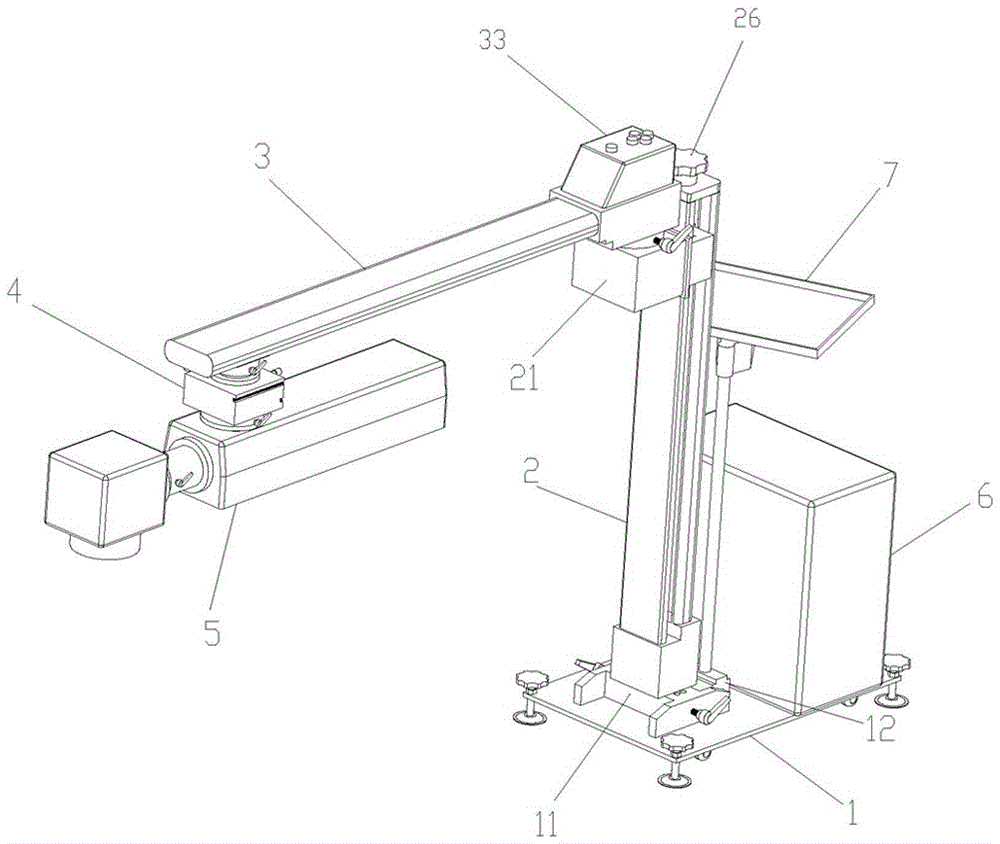

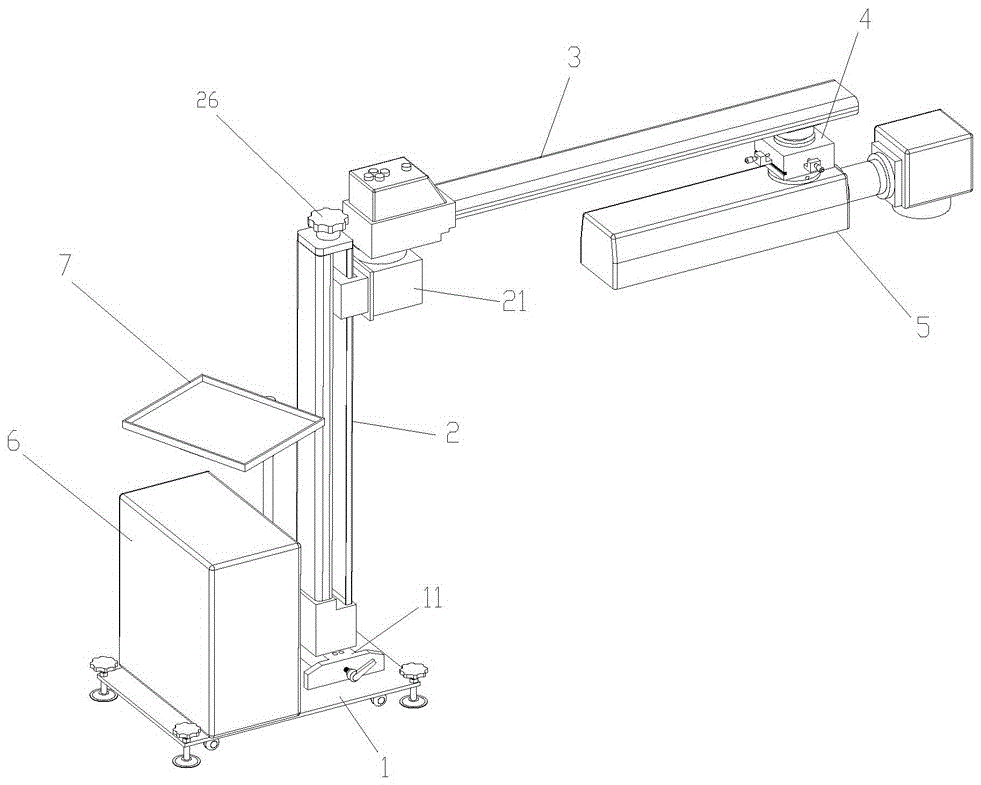

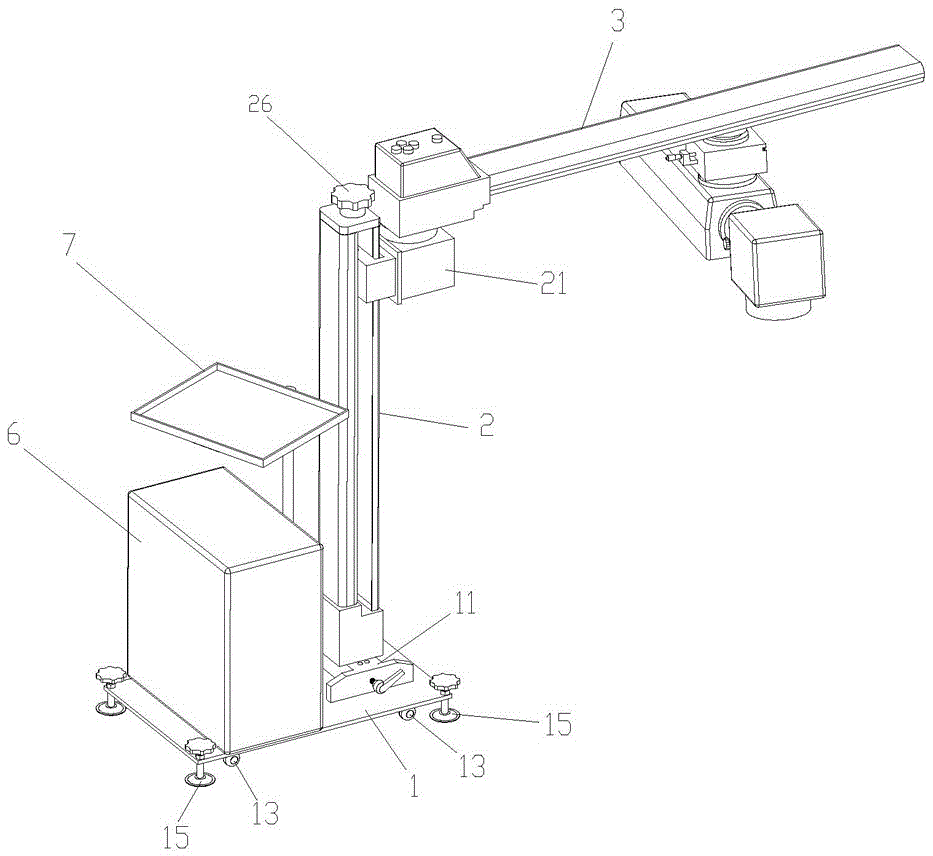

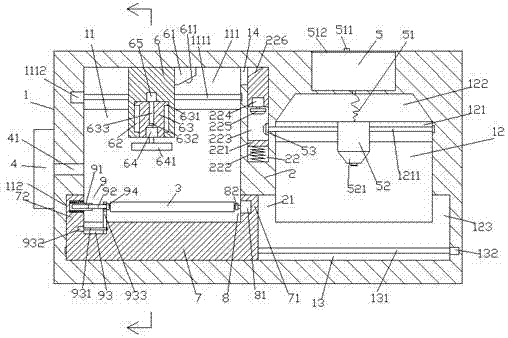

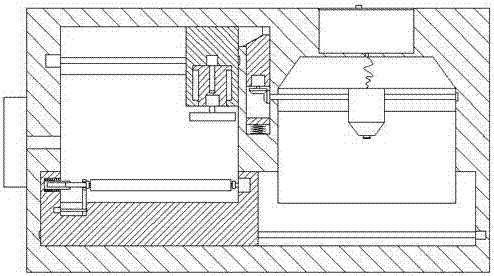

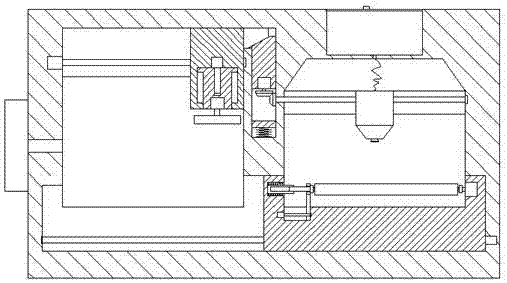

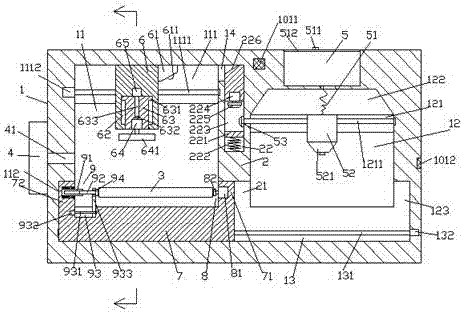

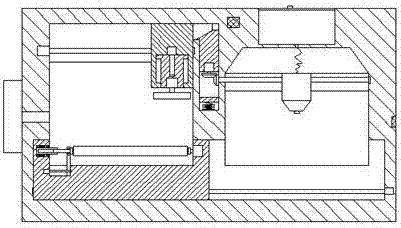

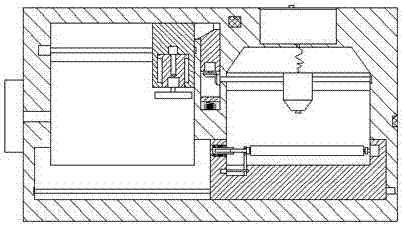

Mold laser engraving machine

ActiveCN105127600AQuick disassemblyReduce volumeLaser beam welding apparatusLaser engravingEngineering

The invention discloses a mold laser engraving machine which comprises a base, a longitudinal driving mechanism, a transverse driving mechanism, a fine adjustment connecting block, a laser head and a main machine box. The main machine box is placed on the base. A longitudinal connecting base is arranged on the base. The bottom of the longitudinal driving mechanism is connected to the longitudinal connecting base in an insertion mode. The end of the transverse driving mechanism is connected to a longitudinal sliding block of the longitudinal driving mechanism in an insertion mode through a rotating shaft and a bearing. The top of the laser head is connected with a transverse sliding block of the transverse driving mechanism through the fine adjustment connecting block. The laser head and the main machine box are connected through a cable and optical fiber. The structure of an engraving machine is designed again, the engraving machine is provided with a plurality of detachable components, the detached components can be carried by one person and can be placed into a trunk of a common household car, assembling is quite convenient and fast, meanwhile, 360-degree full-dimensional non-dead-corner movement of a vibrating mirror is achieved through a middle transmission component of the laser engraving machine, and the mold laser engraving machine has the advantages of being high in precision and convenient to adjust.

