Patents

Literature

58results about How to "Improve engraving quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

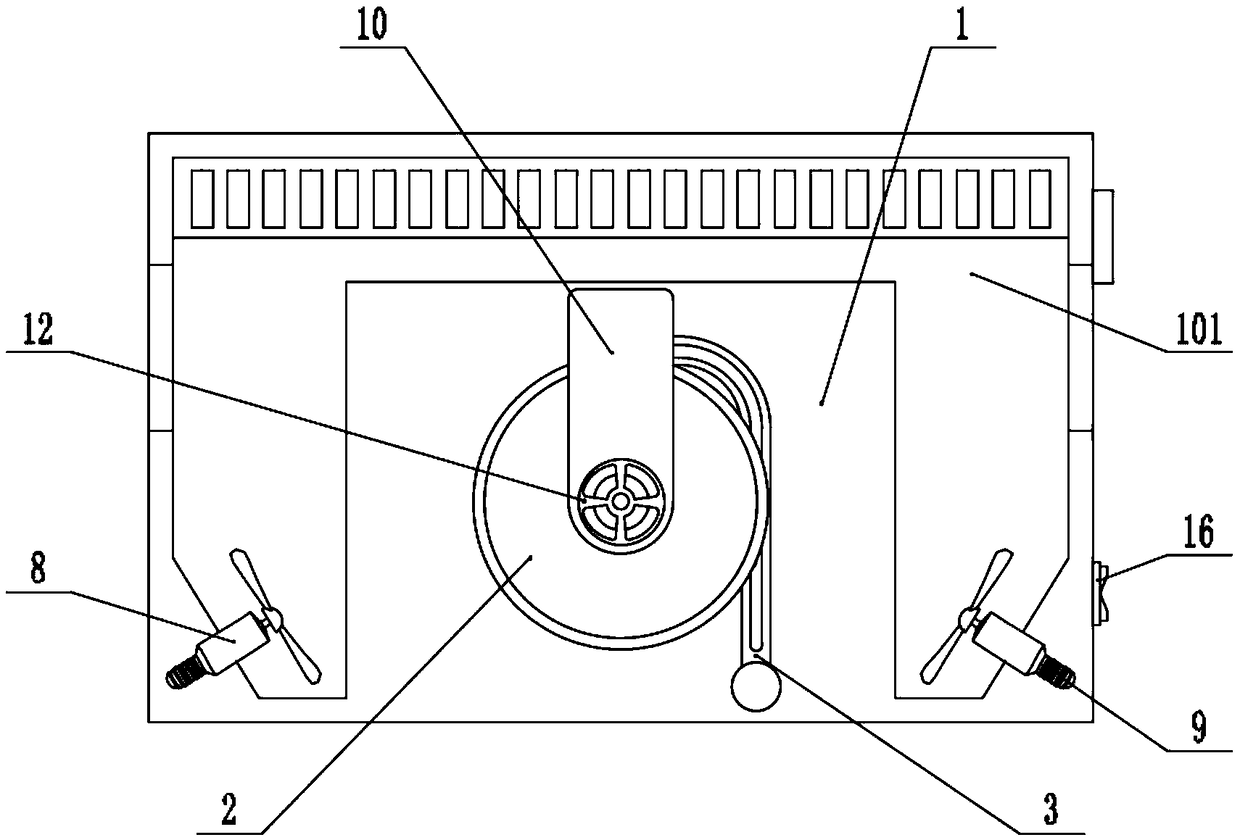

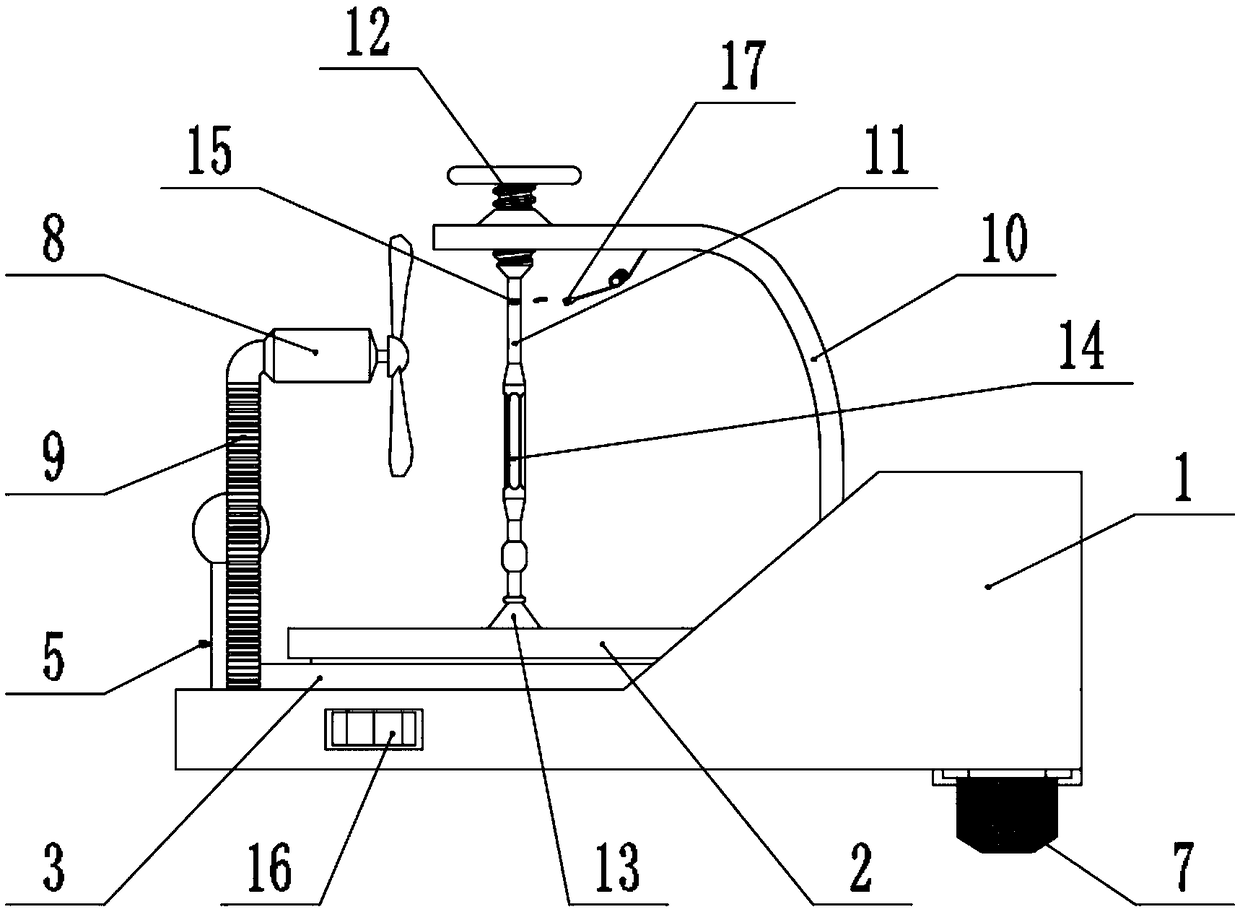

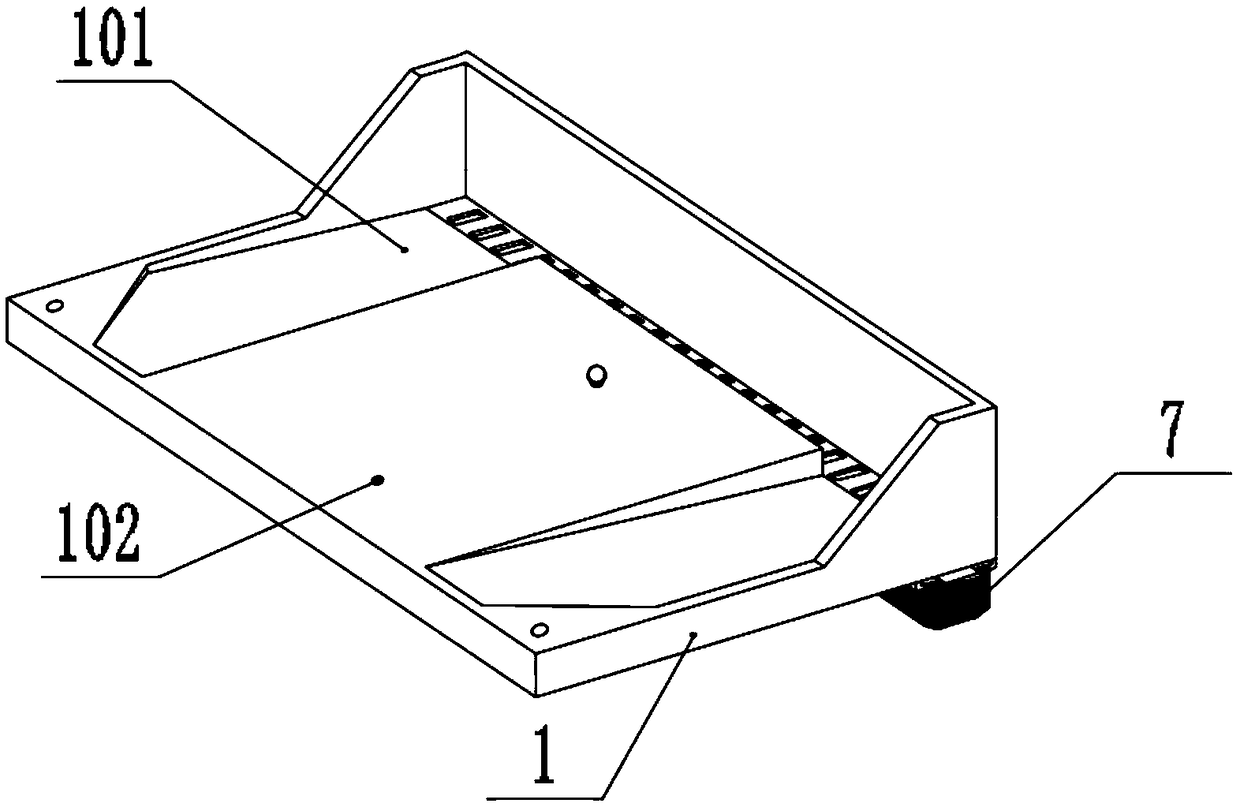

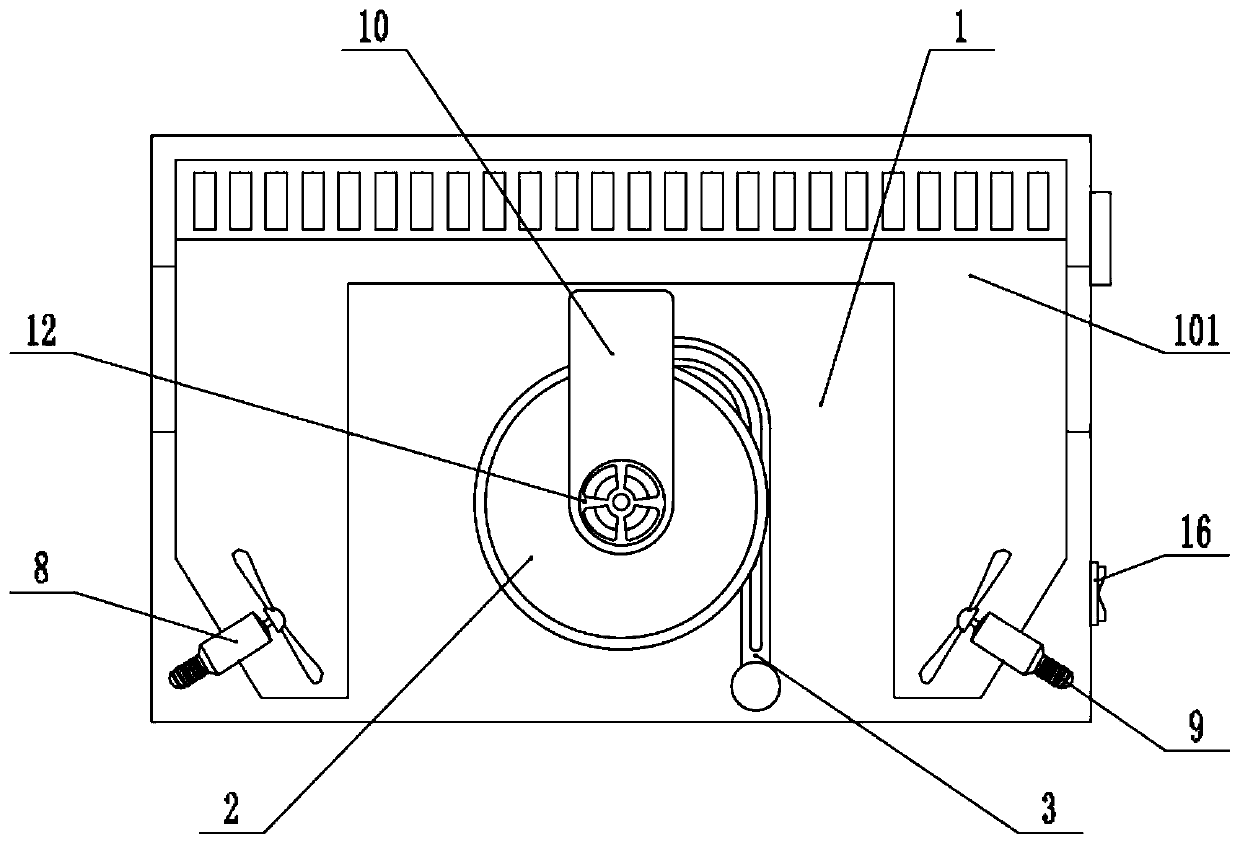

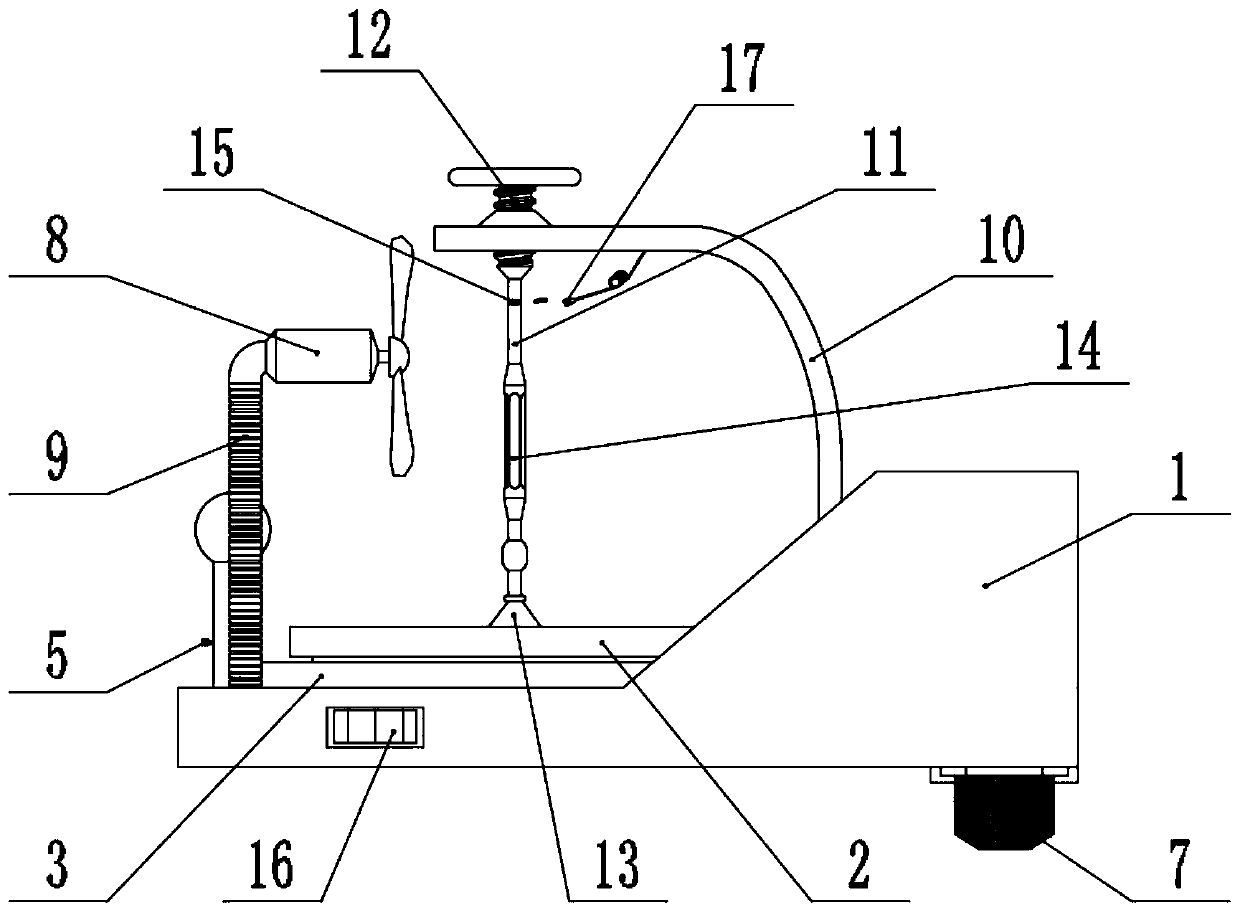

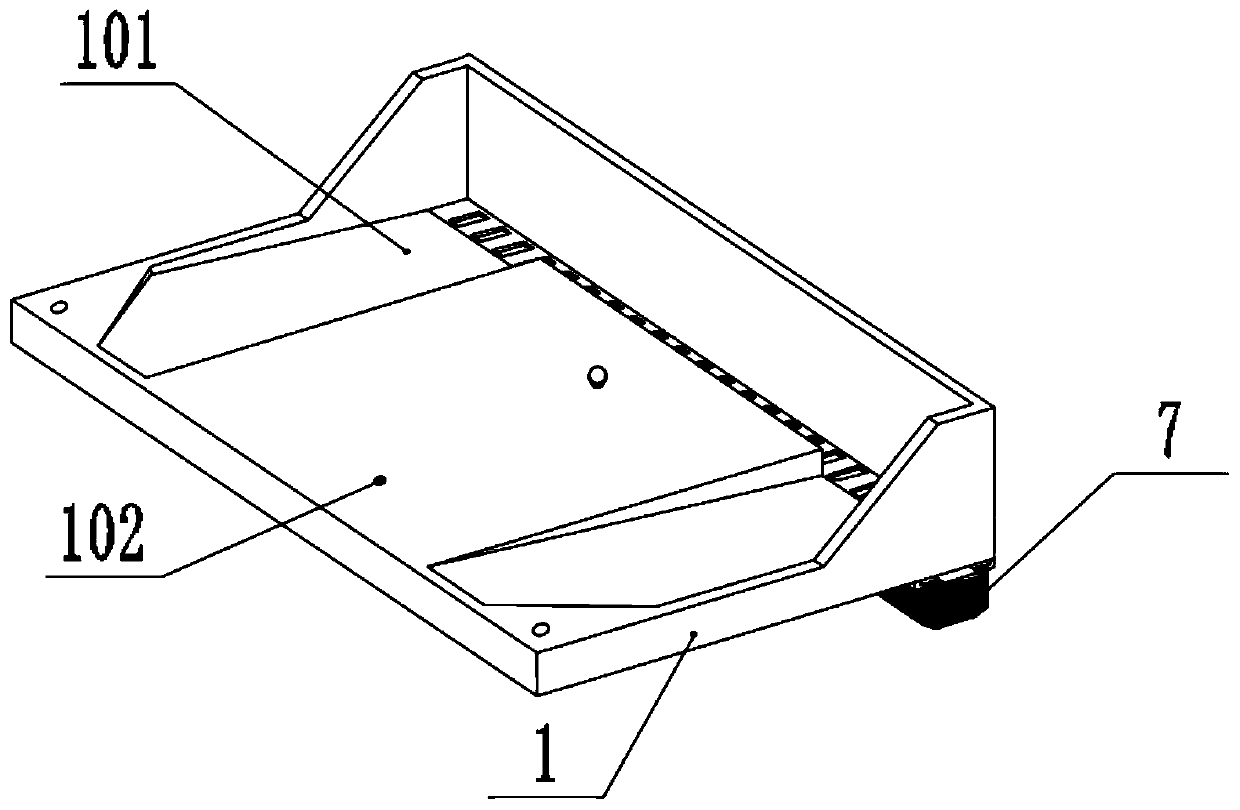

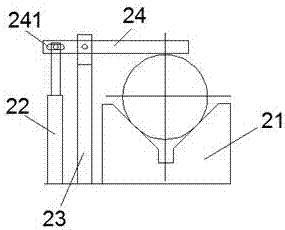

Engraving fixing device for ceramic processing

ActiveCN108909329AConvenient post-engraving workAvoid scatterLighting applicationsMechanical apparatusEngravingWorking environment

