Horizontal numerical control three-dimensional carving machine

A three-dimensional engraving machine, horizontal technology, applied in decorative arts, processing models, etc., can solve the problems of affecting the engraving consistency, difficult to guarantee engraving consistency, failing to meet design requirements, etc., to reduce mechanical wear and engraving tools. Wear and improve the effect of engraving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through a complete specific embodiment.

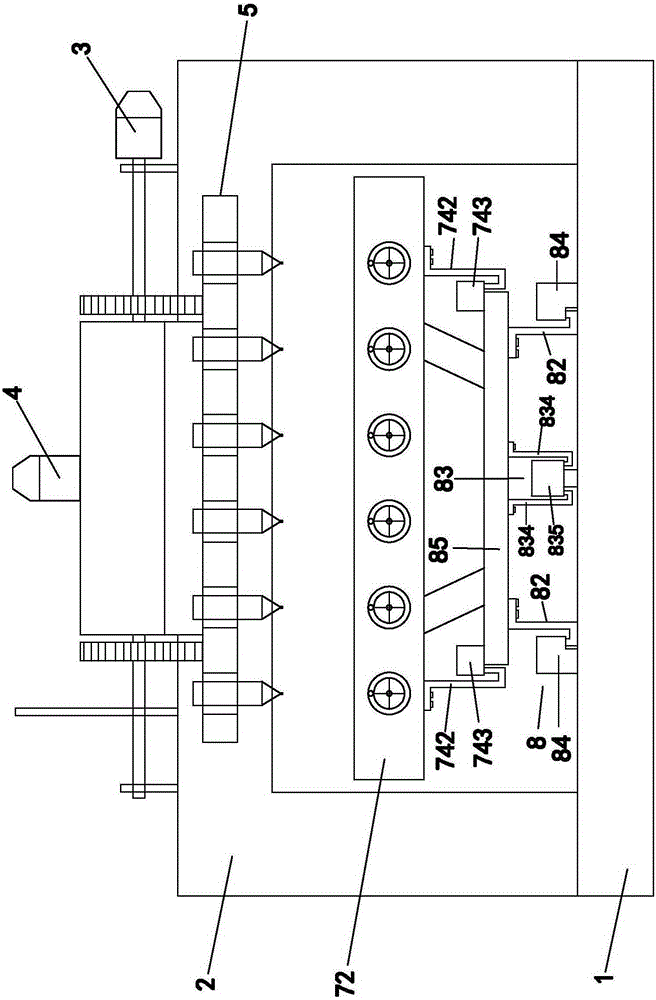

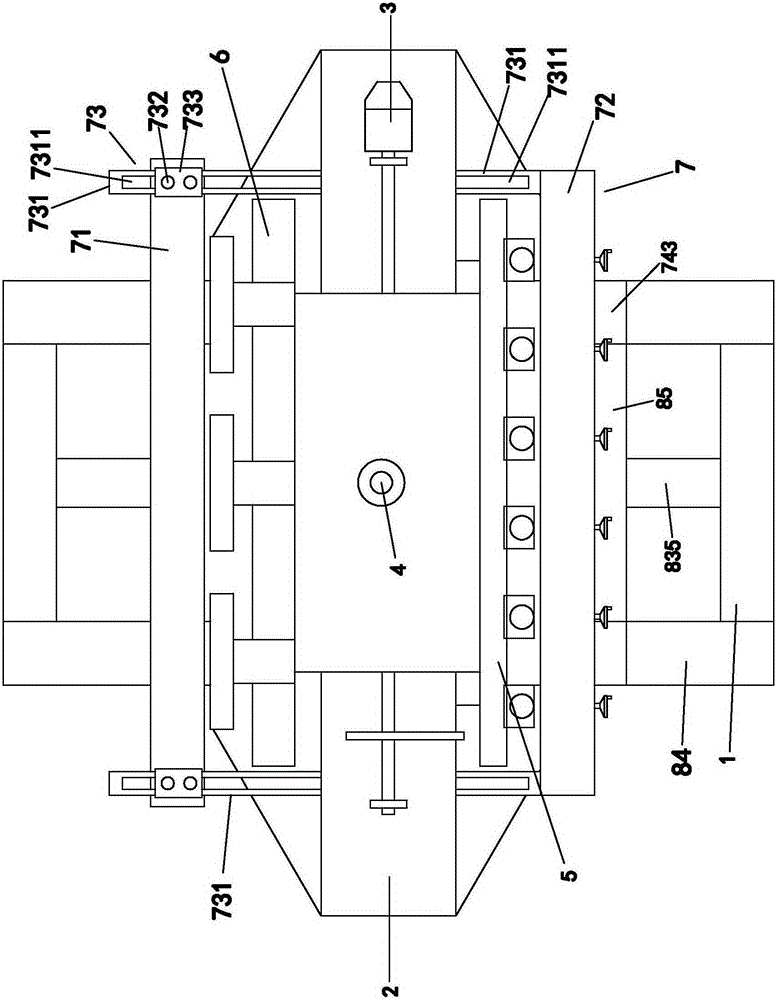

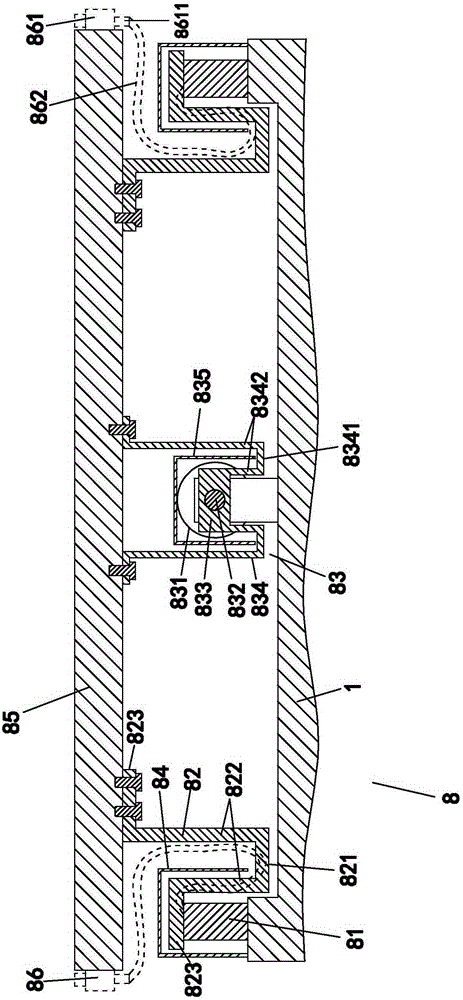

[0055] A horizontal CNC three-dimensional engraving machine, such as figure 1 and figure 2 As shown, it includes: a base 1, a gantry frame 2, a lateral movement mechanism 3, an up and down movement mechanism 4, an engraving tool holder 5, a rough machining tool holder 6, a workpiece clamping device 7 and a front and rear movement mechanism 8.

[0056] The two bottom ends of the gantry frame 2 are fixedly connected to the base 1 respectively.

[0057] The lateral movement mechanism 3 is mounted on the gantry 2 .

[0058] The up and down moving mechanism 4 is erected on the lateral moving mechanism 3 .

[0059] The engraving tool holder 5 is erected on the up-and-down moving mechanism 4, and is used for finely engraving the engraved workpiece, driven by the drive of the lateral moving mechanism 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com