Owner:台州市黄岩东胜机械设备有限公司

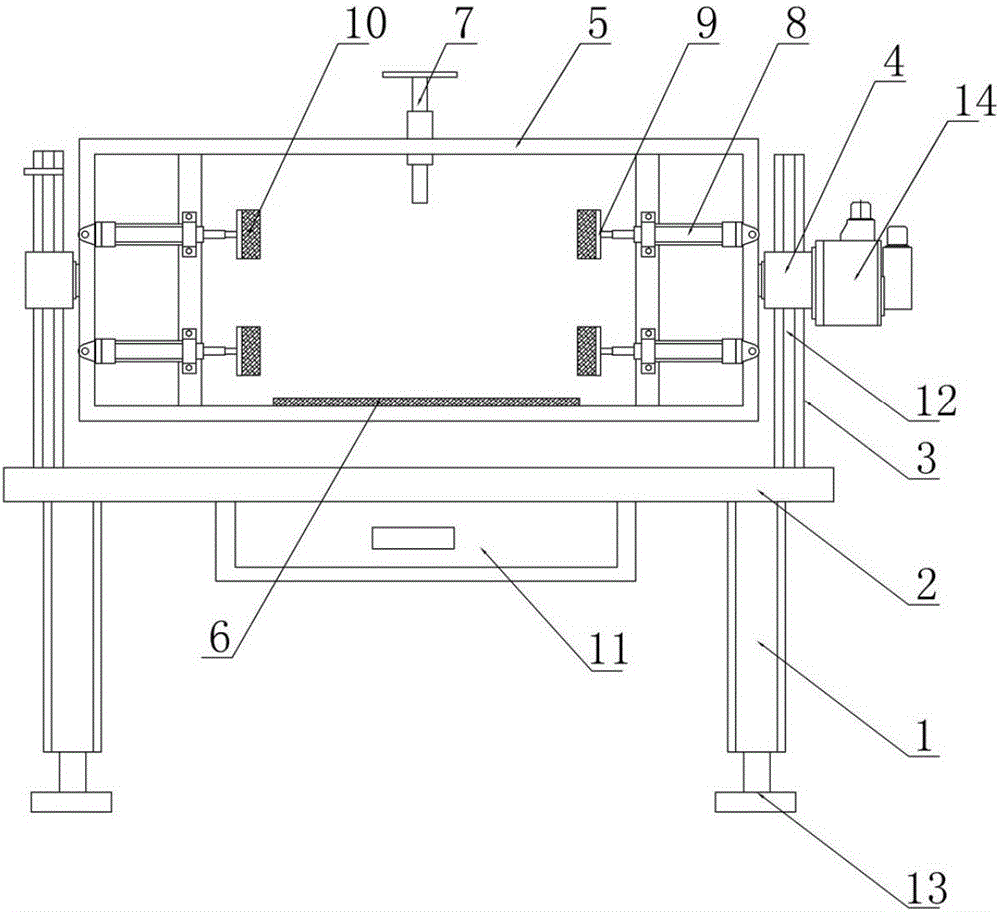

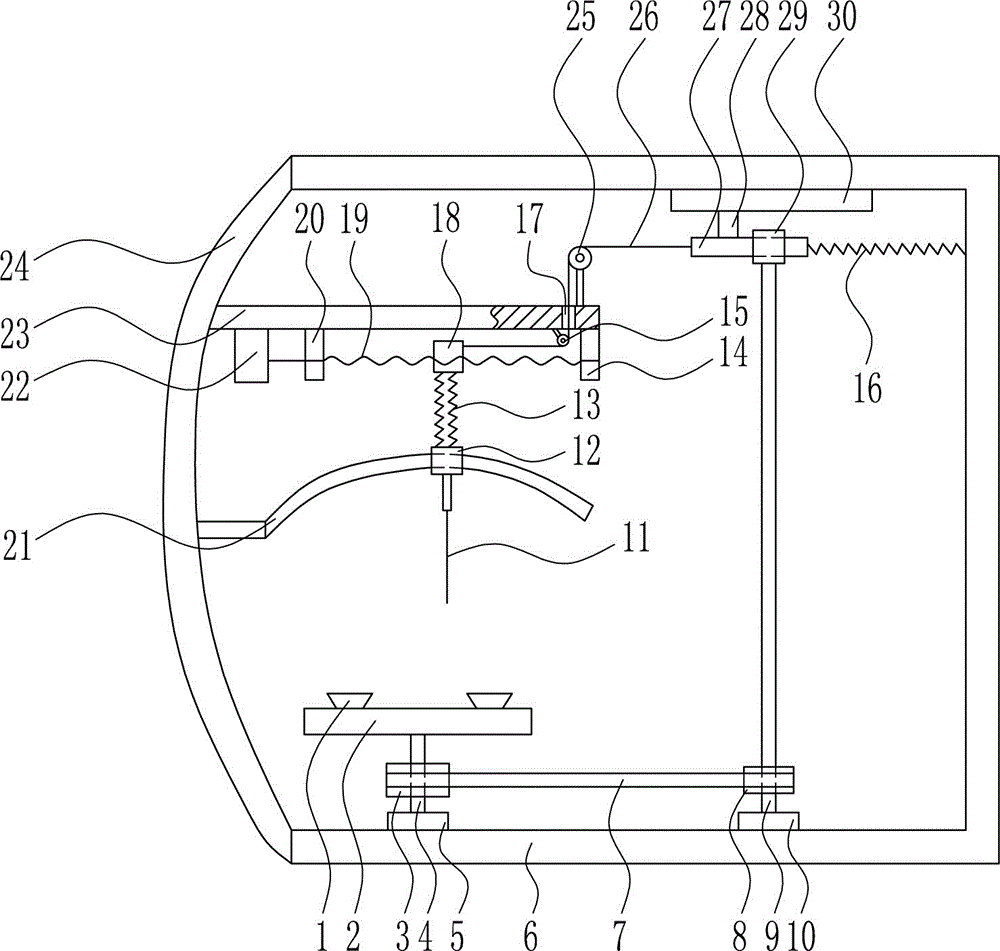

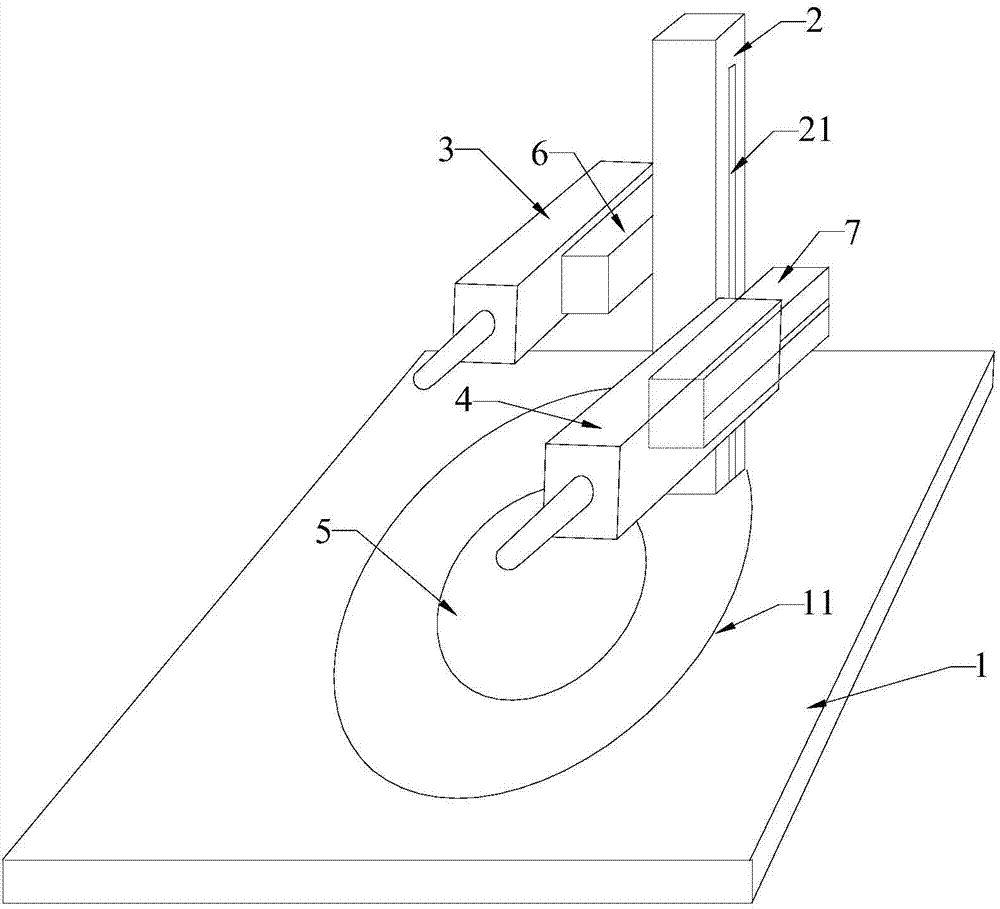

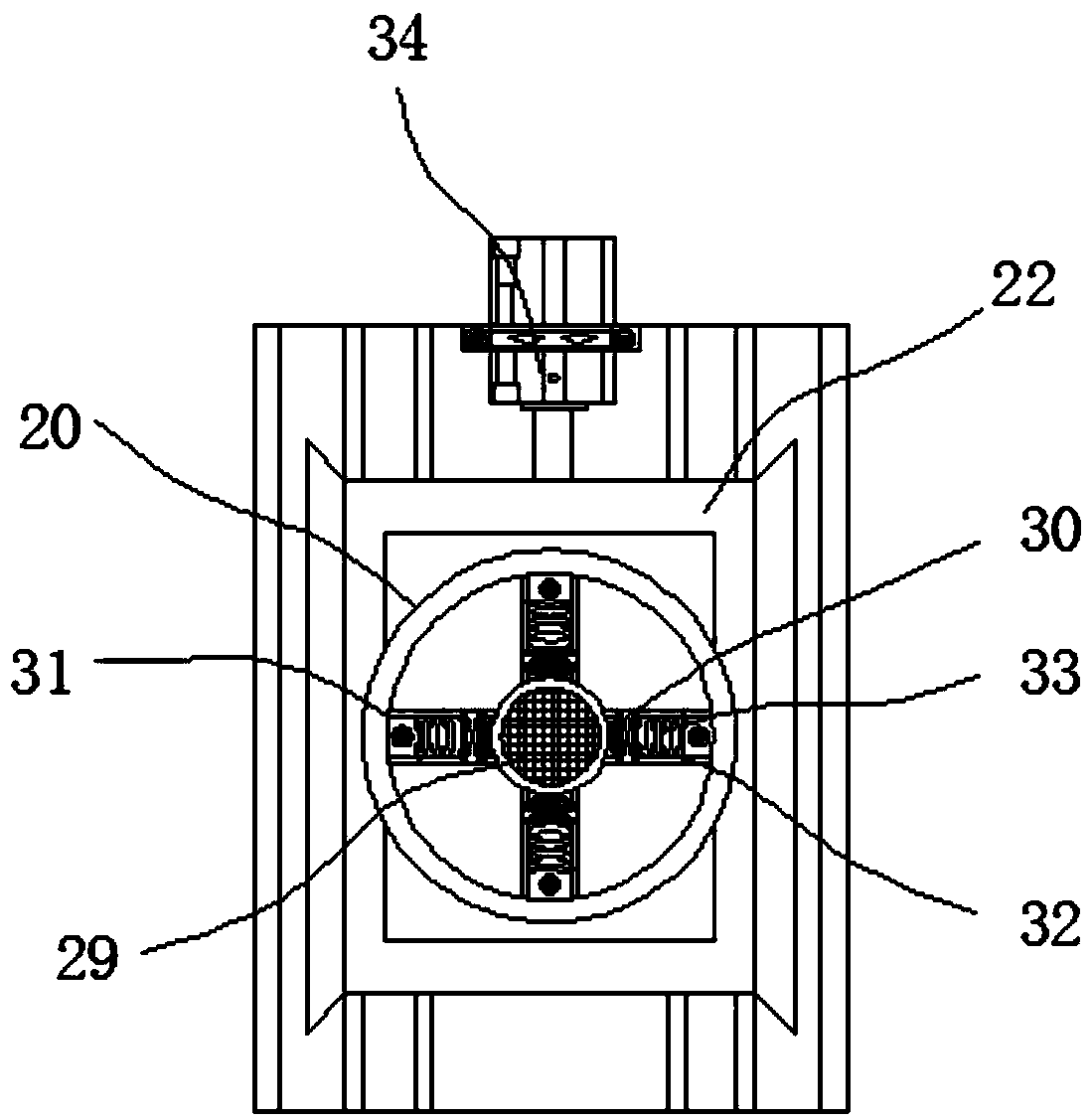

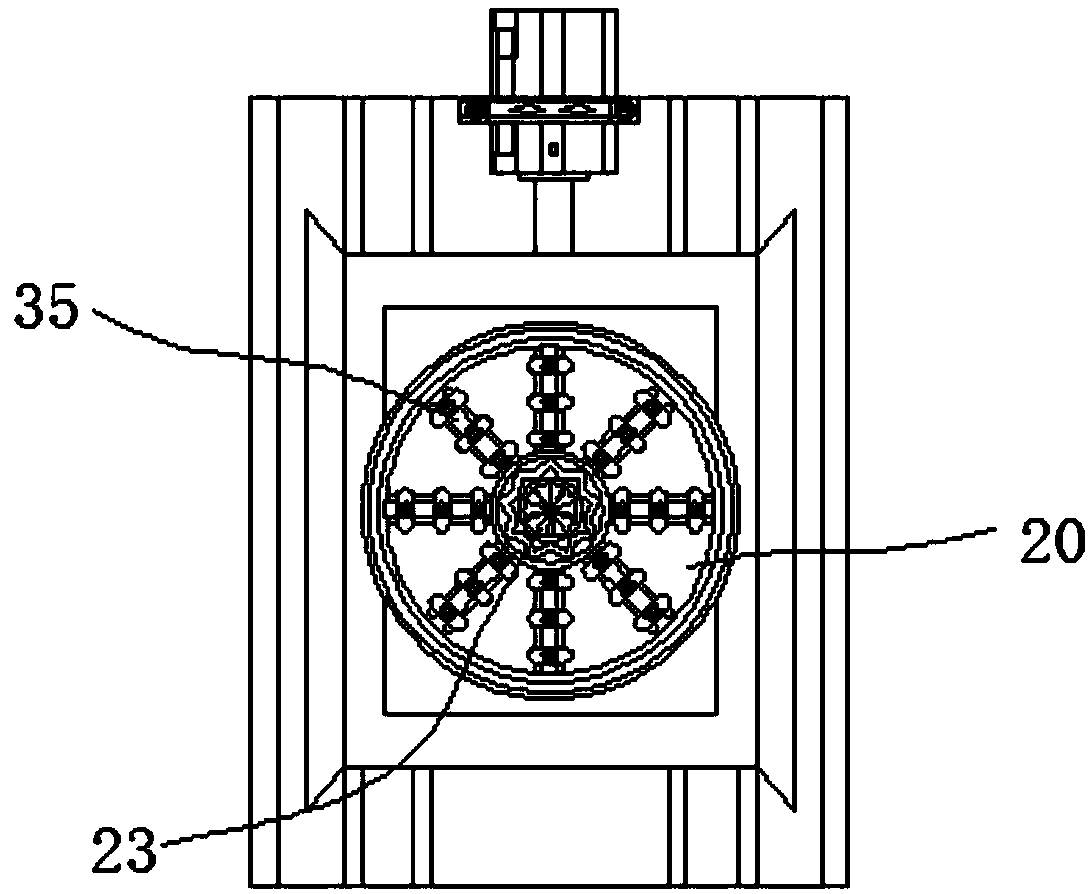

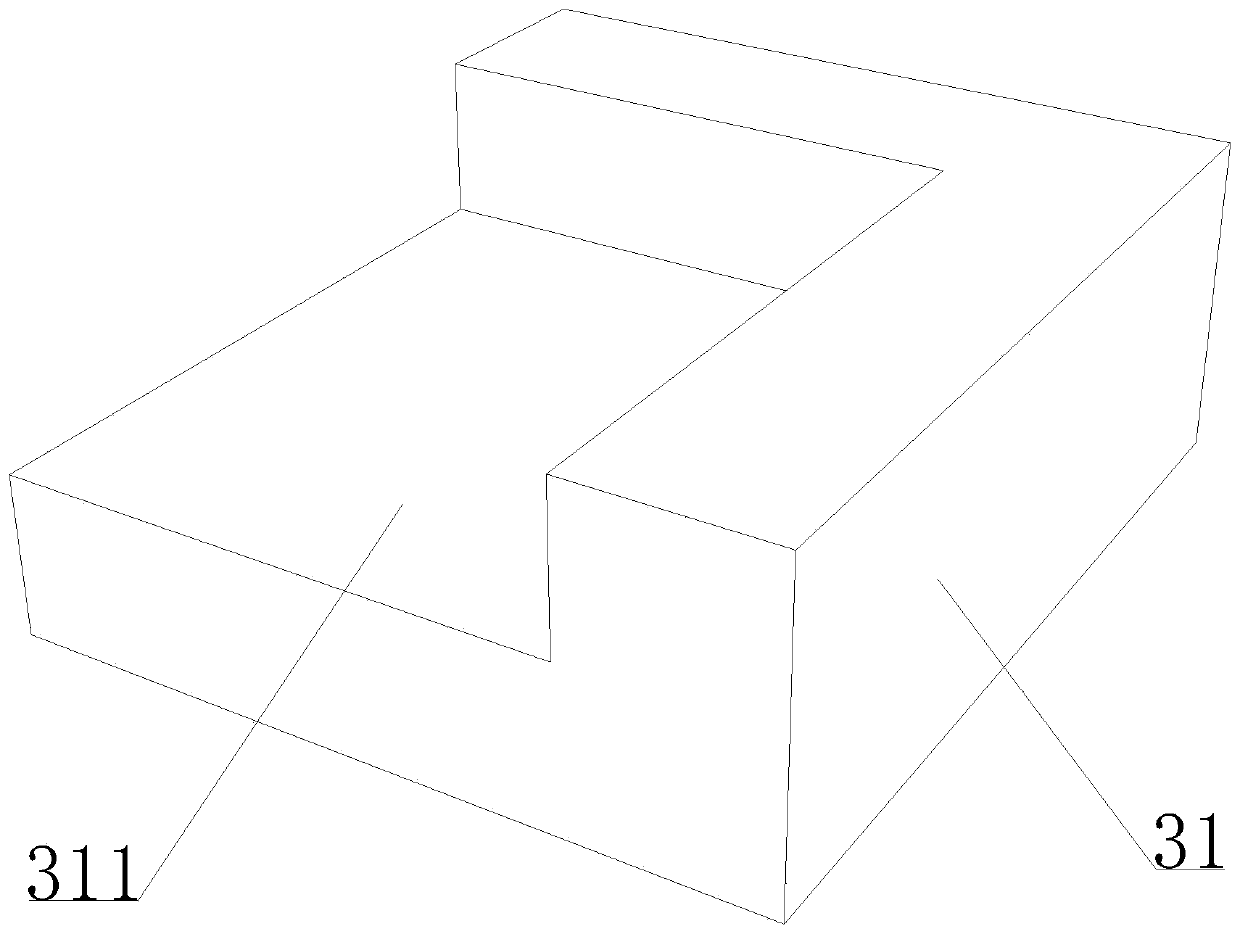

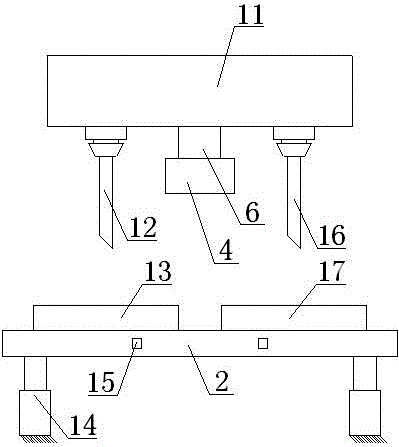

Adjustable carving working table

InactiveCN105881468AReasonable structural designImprove engraving efficiencyWork benchesEngravingLateral positioningEngineering

The invention belongs to the technical field of carving, and discloses an adjustable carving working table. The adjustable carving working table comprises supporting legs, a table plate, two guiding stand columns arranged on the two sides of the table plate, guiding sliding blocks arranged on the guiding stand columns in a sliding fit mode, and a working table body arranged between the two guiding stand columns. The two sides of the working table body are connected with the guiding sliding blocks in a pivoted mode through rotating shafts, and a rotating motor is arranged on one guiding sliding block and is in fit transmission with the corresponding rotating shaft. The working table body comprises a frame body, a rubber lining arranged on the inner wall of the lower side of the frame body, a jacking lead screw arranged on the upper side of the frame body, and multiple sets of clamping air cylinders arranged on the left side and the right side of the frame body. The adjustable carving working table is reasonable and compact in structural design; raw materials are supported through the table plate from the lower portion, and lateral positioning is achieved with the free rotation function of the working table body, so that effective fixing in different directions is achieved, carving efficiency is improved, a good carving environment is provided for carvers, and accidents are avoided.

Owner:石伟赟

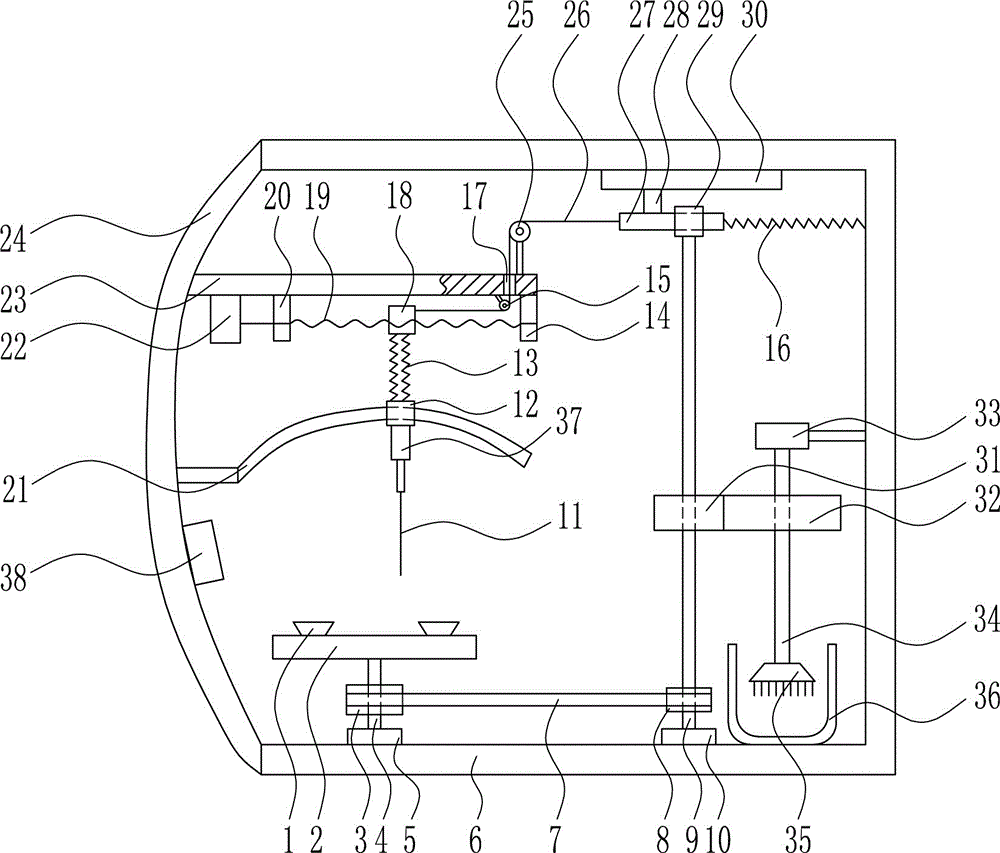

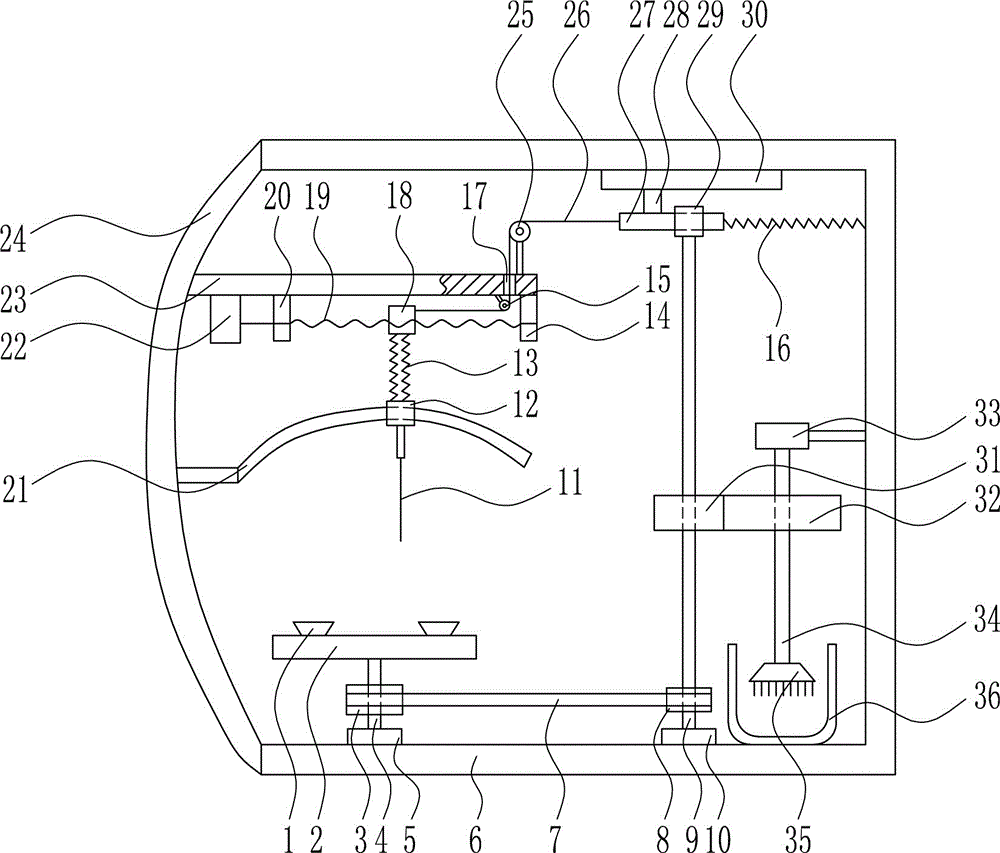

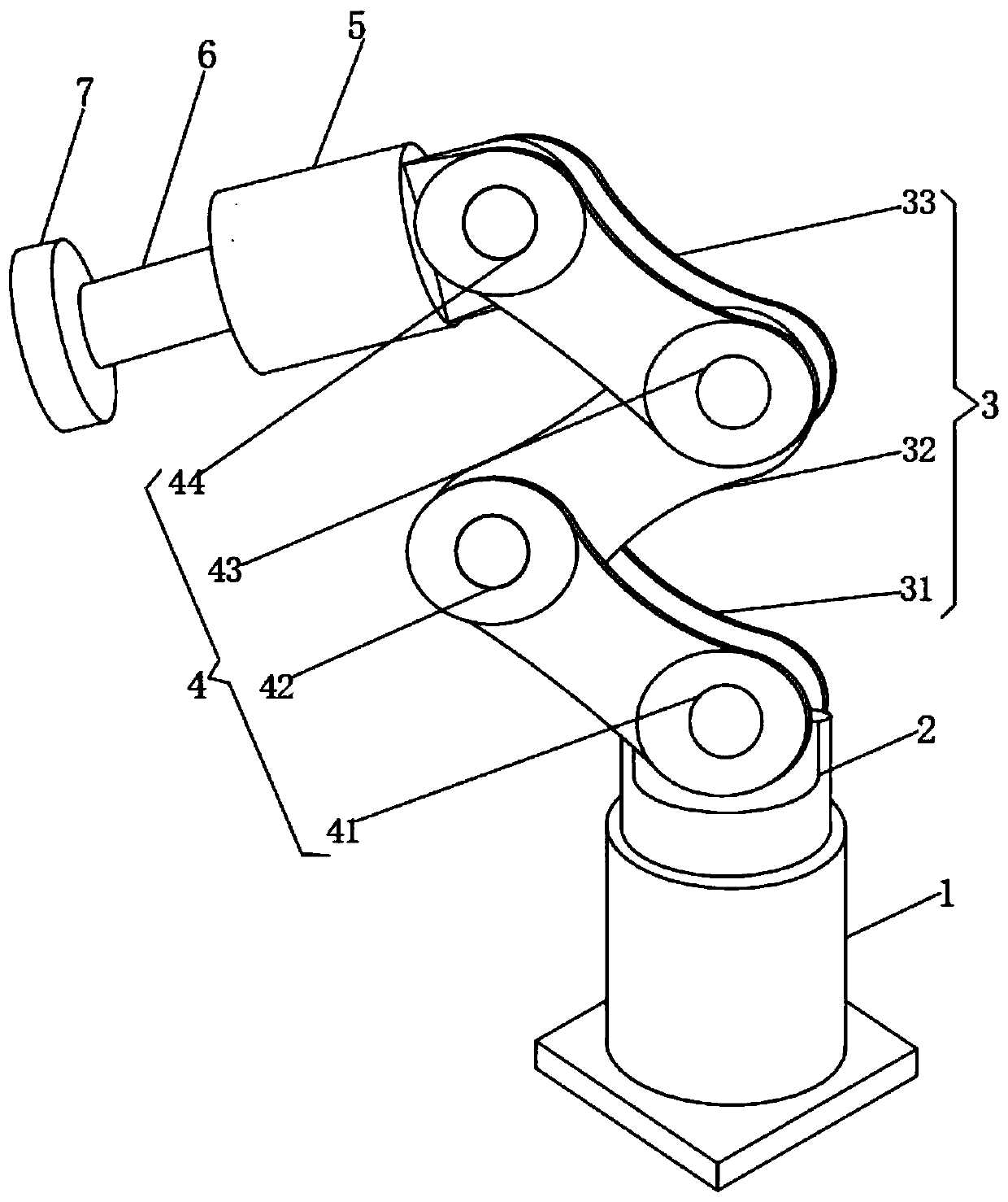

Efficient engraving device for porcelain manufacturing

ActiveCN106584657ASpeed up engravingImprove engraving efficiencyCeramic shaping apparatusDirt cleaningEngineeringSmall hole

The invention relates to an engraving device, in particular to an efficient engraving device for porcelain manufacturing. The efficient engraving device for porcelain manufacturing is high in engraving efficiency and comprises an electric suction cup, a placing plate, a large belt wheel, a first rotating shaft, a first bearing seat, a bracket, a flat belt, a small belt wheel, a second rotating shaft, a second bearing seat and the like. The top end of an arc-shaped silencing plate is connected with the left end of the top of the bracket. The right side of the arc-shaped silencing plate is provided with a fixing plate and an arc-shaped sliding rail. The fixing plate is located above the arc-shaped sliding rail. The right side of the fixing plate is provided with a small hole. The top of the fixing plate is provided with a second pulley. According to the efficient engraving device for porcelain manufacturing, the effect of being high in engraving efficiency is achieved.