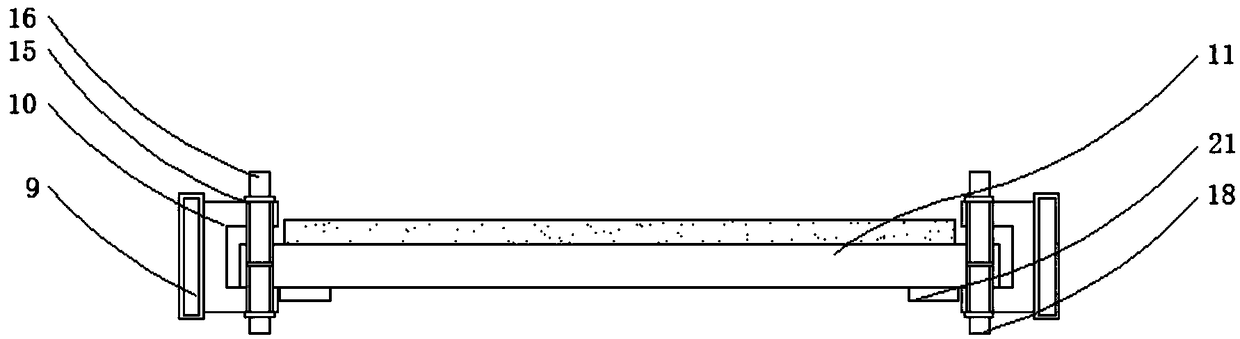

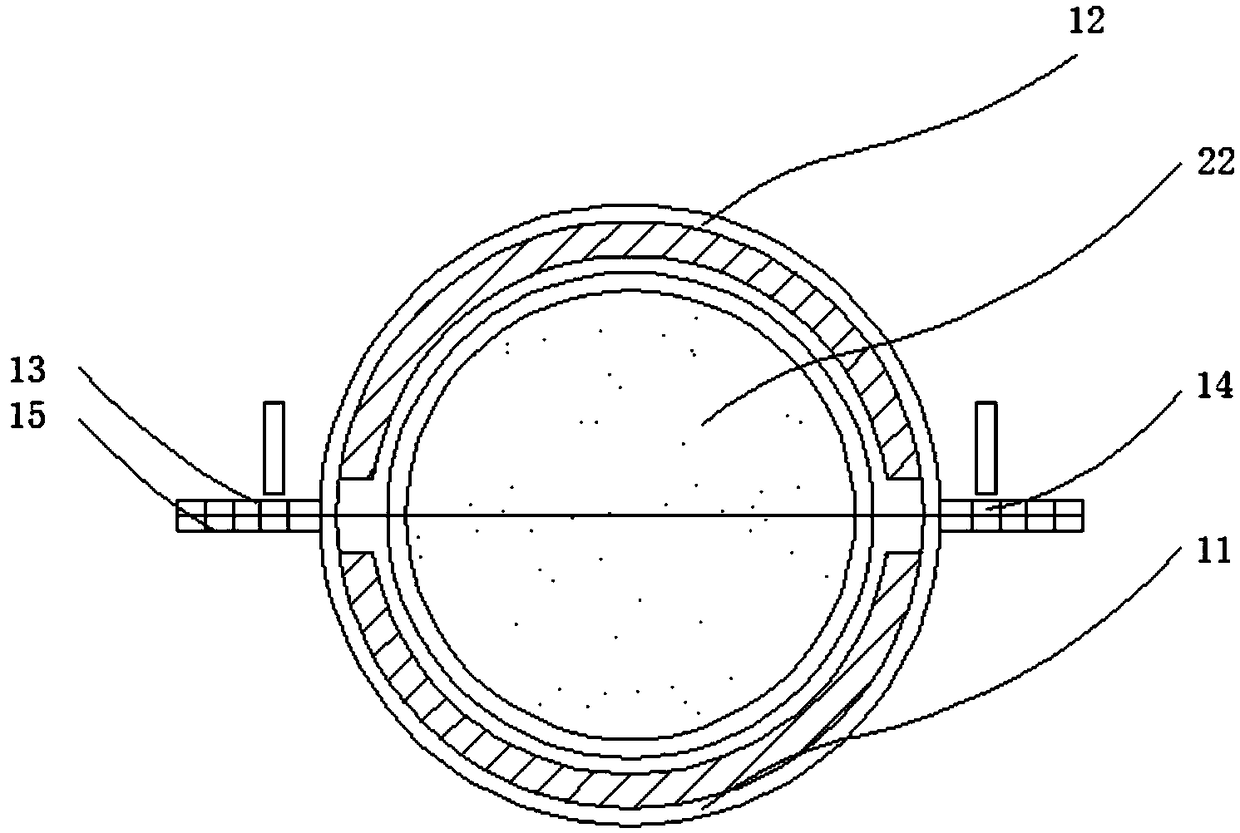

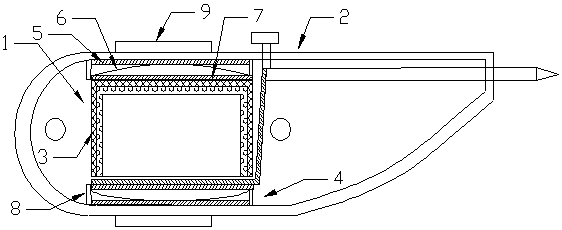

The invention provides an engraving fixing device for ceramic processing. The engraving fixing device comprises a power source switch and a miniature power source plug, wherein the top part of an engraving table is provided with a material leaking groove; the bottom part of the material leaking groove is of a hollow structure; the front end of the end surface of the top part of the engraving tableis provided with a circular positioning groove, and the bottom part of an inserting bolt is glidingly connected with the interior of the positioning groove; the top part of a rotary disc is of a circular plate-shaped structure, and the rotary disc is positioned at the end surface of the top part of the engraving table; a rotary handle is of an L-shaped strip structure, and the bottom part of therotary handle is glidingly connected with the end surface of the top part of the engraving table; a rubber gasket is attached to the inside sawtooth-shaped structure of the rotary handle. The engraving fixing device has the advantages that when an operator engraves a bottled magnetic blank, the crushed residue of porcelain clay from the engraving is blown away from the surface of the magnetic blank, the exterior of the magnetic blank is cleaner, and the operator can conveniently perform the engraving operation lately; by arranging the material leaking groove and a net cage, the previous blowncrushed residue of porcelain clay away from the surface of the magnetic blank can be collected, so as to avoid the pollution to working environment due to scattering of the crushed residue of the porcelain clay.

Owner:陈春燕

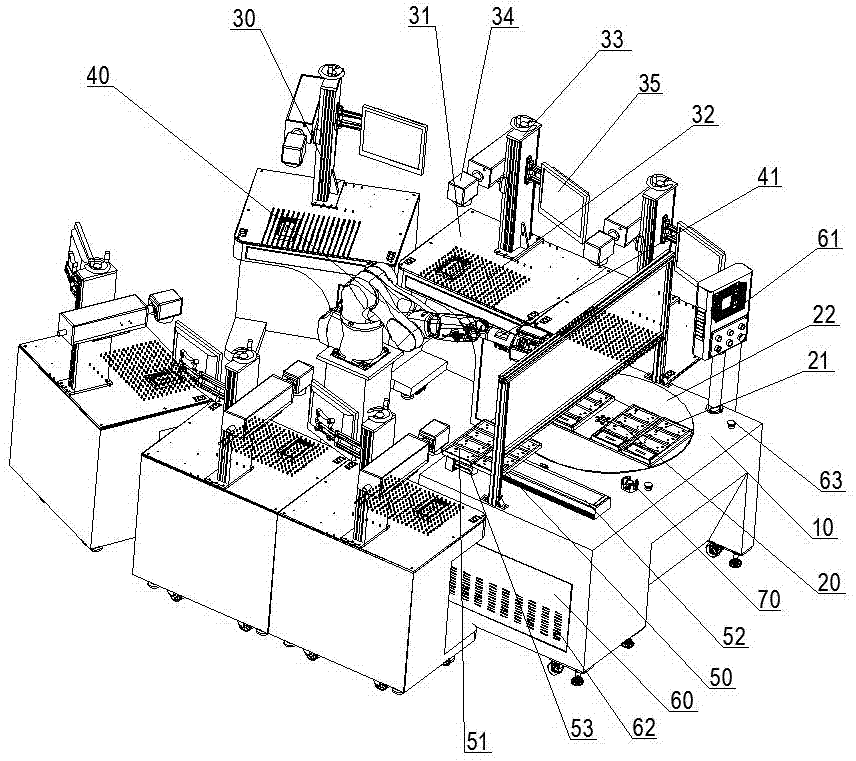

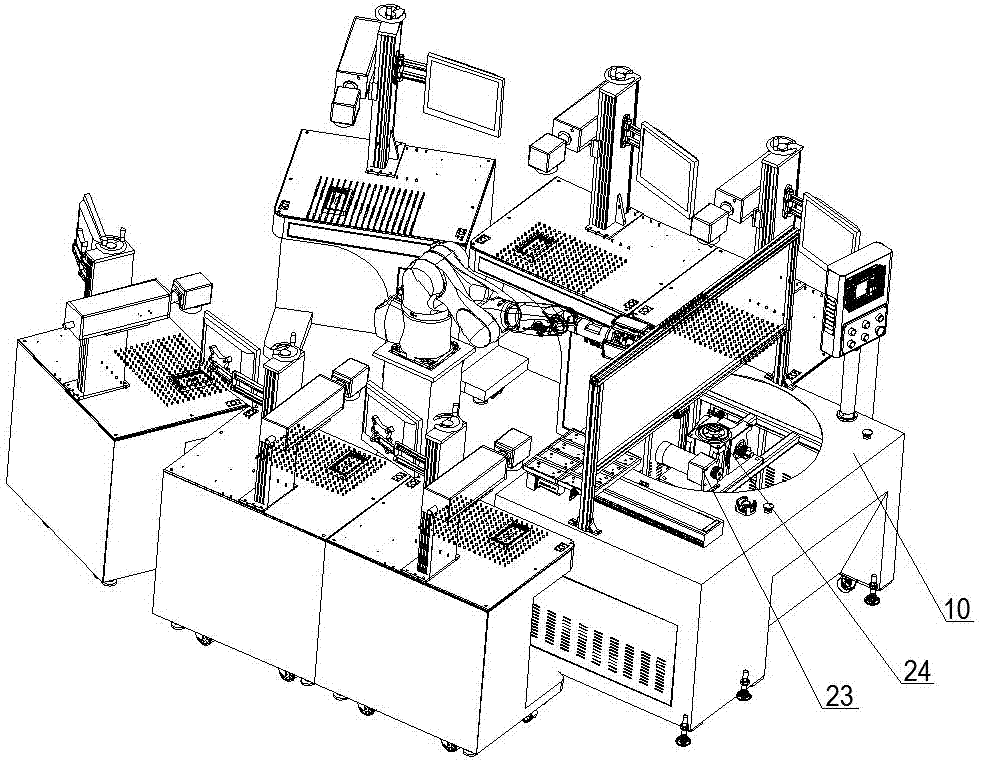

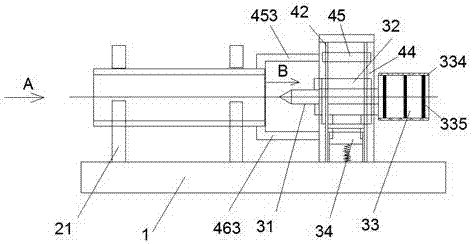

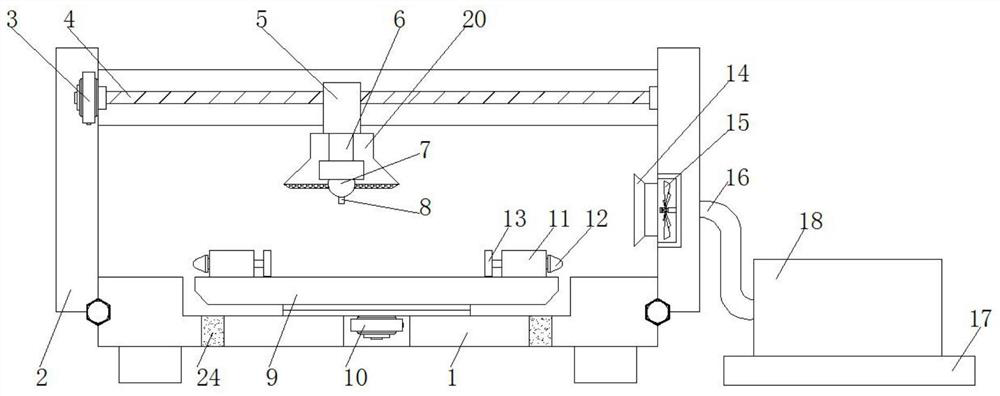

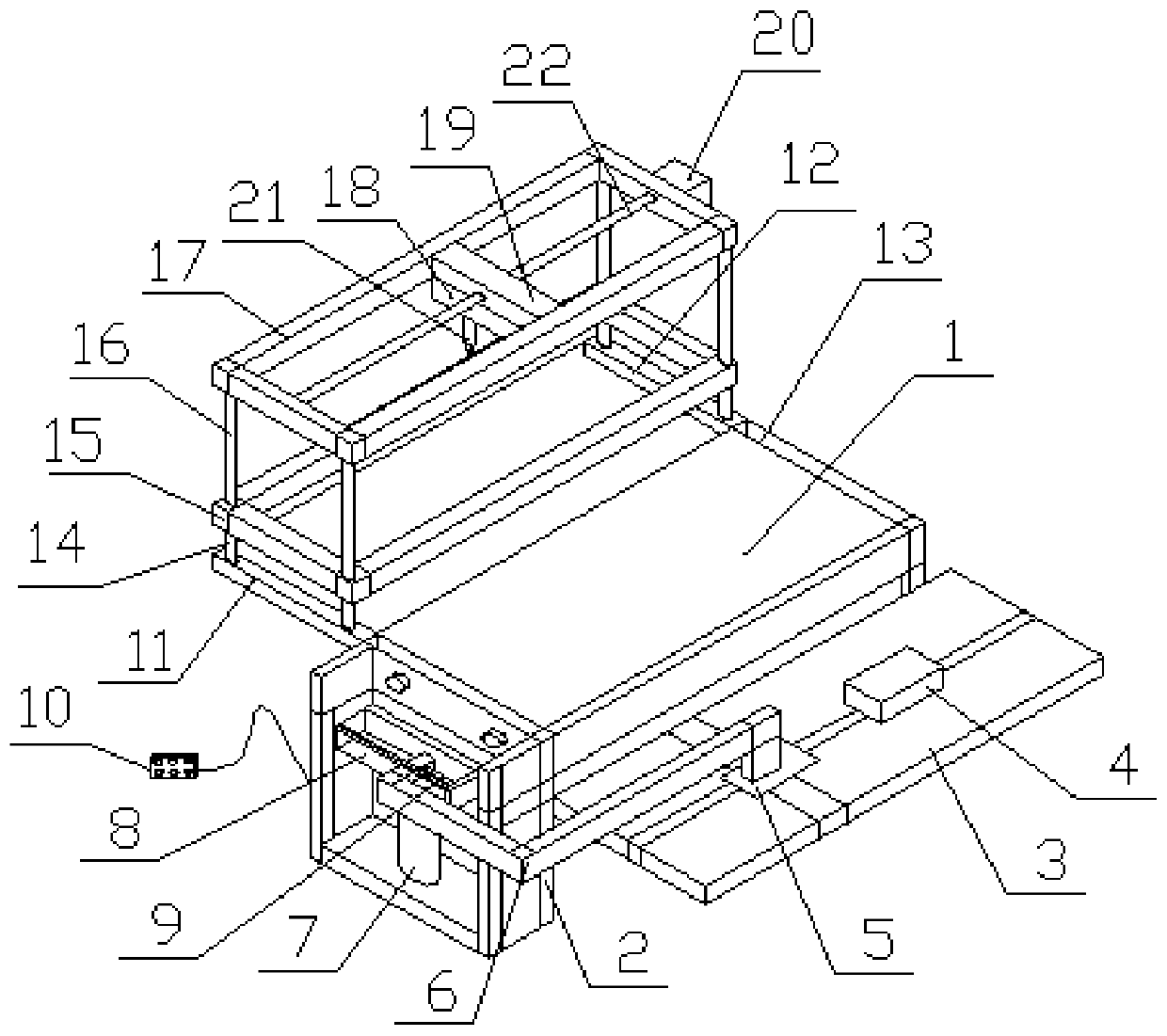

Full-automatic laser engraving equipment

InactiveCN107186348AWill not affect the marking pass rateHigh degree of automationLaser beam welding apparatusHigh volume manufacturingLaser engraving

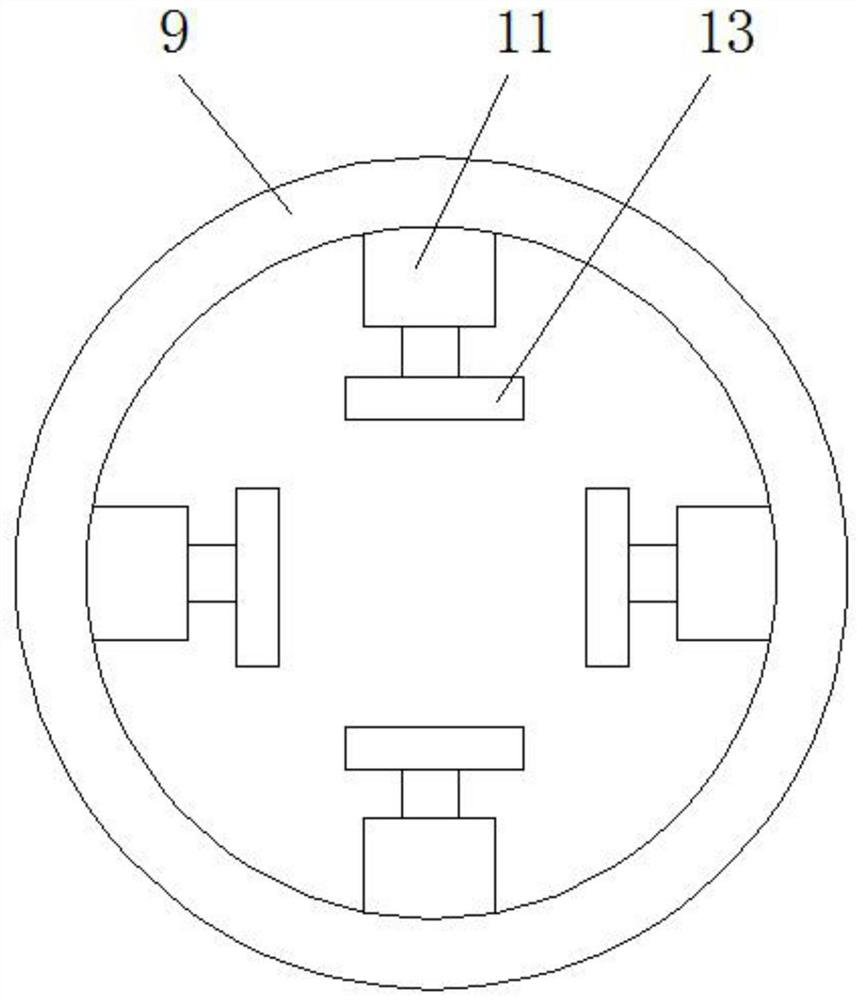

The invention belongs to the field of laser engraving, and particularly relates to full-automatic laser engraving equipment. The full-automatic laser engraving equipment comprises an operating table, a feeding mechanism, a discharging mechanism, at least one laser engraving mechanism, a conveying mechanism and a control mechanism, wherein the feeding mechanism and the discharging mechanism are arranged on the operating table, the laser engraving mechanisms and the conveying mechanism are arranged at the rear side of the operating table, and the control mechanism is electrically connected with the feeding mechanism, the laser engraving mechanism and the discharging mechanism. According to the full-automatic laser engraving equipment, the automation degree is high, meanwhile, because at least one laser engraving mechanism is arranged, simultaneous working of a plurality of marking machines can be achieved, the production efficiency is enhanced greatly, and the volume-production requirements can be met; only one operator is needed to operate on the site in the whole operating process, the time and the labor are saved, the situation that visual fatigue caused by long-time working of the operator influences the marking qualified rate cannot happen, and the engraving quality of a product is improved; and the equipment conforms to the fast-rhythm and high-quality production tenet of the current society, can be applied to flow work, and has a wide market prospect.

