Water glass device

A technology of water cups and empty tanks, which is applied in spraying devices, decorative arts, painting tools, etc., can solve the problems of increased workload and labor intensity, cumbersome steps, and poor environmental protection functions, and achieves simple structure, reduced labor, and environmental protection functions strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

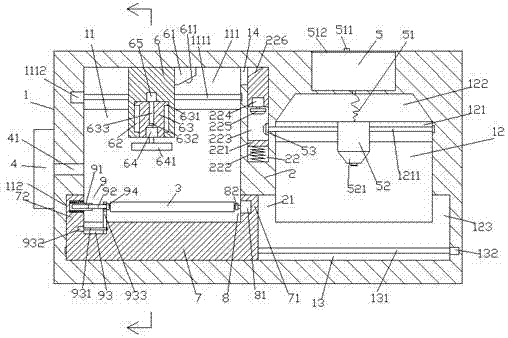

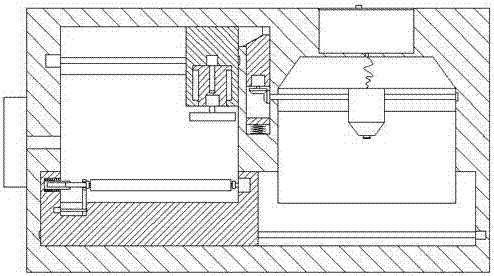

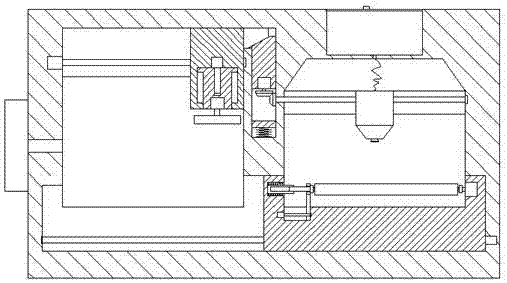

[0024] Such as Figure 1-Figure 4 As shown, a water cup device of the present invention includes a frame body 1 with a first cavity 11 and a second cavity 12 inside the left and right sides, the first cavity 11 and the second cavity 12 A spacer 2 is arranged between them, and the inner bottom of the first empty groove 11 is provided with guide grooves 13 that are expanded to the left and right sides, and the bottom of the spacer 2 is provided with a bottom that communicates with the guide groove 13. The first slot 21, the first sinker 112 is arranged inside the left side of the first empty slot 11 opposite to the left side of the first slot 21, and the second sinker 112 is provided on the right side of the first slot 21. The inside of the right side of the empty groove 12 is provided with a second sinking groove 123, and the left and right of the first slot 21 are extended with a first screw 131, and the first screw 131 is provided with a matching and connected engraving platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com