Owner:浙江源端网络科技有限公司

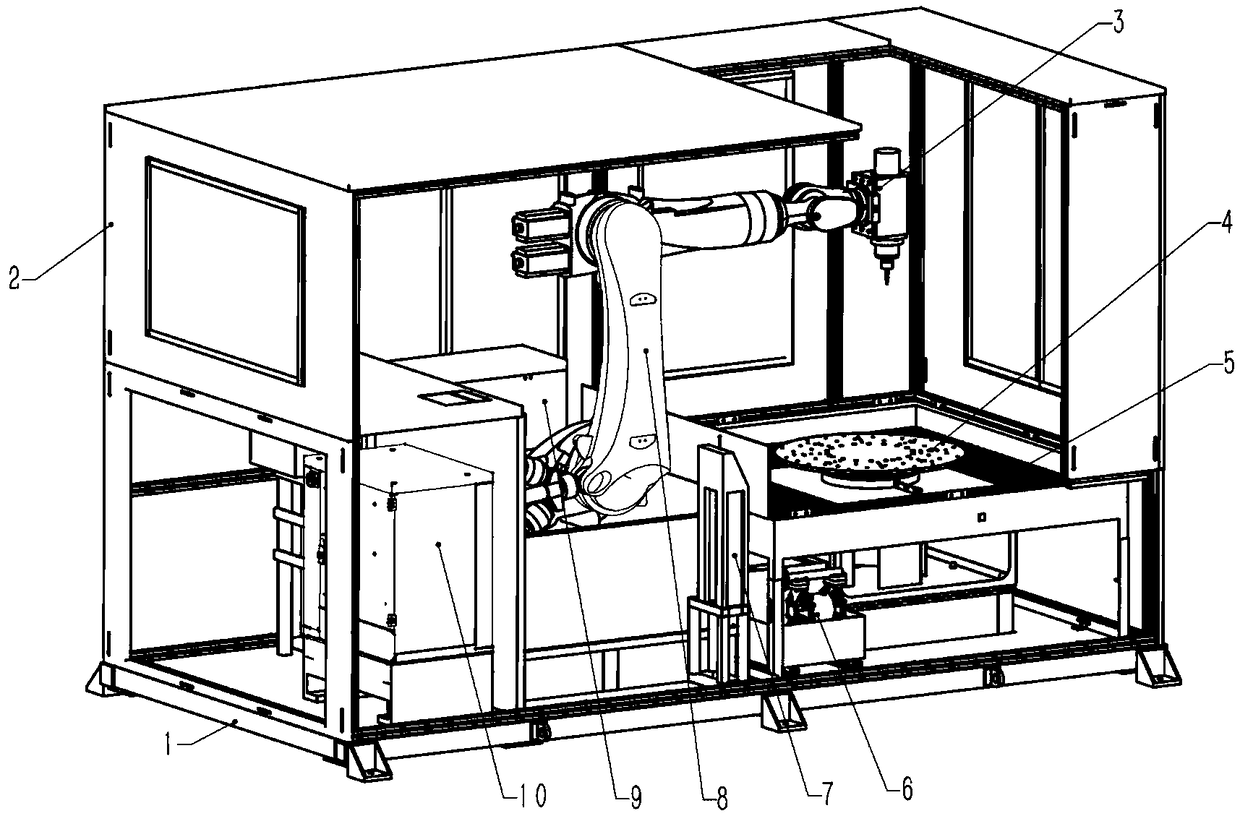

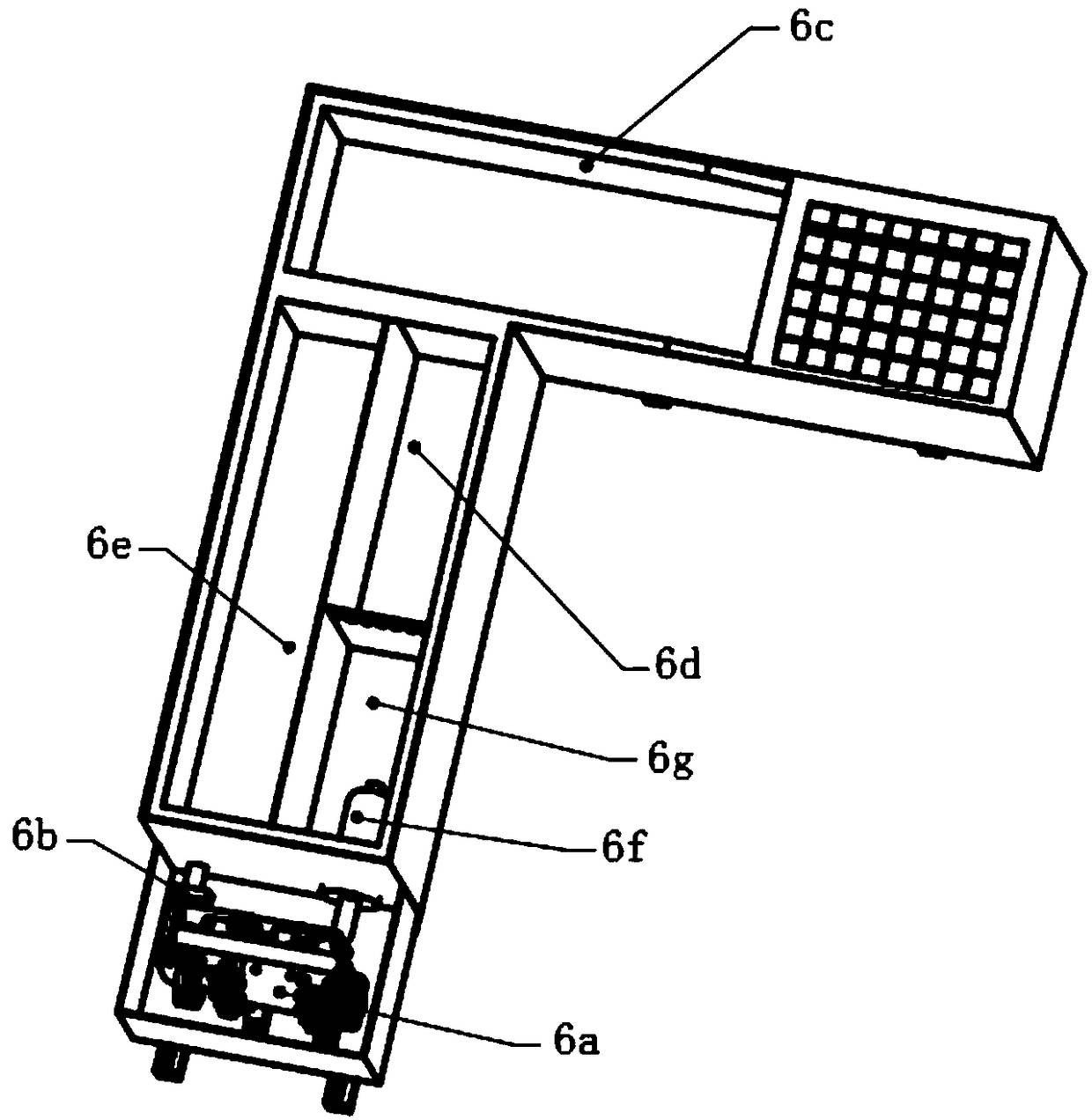

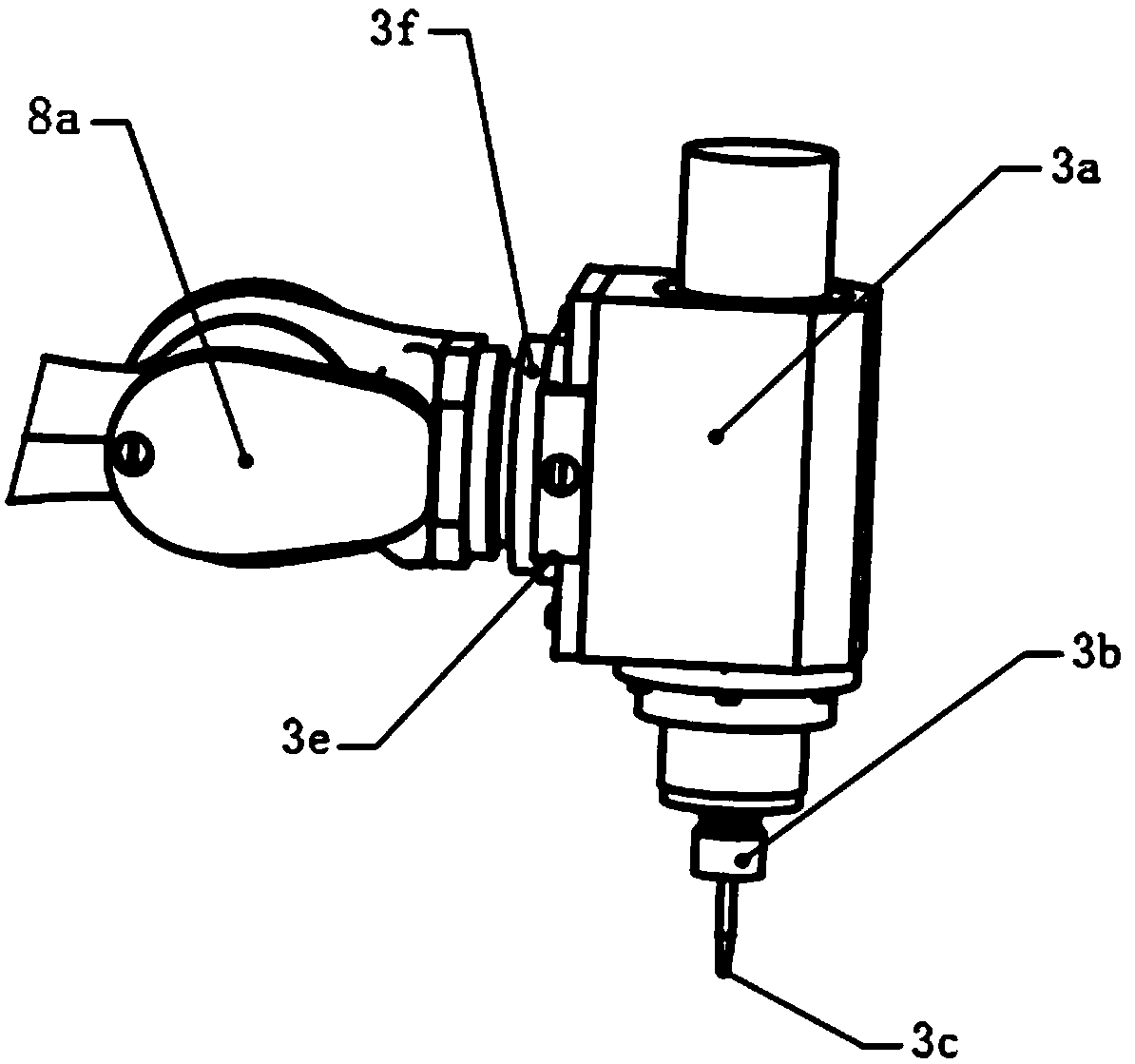

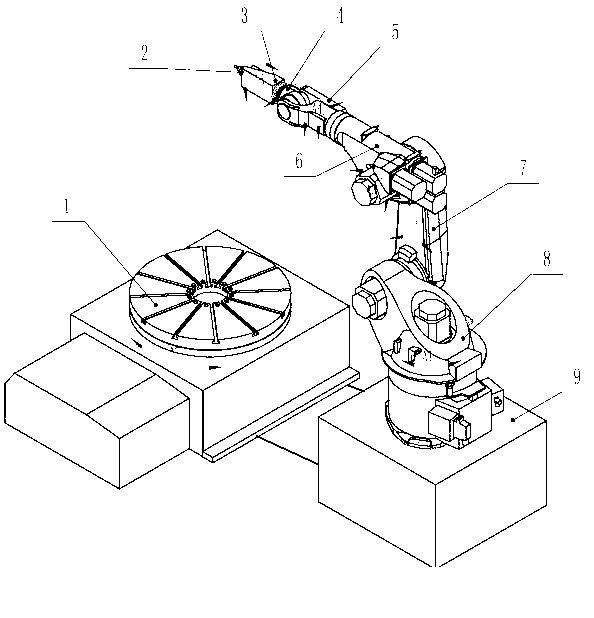

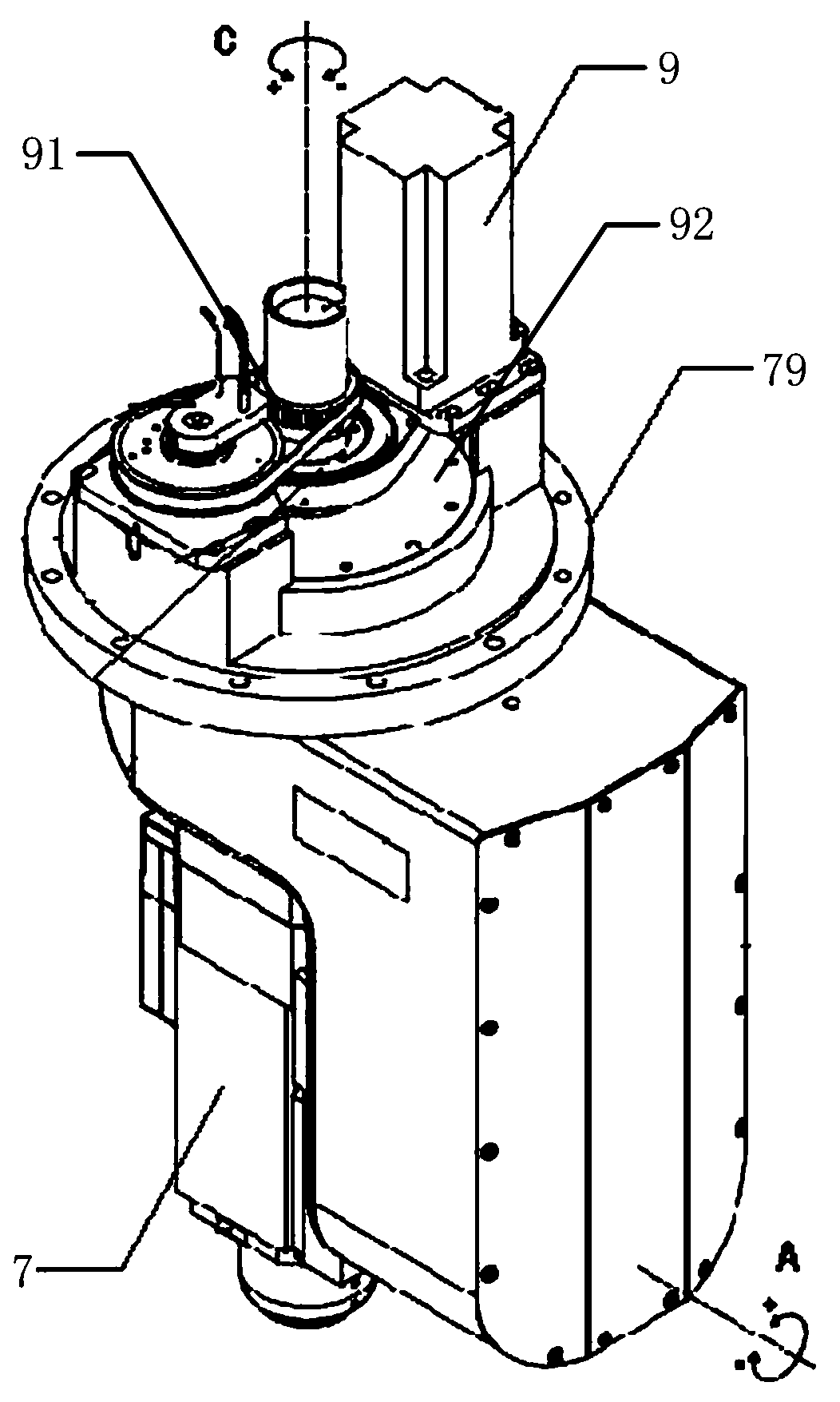

Carving robot system

PendingCN108942967AReduce waste water dischargeProtect environmentWorking accessoriesManipulatorFilter systemCarving

The invention provides a carving robot system, and belongs to the technical field of robots. The carving robot system comprises a robot base, a robot, a rotary platform and a controller used for controlling actions of the robot are arranged on the robot base, the robot comprises a mechanical arm, and a multifunctional carving head is arranged at the tail end of the mechanical arm; and a water collecting tank is arranged on the robot base, the rotary platform is located above the water collecting tank, and the carving robot system further comprises a filtering system, wherein the filtering system communicates with the water collecting tank. According to the carving robot system, waste water and waste residues can be well collected and treated through the water collecting tank and the filtering system correspondingly, the waste water discharge is reduced, the environment is protected, cutter replacement can be automatically achieved on the multifunctional carving head, and the product quality and the carving efficiency are improved.