Owner:SUZHOU SHOLASER TECH CO LTD

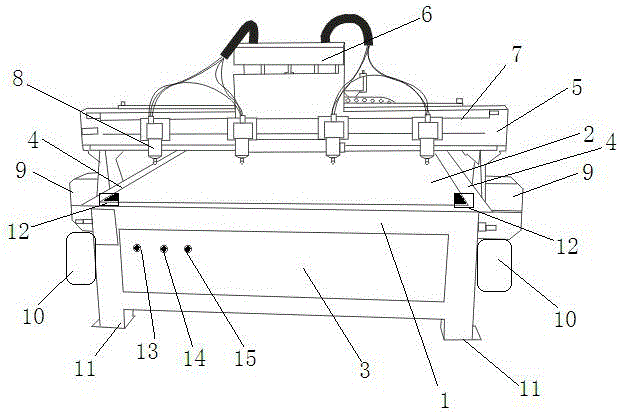

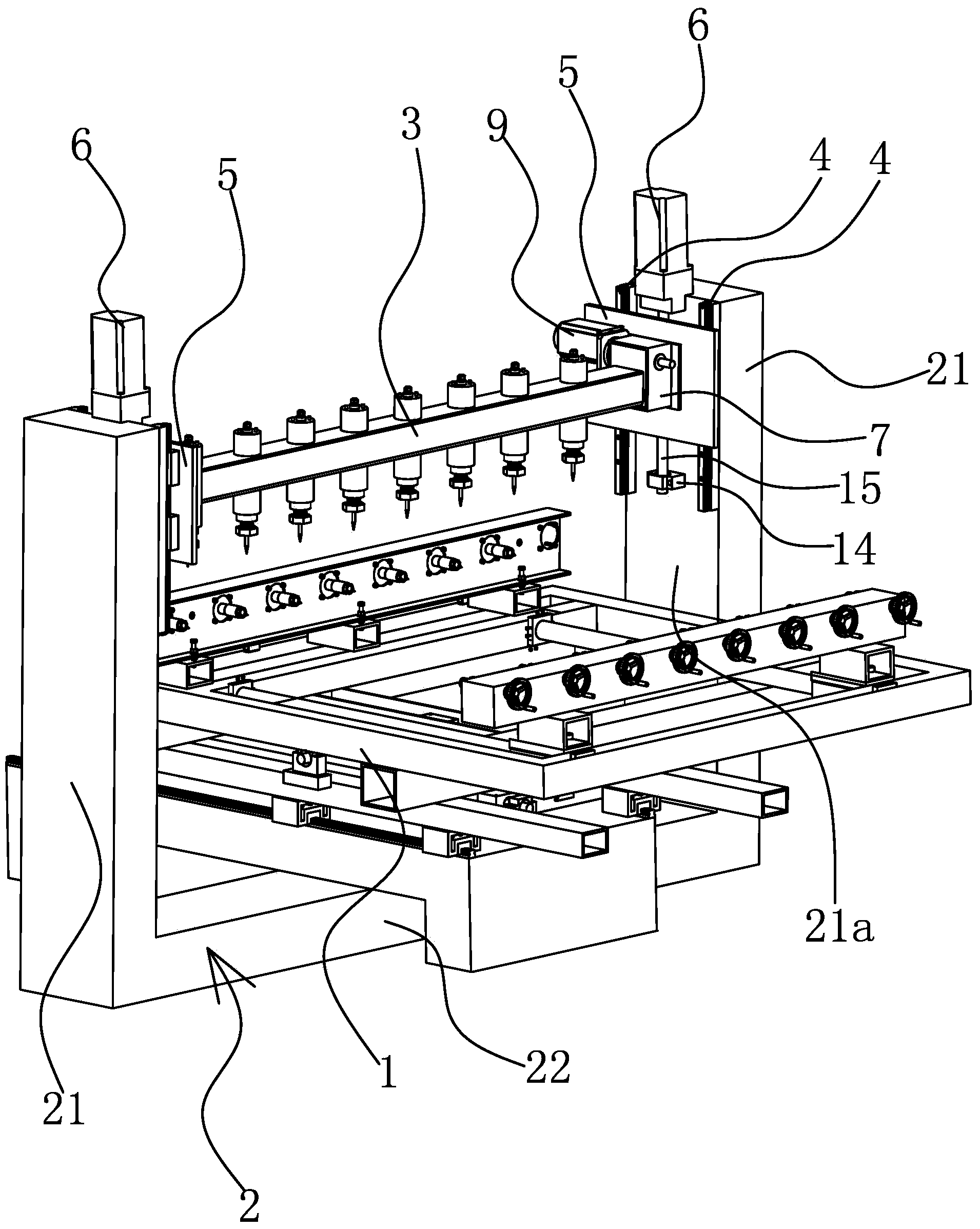

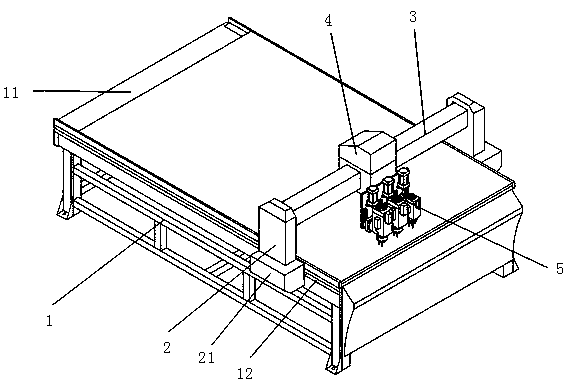

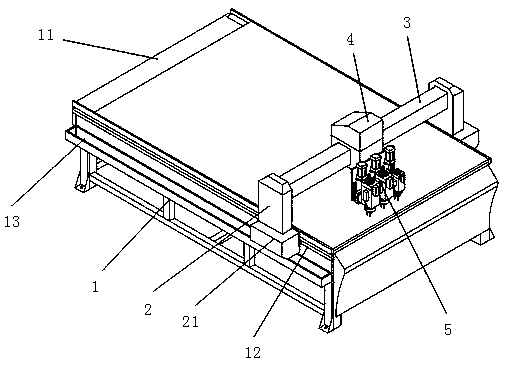

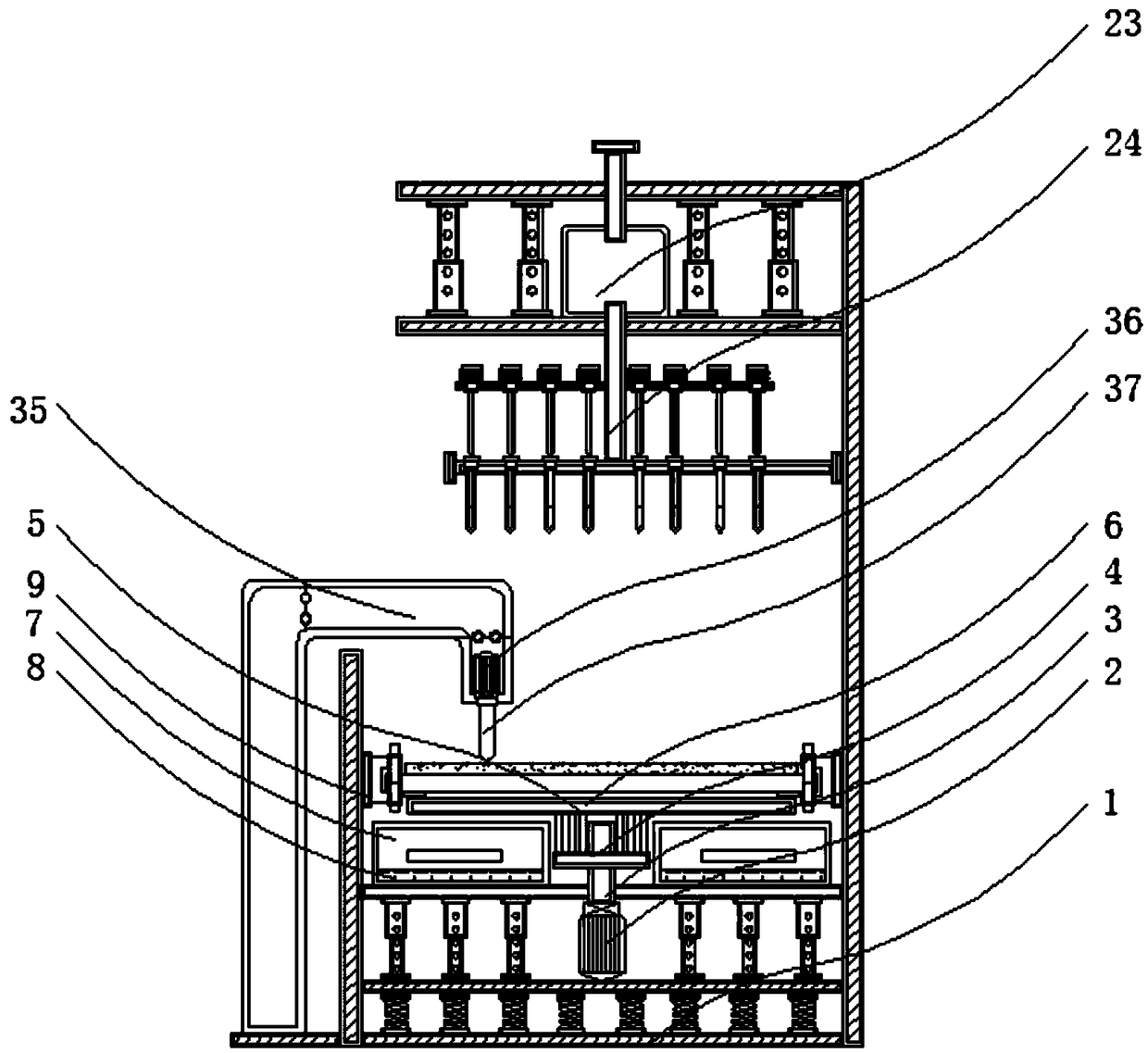

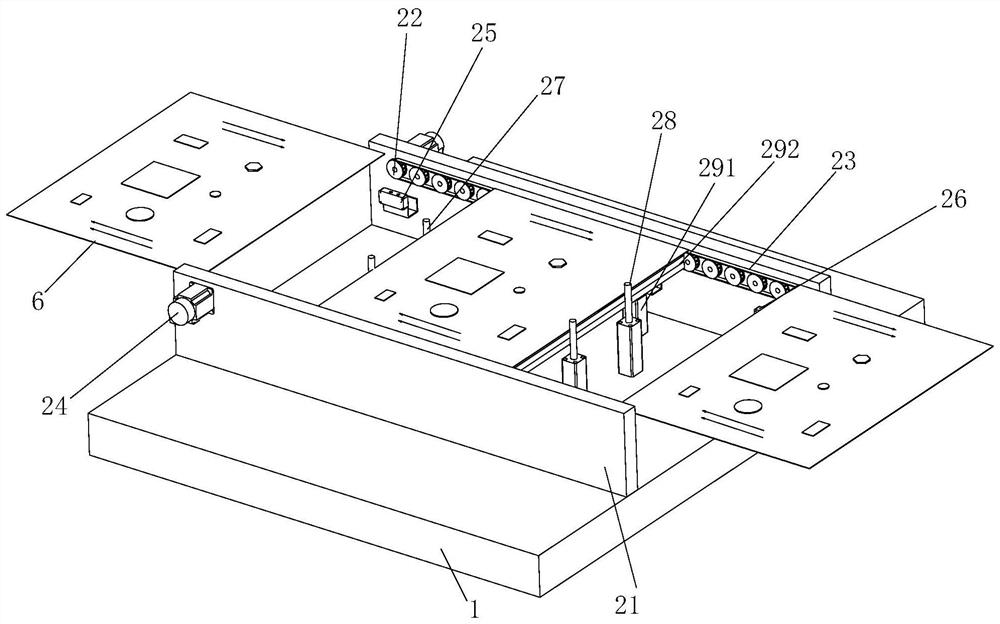

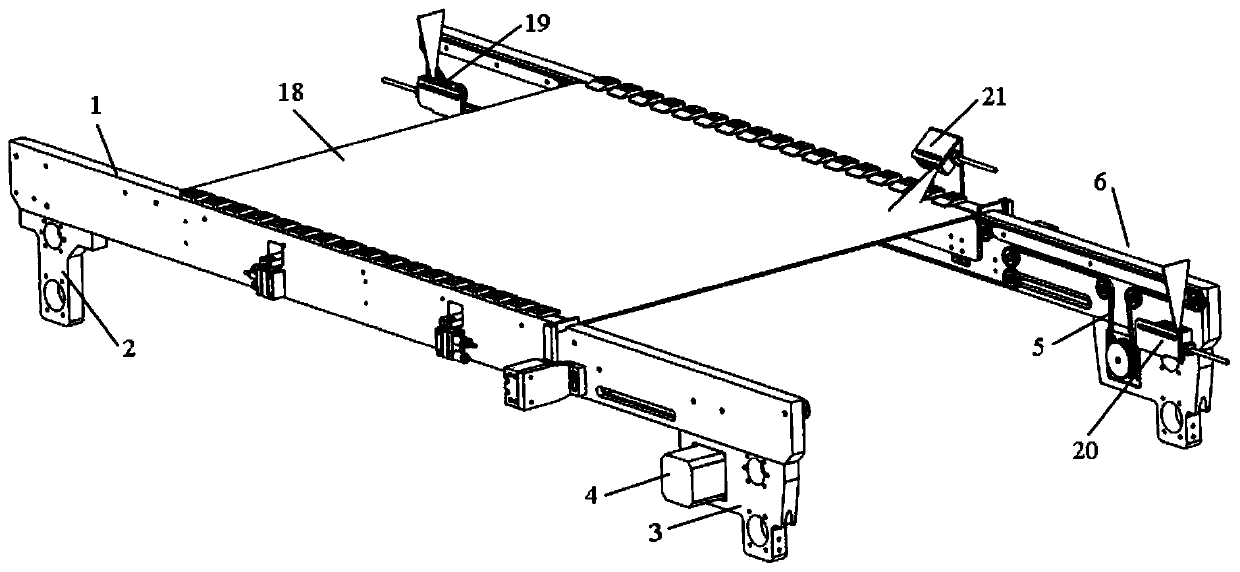

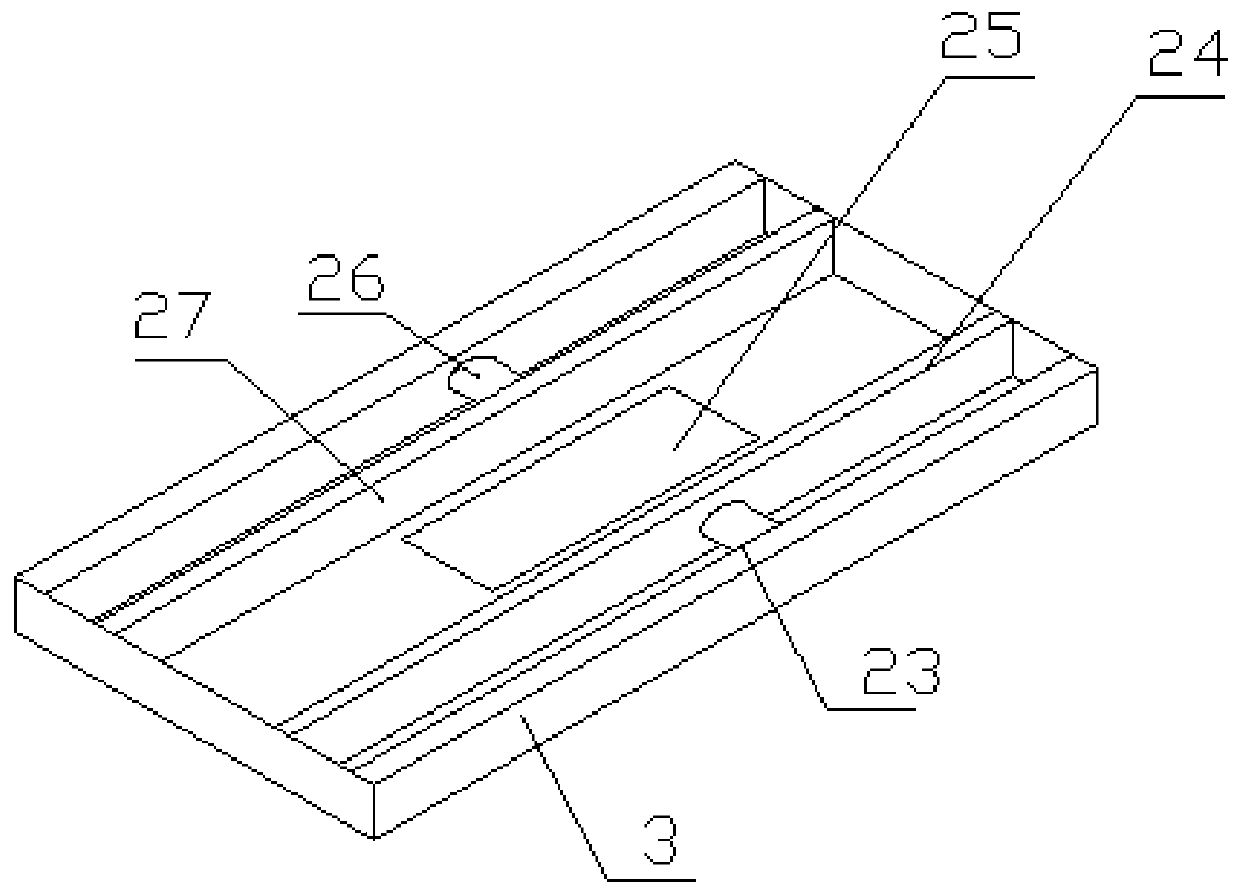

Multi-head woodworking carving machine

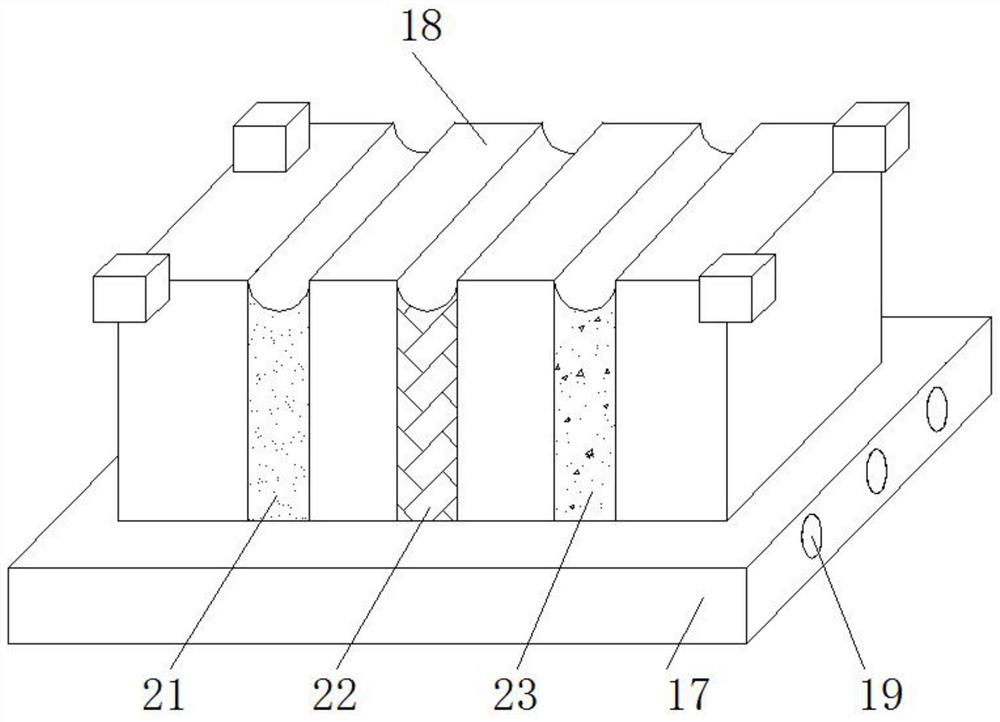

InactiveCN106427333AImprove engraving efficiencyImprove engraving qualityOther artistic work equipmentsModel makingDrive motorEngineering

The invention discloses a multi-head woodworking carving machine. The multi-head woodworking carving machine comprises a working base, sliding rails are arranged on the two side edges of the upper surface of the working base, a cross beam frame is installed between the two sliding rails, the cross beam part of the cross beam frame is arranged over the upper surface of the working base, a driving motor is installed on the cross beam part of the cross beam frame and controls the ends of the cross beam frame to slide on the sliding rails, two groove strips distributed in parallel are arranged on the side face of the cross beam part of the cross beam frame, a plurality of sets of carving heads are distributed on the side face of the cross beam part of the cross beam frame at equal intervals and are connected with a control unit through cables, suction fans parallel to the upper surface of the working base are installed below the two ends of the cross beam frame respectively and are used for sucking away wood dust generated in the process of carving a board on the upper surface of the working base, and the suction fans and the driving motor are connected with the control unit through cables respectively. The multi-head woodworking carving machine improves carving efficiency and carving quality, is simple in structure and easy to realize and has good application prospects.