Owner:云浮中科石材创新科技有限公司 +1

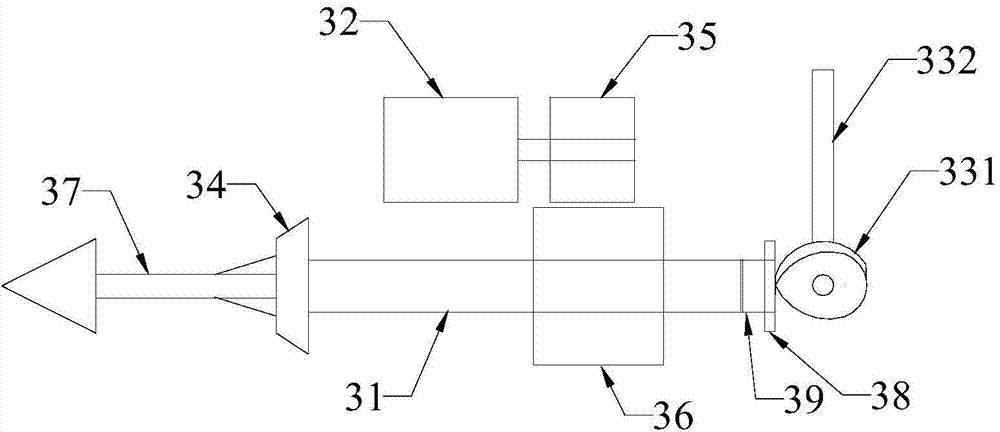

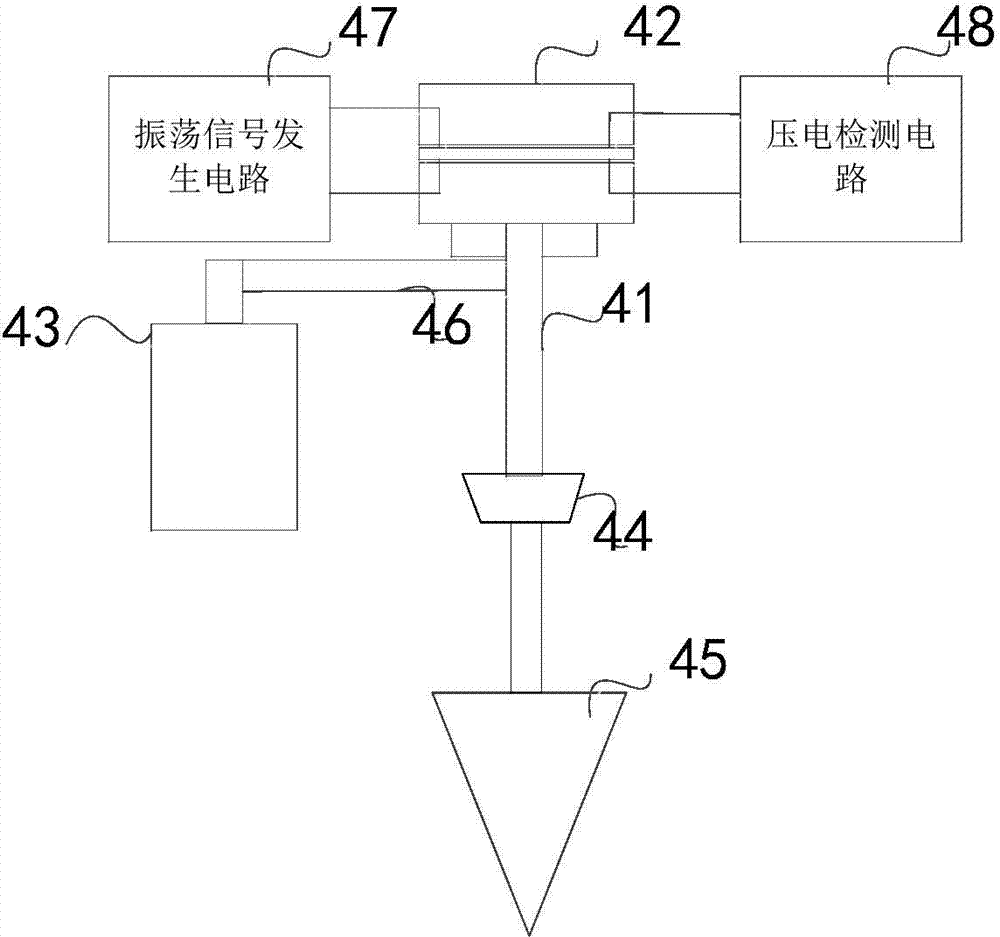

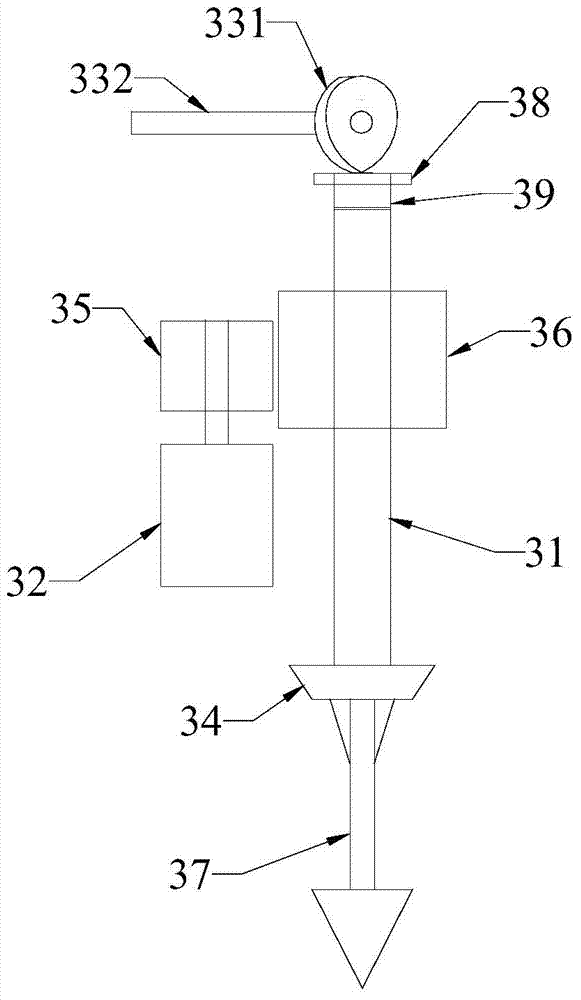

Single-pillar rough and finish machining integrated machine

InactiveCN104842697AImprove engraving finenessImprove engraving efficiencyEngravingDrive motorUltrasonic oscillation

The invention discloses a single-pillar rough and finish machining integrated machine comprising a workbench, a pillar, a rough carving device and a finish carving device. The rough carving device and the finish carving device are slidably arranged on guide rails on two sides of the pillar, the rough carving device comprises a third sliding device, a first spindle, a cam gear and a first driving motor, the first spindle is driven by the first driving motor to rotate and driven by the cam gear to vibrate axially at the same time, the finish carving device comprises a fourth sliding device, a second spindle, an ultrasonic oscillation device and a second driving motor, and the second spindle is driven to rotate by the second driving motor and driven to vibrate at high frequency by the ultrasonic oscillation device. The single-pillar rough and finish machining integrated machine is high in carving efficiency and applicable to vertical workpiece carving.

Owner:福建省天大精诺信息有限公司

Small stone sculpture laser-engraving equipment convenient to use

InactiveCN107486631AEasy to useEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelStone carving

The invention provides small stone sculpture laser-engraving equipment convenient to use, relating to the field of laser engraving. The small stone sculpture laser-engraving equipment comprises a fixing seat, wherein a base is fixedly connected to the bottom part of the inner wall of the fixing seat; a first motor is fixedly connected to the top part of the base; and the output end of the first motor is fixedly connected with a driving wheel seat. According to the small stone sculpture laser-engraving equipment provided by the invention, the effect of driving a placement disc on a rotating rod to rotate is achieved by matching of a driving wheel, a driven wheel and a first bearing seat under the rotation of the first motor, so that the effect of rotating stones arranged on the placement disc and needing to be engraved is achieved, the stone engraving becomes simpler and is easy to operate, the all-directional no-dead-angle rotary engraving is achieved when the stones are engraved, and the problems of slow engraving work, low efficiency and difficult operation caused by inconvenience in use of the laser-engraving equipment when the small stone sculptures are engraved through conventional methods are solved.

Owner:SUZHOU MIKE LASER TECH SERVICE CO LTD

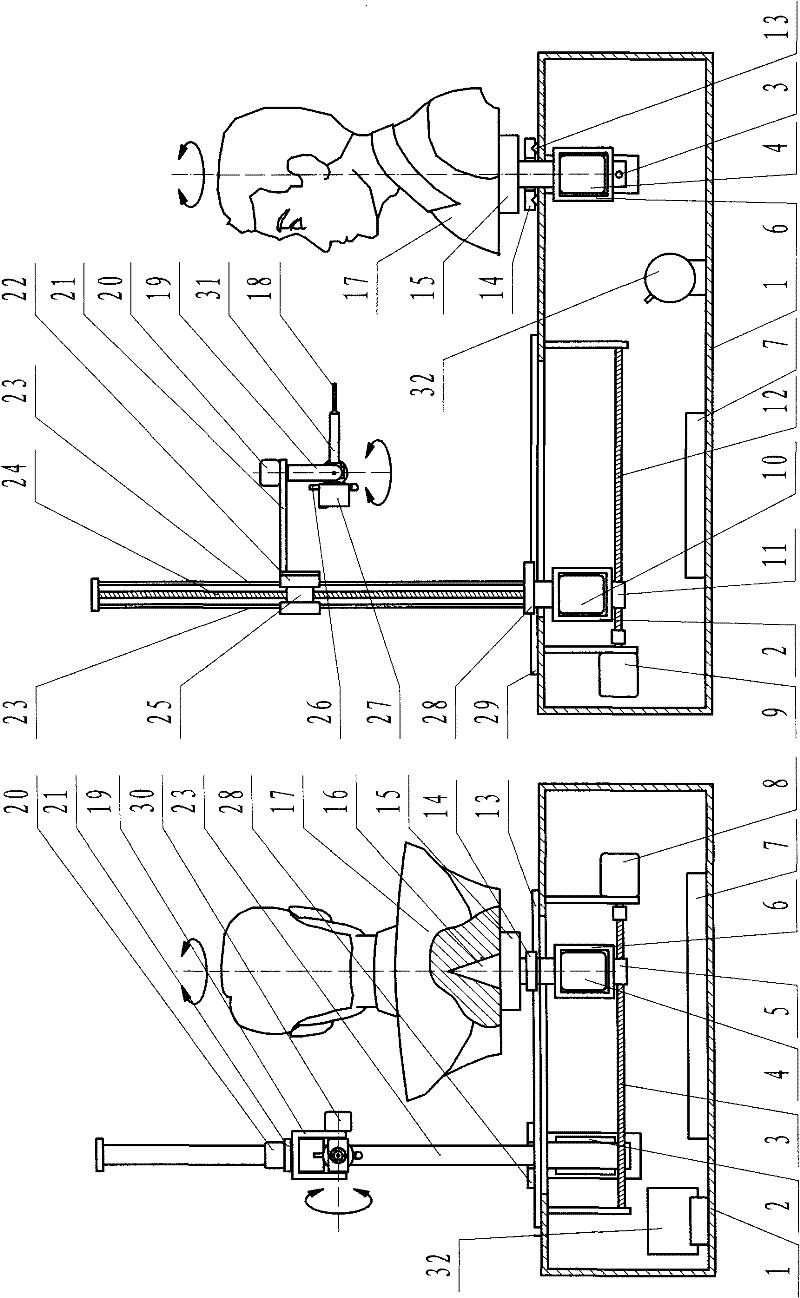

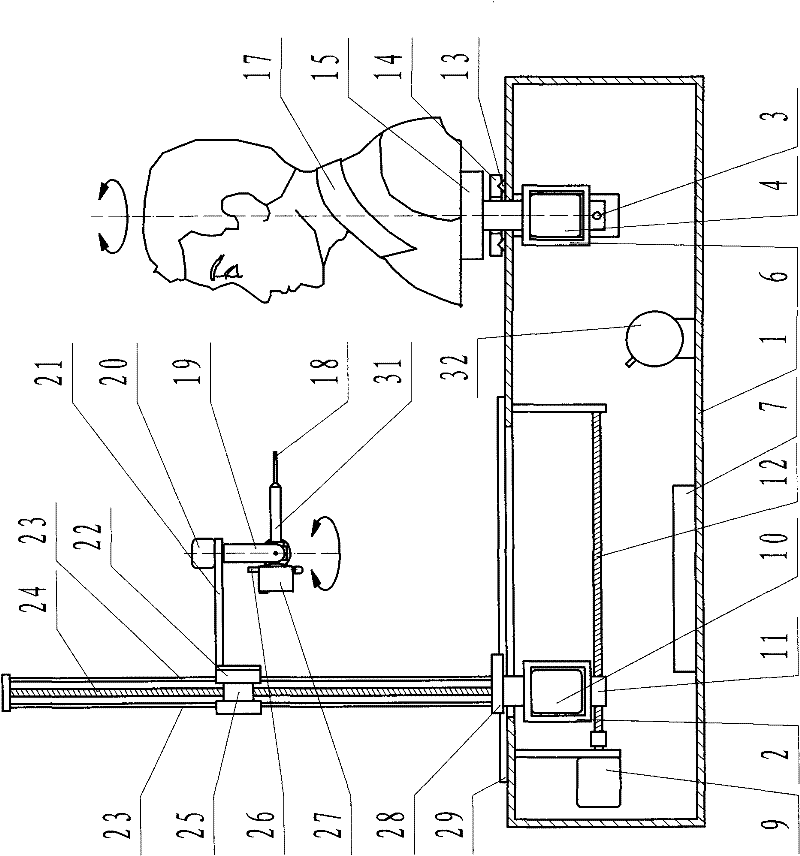

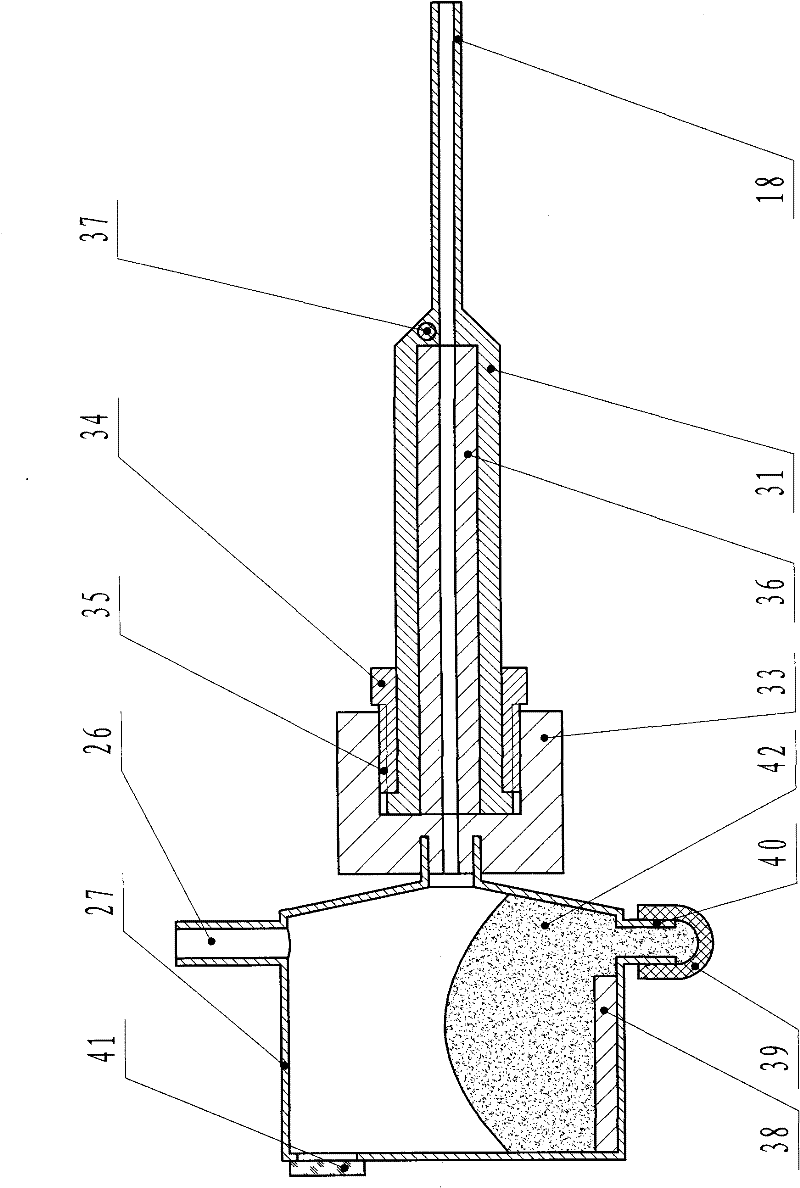

Movement mechanism of waxen image carving machine

InactiveCN102632752AReduce manufacturing difficulty and costProcessing and cutting resistance is smallModel makingManipulatorEngineering

The invention relates to a movement mechanism of a waxen image carving machine. The movement mechanism is a numerical control six-spindle low-cost machining tool using a hot knife; a wax blank is fixed on a rotary tray capable of translating transversely; and the hot knife is mounted on a double-joint manipulator to form any space position and angle relative to the wax blank.

Owner:邢刚

Multi-shaft carving machine

The invention relates to a multi-shaft carving machine which comprises a base, a general control system and a rotation worktable. The multi-shaft carving machine is characterized in that the upper portion of the base is provided with a first rotation joint, a first rotation motor and a first driving system are arranged in the first rotation joint, the first driving system is vertically arranged, the first rotation motor and the first driving system mesh through a first gear mechanism, a first rotation arm is arranged on the upper portion of the first driving system, and a plurality of rotation arms are sequentially connected to the tail end of the first rotation arm. The multi-shaft carving machine has the advantages of compact mechanical structure, high mechanical strength, good rigidity, high accuracy of transmission mechanism, many degrees of freedom, and low maintenance cost.

Owner:QINGDAO SUBA CNC EQUIP

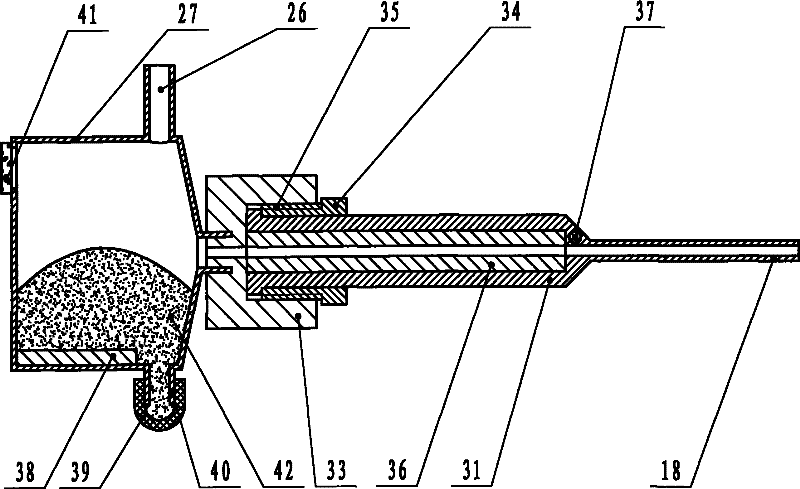

Hot knife of waxen image engraving machine

InactiveCN102632753ANo saggingProcessing and cutting resistance is smallModel makingEngineeringElectric heating

The invention relates to a hot knife of a waxen image engraving machine. An electric heating core and a temperature sensor are mounted in the knife, the knife is connected with an air exhausting system, and the temperature of a knife head is precisely controlled through a computer, so that the hot knife can process a three-dimensional waxen human image by using a melting method.

Owner:邢刚

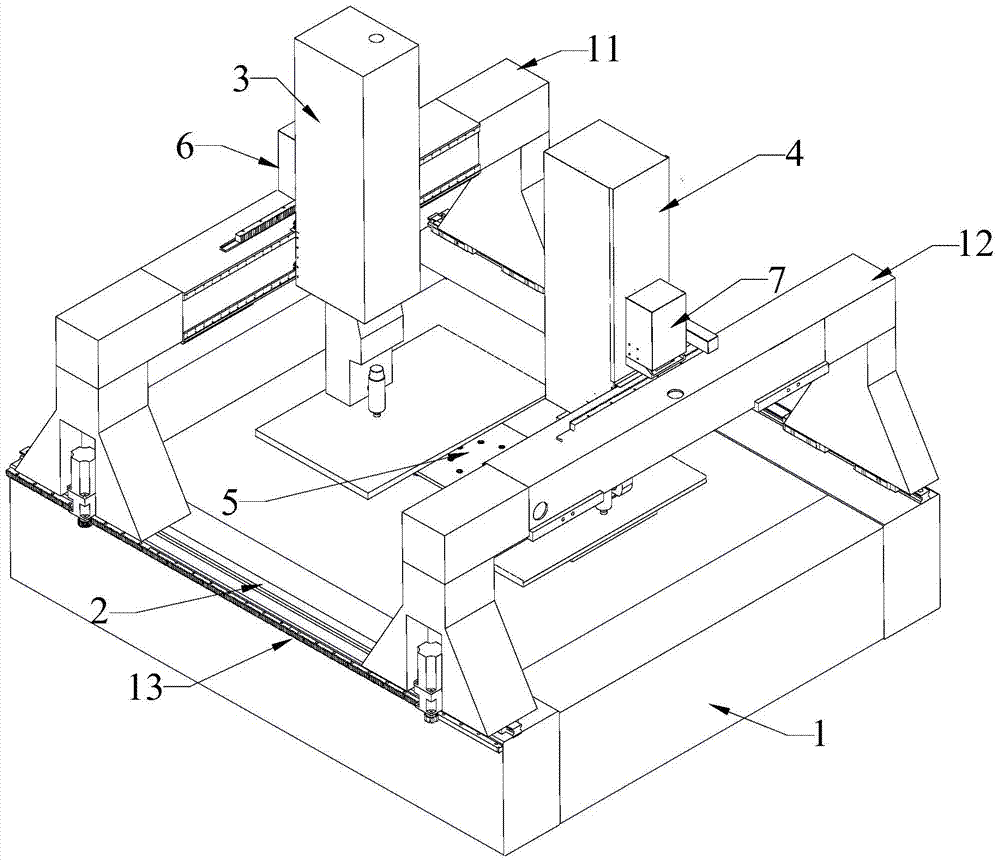

Wood and stone engraving machine

InactiveCN104842696AImprove engraving finenessImprove engraving efficiencyModel makingCamPortal frame

The invention discloses a wood and stone engraving machine. The wood and stone engraving machine comprises a workbench, a first portal frame, a second portal frame, a coarse engraving device and a fine engraving device. The coarse engraving device is slidably arranged on the first portal frame, and the fine engraving device is slidably arranged on the second portal frame. The coarse engraving device comprises a third sliding device, a first spindle, a cam device and a first driving motor. The first spindle is driven by the first driving motor to rotate and is driven by the cam device to axially vibrate. The fine engraving device comprises a fourth sliding device, a second spindle, an ultrasonic oscillation device and a second driving motor. The second spindle is driven by the second driving motor to rotate and is driven by the ultrasonic oscillation device to vibrate at high frequency. The wood and stone engraving machine is high in engraving efficiency.

Owner:福建省天大精诺信息有限公司

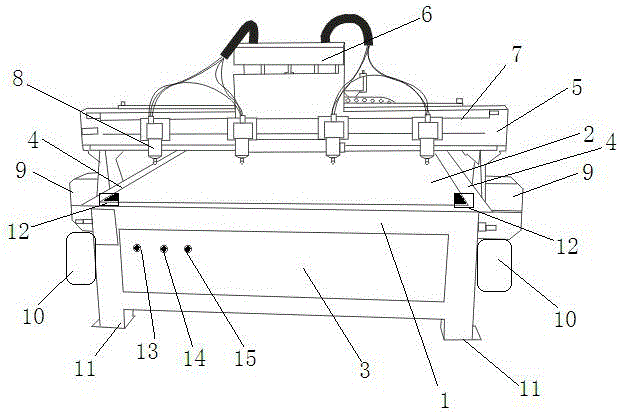

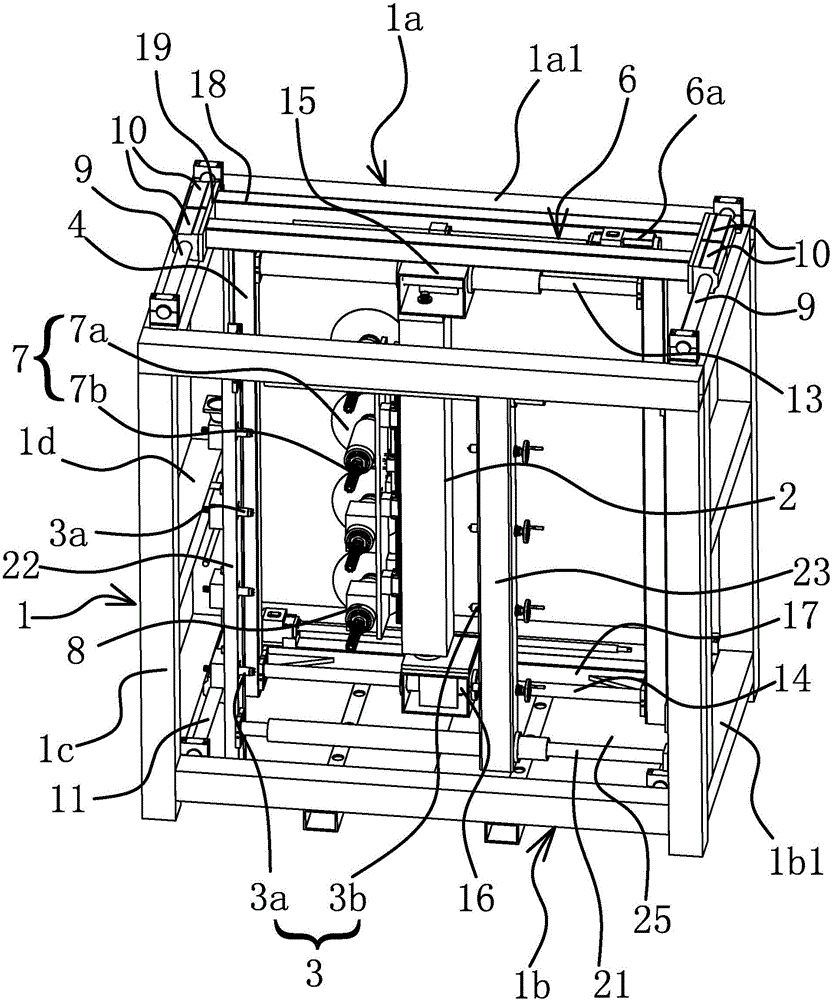

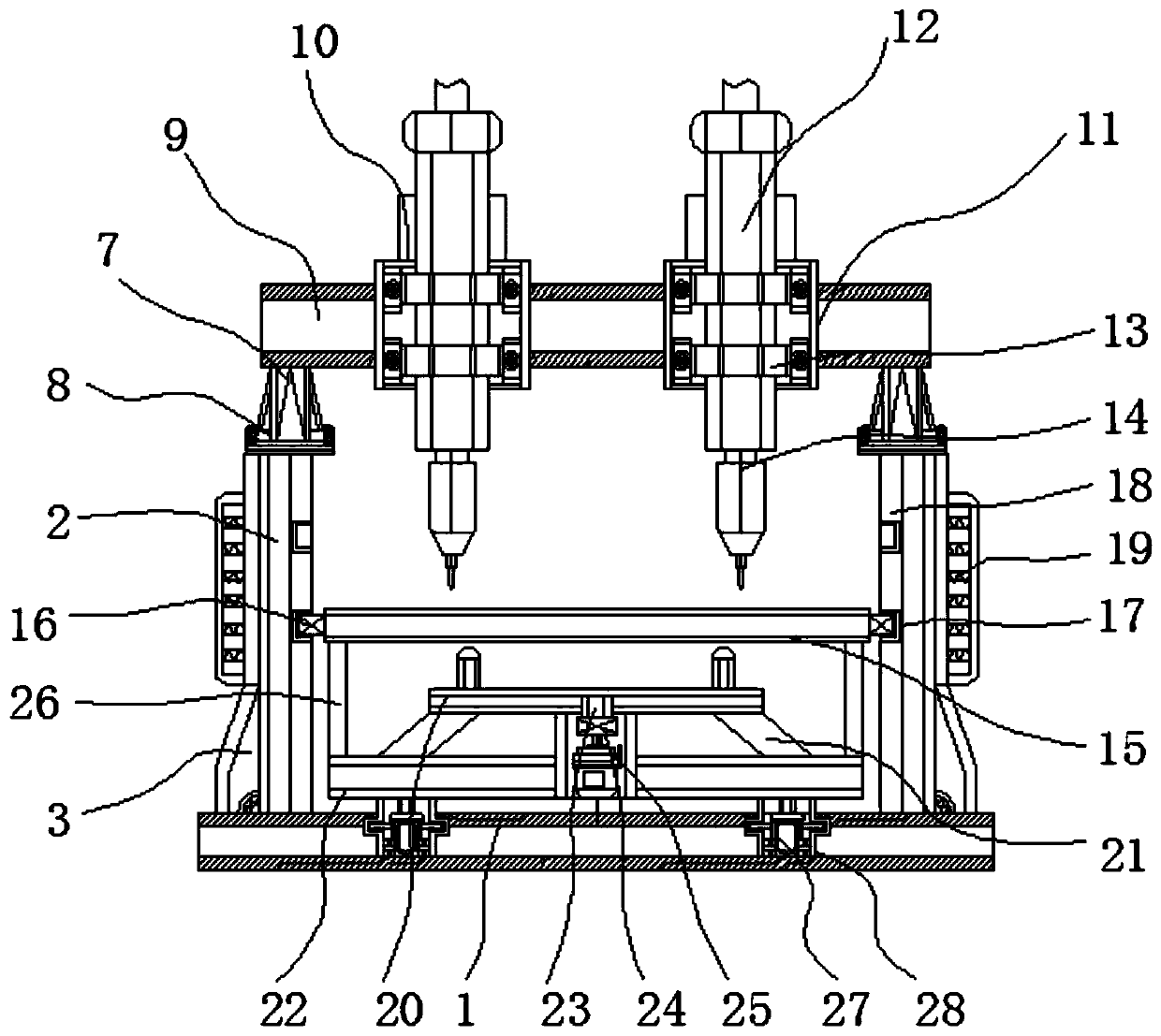

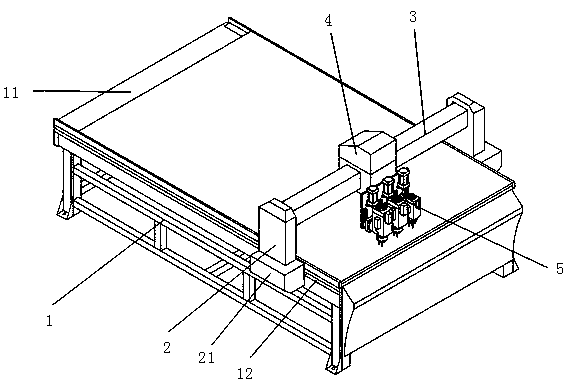

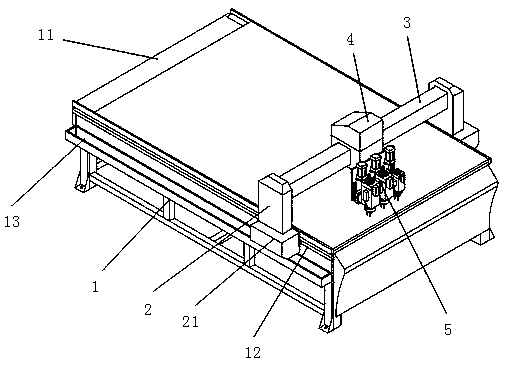

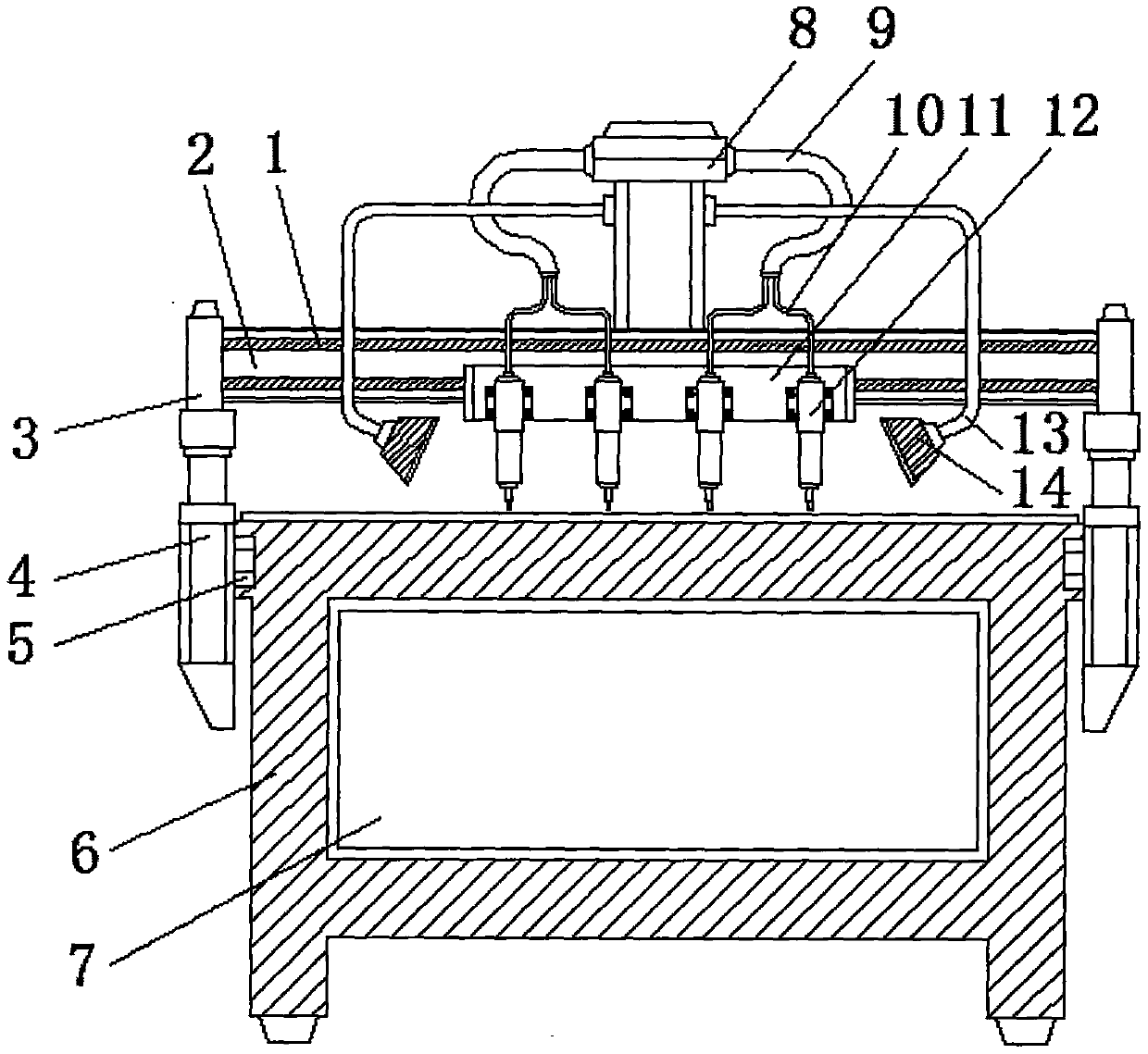

Multi-head woodworking carving machine

InactiveCN106427333AImprove engraving efficiencyImprove engraving qualityOther artistic work equipmentsModel makingDrive motorEngineering

The invention discloses a multi-head woodworking carving machine. The multi-head woodworking carving machine comprises a working base, sliding rails are arranged on the two side edges of the upper surface of the working base, a cross beam frame is installed between the two sliding rails, the cross beam part of the cross beam frame is arranged over the upper surface of the working base, a driving motor is installed on the cross beam part of the cross beam frame and controls the ends of the cross beam frame to slide on the sliding rails, two groove strips distributed in parallel are arranged on the side face of the cross beam part of the cross beam frame, a plurality of sets of carving heads are distributed on the side face of the cross beam part of the cross beam frame at equal intervals and are connected with a control unit through cables, suction fans parallel to the upper surface of the working base are installed below the two ends of the cross beam frame respectively and are used for sucking away wood dust generated in the process of carving a board on the upper surface of the working base, and the suction fans and the driving motor are connected with the control unit through cables respectively. The multi-head woodworking carving machine improves carving efficiency and carving quality, is simple in structure and easy to realize and has good application prospects.

Owner:SUZHOU HENGDAL IND MATERIALS CO LTD

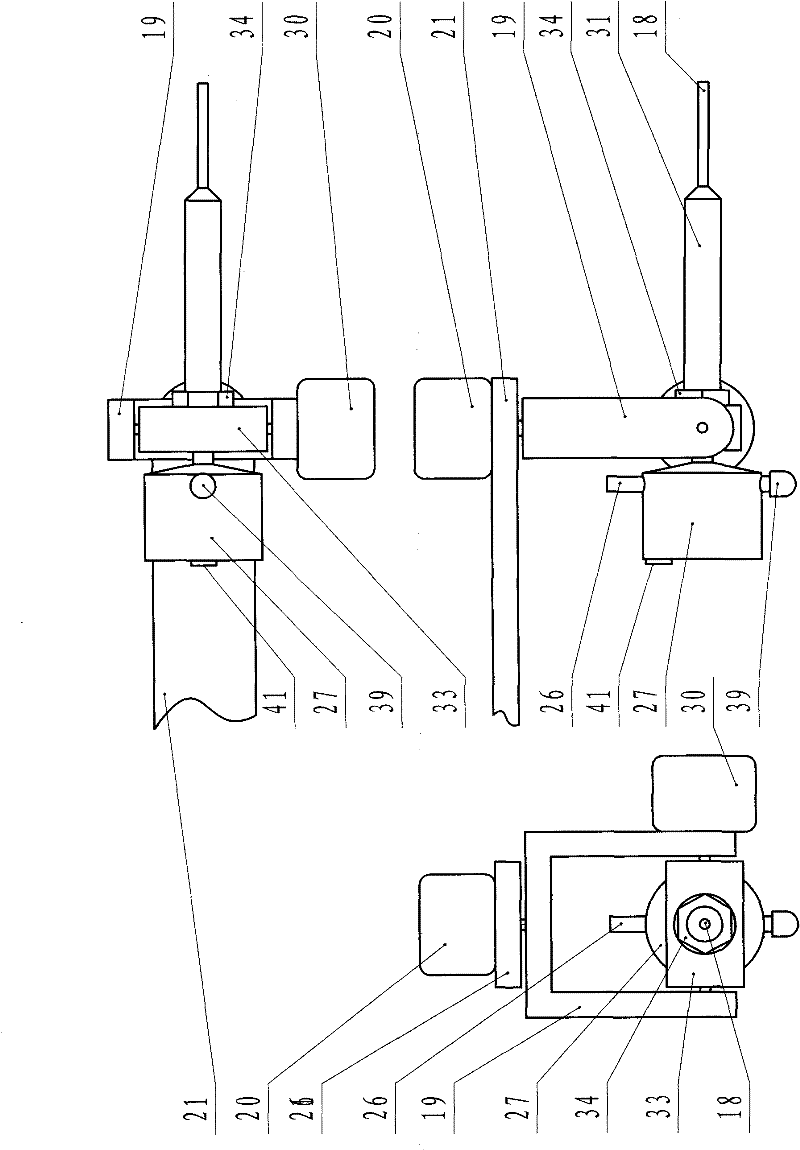

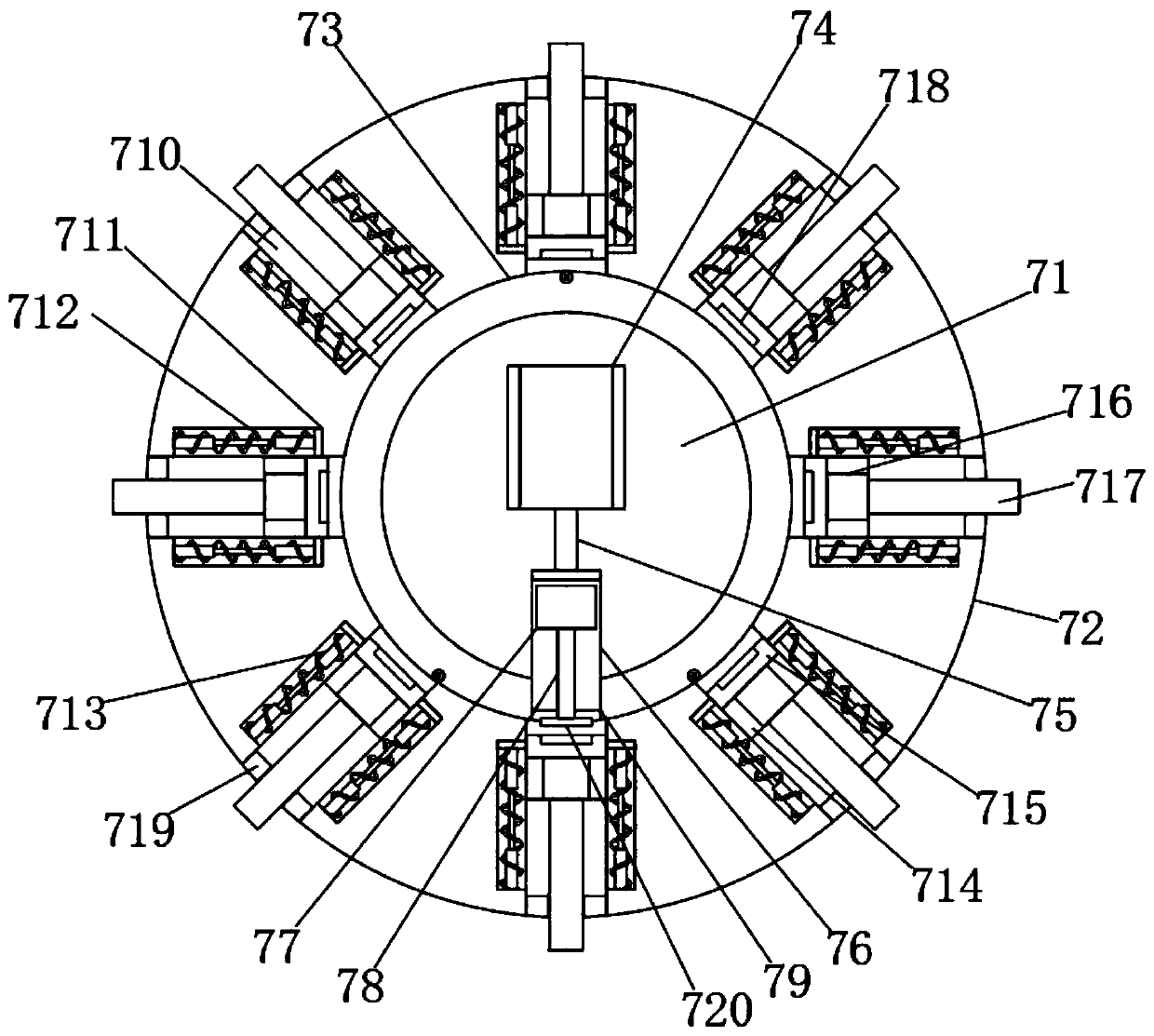

Multi-joint robot engraving machine

PendingCN110815257AExtended range of movementLifelike qualityProgramme-controlled manipulatorPositioning apparatusCrankControl engineering

The invention relates to a multi-joint robot engraving machine. The multi-joint robot engraving machine comprises a rotary motor, wherein an installation seat is fixedly connected to an output end ofthe rotary motor; a multi-joint crank arm is fixedly connected to the top of the installation seat; and a second angle motor is arranged on the multi-joint crank arm to adjust the state of the multi-joint crank arm. According to the multi-joint robot engraving machine, in specific operation, a drive device moves downwards under the driving of an electric push rod, the drive device makes contact with a location clamping sleeve, and under the rotation of the drive device, the location clamping sleeve can be driven to rotate; a drill bit installation mechanism is connected into a rotary block ina sleeved manner, so that a drill bit can be driven to rotate; during changing for the drill bit, the drive device ascends, a tool changing disc rotates, and in this way, the step of tool changing canbe rapidly carried out, so that the drill bit can be changed without the need of enabling an engraving tool disc to enter into and exit out of a cavity body; and the tool changing manner is rapid, and capable of increasing the operation efficiency, and carrying out changing operation on a plurality of tools in a short time.