Owner:SUZHOU HENGDAL IND MATERIALS CO LTD

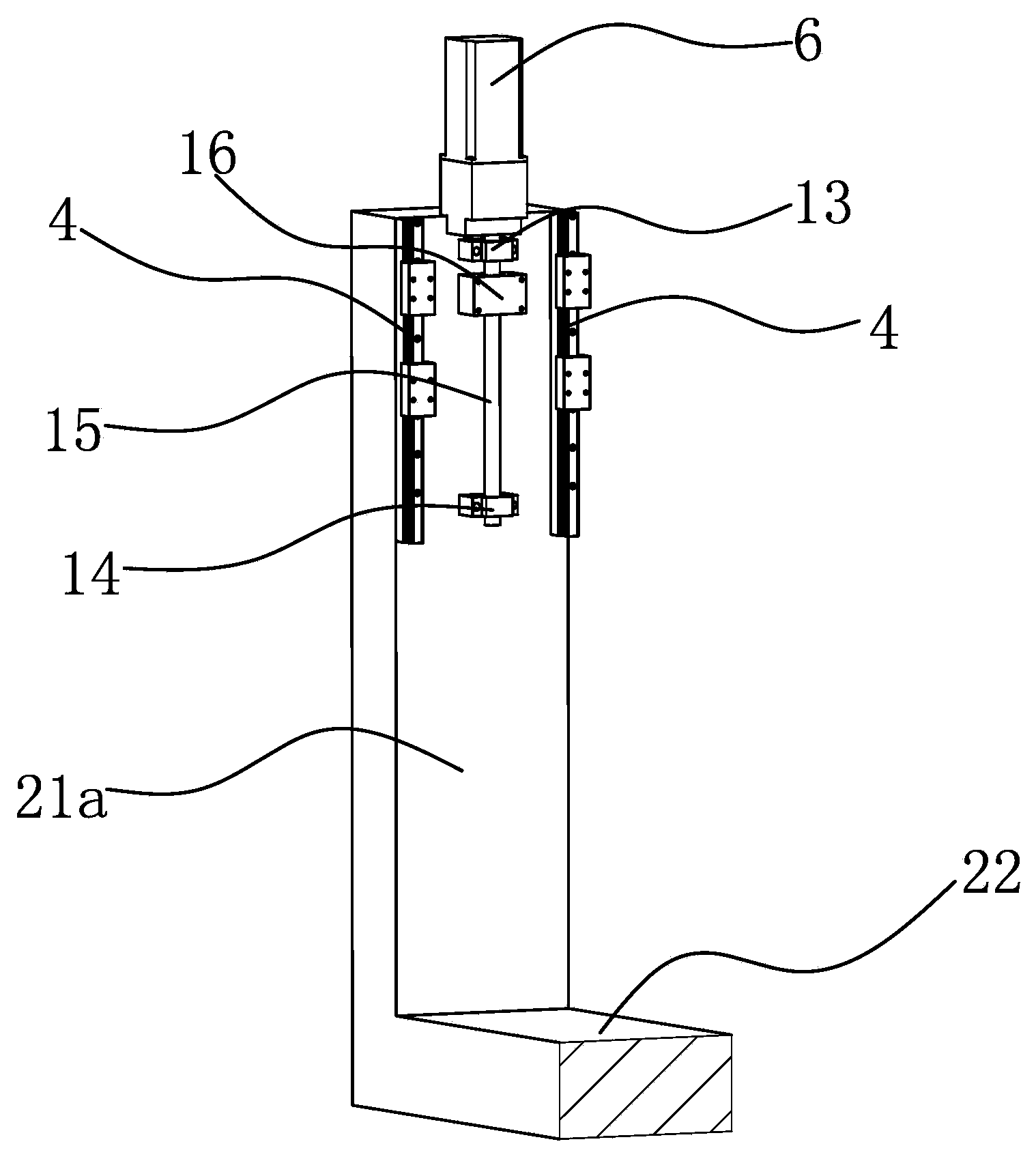

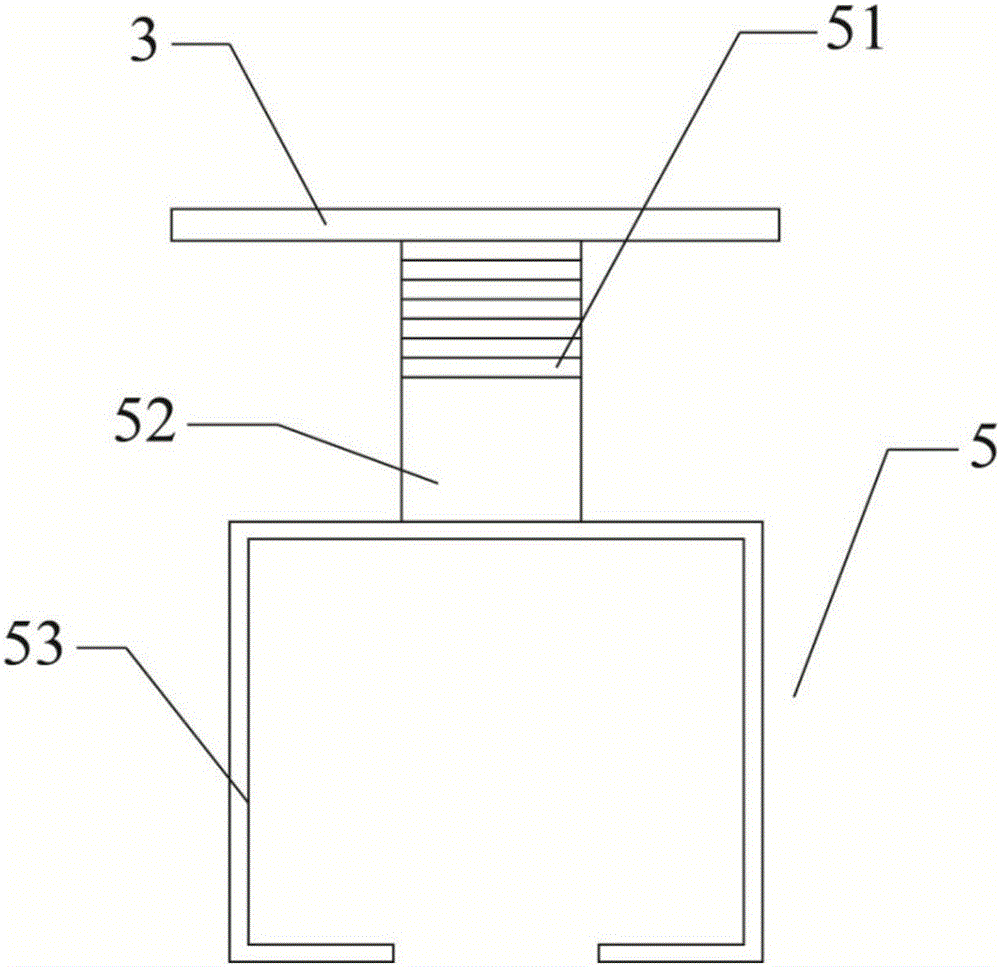

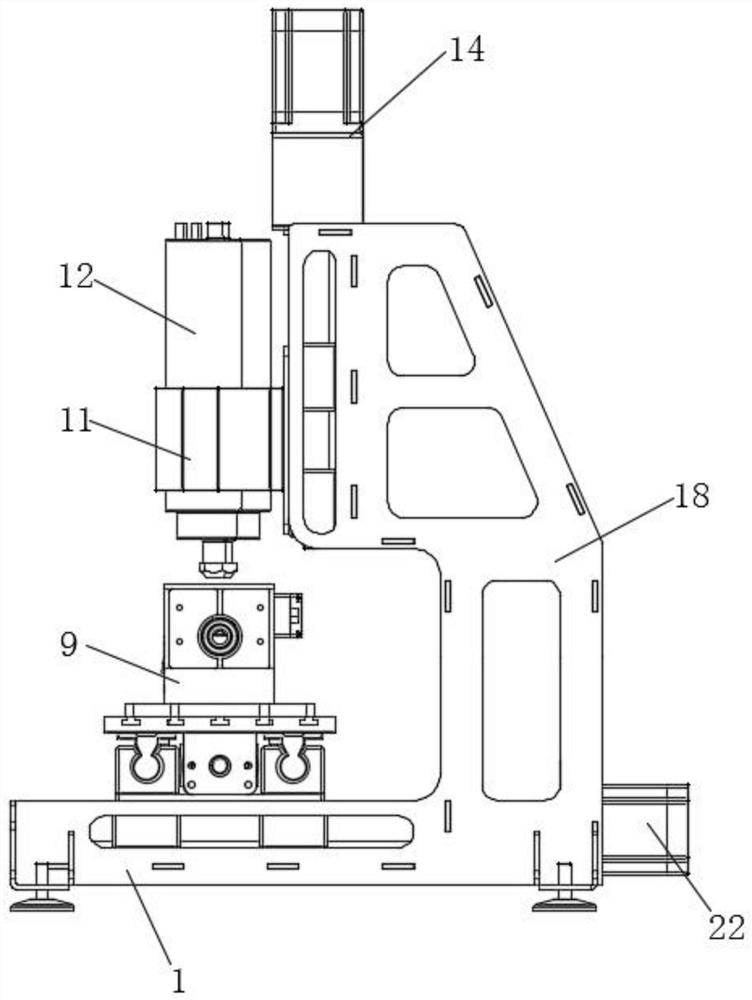

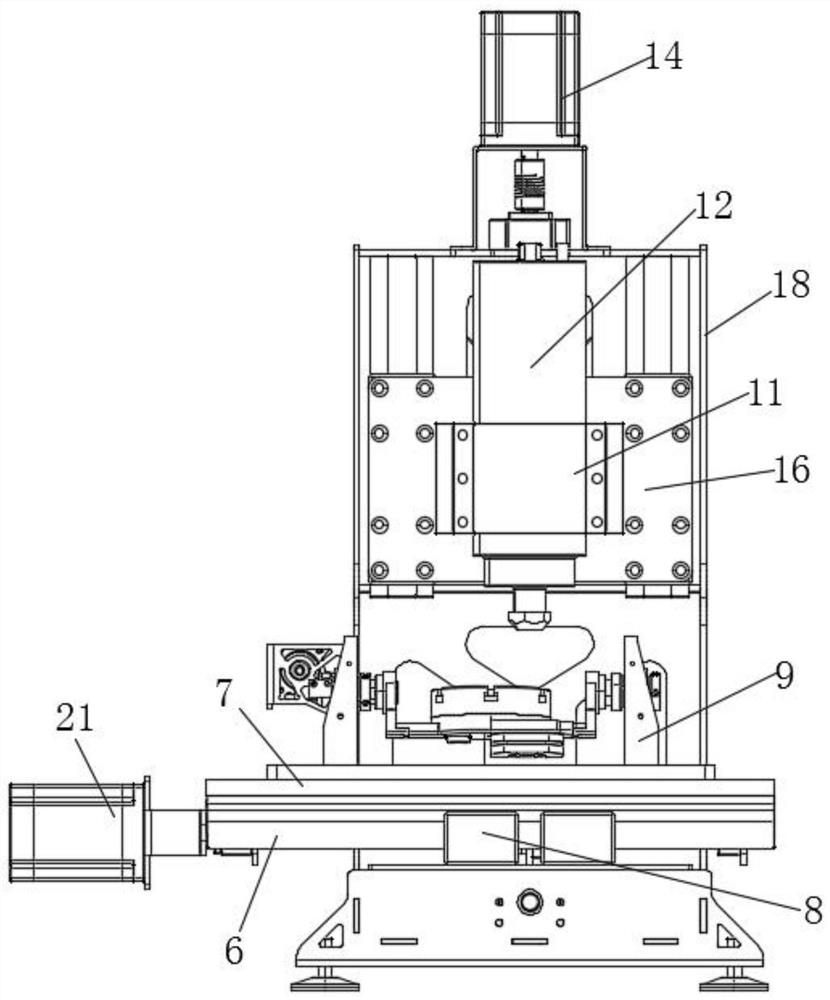

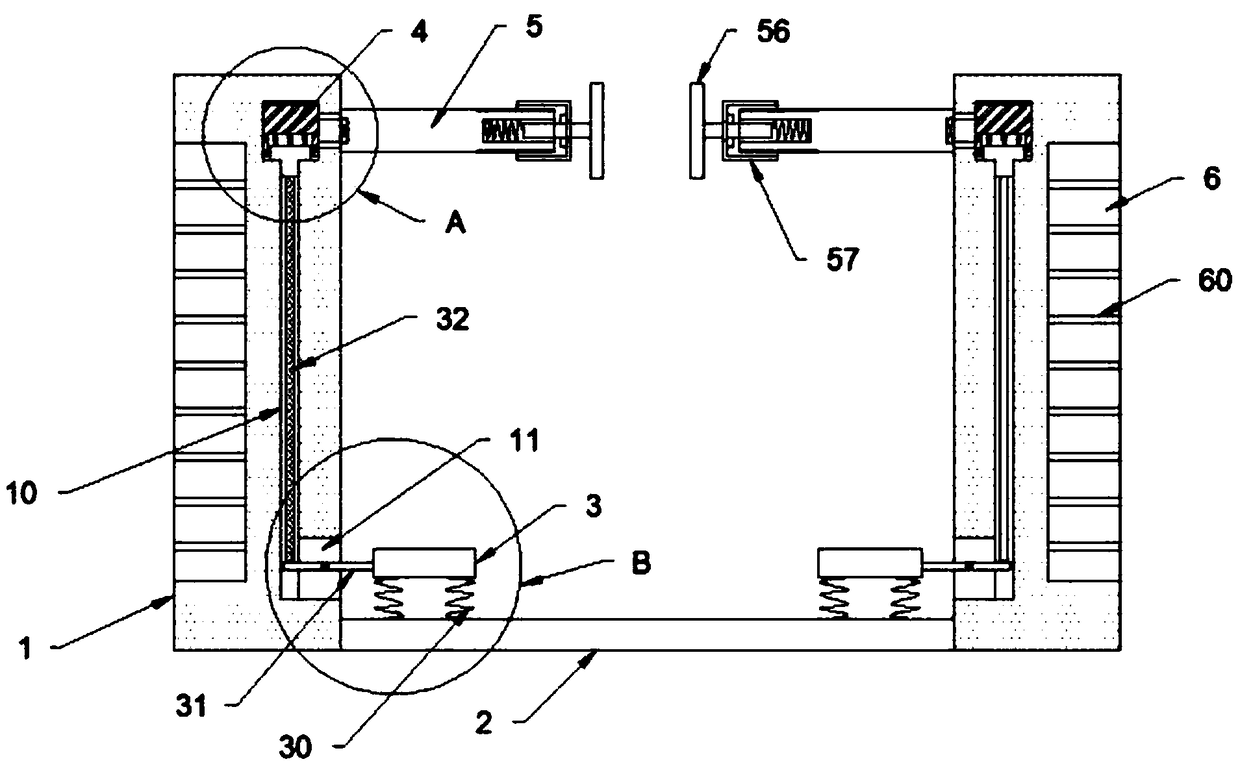

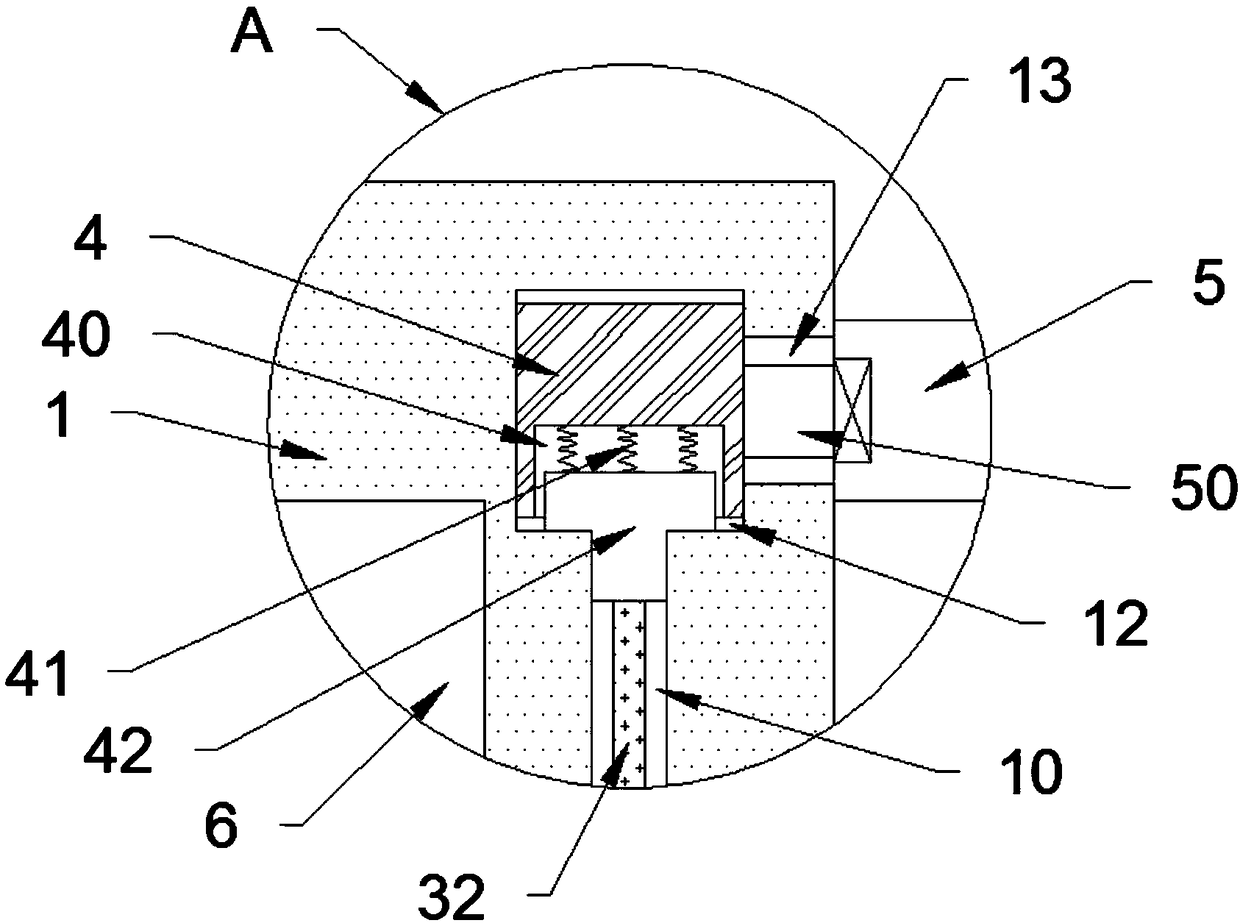

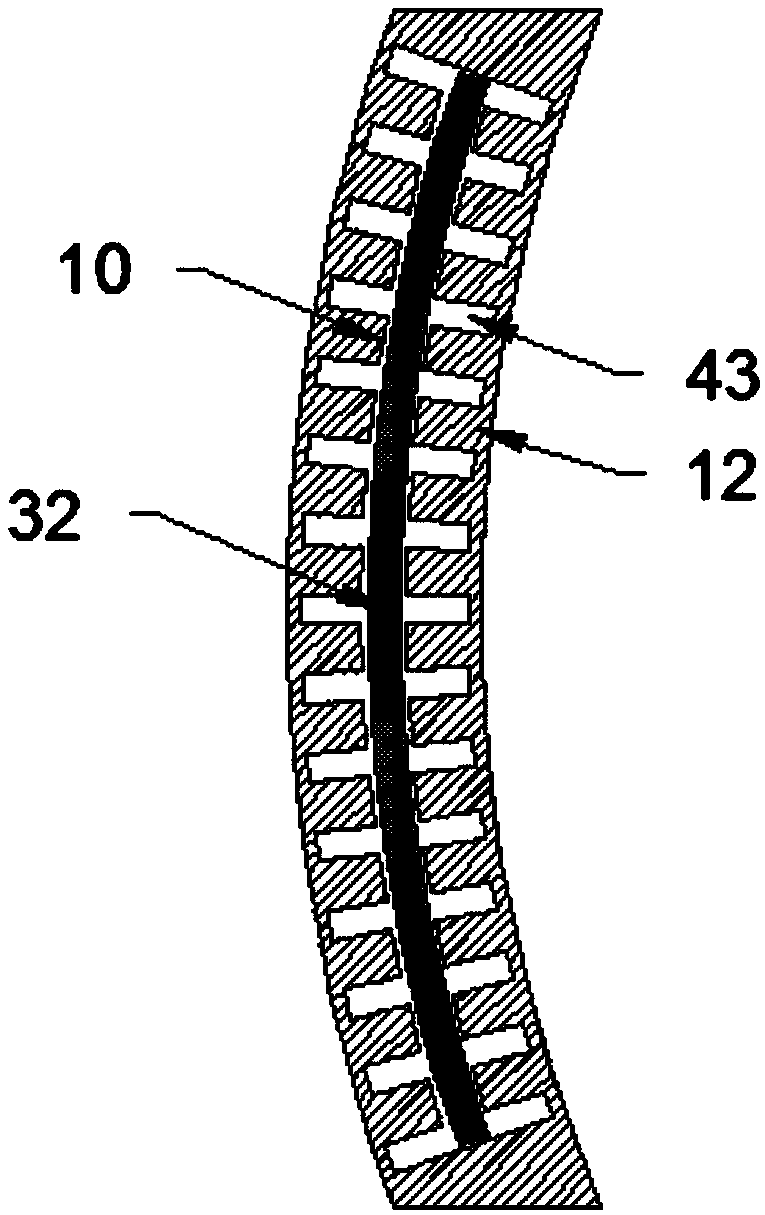

Three-dimensional engraving machine

The invention provides a three-dimensional engraving machine, and belongs to the technical field of an engraving machine. The three-dimensional engraving machine solves the problem of poor stability of a three-dimensional engraving machine in the engraving process in the prior art. The three-dimensional engraving machine comprises a machine frame and a movable engraving platform arranged on the machine frame, wherein a straight strip-shaped cutter frame used for fixing a cutter is arranged above the engraving platform, the machine frame comprises two upright posts, the two upright posts are respectively and vertically arranged at the two sides of the engraving platform, guide rails in vertical arrangement are respectively arranged on each upright post, a support plate capable of vertically moving along the guide rail is arranged on each corresponding guide rail, the two ends of the cutter frame are respectively connected onto the corresponding support plates, and ascending and descending motors driving the support plates to synchronously and vertically move are also arranged on the machine frame. The three-dimensional engraving machine has the advantages that the operation is stable, and the processing precision is high.

Owner:吴善旺

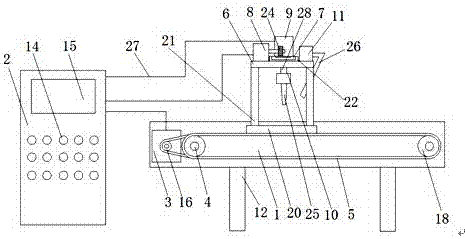

Carving device applied to furniture parts

ActiveCN107253415AImprove processing qualityImprove engraving qualityOther artistic work equipmentsEngravingRotational axisElectric machinery

The invention provides a carving device applied to furniture parts. The carving device applied to the furniture parts comprises an operation platform, a control cabinet, a first motor, a rotating shaft, a conveying belt, a bearing plate, an adjusting plate, a second motor, an air cylinder, a carving motor and a dust collection motor. The carving device applied to the furniture parts is characterized in that the operation platform is arranged on a bracket, the control cabinet is arranged on one side of the operation platform, the first motor is arranged in the operation platform, the rotating shaft is arranged in the operation platform, the conveying belt is arranged between rotating wheels, and the bearing plate is arranged on a fixing plate through a supporting rod. According to the carving device applied to the furniture parts, the first motor and the second motor are arranged as servo motors, the fixing plate can move back and forth on the conveying belt, the adjusting plate can drive the air cylinder to move back and forth, a piston rod of the air cylinder drives the carving motor to move back and forth, carving of different positions is conducted on the furniture parts needing to be carved in the operation platform, the working efficiency and working quality of furniture part carving are improved, and the machining quality of furniture is also enhanced.

Owner:彭波

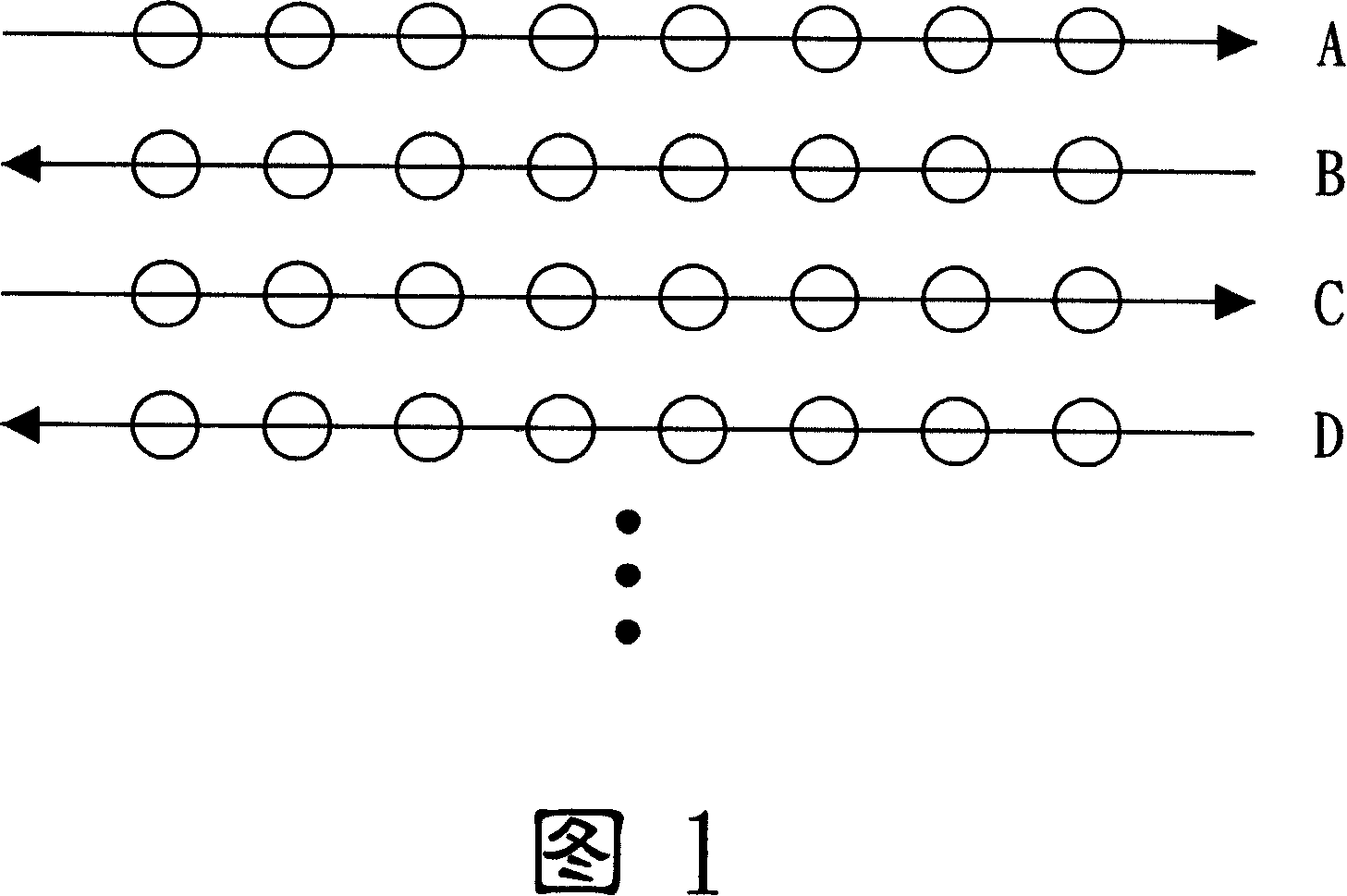

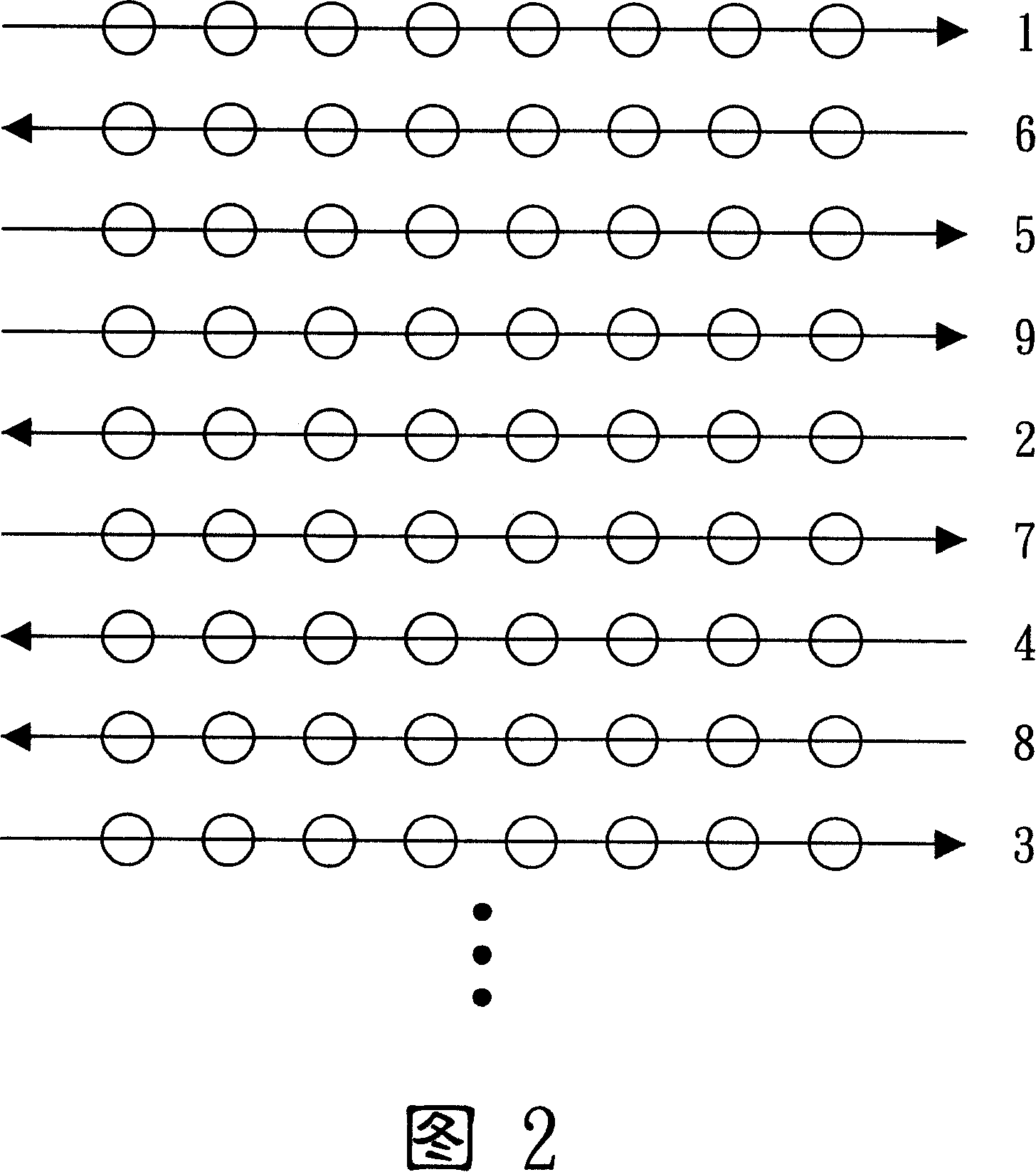

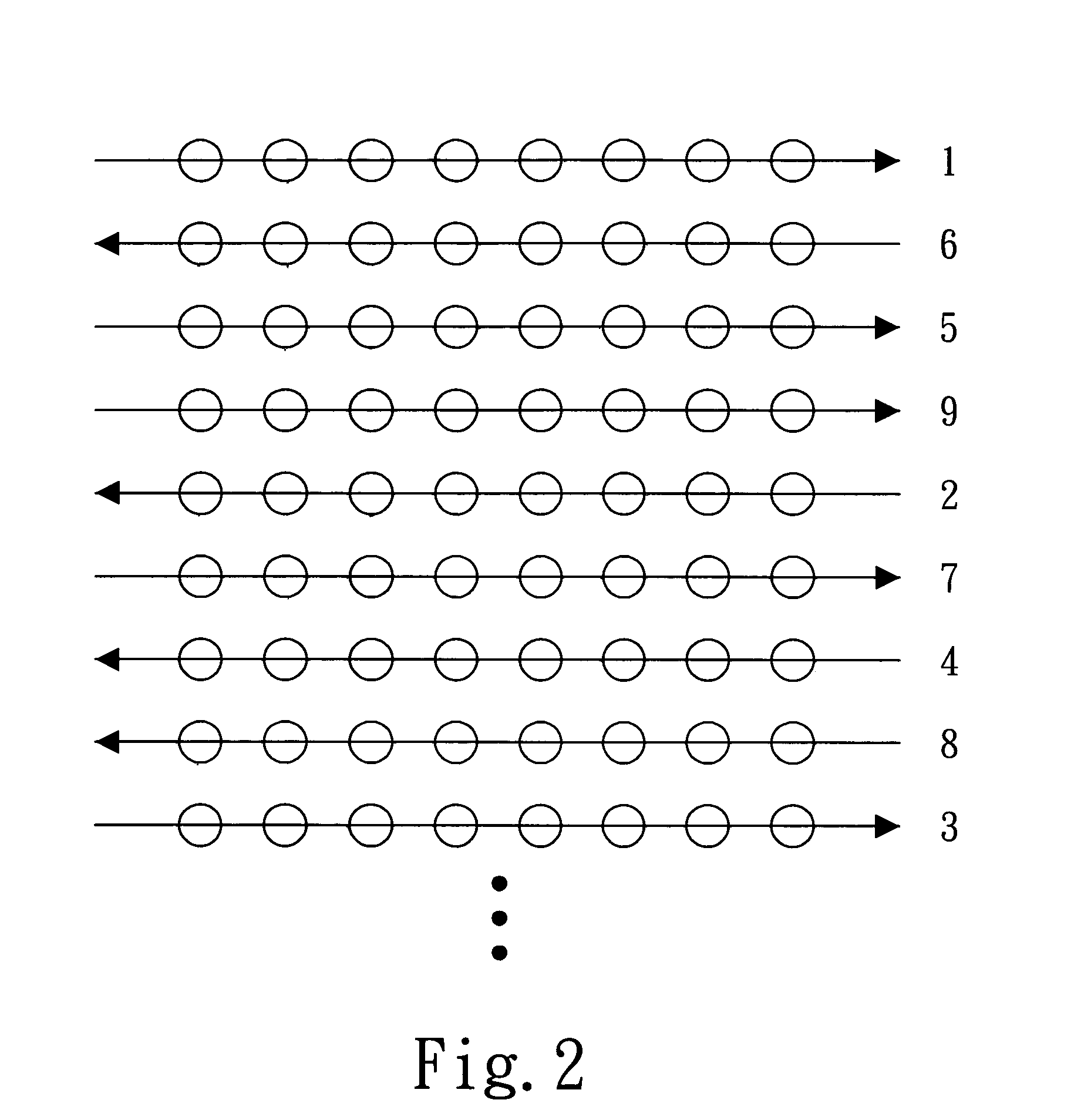

Laser engraving machine engraving method

InactiveCN101104366AImprove engraving qualityImprove the ripple phenomenonEngravingLaser engravingEngineering

Disclosed is engraving method of a laser engraving machine, characterized in that after engraving a horizontal number graduation, the engraving device of the laser engraving machine engraves the next horizontal graduation in a skipping way so as to improve the waves and improve the engraving quality, and the number graduations within the horizontal number graduation can also be engraved in the skipping way, further improving the quality of the carving. The invention can effectively avoid the problem of visual brightness variance on the carvings produced with current engraving technology.

Owner:XINGYUN COMP

An engraving fixture for ceramic processing

ActiveCN108909329BConvenient post-engraving workAvoid scatterLighting applicationsMechanical apparatusEngravingWorking environment

The invention provides an engraving fixing device for ceramic processing. The engraving fixing device comprises a power source switch and a miniature power source plug, wherein the top part of an engraving table is provided with a material leaking groove; the bottom part of the material leaking groove is of a hollow structure; the front end of the end surface of the top part of the engraving tableis provided with a circular positioning groove, and the bottom part of an inserting bolt is glidingly connected with the interior of the positioning groove; the top part of a rotary disc is of a circular plate-shaped structure, and the rotary disc is positioned at the end surface of the top part of the engraving table; a rotary handle is of an L-shaped strip structure, and the bottom part of therotary handle is glidingly connected with the end surface of the top part of the engraving table; a rubber gasket is attached to the inside sawtooth-shaped structure of the rotary handle. The engraving fixing device has the advantages that when an operator engraves a bottled magnetic blank, the crushed residue of porcelain clay from the engraving is blown away from the surface of the magnetic blank, the exterior of the magnetic blank is cleaner, and the operator can conveniently perform the engraving operation lately; by arranging the material leaking groove and a net cage, the previous blowncrushed residue of porcelain clay away from the surface of the magnetic blank can be collected, so as to avoid the pollution to working environment due to scattering of the crushed residue of the porcelain clay.