Owner:HEFEI SIGNRIGHT NUMERICAL CONTROL EQUIP

A mold laser engraving machine

ActiveCN105127600BQuick disassemblyReduce volumeLaser beam welding apparatusLaser engravingMechanical engineering

The invention discloses a mold laser engraving machine which comprises a base, a longitudinal driving mechanism, a transverse driving mechanism, a fine adjustment connecting block, a laser head and a main machine box. The main machine box is placed on the base. A longitudinal connecting base is arranged on the base. The bottom of the longitudinal driving mechanism is connected to the longitudinal connecting base in an insertion mode. The end of the transverse driving mechanism is connected to a longitudinal sliding block of the longitudinal driving mechanism in an insertion mode through a rotating shaft and a bearing. The top of the laser head is connected with a transverse sliding block of the transverse driving mechanism through the fine adjustment connecting block. The laser head and the main machine box are connected through a cable and optical fiber. The structure of an engraving machine is designed again, the engraving machine is provided with a plurality of detachable components, the detached components can be carried by one person and can be placed into a trunk of a common household car, assembling is quite convenient and fast, meanwhile, 360-degree full-dimensional non-dead-corner movement of a vibrating mirror is achieved through a middle transmission component of the laser engraving machine, and the mold laser engraving machine has the advantages of being high in precision and convenient to adjust.

Owner:台州市黄岩东胜机械设备有限公司

Five-axis linkage carving machine for processing redwood furniture

PendingCN109249734AOptimize the mechanical structureImprove machining accuracyModel makingEngravingCarvingChassis

The invention discloses a five-axis linkage carving machine for processing redwood furniture. The five-axis linkage carving machine for processing redwood furniture comprises a gantry bottom rack, wherein two supports are separately arranged at two ends of the gantry bottom rack; a gantry stand column is supported on the top of each support; the bottom surface of each gantry stand column is weldedto the top surface of the corresponding support; a linear rolling guide track is slidably connected with a ram; a Z-axis box body is fixed on the ram; a double-oscillation electric spindle is arranged on the bottom of the Z-axis box body; a screw is arranged on a side of the Z-axis box body; a cylinder is fixed on the top of the Z-axis box body; the bottom of the cylinder is connected with a cylinder rod; the cylinder rod penetrates in the ram; the cylinder drives the cylinder rod to lift; and the double-oscillation electric spindle is fixed on the bottom of the cylinder rod and lifts along with the cylinder rod.

Owner:东阳甬创智诚家具设计有限公司

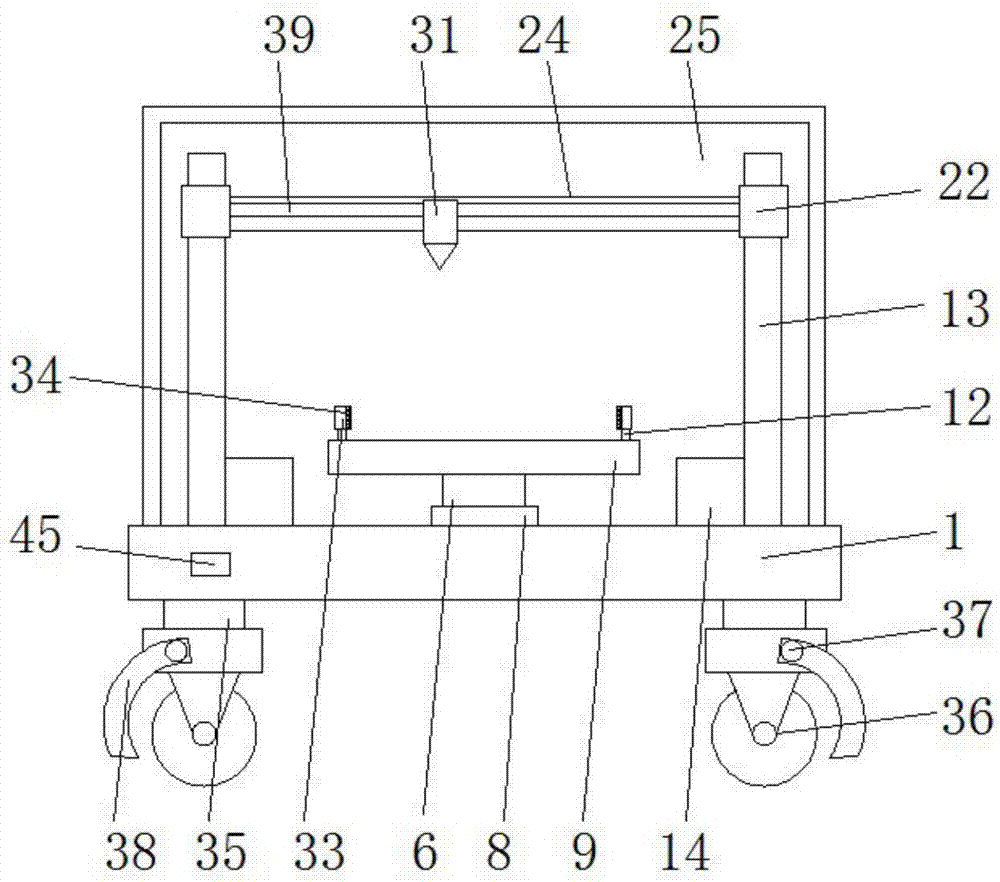

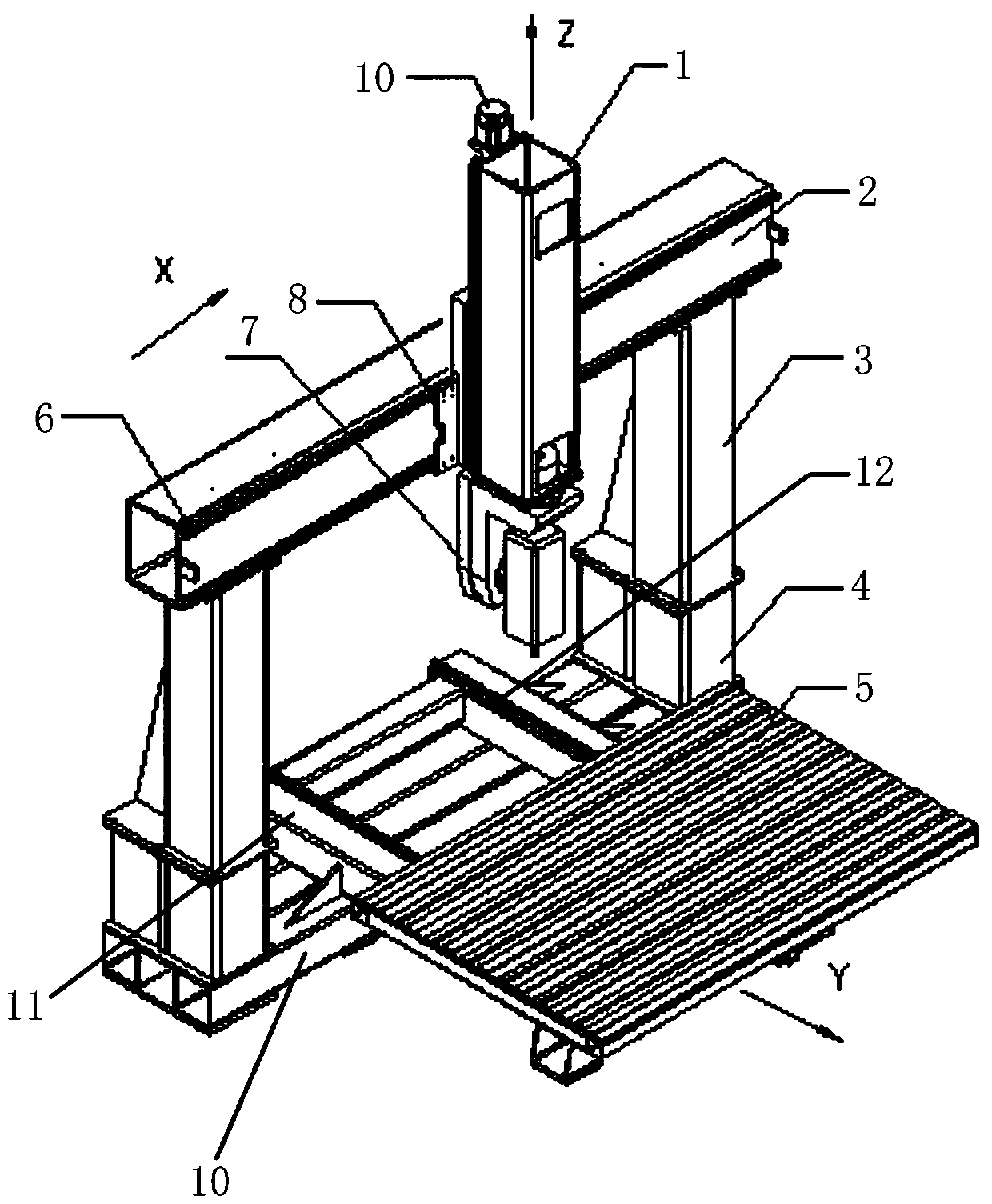

Horizontal numerical control three-dimensional carving machine

ActiveCN105252945AAffects engraving accuracyAffect consistencyModel makingNumerical controlEngineering

The invention discloses a horizontal numerical control three-dimensional carving machine which comprises a base, a portal frame, a workpiece clamping device, a transverse moving mechanism, a vertical moving mechanism and a carving tool frame. The workpiece clamping device comprises a fixed beam, a movable beam and a moving and fixing mechanism. A front-back moving mechanism is arranged between the workpiece clamping device and the base, and comprises two slide rails, slide blocks, a driving structure, slide rail waterproof covers and a movable base plate. The slide rails are fixedly arranged on the base. The driving structure is arranged in the middle. The slide blocks are arranged on the two sides, corresponding to the two slide rails, of the movable base plate respectively. The slide blocks are each of a crank structure. One end of each slide block slides on the corresponding slide rail, and the other end of each slide block is fixedly connected with the movable base plate. The slide water waterproof covers cover the two slide rails and cover the ends, correspondingly sliding on the slide rails, of the slide blocks respectively. The carving machine is high in structural weight capacity, stable in structure and smooth and stable in mechanical actions, and factors influencing carving accuracy and carving consistency can be reduced as much as possible.

Owner:福建省农球机械科技有限公司

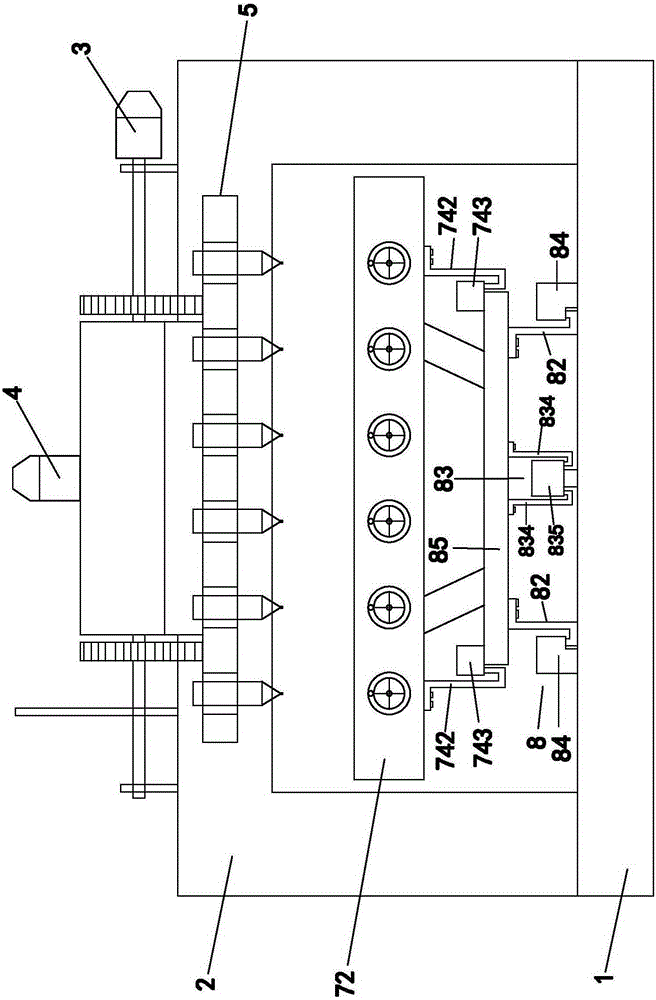

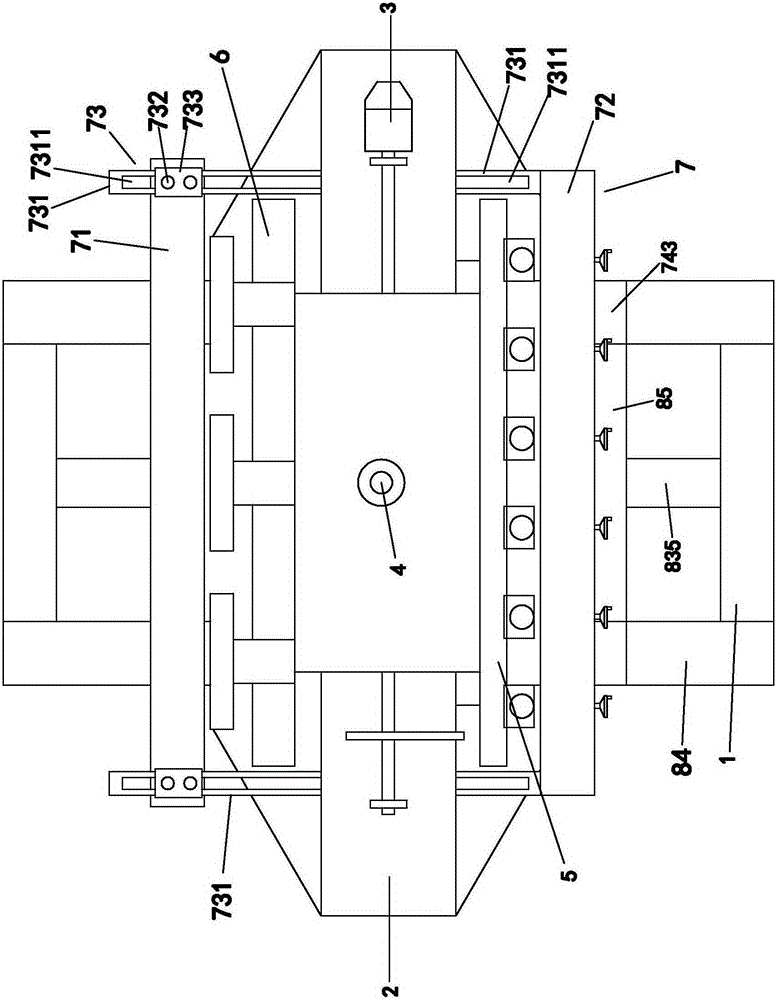

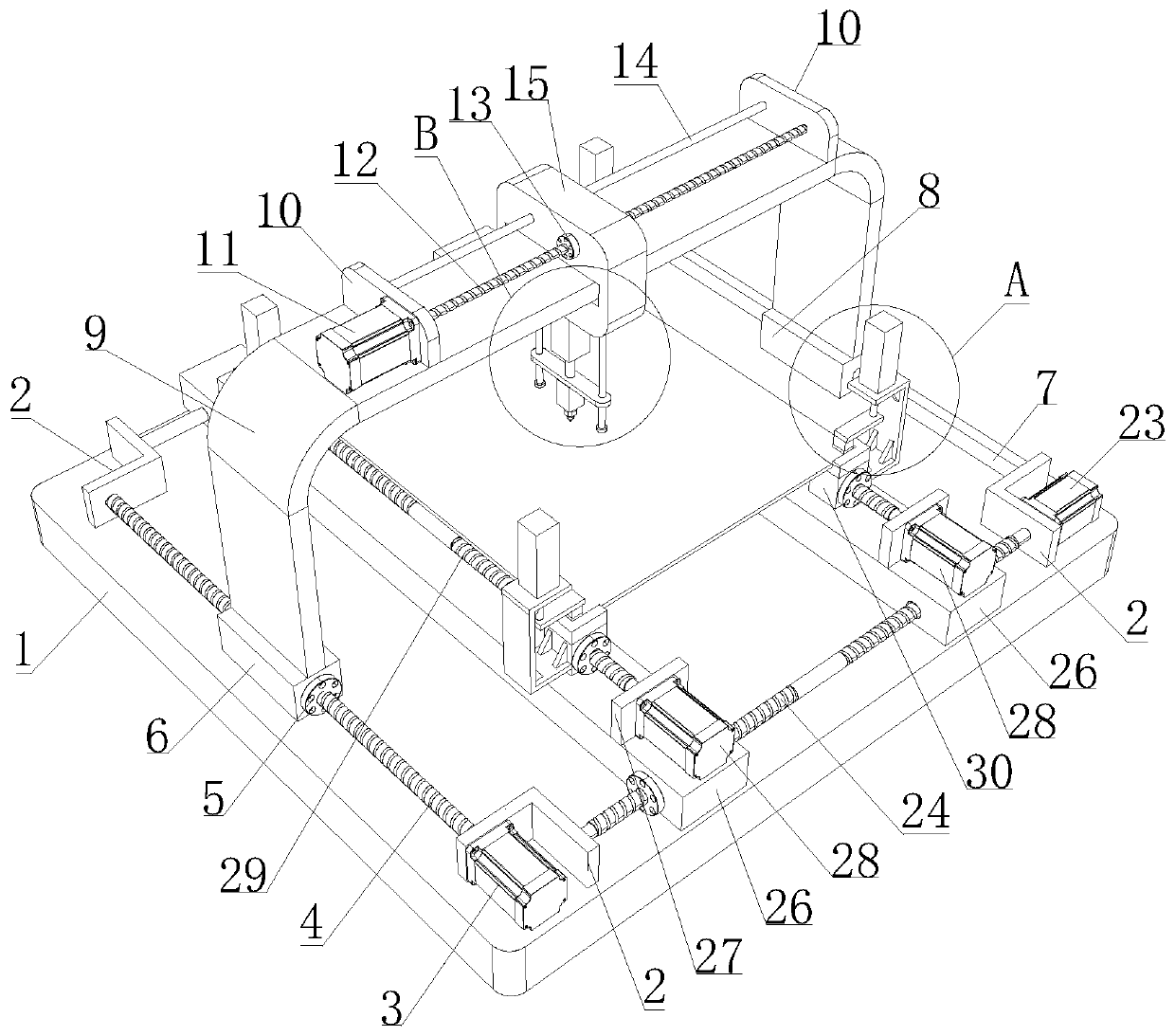

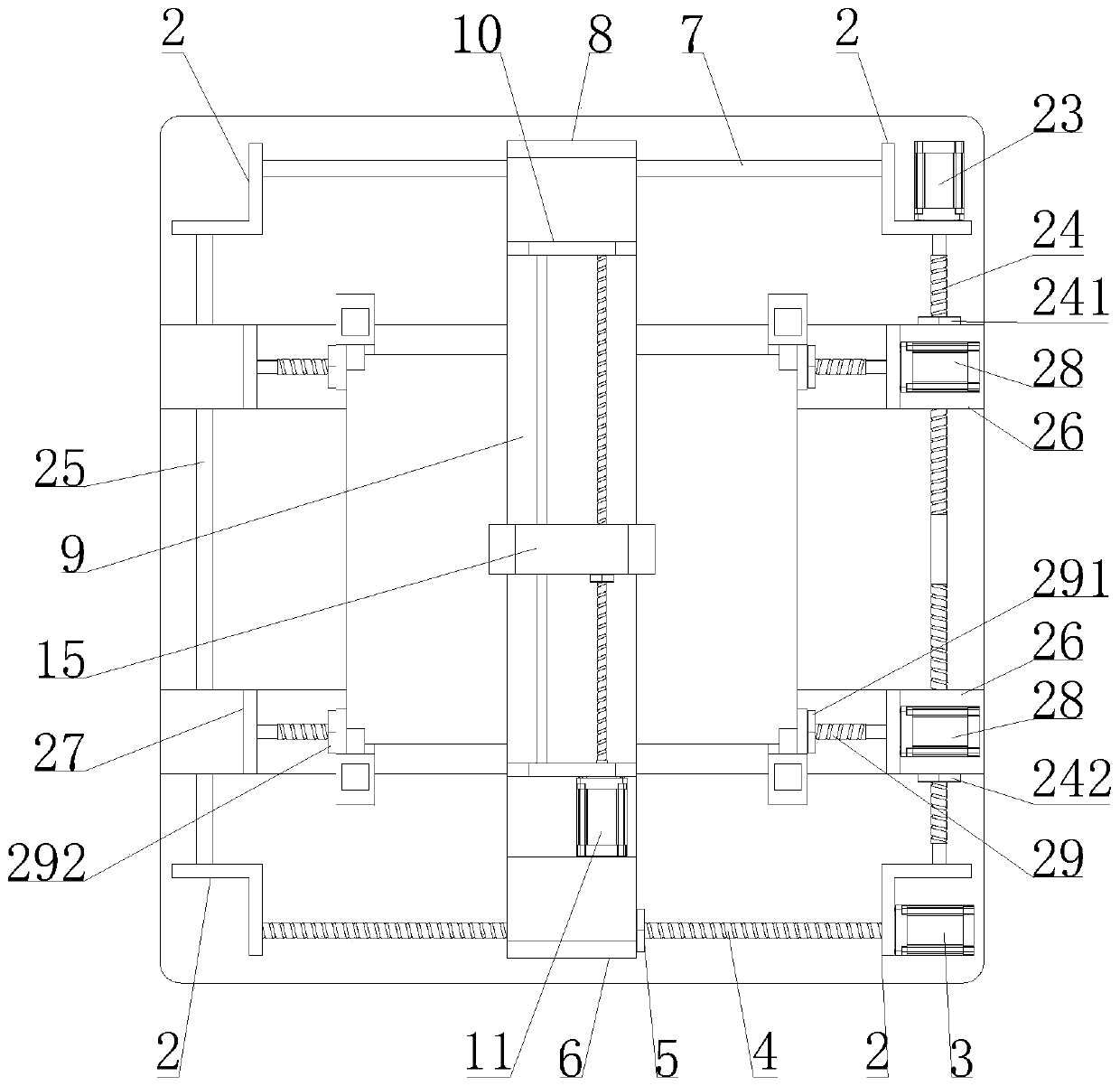

Carving machine

ActiveCN106218289ADoes not affect engraving accuracyImprove engraving accuracyOther artistic work equipmentsModel makingEngineeringCarving