Owner:陈春燕

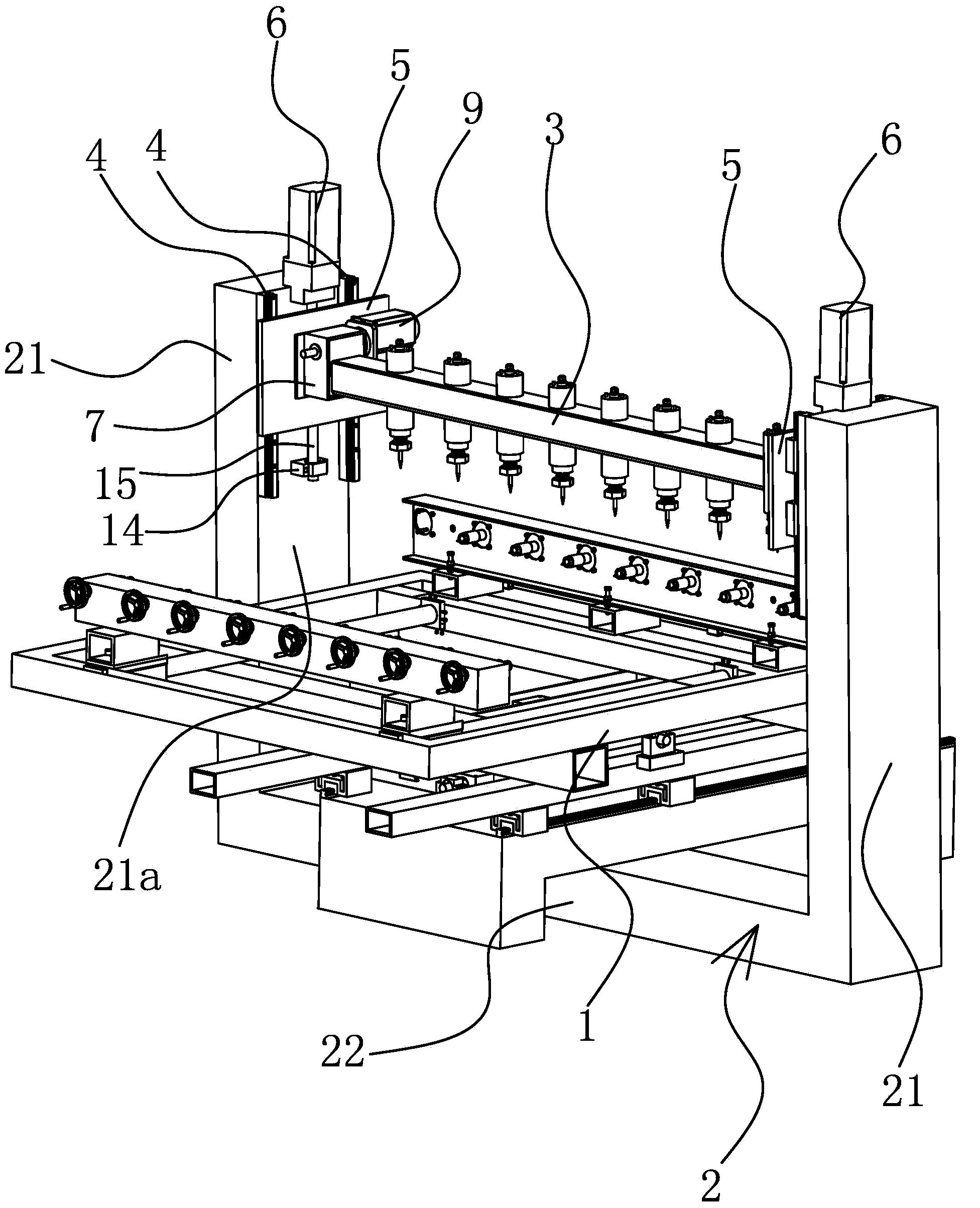

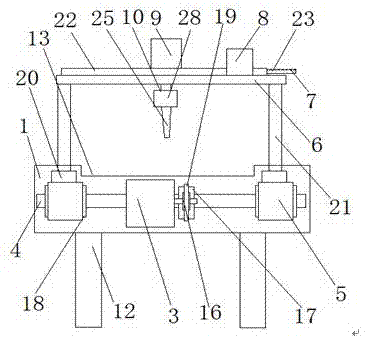

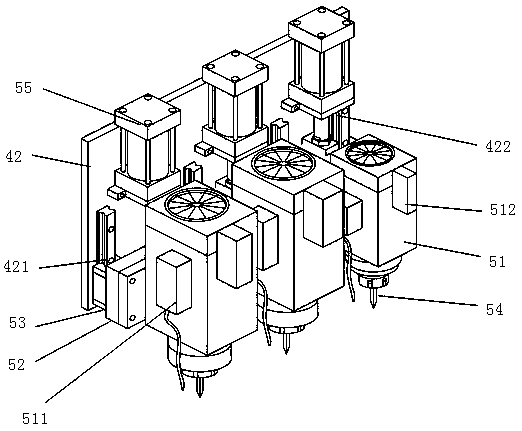

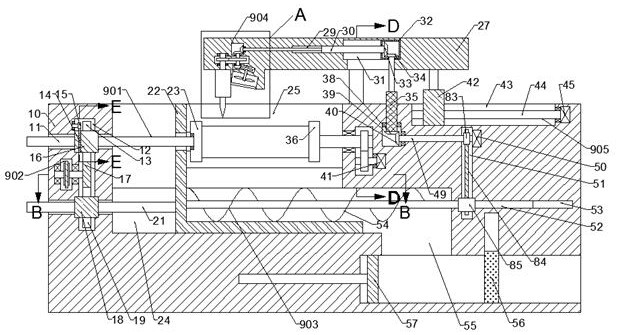

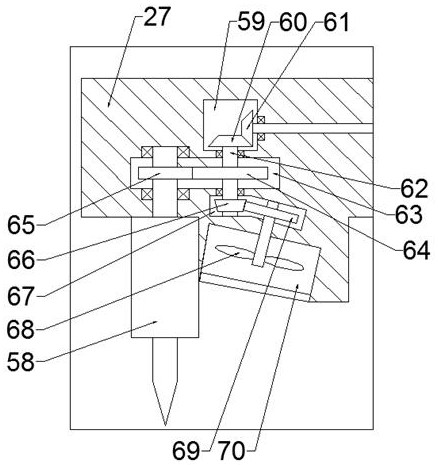

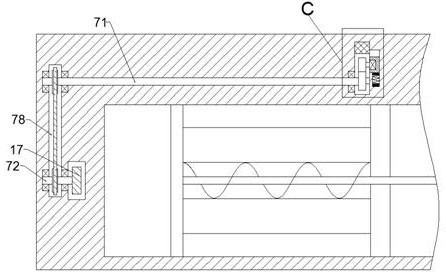

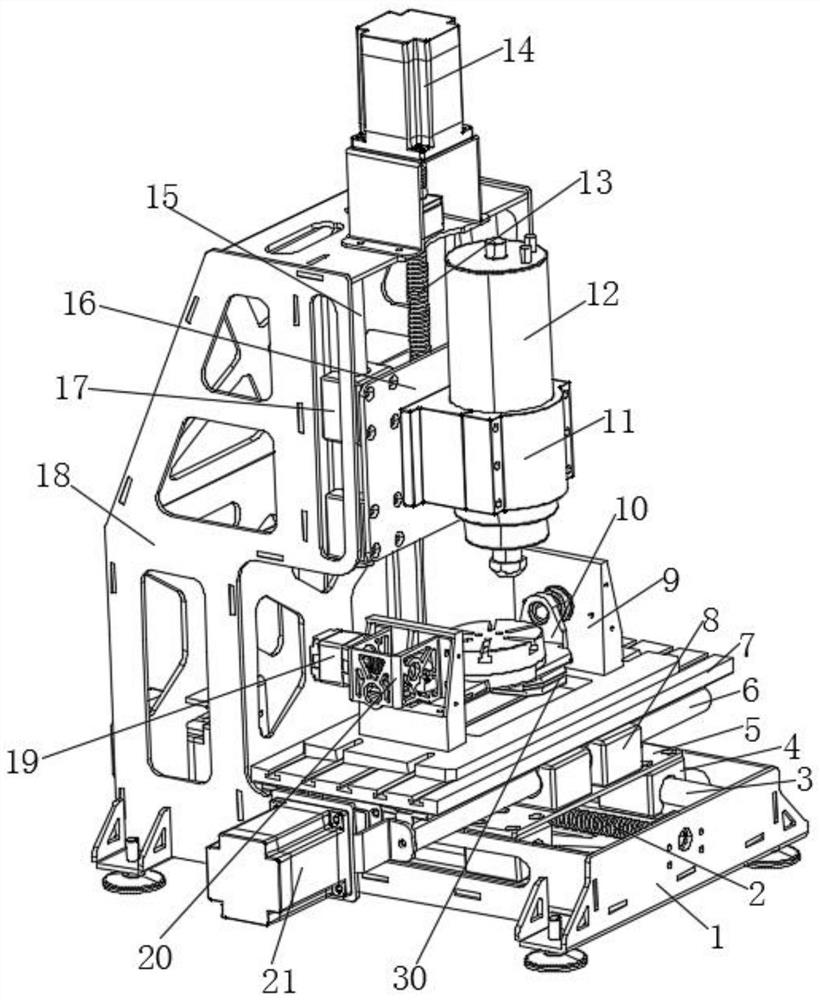

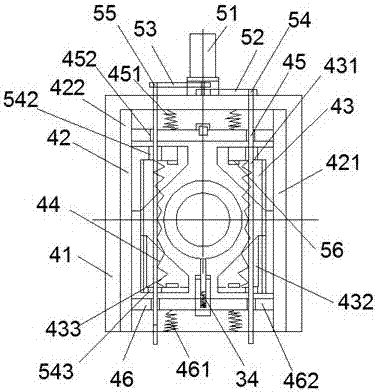

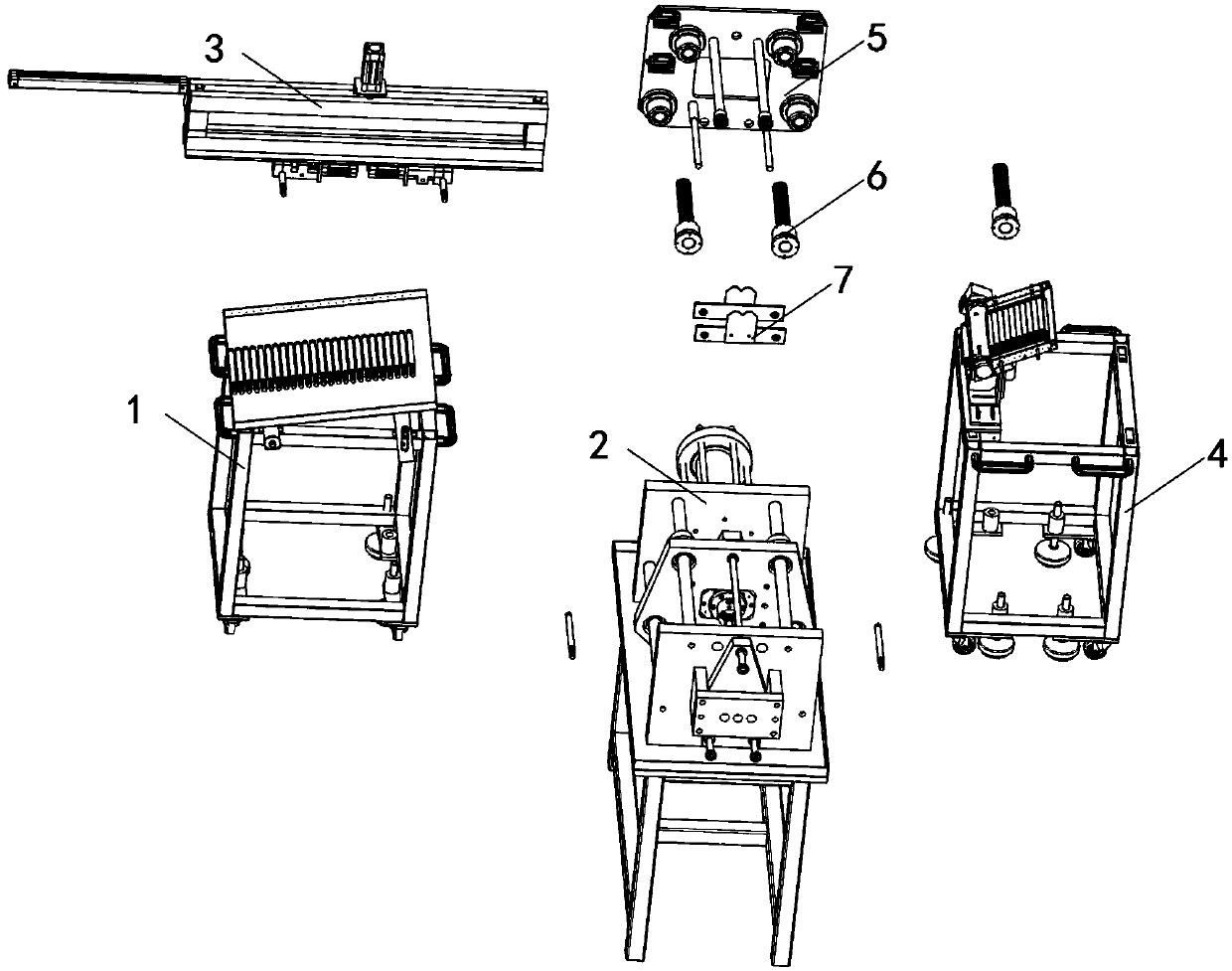

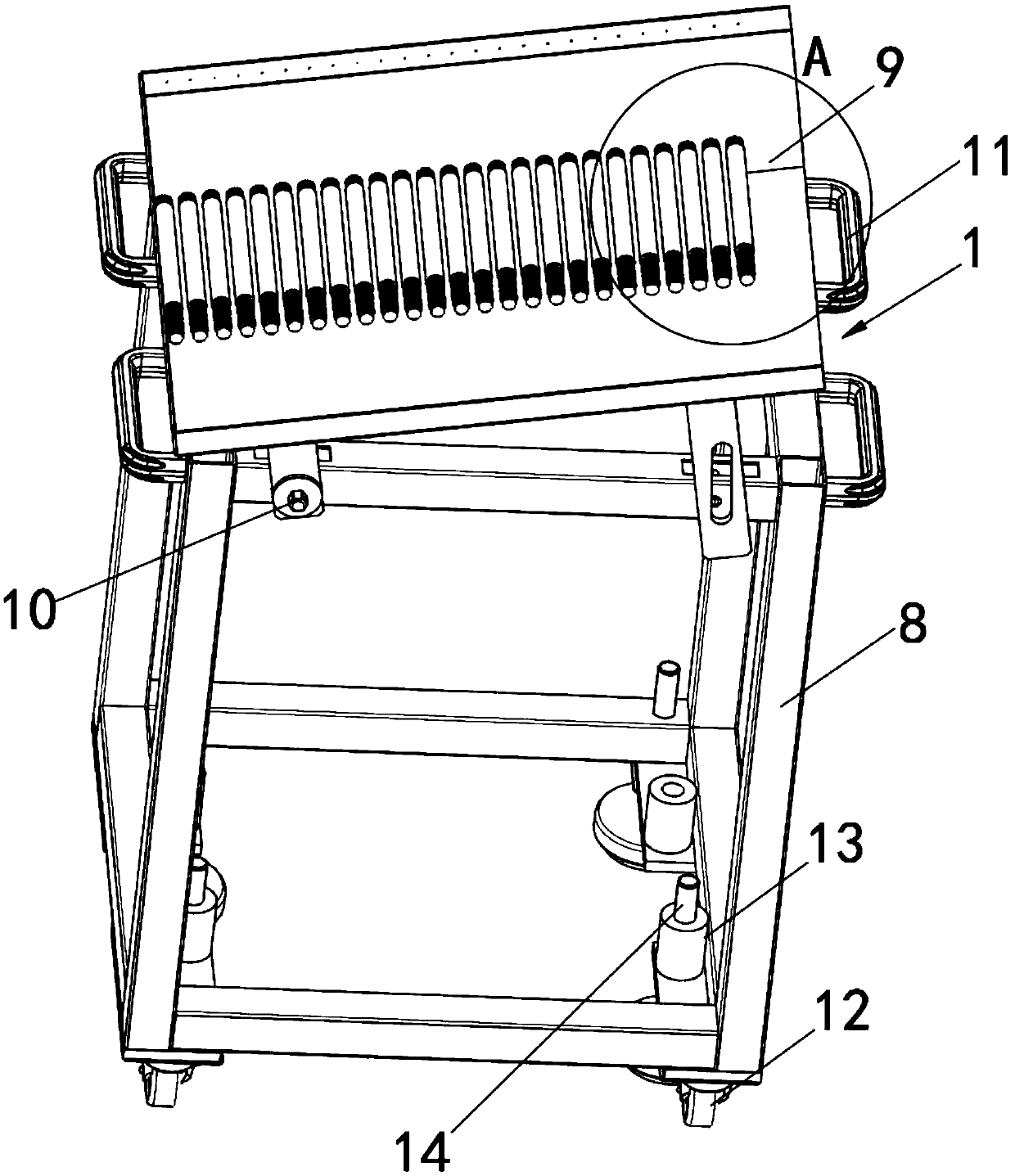

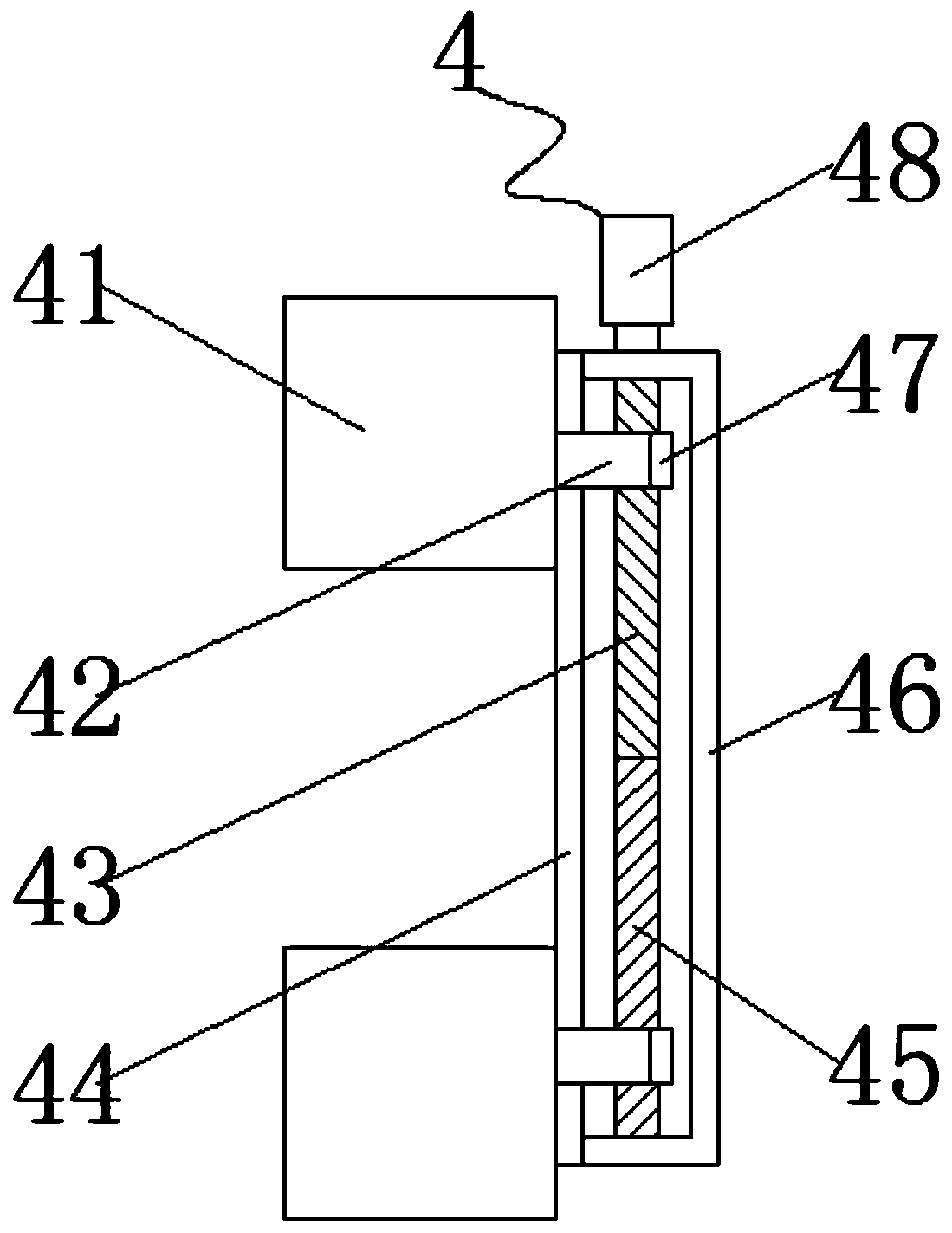

Multifunctional automatic tool changing numerical control engraving machine

InactiveCN109050131AImprove engraving quality and service lifeImprove engraving efficiencyModel makingEngravingMultiple functionEngraving

The invention discloses a multifunctional automatic tool changing numerical control engraving machine. The multifunctional automatic tool changing numerical control engraving machine comprises a frame, transverse moving mechanisms, a cross beam, a longitudinal moving mechanism and an engraving mechanism. The engraving mechanism is composed of a plurality of tool spindle frames. Each tool spindle frame comprises a tool spindle. A lifting seat is arranged on the side, opposite to a vertical moving seat, of each tool spindle. A third sliding component is arranged on each lifting seat. A third guide rail matched with the corresponding third sliding component is arranged at the position, corresponding to the third sliding component, of the vertical moving seat. A tool chuck for installing a tool is fixed at the end of each tool spindle. According to the multifunctional automatic tool changing numerical control engraving machine, a heat dissipation and dust removal device and a laser detector are arranged, so that the tool engraving quality is improved, the service life of the tool is prolonged, and the precision of the tool displacement is improved; and the tool changing operation can be automatically realized in the whole engraving process without manned shut-down, and the engraving efficiency is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

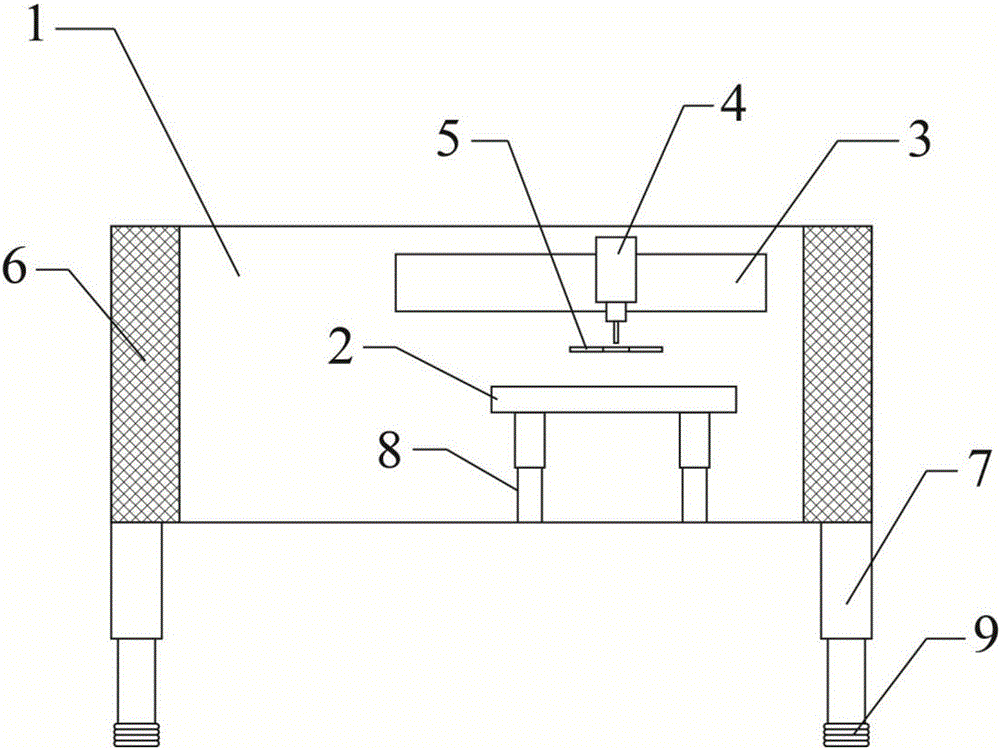

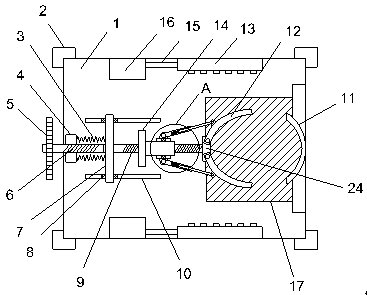

Radio-frequency carving machine

InactiveCN105711313AEasy to unloadImprove engraving qualityLaser beam welding apparatusModel makingPulp and paper industryRadio frequency

The invention provides a radio-frequency carving machine. The radio-frequency carving machine comprises a machine body, a workbench, a work frame and a carving machine head. The machine body is a cuboid cavity. The workbench, the work frame and the carving machine head are all arranged inside the machine body. The carving machine head is connected with the work frame. The carving machine head corresponds to the workbench in position. The radio-frequency carving machine is characterized in that purifying chambers are arranged on the two sides of the interior of the machine body, the bottom of the machine body is connected with machine body supporting columns, bottom feet are arranged at the bottoms of the machine body supporting columns, and two workbench supporting columns are arranged at the bottom of the workbench; the bottoms of the workbench supporting columns are fixed to an inner wall bottom plate of the machine body; the machine body supporting columns and the workbench supporting columns are each of a telescopic structure; and a clamping part is further arranged above the workbench, and one end of the clamping part stretches into the work frame. The purifying chambers are arranged in the machine body so that dust can be treated, and meanwhile the machine body supporting columns of the telescopic structure and the workbench supporting columns of the telescopic structure are arranged so that discharging can be convenient.

Owner:TIANJIN HONGGUANG WEIYE LASER TECH CO LTD

Three-dimensional wood carving equipment capable of collecting wood chips

InactiveCN112060216AReduce the scope of collection and processingQuick collectionStationary drilling machinesLighting and heating apparatusTool bitRatchet

The invention discloses three-dimensional wood carving equipment capable of collecting wood chips. The three-dimensional wood carving equipment comprises a machine body, wherein a carving cavity is formed in the machine body, and a clamping and rotating device capable of fixing a woodcarving and rotating the woodcarving is arranged on the left side of the carving cavity. According to the three-dimensional wood carving equipment, the clamping and rotating device is arranged, a first clamping block moves rightwards to be matched with a second clamping block for clamping, and backward rotation isavoided after fixing due to the action of a ratchet wheel on a second rotating block; a sliding collecting device is arranged and can slide and contract according to the size of the woodcarving clamped between the first clamping block and the second clamping block, so that the wood chip collecting and processing range is effectively reduced, and the wood chips can be collected more quickly and conveniently; and a carving device is arranged, a tool bit on the lower side of a carving drill bit can be cooled through rotation of a cooling fan, the wood chips left on the upper side of the woodcarving after carving can be blown away, and therefore carving quality is effectively improved.

Owner:温岭云歌工艺品有限公司

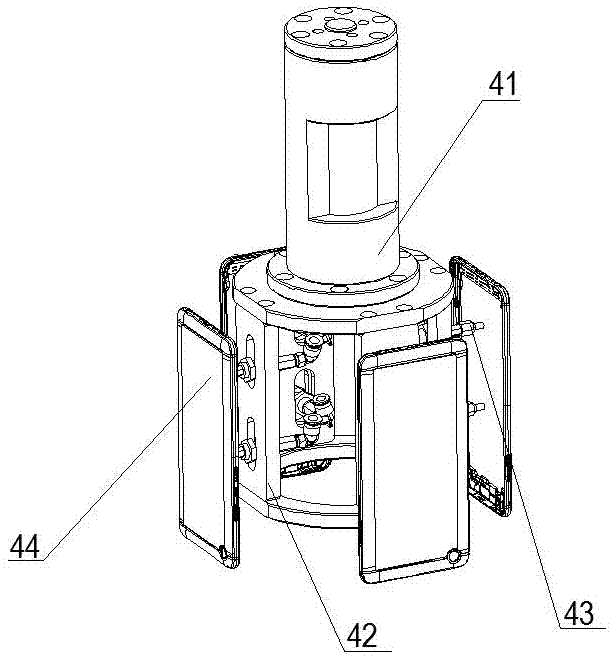

All-direction-polishing intelligent engraving and etching equipment capable of conveniently collecting waste

ActiveCN109396656AEasy to collectEasy to spin freelyLaser beam welding apparatusEngravingFree rotation

The invention discloses all-direction-polishing intelligent engraving and etching equipment capable of conveniently collecting waste, and relates to the technical field of metal engraving. The equipment specifically comprises a working platform, a waste collecting box, an engraved metal sheet, a grease storage box and a mechanical arm; a first driving motor is arranged inside the working platform,a connecting pipe is arranged below an output end of a shunting pipe, a fixing rod is fixedly arranged above a collecting pipe, and a dredging pipe is arranged in a limiting groove; and the mechanical arm is arranged on the left side of the working platform, a second driving motor is arranged in the tail end of the mechanical arm, and an output end of the second driving motor is connected with aengraving head through a shaft. According to the all-direction-polishing intelligent engraving and etching equipment capable of conveniently collecting waste, the height of a supporting stand column can be adjusted through rotating a rotating nut, so that a user can freely rotate a polishing disc to a required position conveniently; the equipment not only has the polishing effect on the engraved metal sheet, but also has a supporting effect on the engraved metal sheet.

Owner:江苏卓燃高新科技有限公司

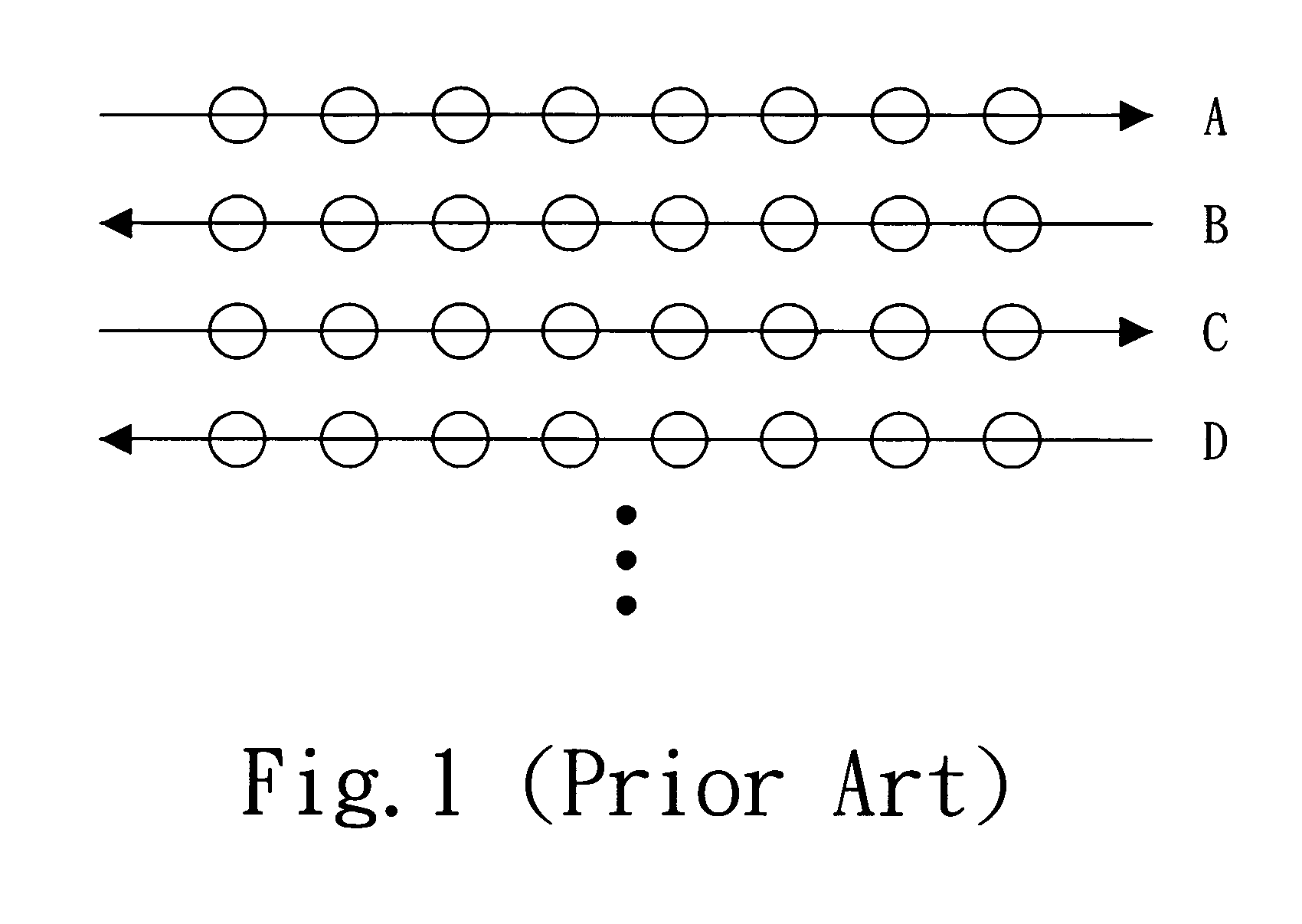

Engraving method for a laser engraver

InactiveUS7889396B2Improve engraving qualityEnhance the banding phenomenonDigitally marking record carriersDigital computer detailsLaser engravingEngineering

In an engraving method for a laser engraver, an engraving apparatus of the laser engraver performs an engraving for data of a transversal engraving line and then engraves for data of a transversal engraving line in a jumping mode to improve a banding phenomenon and enhance the engraving quality, further the engraving data points of each transversal engraving line can also be engraved in the jumping mode, so as to enhance the overall quality of the engraved object and effectively lower the visual effect of an uneven brightness of traditional laser engravers.

Owner:XINGYUN COMP

Carving machine workbench for gourd carving

ActiveCN110341361AImprove engraving qualityImprove buffering effectModel makingEngravingGourdEngineering

The invention discloses a carving machine workbench for gourd carving. The carving machine workbench comprises an operation table, supporting legs are vertically and fixedly arranged at four corners of the bottom of the operation table, a limiting sleeve plate is vertically and fixedly arranged on the operation table, a first screw rod is horizontally arranged in the limiting sleeve plate in a penetrating mode, an exhaust fan and a collecting box are arranged in a communicating mode through a conveying pipe, and the inlet end of the exhaust fan faces towards the direction of a clamping arc plate. According to the carving machine workbench for gourd carving, a first hand wheel is rotated to drive the first screw rod to rotate so that the transverse movement of a support can be realized, andthen adjustment is carried out according to the length of a gourd to be carved; and a second hand wheel is rotated to drive a threaded sleeve to move left and right relative to a second screw rod sothat a telescopic rod can drive the clamping arc plate to rotate so as to adapt to the gourds with different widths, the extension and compression of a limiting spring are limited, a good buffering role is achieved, and the stability of the adjusting process and the stability of the carving process are improved. According to the carving machine workbench, the adjustment is simple and convenient, the adaptability is high, the carving quality of the gourd is effectively improved, and the working efficiency is greatly improved.

Owner:安徽姜尚工艺品有限公司

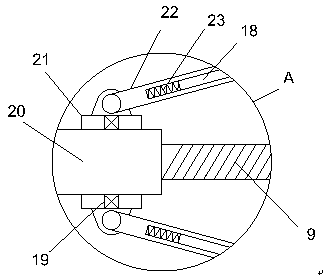

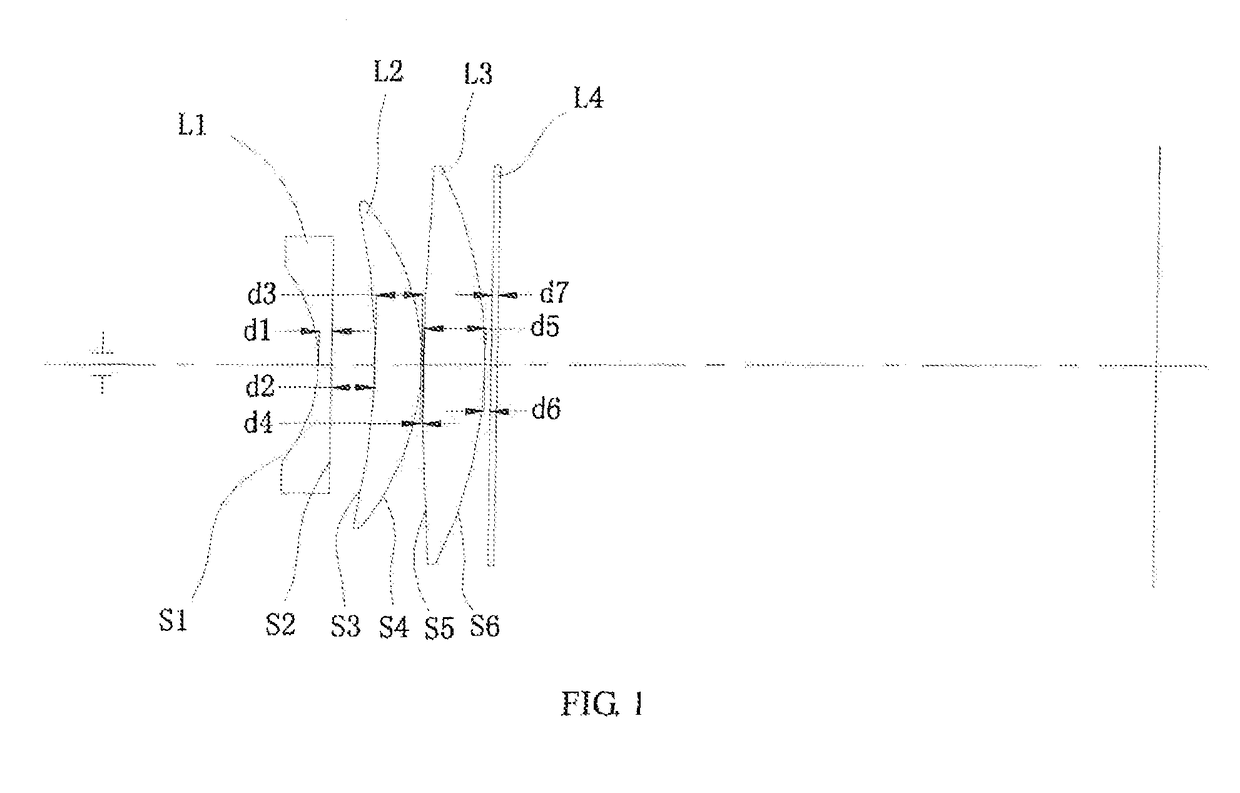

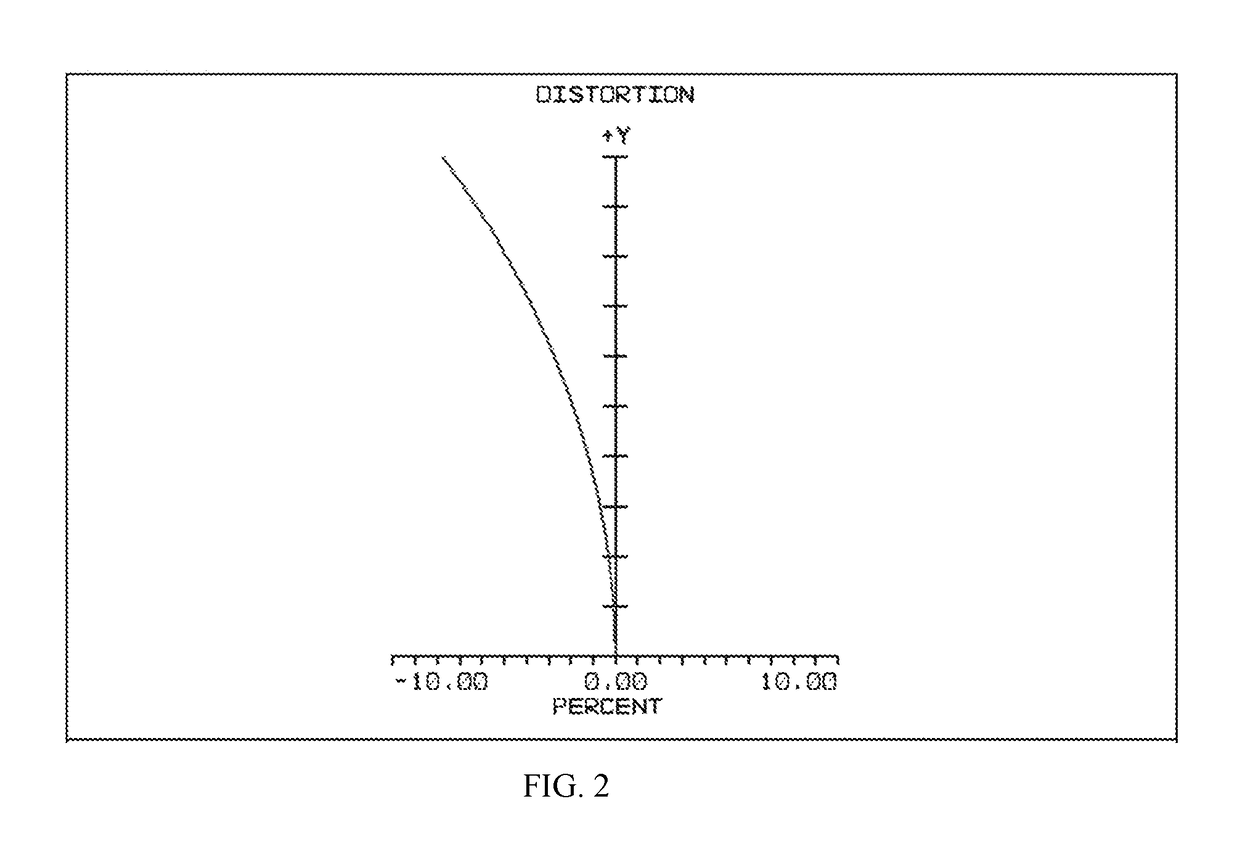

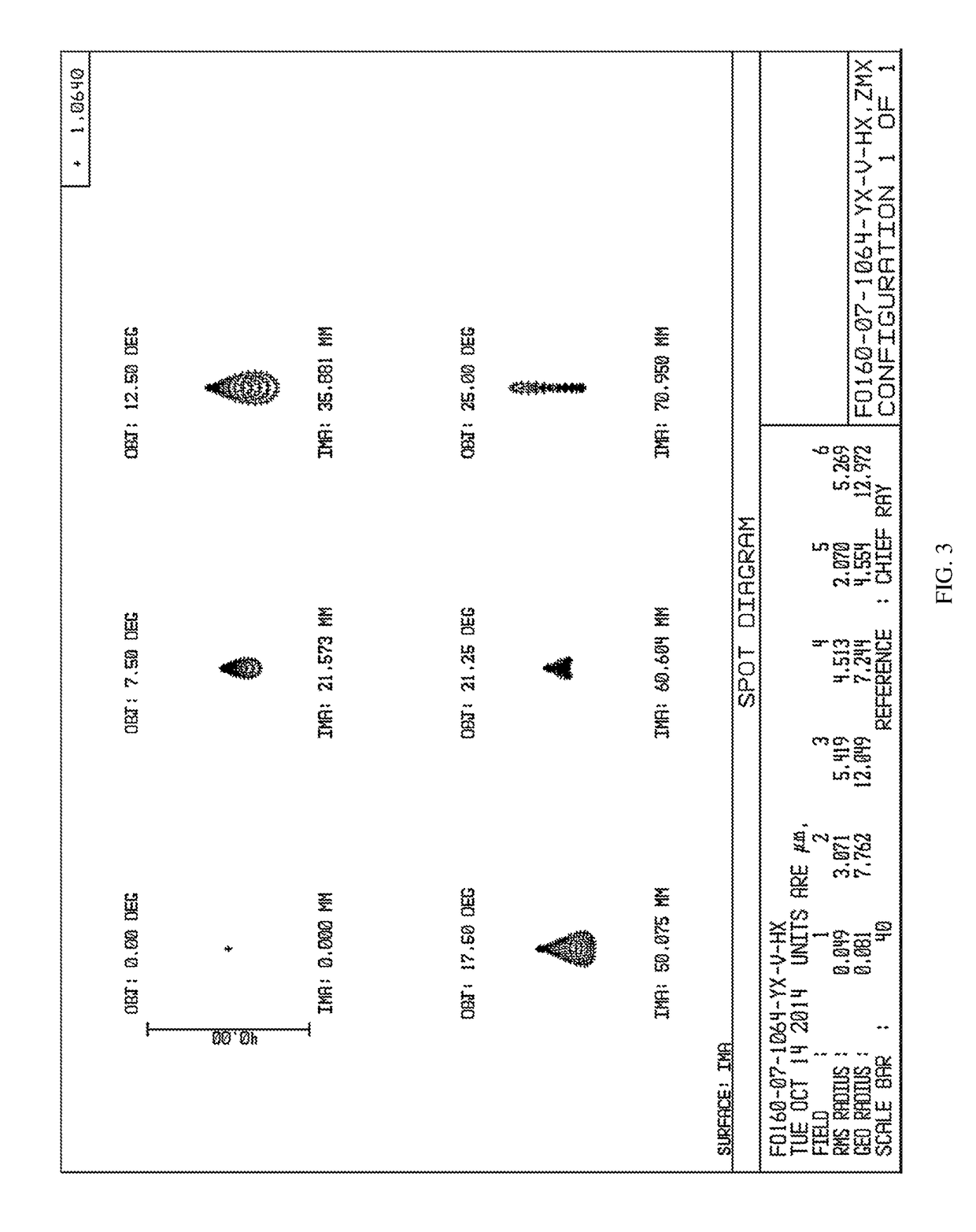

Optical lenses for laser marking

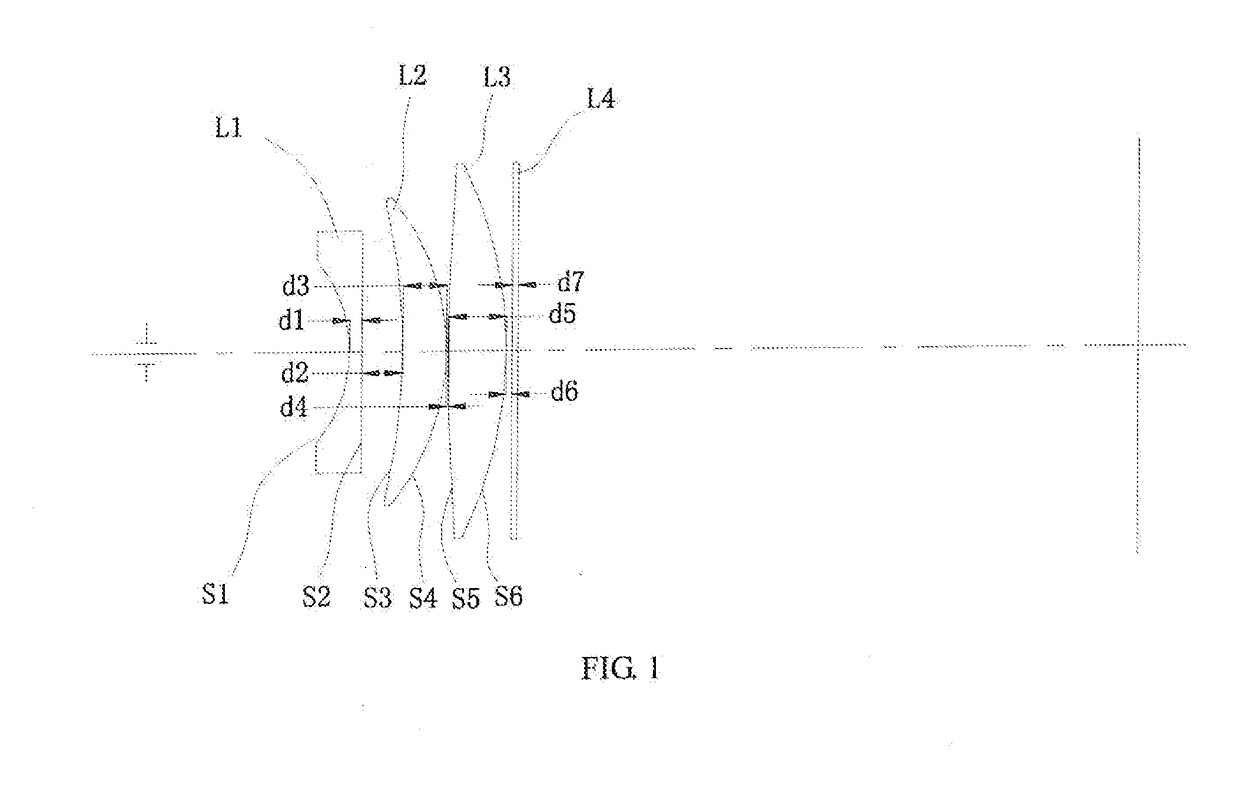

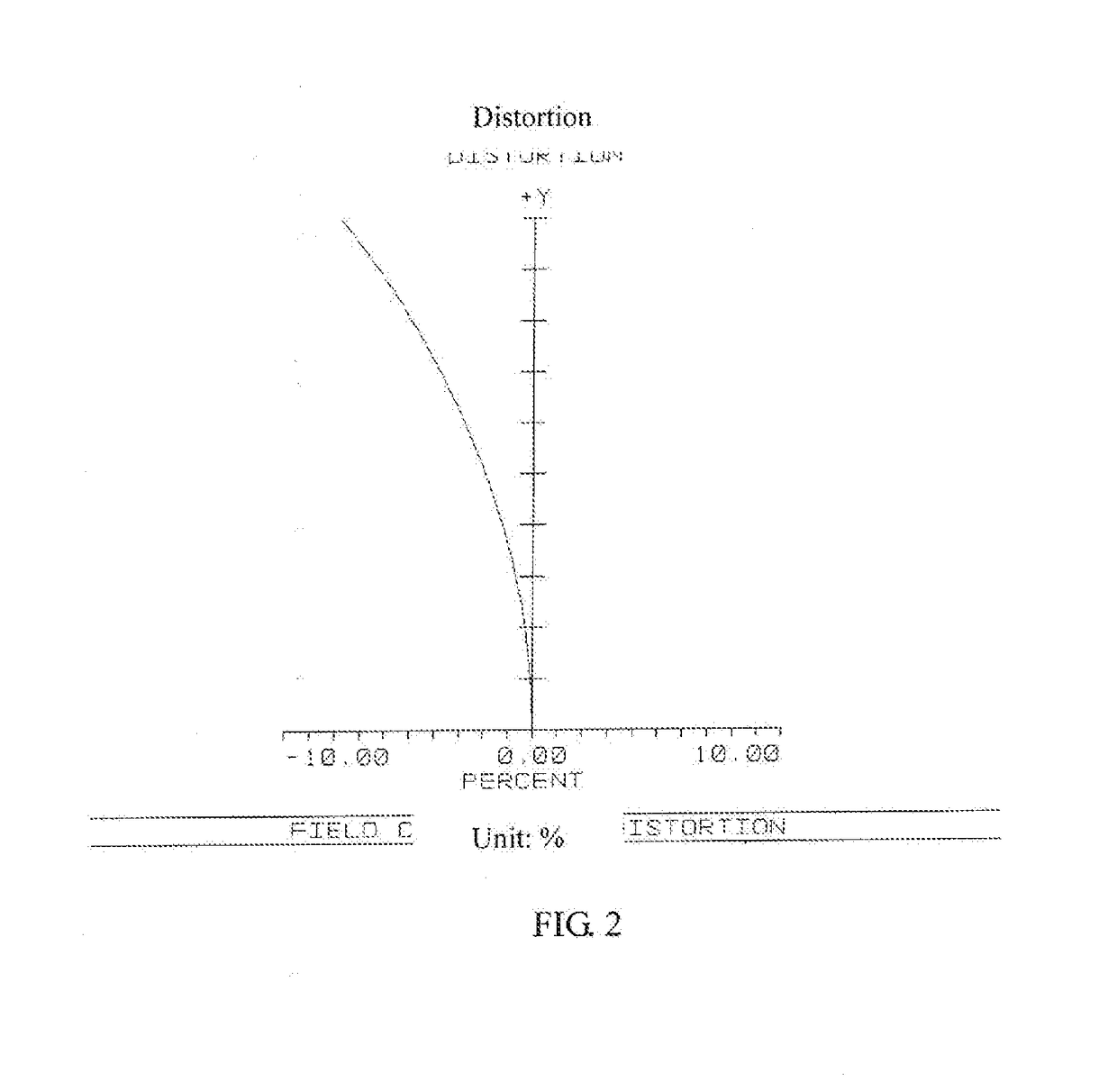

ActiveUS20170312851A1High engraving qualityHigh engrave speedLaser beam welding apparatusOptical elementsOptoelectronicsLenticular lens

An optical lens for laser marking includes a first lens (L1), a second lens (L2), and a third lens (L3), which are successively coaxially arranged along a transmission direction of incident light, wherein the first lens (L1) and the second lens (L2) are meniscus lenses, and the third lens (L3) is a biconvex lens; wherein the first lens (L1) has a first surface (S1) and a second surface (S2), the second lens (L2) has a third surface (S3) and a fourth surface (S4), the third lens (L3) has a fifth surface (S5) and a sixth surface (S6); the first surface (S1) to the sixth surface (S6) are successively arranged along the transmission direction of the incident light; wherein radii of curvature of the first surface to the sixth surface are −47±5% mm, ∞, −218±5% mm, −81±5% mm, 778±5% mm, and −142±5% mm, respectively; wherein central thicknesses of the first lens, the second lens, and the third lens are 4±5% mm, 15±5% mm, and 18±5% mm, respectively. The optical lens for laser marking not only has high engraving quality, but also has a high engraving speed with a higher efficiency than conventional engraving lens.