The invention provides a carving machine, and belongs to the technical field of carving devices. The carving machine solves the technical problems that an existing carving machine is complex in structure and high in manufacturing cost. The carving machine comprises a machine frame and a workpiece clamping mechanism arranged in the machine frame. A straight-strip-shaped tool frame located on one side of the workpiece clamping mechanism is further arranged in the machine frame. Clamping assemblies arrayed in the vertical direction are arranged in the workpiece clamping mechanism. A rectangular vertically-arranged movement frame is arranged in the machine frame and is driven by a first lead screw mechanism to move back and forth in the horizontal and longitudinal directions. The tool frame mentioned above is arranged in the vertical direction, connected to the interior of the movement frame and driven by a second lead screw mechanism to move back and forth in the horizontal and transverse directions. Tool assemblies corresponding to the clamping assemblies one to one in number are arranged on the tool frame. Each tool assembly is driven by a corresponding carving motor. The carving machine has the beneficial effects of being high in carving precision and carving efficiency.

Owner:玉环圣弘法数控雕刻设备有限公司

Processing method for profile artistic carving for architectural decoration

InactiveCN102765288AReduce the temperatureReduce deformationDecorative surface effectsLaser engravingEngineering

The invention relates to a processing method for profile artistic carving for architectural decoration. After profiles are subjected to working procedures such as extrusion and shaping, a carving procedure is particularly added and is realized by a laser carving machine. By the carving procedure, the profiles not only are practical, but also give artistic aesthetic feeling. Therefore, the added value of products is improved.

Owner:刘锋

Environment-friendly vertical five-axis intelligent engraving equipment convenient to clean

The invention discloses environment-friendly vertical five-axis intelligent engraving equipment convenient to clean and relates to the technical field of engraving equipment. The environment-friendlyvertical five-axis intelligent engraving equipment comprises a supporting base and a machining platform, the left end and the right end of the top of the supporting base are connected with vertical upright rods correspondingly, the vertical upright rods and the supporting base are positioned and assembled through pins, the machining platform is arranged at the middle end of the top of the supporting base, the supporting base and the machining platform are movably connected, and the top ends of the vertical upright rods are fixedly connected with connecting rods in a welded mode. The environment-friendly vertical five-axis intelligent engraving equipment has the beneficial effects that the environment-friendly vertical five-axis intelligent engraving equipment convenient to clean is provided with a main baffle and an auxiliary baffle, thus a rotating table drives a workpiece to achieve multi-angle machining, the main baffle and the auxiliary baffle can shield and hinder disintegrating slag spattering out due to rotation according to the height difference between the main baffle and the rotating table as well as between the auxiliary baffle and the rotating table, and by hindering spattering of the disintegrating slag, the situation that the number of shutdown times is indirectly increased due to blockage of the disintegrating slag can be avoided effectively.

Owner:东莞市燕丰数控设备有限公司

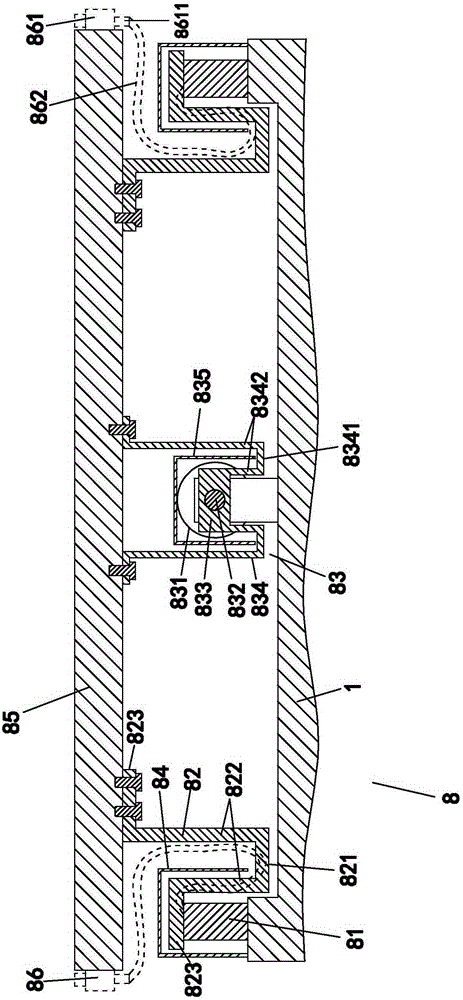

Water glass device

InactiveCN107215136AReduce laborImprove work efficiencySpraying apparatusOther artistic work equipmentsArchitectural engineering

The invention discloses a water cup device, which comprises a frame body with a first empty slot and a second empty slot on the left and right sides, a spacer is arranged between the first empty slot and the second empty slot, and the first empty slot The inner bottom is provided with guide grooves extended to the left and right sides, the bottom of the spacer is provided with a first slot connected to the bottom and the guide groove, and the left side of the first slot opposite to the left side of the first slot is provided with a The first sinking groove, the second sinking groove on the right side opposite to the right side of the first slot is provided with the second sinking groove, the first screw rod is extended left and right in the first slot, and the first screw rod is provided with engravings for matching connection There is a positioning device on the upper left side of the engraving table, a rotating mechanism on the upper right side of the engraving table, a first chute on the top of the first empty slot, and a second left and right expansion set in the first chute The screw rod and the second screw rod are rotated and connected with a sliding frame; the invention has the advantages of simple structure, convenient operation, high work efficiency and strong environmental protection function.

Owner:詹荃斐

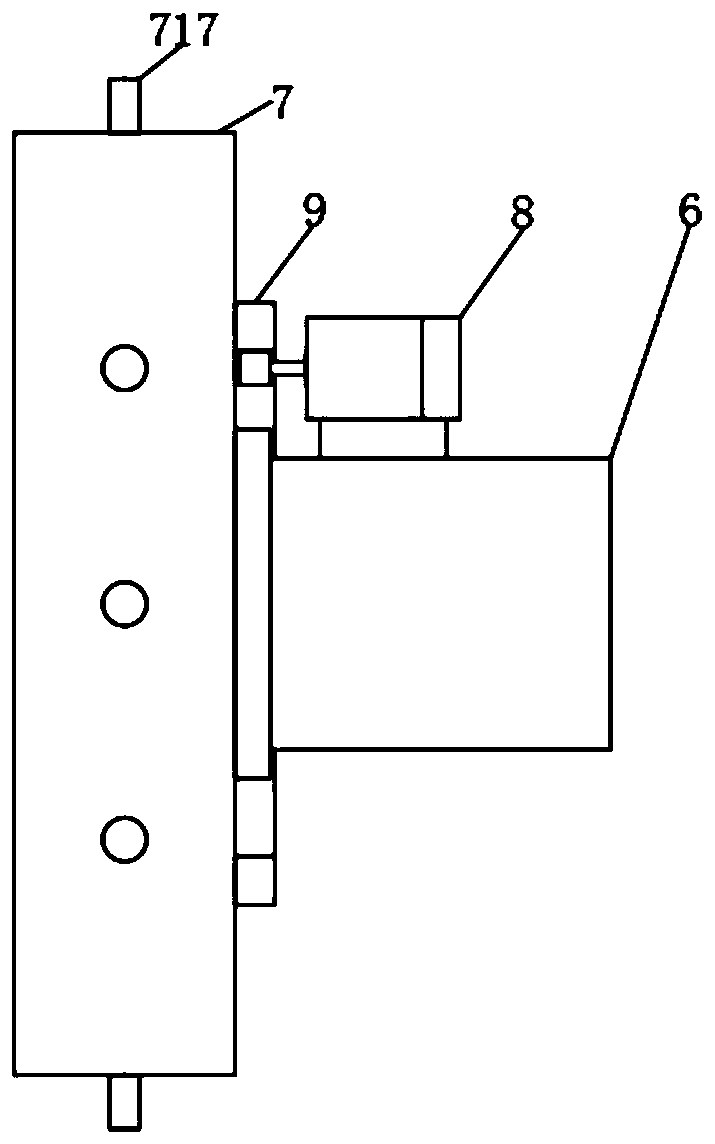

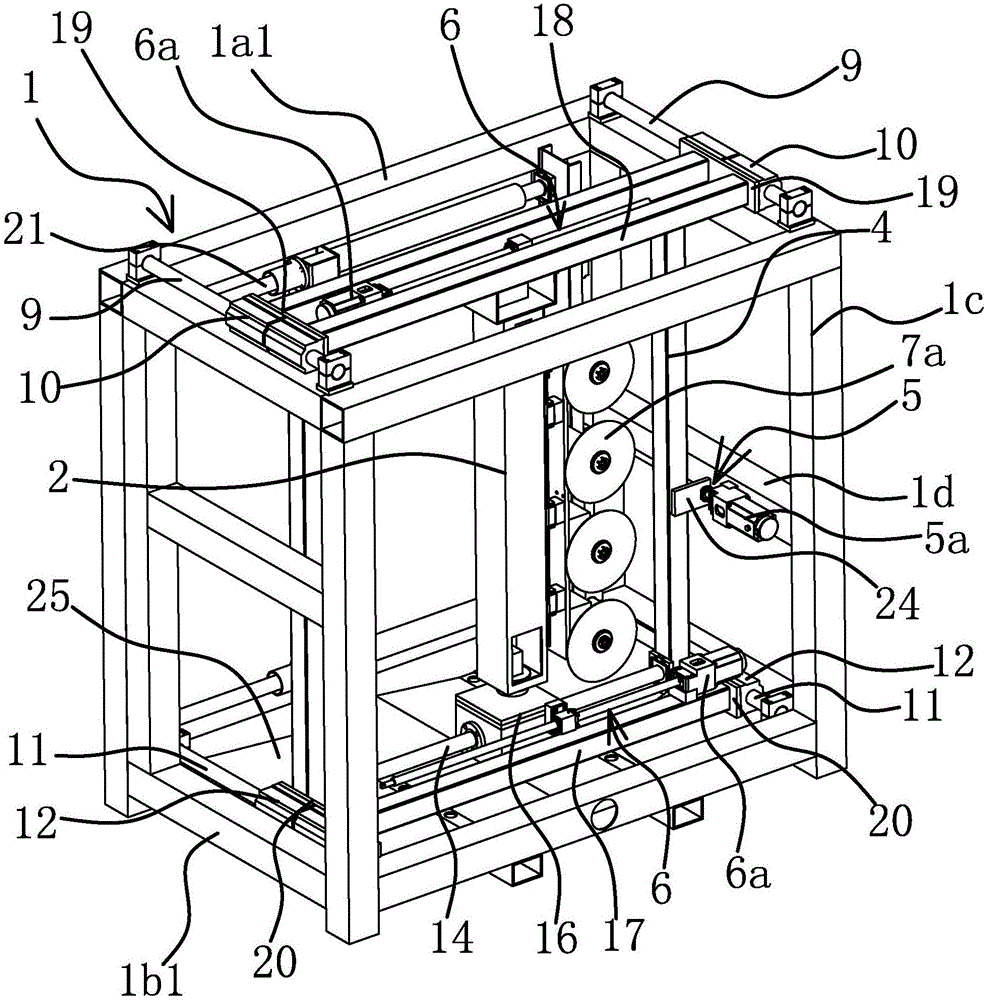

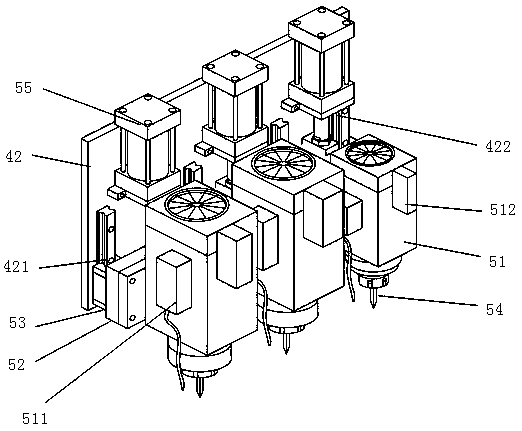

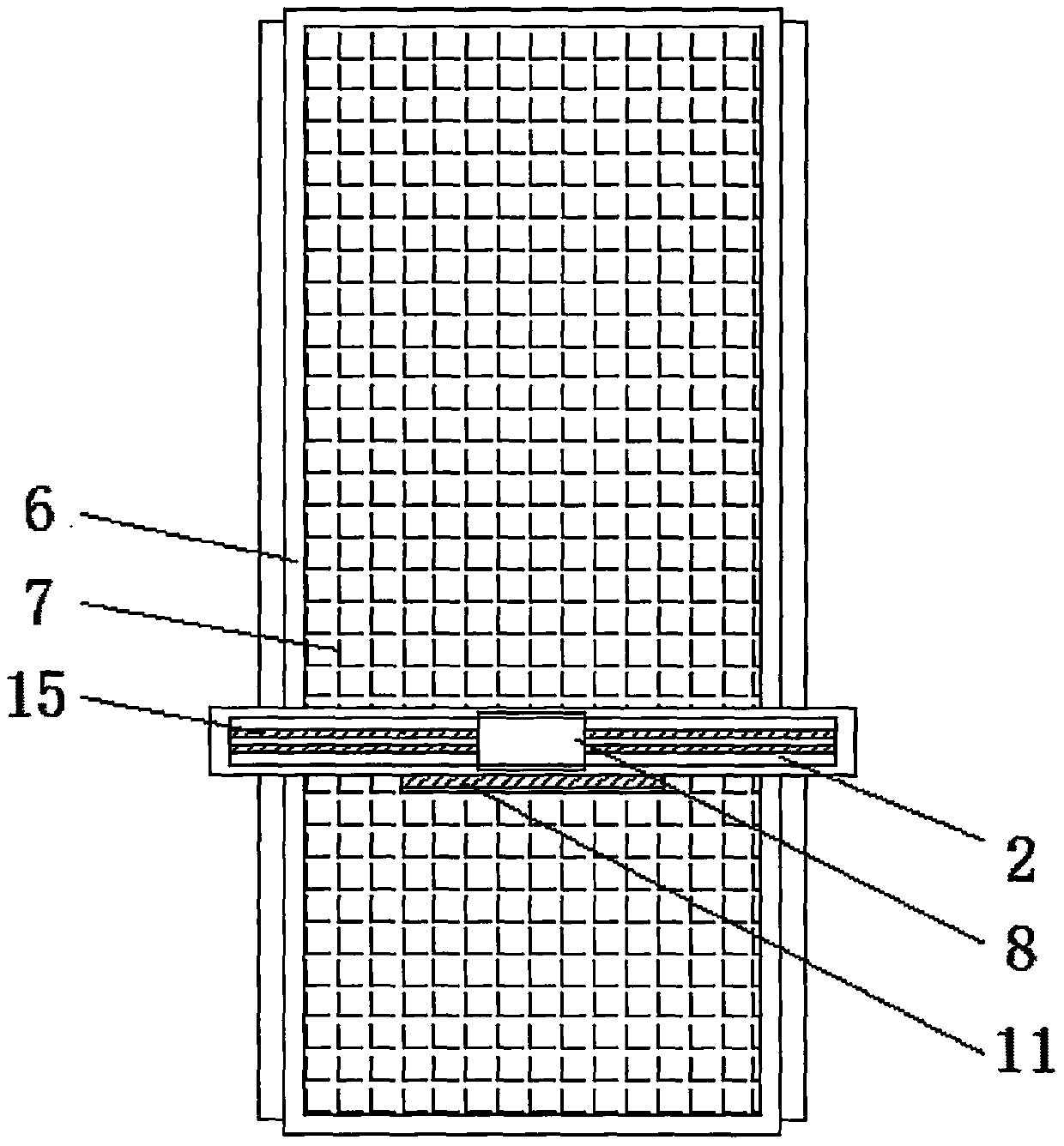

Multifunctional automatic tool changing numerical control engraving machine

InactiveCN109050131AImprove engraving quality and service lifeImprove engraving efficiencyModel makingEngravingMultiple functionEngraving

The invention discloses a multifunctional automatic tool changing numerical control engraving machine. The multifunctional automatic tool changing numerical control engraving machine comprises a frame, transverse moving mechanisms, a cross beam, a longitudinal moving mechanism and an engraving mechanism. The engraving mechanism is composed of a plurality of tool spindle frames. Each tool spindle frame comprises a tool spindle. A lifting seat is arranged on the side, opposite to a vertical moving seat, of each tool spindle. A third sliding component is arranged on each lifting seat. A third guide rail matched with the corresponding third sliding component is arranged at the position, corresponding to the third sliding component, of the vertical moving seat. A tool chuck for installing a tool is fixed at the end of each tool spindle. According to the multifunctional automatic tool changing numerical control engraving machine, a heat dissipation and dust removal device and a laser detector are arranged, so that the tool engraving quality is improved, the service life of the tool is prolonged, and the precision of the tool displacement is improved; and the tool changing operation can be automatically realized in the whole engraving process without manned shut-down, and the engraving efficiency is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

Electric turntable spring blade bounce carving process

ActiveCN108297603AStrong sense of hierarchySave time at workDecorative surface effectsCooking & bakingEngineering

The invention provides an electric turntable spring blade bounce carving process. The process comprises the following steps: (1) argil is molded; and the surface of a molded blank is condensed; (2) the surface of the blank is colored and aired; (3) the blank is placed on an electric turntable; the electric turntable is started; when the electric turntable drives the blank to rotate, the bent tailend of a spring blade is near the blank; under driving by the electric turntable, the spring blade can automatically bounce; and the bounce collision force of the spring blade is used for carving thesurface of the blank to finally finish surface carving of the blank; (4) the carved blank is dried in a baking room; and glaze is sprayed to the surface of the dried blank; and (5) the blank is firedin a kiln, and is discharged from the kiln to form a finished product. The process can manufacture blades bent at different degrees according to requirements to cave lines of different cloth styles, comprising lines such as barks incapable of being manually carved, greatly shortens the working time, and improves the carving efficiency.

Owner:陈荣启

Multipurpose cup device

InactiveCN107264154AAchieve left and right movementReduce laborLiquid surface applicatorsCoatingsEngineering

The invention discloses a multi-purpose water cup device, which comprises a frame body with a first empty slot and a second empty slot on the left and right sides respectively, a spacer is arranged between the first empty slot and the second empty slot, and the second empty slot is provided with a spacer. The inner bottom of an empty slot is provided with guide slots extending to the left and right sides, the bottom of the spacer is provided with a first slot connected to the bottom and the guide slot, and the left side of the first slot is opposite to the left side of the first empty slot. There is a first sinking groove inside, and a second sinking groove is arranged inside the right side of the second empty groove opposite to the right side of the first slot, and a first screw rod is arranged left and right in the first slot, and a matching screw rod is provided on the first screw rod. Connected engraving table, there is a positioning device on the upper left side of the engraving table, a rotating mechanism on the upper right side of the engraving table, a first chute on the top of the first empty slot, and left and right expansion settings in the first chute The second screw rod is rotated and connected with a sliding frame; the invention has the advantages of simple structure, convenient operation, high work efficiency and strong environmental protection function.

Owner:詹荃斐

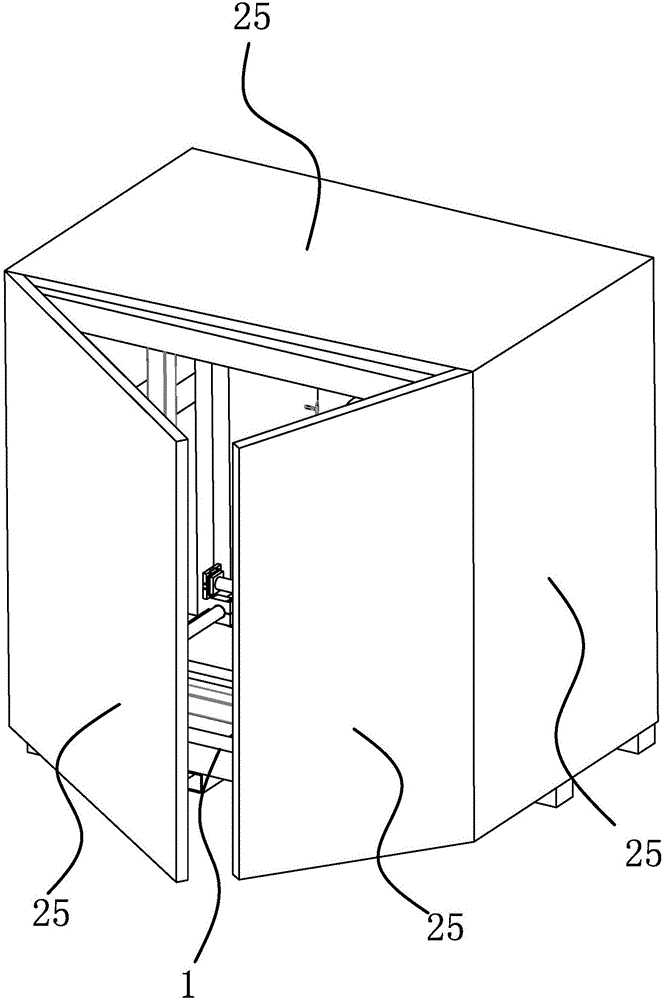

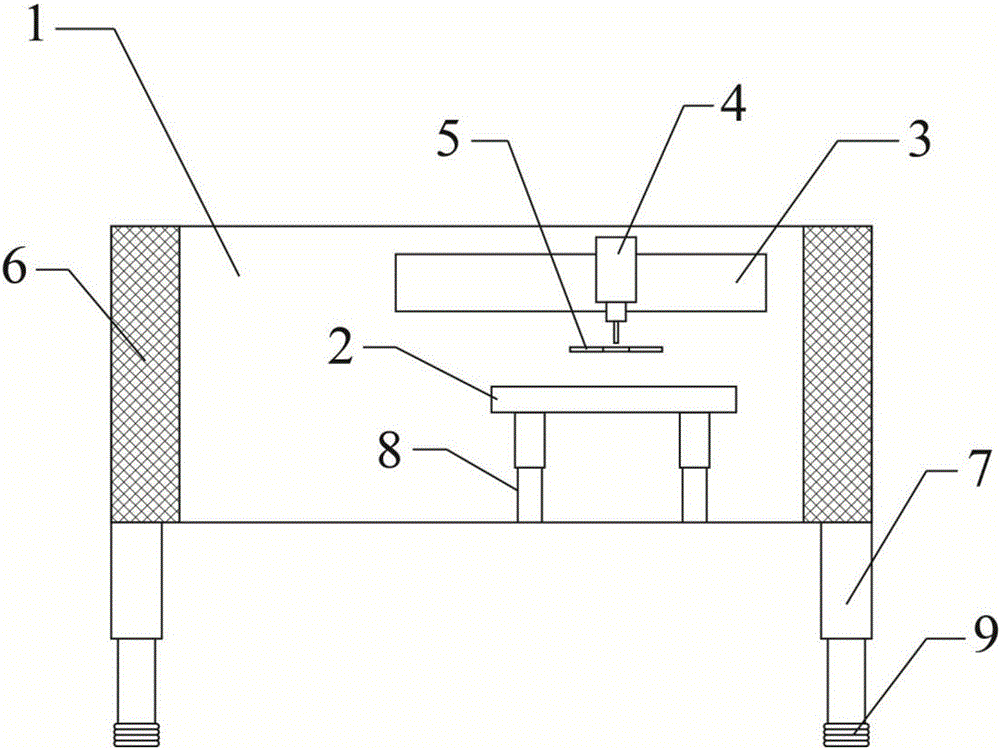

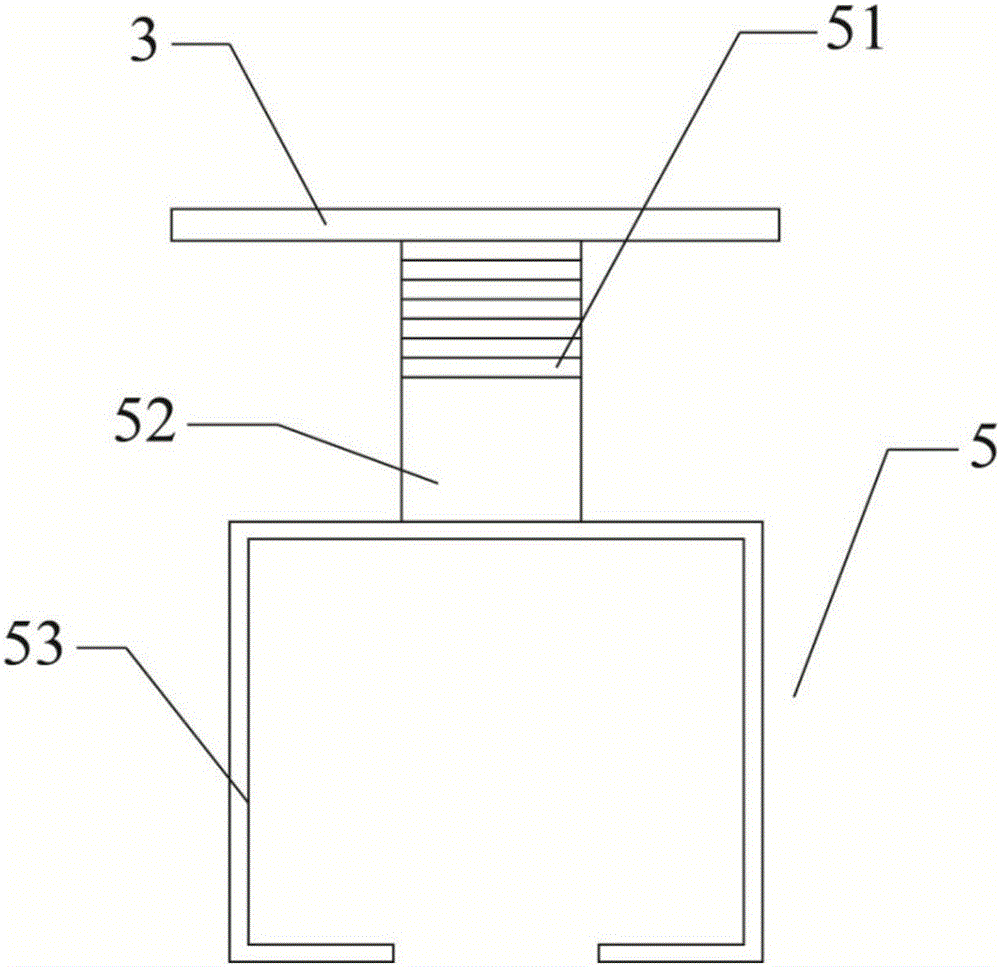

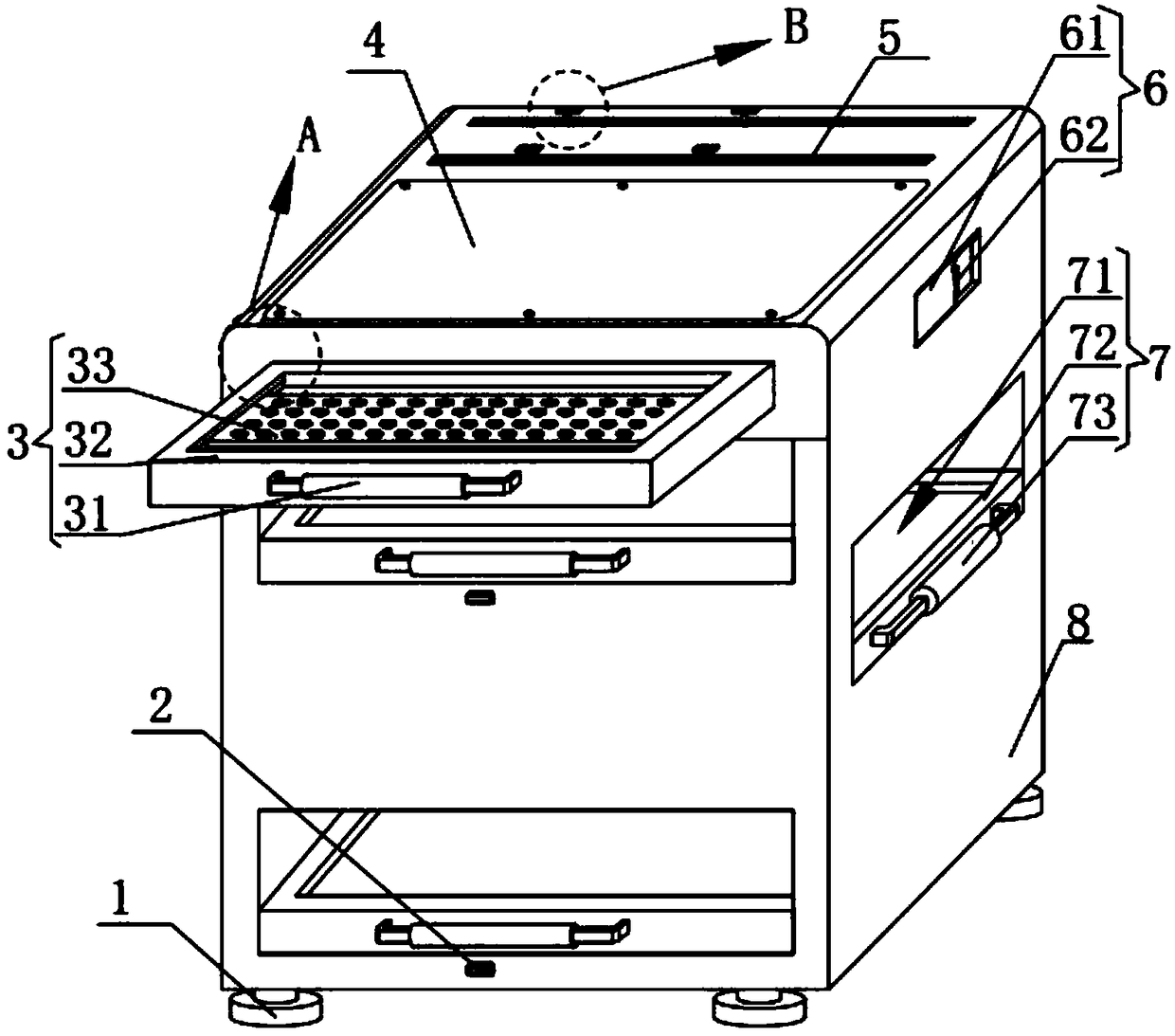

Radio-frequency carving machine

InactiveCN105711313AEasy to unloadImprove engraving qualityLaser beam welding apparatusModel makingPulp and paper industryRadio frequency

The invention provides a radio-frequency carving machine. The radio-frequency carving machine comprises a machine body, a workbench, a work frame and a carving machine head. The machine body is a cuboid cavity. The workbench, the work frame and the carving machine head are all arranged inside the machine body. The carving machine head is connected with the work frame. The carving machine head corresponds to the workbench in position. The radio-frequency carving machine is characterized in that purifying chambers are arranged on the two sides of the interior of the machine body, the bottom of the machine body is connected with machine body supporting columns, bottom feet are arranged at the bottoms of the machine body supporting columns, and two workbench supporting columns are arranged at the bottom of the workbench; the bottoms of the workbench supporting columns are fixed to an inner wall bottom plate of the machine body; the machine body supporting columns and the workbench supporting columns are each of a telescopic structure; and a clamping part is further arranged above the workbench, and one end of the clamping part stretches into the work frame. The purifying chambers are arranged in the machine body so that dust can be treated, and meanwhile the machine body supporting columns of the telescopic structure and the workbench supporting columns of the telescopic structure are arranged so that discharging can be convenient.

Owner:TIANJIN HONGGUANG WEIYE LASER TECH CO LTD

Engraving device special for processing phenolic aldehyde cotton cloth plates

InactiveCN110356152AImprove engraving efficiencyImprove engraving accuracyOther artistic work equipmentsModel makingEngravingCotton cloth

The invention belongs to the field of cotton cloth plate processing equipment, and particularly relates to an engraving device special for processing phenolic aldehyde cotton cloth plates. A scheme isput forward considering the problems that the existing manual engraving efficiency is low, the precision is low, and the application range of equipment engraving is small. According to the scheme, the engraving device comprises a base, a first bracket, a mounting bracket, a mounting table, a mounting plate, a cutter disc, an engraving knife, a fifth driving device, a first bidirectional screw rod, a fourth guide rod, third moving tables, a third support, a sixth driving device, a second bidirectional screw rod, fourth moving tables and a clamping table. The two third moving tables move closeto or away from each other in the longitudinal direction on the first bidirectional screw rod and the fourth guide rod. The sixth driving device is in transmission connection with the second bidirectional screw rod. The fourth moving tables are in sliding connection with the third moving tables. The two fourth moving tables move close to or away from each other in the transverse direction on the second bidirectional screw rod. By means of the engraving device, the engraving efficiency and the engraving precision of the phenolic aldehyde cotton cloth plates are improved, and the application range is enlarged.

Owner:徐州嘉搏纺织股份有限公司

Engraving processing method for stone window

InactiveCN107757221ASolve the fragileQuality improvementDecorative surface effectsNumerical controlMachining time

The invention discloses an engraving processing method for a stone window. The engraving processing method comprises the following steps: (1) preparing raw materials; (S2) determining a pattern; (S3)designing a drawing; (S4) generating an embossment processing program by virtue of numerical control software; (S5) generating a water jet scalpel processing program by virtue of the numerical controlsoftware; (S6) standing until the programs are generated; (S7) carrying out embossment processing; (S8) carrying out water jet scalpel processing; (S9) cleaning, and airing; and (S10) carrying out acceptance inspection and packaging. By carrying out hollowing processing by virtue of an embossment technique, a water jet scalpel technique and the water jet scalpel according to the designed pattern,the problem that embossment window grilles of the stone window are easily damaged is effectively solved; compared with a traditional manual stone window processing method, the engraving processing method has the advantages that the embossment process and the like are greatly broken through when the stone window is processed, a stone window embossment processing process is innovated, a stone window embossment technique is successfully improved, and the high quality, high yield and high efficiency of the processing of the stone window are truly realized; and by utilizing a stone window embossment processing technique, the culture connotation of the stone window is enriched, and the market competitiveness of the stone window market is improved.

Owner:NANTONG OUKE CNC EQUIP CO LTD

Carving device for processing bamboo and wood crafts

InactiveCN107755897AImprove engraving efficiencyImprove cleanlinessLaser beam welding apparatusEngineeringSlide plate

The invention discloses a carving device for processing bamboo and wood crafts. The device comprises a protective frame, wherein the protective frame is installed on the outer side of a workbench; baffles are installed on the upper parts of hydraulic devices; the baffles are installed at the two ends of a sliding rail plate; a first sliding rod is installed on one side of the sliding rail plate; laser engraving devices are installed on a sliding plate; a second sliding rod is installed at the top of the sliding rail plate; dust collecting pipes are installed on the two sides of the lower position of a main machine; one end of each dust collecting pipe is provided with a dust collecting cover. According to the carving device for processing the bamboo and wood crafts, one side of the slidingrail plate is provided with the sliding plate through the first sliding rod, the four laser engraving devices are installed on the sliding plate, the carving efficiency is effectively improved through the four laser engraving devices, the four dust suction pipes are installed on the two sides of the main machine, the dust collecting cover is arranged at one end of each of the four dust suction pipes, waste chips in the carving process can be recycled through the four dust suction pipes, and thus the cleanliness of the processing environment is improved.

Owner:广西容县方园工艺品有限公司

Detection platform for workpiece engraving

The invention discloses a detection platform for workpiece engraving. The detection platform comprises bases, a limiting structure, a driving block, a limiting block, a return spring, an illuminationstructure, a first push rod, a storage box, LED lamps, tempered glass, a clamping structure, guide grooves, sliding blocks, fixing rods, pressure plates, a starting structure, a waterproof cover plate, a power switch, storage structures, limiting grooves, supporting frames, second push rods, a shell and a scale bar. The detection platform has the beneficial effects that the supporting frames whichare arranged in a staggered way are arranged inside the shell, and the supporting frames are slidably connected with the shell, so that workpiece storage boxes are conveniently placed on the limitinggrooves inside the supporting frames, and the space is reasonably utilized; the LED lamps are arranged on the portion, at the bottom end, of the tempered glass, of the shell so that a detection lightsource is provided conveniently, and the detection quality is improved; and meanwhile, primary self-detection of workpieces is facilitated due to the scale bar at the same end as the tempered glass,the workpiece engraving efficiency is improved, the sliding blocks and the pressure plates are fixed by the fixing rods, and fixing of the secondarily-processed workpieces is facilitated.

Owner:夏巧巧

Surface depainting carving process for plate with curved surface

InactiveCN106274219ASimple and fast operationImprove engraving efficiencyDecorative surface effectsOrnamental structuresLacquer3D modeling

The invention discloses a surface depainting carving process for a plate with a curved surface. The surface depainting carving process mainly comprises the following steps: A, manufacturing an injection mold, and selecting suitable materials to carry out injection molding production; B, spraying paint on an injection molding product; C, manufacturing a carving fixing jig according to the product; D, manufacturing a curved surface carving document by 3D modeling, and determining a carving region; E,, fixing the product on the fixing jig and carving; and F, cleaning the surface of the plate with the curved surface, and then neatening and packing. The carving process provided by the invention is simple and convenient to operate and high in carving efficiency. Carved patterns are high in 3D third dimension, high in simulation degree and smooth in grain.

Owner:WENZHOU QIHAO LASER TECH

Workbench of 3D engraving machine

ActiveCN106240212AShorten the processing cycleAvoid deformationOther artistic work equipmentsModel makingHydraulic cylinderEngineering

The invention relates to a workbench of an engraving machine. The workbench comprises a traveling tool rest and a bottom plate. A guide rail is arranged at the bottom of the traveling tool rest. A supporting plate is arranged on the upper portion of the right side of the traveling tool rest. A fixing plate is arranged at the top of the right side of the supporting plate. A hydraulic cylinder is arranged in the center of the top of the traveling tool rest. The telescopic end of the hydraulic cylinder is connected with a movable rod through a connecting block. A tool fixing plate is arranged at the right end of the movable rod. A machining tool A and a machining tool B are arranged at the bottom of the tool fixing plate. Telescoping devices are arranged at the bottom of the bottom plate. A workpiece holding plate A and a workpiece holding plate B are arranged on the bottom plate. Displacement sensors B are arranged on the bottom plate. The workbench has the advantages of being simple in structure, convenient to operate, high in efficiency and good in economical efficiency.

Owner:浙江开洋木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com