Owner:HANS LASER TECH IND GRP CO LTD

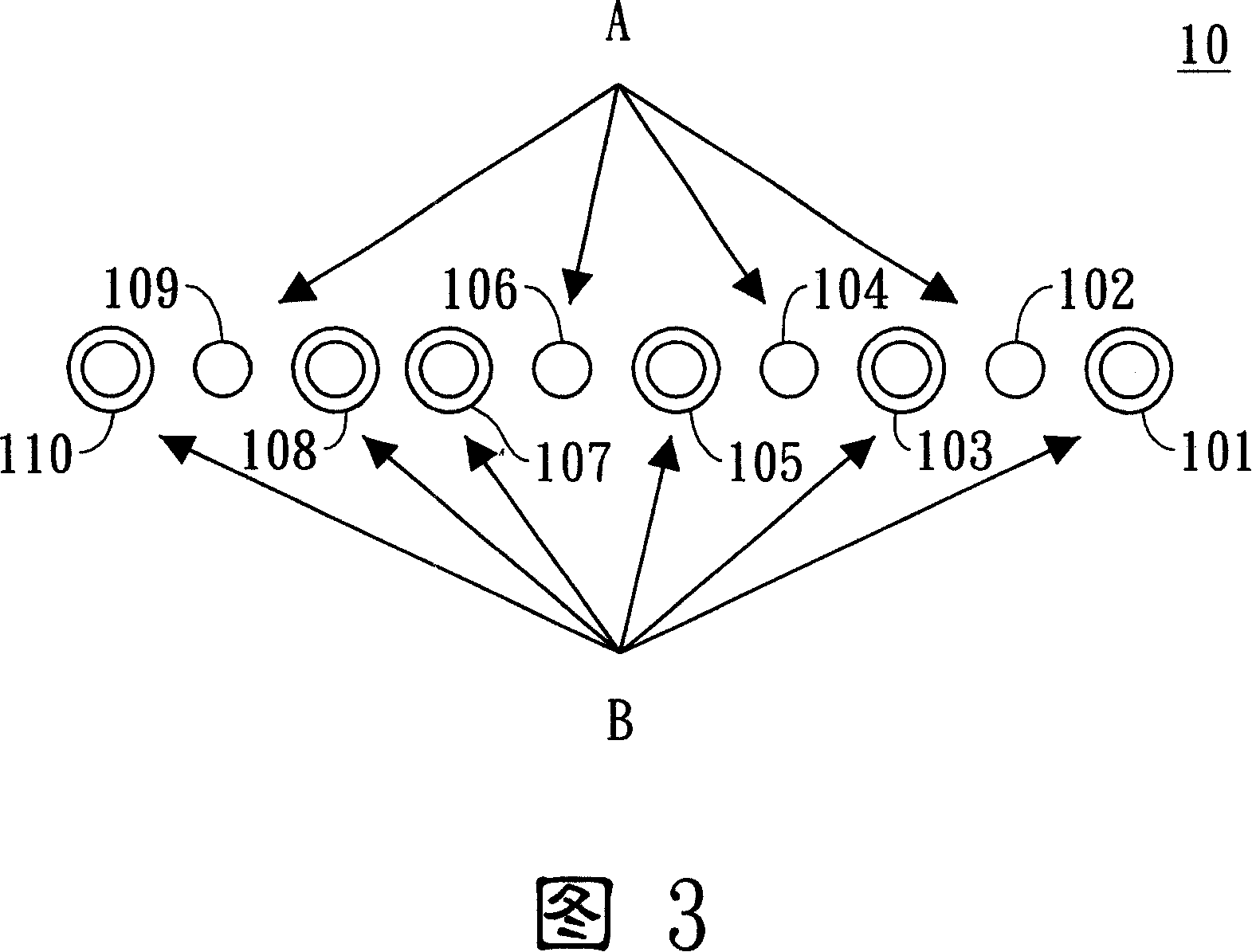

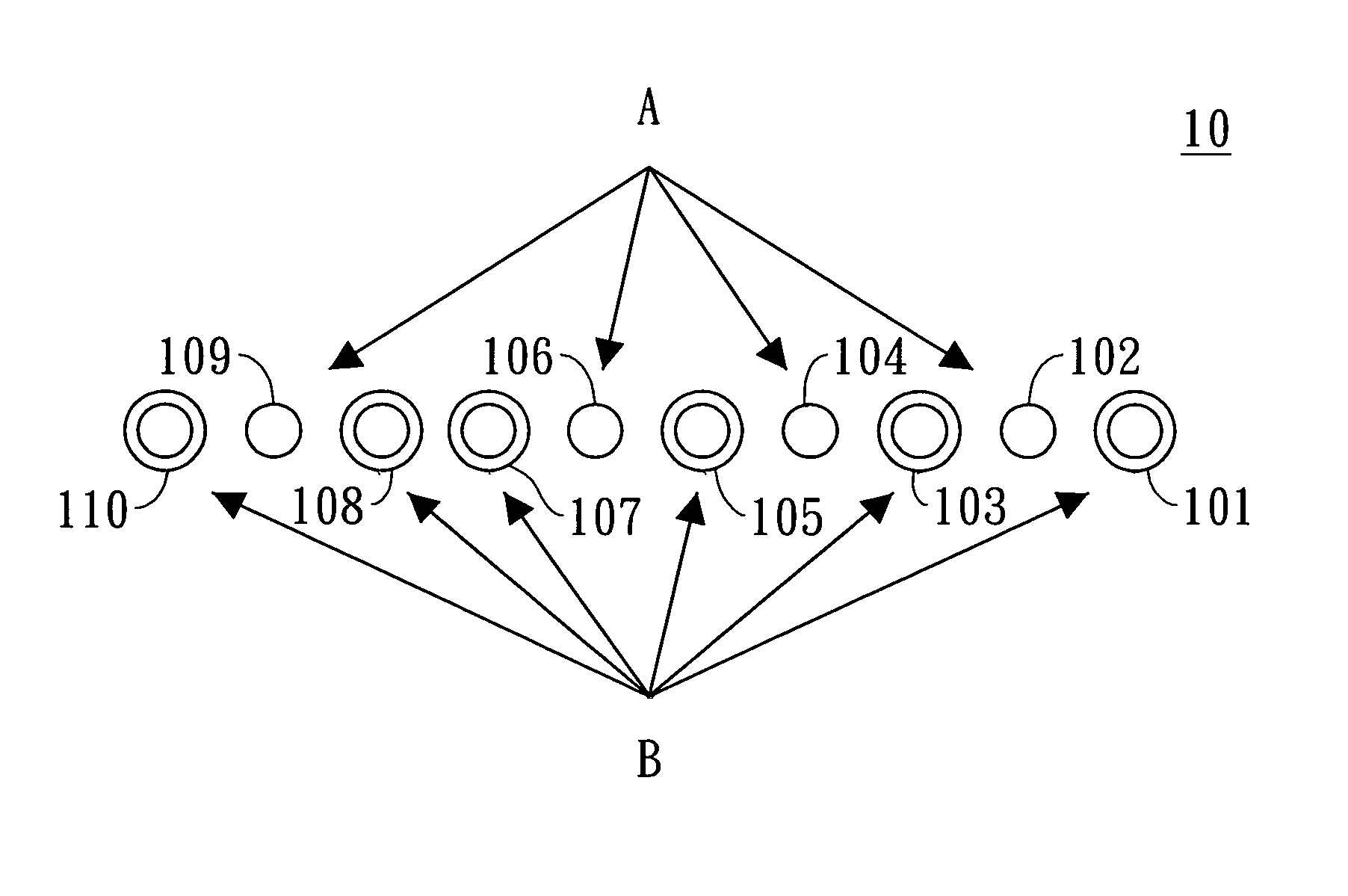

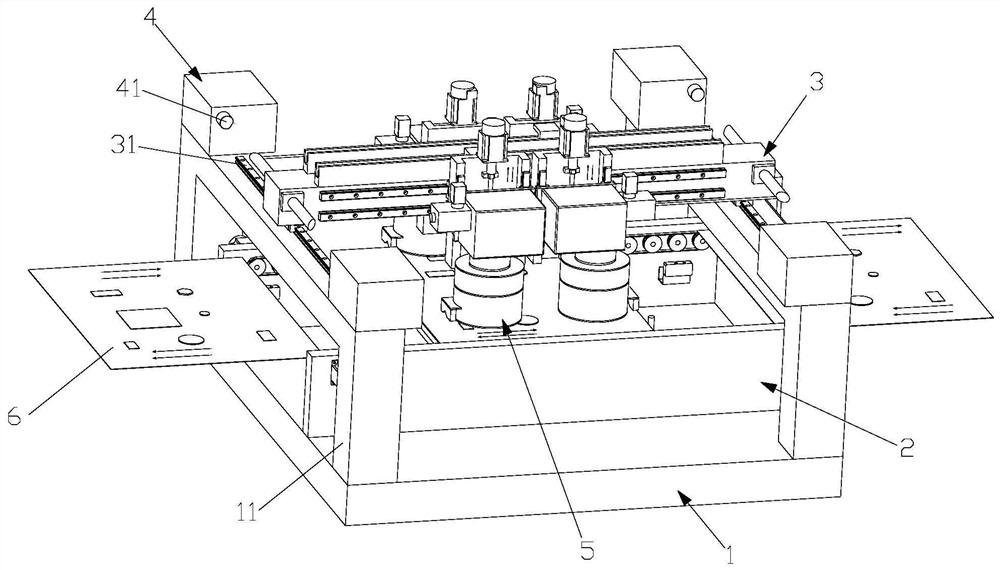

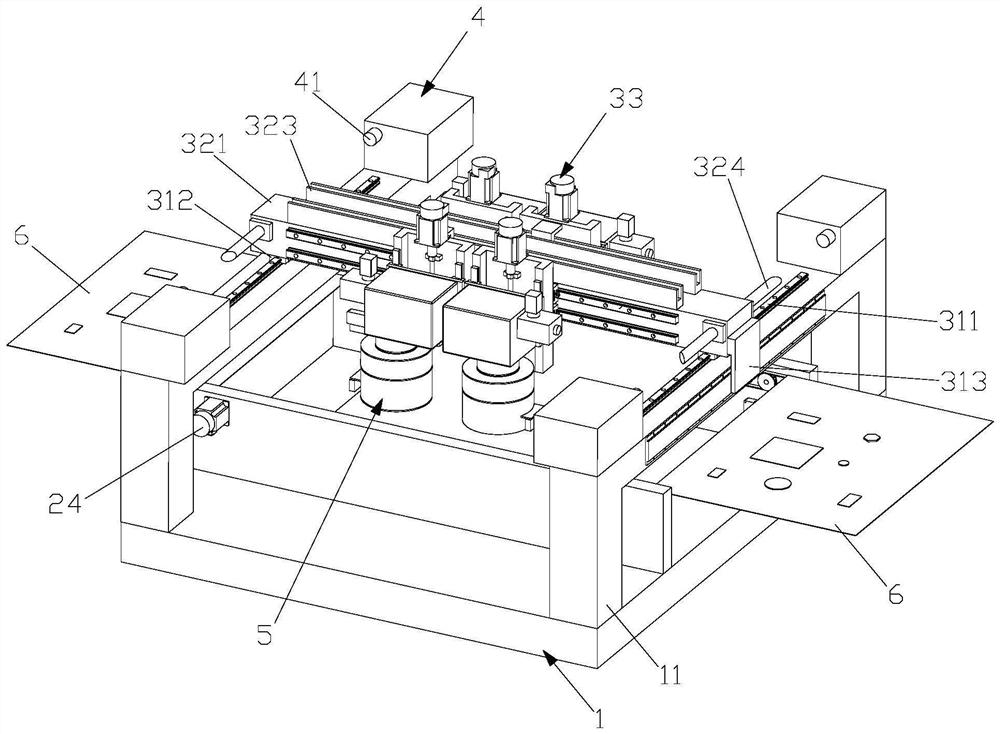

Multi-laser-head carving device and carving method thereof

PendingCN112091439AAvoid bendingImprove engraving qualityWelding/cutting auxillary devicesAuxillary welding devicesErbium lasersMaterials science

The invention relates to a multi-laser-head carving device and a carving method. The multi-laser-head carving device comprises a base, a conveying rail mechanism, a three-dimensional positioning mechanism, laser devices, a carving mechanism and a control module. The conveying rail mechanism is fixed on the base through opposite belt pulley fixing plates, the three-dimensional positioning mechanismis slidably mounted on supports, the laser devices are fixed on the supports, the carving mechanism is mounted on the three-dimensional positioning mechanism and carries out XYZ three-dimensional movement under the action of the three-dimensional positioning mechanism, and lasers emitted by the laser devices fall into substrates after being refracted multiple times to carve the substrates. The device is combined with the carving method, the problems existing in traditional carving equipment can be solved, the machining speed and the machining efficiency of the substrates are improved, meanwhile, detection can be carried out while carving is carried out, a PLC outputs the carving quality while the substrates are output, and the carving quality of the substrates is visually known.

Owner:深圳市易安锐自动化设备有限公司

Engraving equipment for wood product processing and using method thereof

InactiveCN112008810AStable positionRealize the engraving workProfiling/shaping machinesThreaded pipeGear wheel

The invention discloses engraving equipment for wood product processing. The engraving equipment comprises a base and a fixing frame, a first motor is arranged on the side wall of one side of the base, first sliding rods are arranged at the two ends in the base correspondingly, the two first sliding rods are fixedly arranged on the inner walls of the two sides of the base correspondingly, and a bolt is matched with a threaded pipe, so that a circular clamping plate is fixed on a transmission gear, and wood products needing to be machined are installed in multiple clamping grooves in the circular clamping plate. The output end of an adjusting motor drives a driving gear to rotate, the driving gear is positioned in the circular plate and is in meshed connection with the transmission gear, the transmission gear is driven to rotate, then the circular clamping plate is driven to rotate, and the angle and direction of the wood products on the circular clamping plate are changed, so that a carving machine head can carve all the wood products on the circular clamping plate conveniently, machining of the multiple wood products is completed at a time, manual position adjustment of all the wood products is not needed, and the carving efficiency is improved.

Owner:阜南县艺达工艺品有限公司

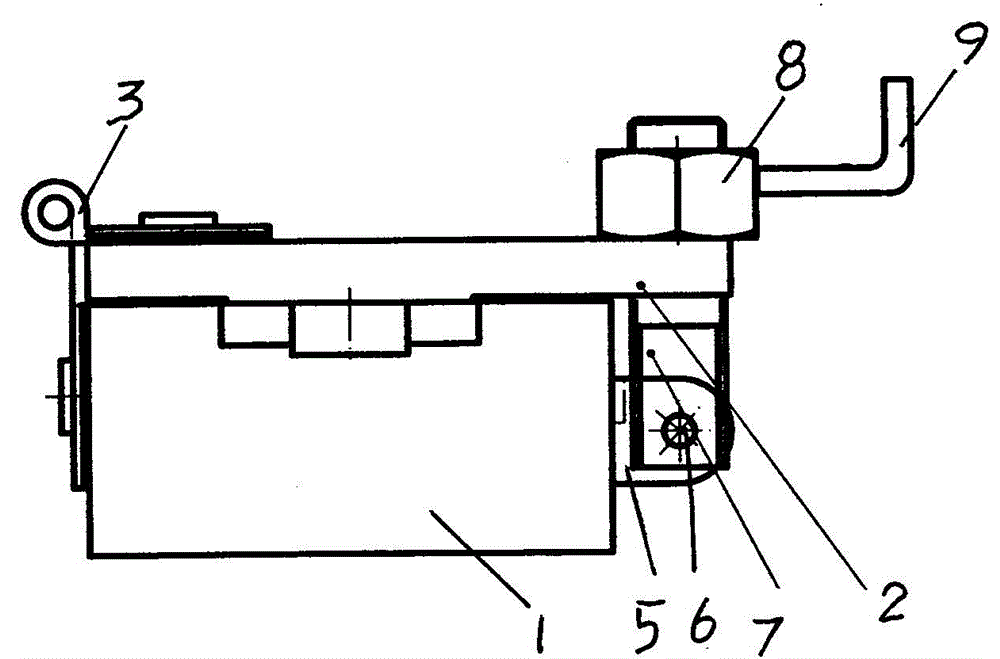

Novel cup device

ActiveCN107097576AQuick centering operationEasy to operateOther artistic work equipmentsEngravingEngineering

The invention discloses a novel cup device. The novel cup device comprises a control frame, a clamping part, an engraving part and a locking part, wherein the clamping part is fixed to the upper surface of the control frame; the engraving part is installed at the midpoint of the locking part; and the locking part is installed on the upper surface of the part, at the right side of the clamping part, of the control frame, and is capable of smoothly sliding in a left-right direction. The novel cup device disclosed by the invention is simple in structure, convenient and fast to operate, firm in clamping, and capable of realizing automatic adjustment for an engraving position, improving the accuracy of the engraving position, increasing the engraving efficiency and improving the engraving quality.

Owner:平湖市浩鑫塑胶股份有限公司

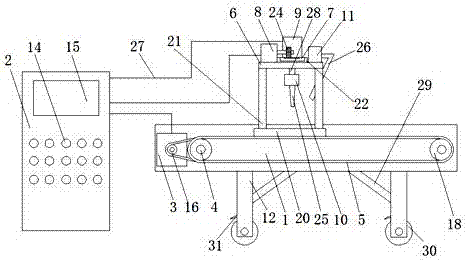

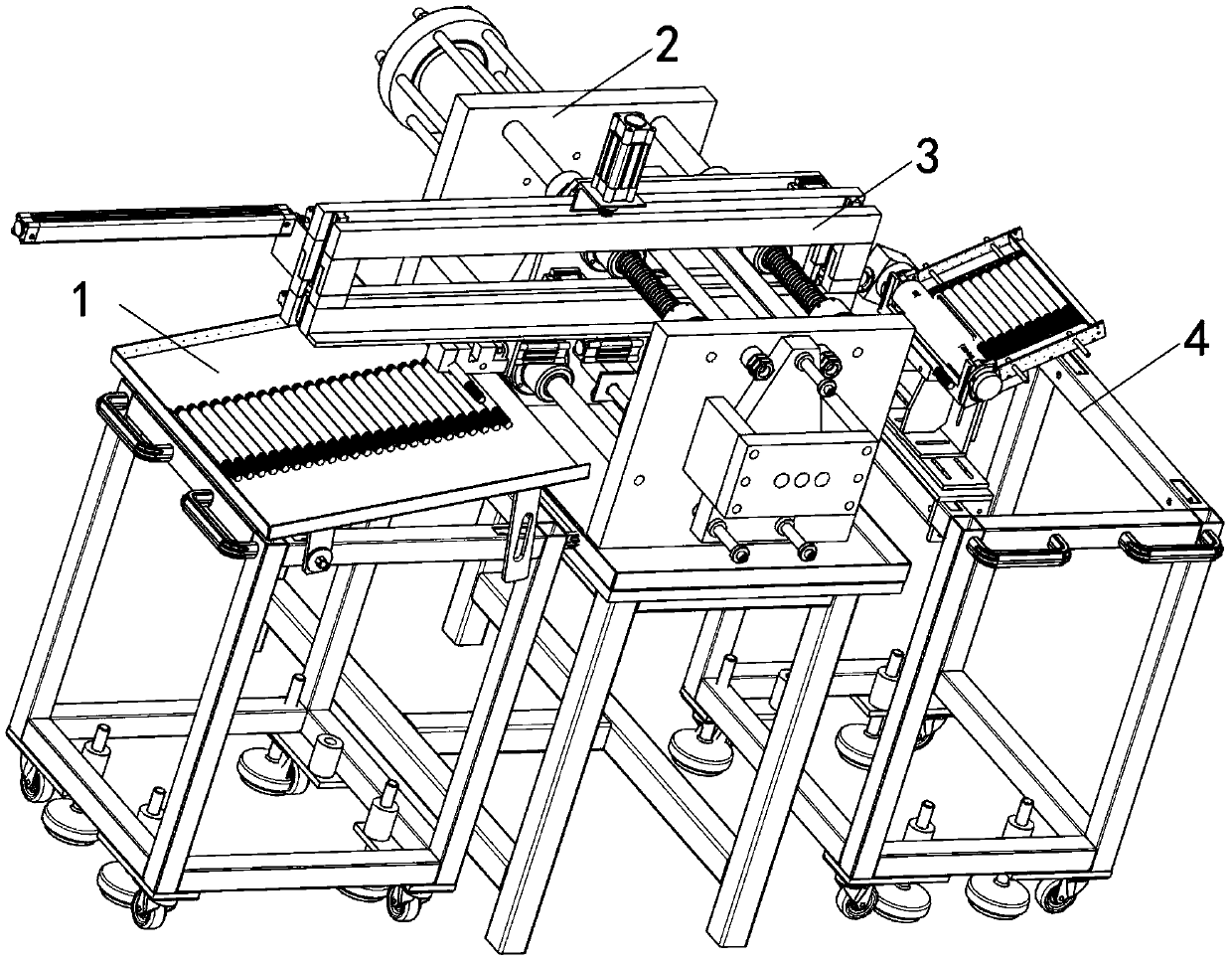

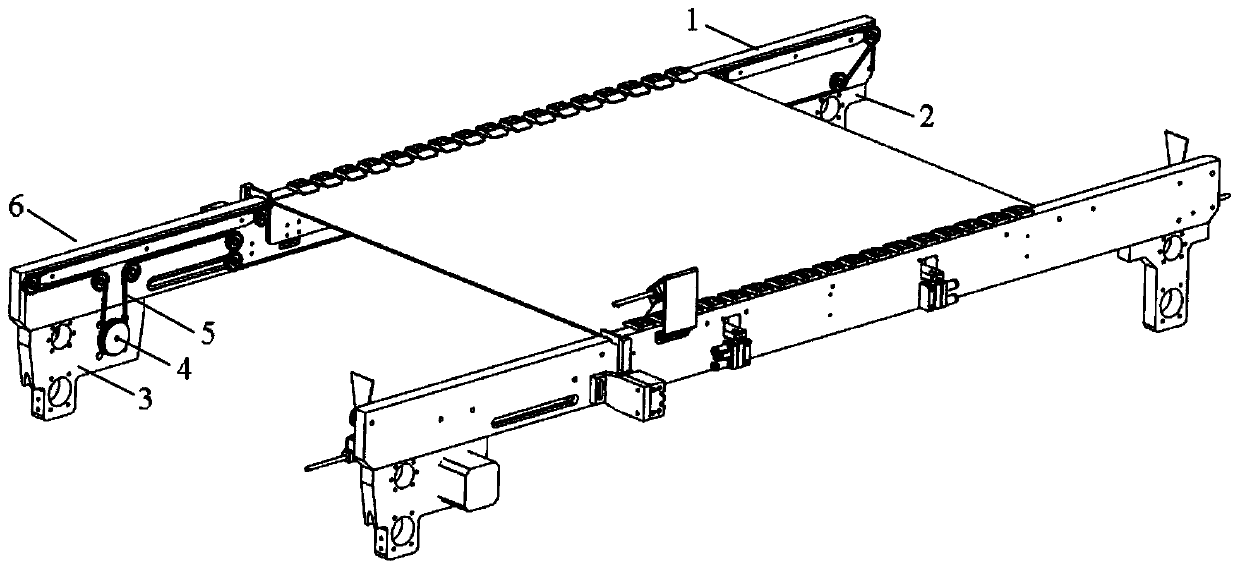

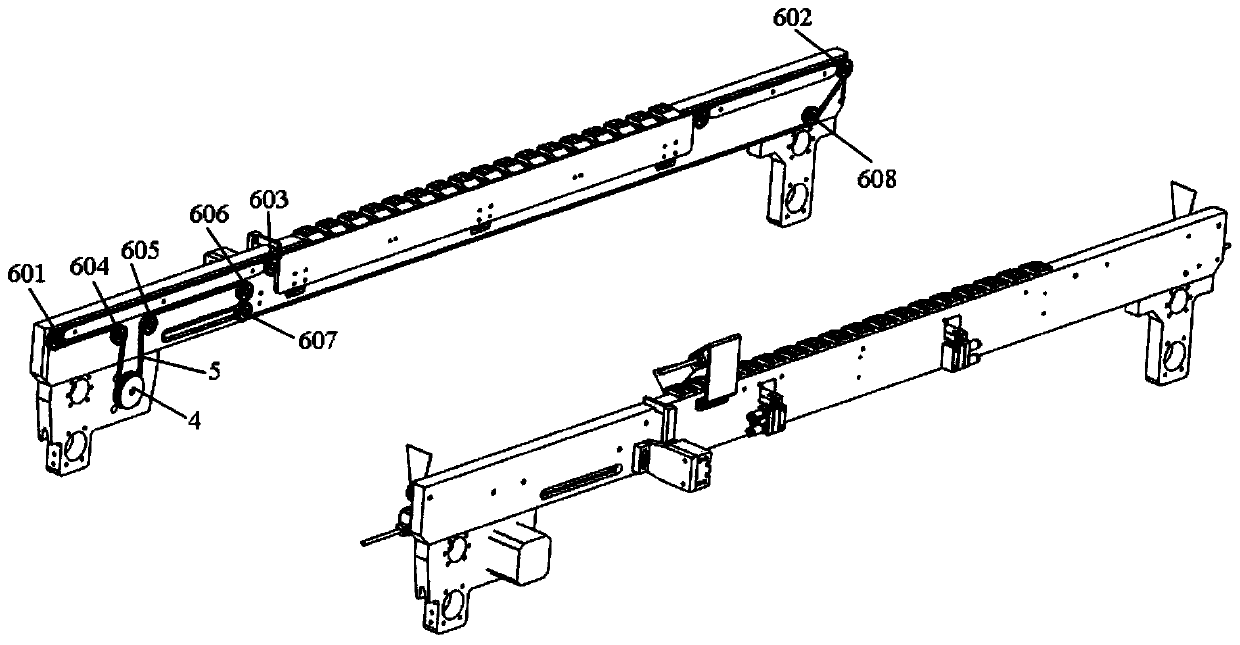

Conveying and carving mechanism for electronic accessory processing assembly line and working method of conveying and carving mechanism

ActiveCN109515049AEasy to moveMobile solidOther artistic work equipmentsModel makingHobbingEconomic benefits

The invention discloses a conveying and carving mechanism for an electronic accessory processing assembly line. The conveying and carving mechanism for the electronic accessory processing assembly line comprises a front transmission table, an inner transmission table, a carving disc and a back transmission table, wherein the inner transmission table is arranged between the front and the back transmission tables, the front and back transmission tables are separately connected with both ends of the inner transmission table through bolts, and the carving disc is arranged at the upper end of the inner transmission table. The conveying and carving mechanism for the electronic accessory processing assembly line has the beneficial effects that a plurality of tooth rings drive rotating sleeves torotate through a plurality of rolling teeth arranged on the side walls of the tooth rings at equal radians to drive electronic accessories to move and be transported, and the electronic accessories being transported and moves more smoothly and reliably on the mechanism are ensured; and a third motor on the back transmission table drives a tilting and conveying disk to reverse and adjust the angleof the electronic accessories, so that the mechanism is ensured to be more accurate and suitable during transporting the electronic accessories with different sizes to a next processing point position, and the flexibility of the use is ensured. The mechanism has convenient operation, high automation degree of working, good social and economic benefits, and is suitable for popularization and use.

Owner:徐州彤宇自动化科技有限公司

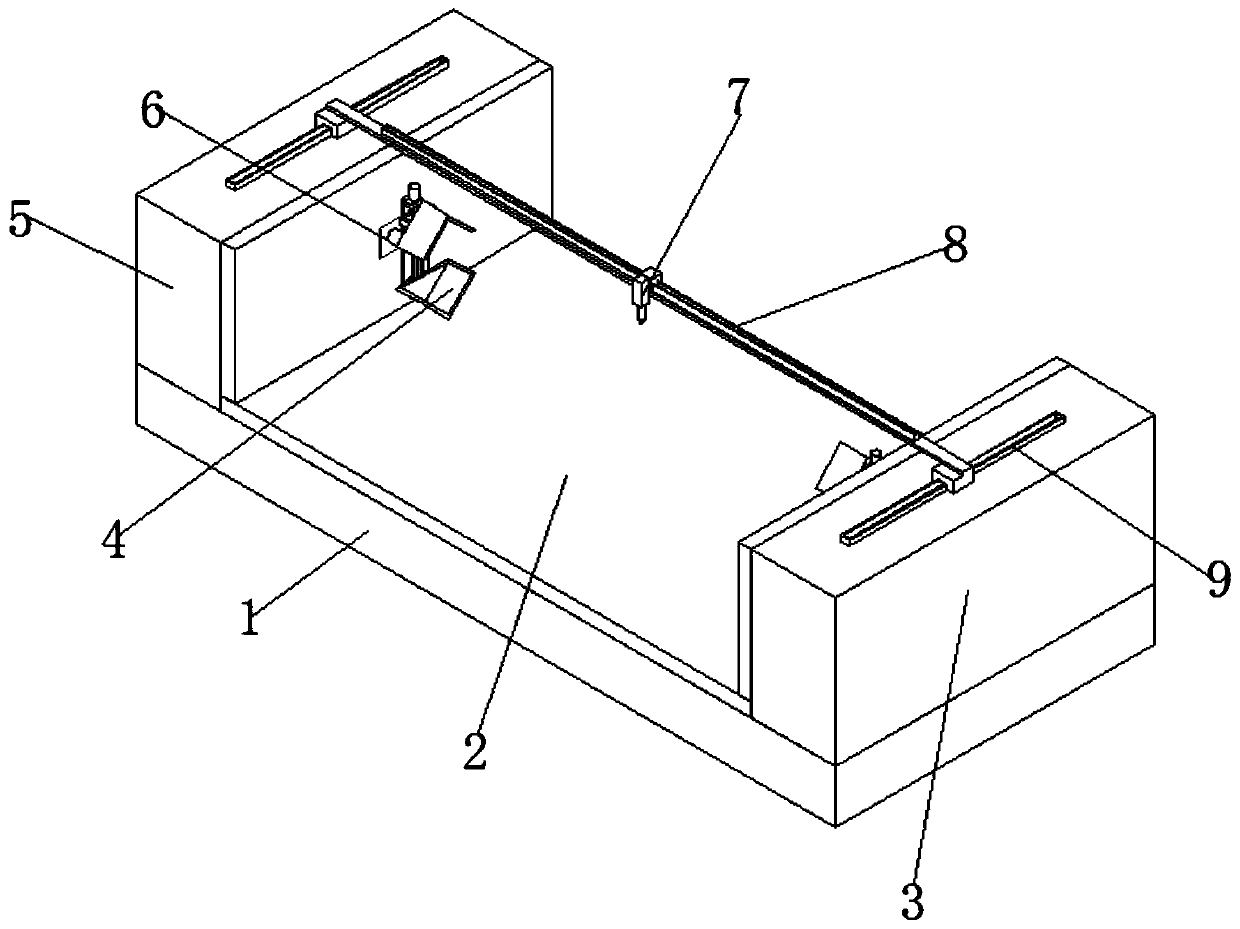

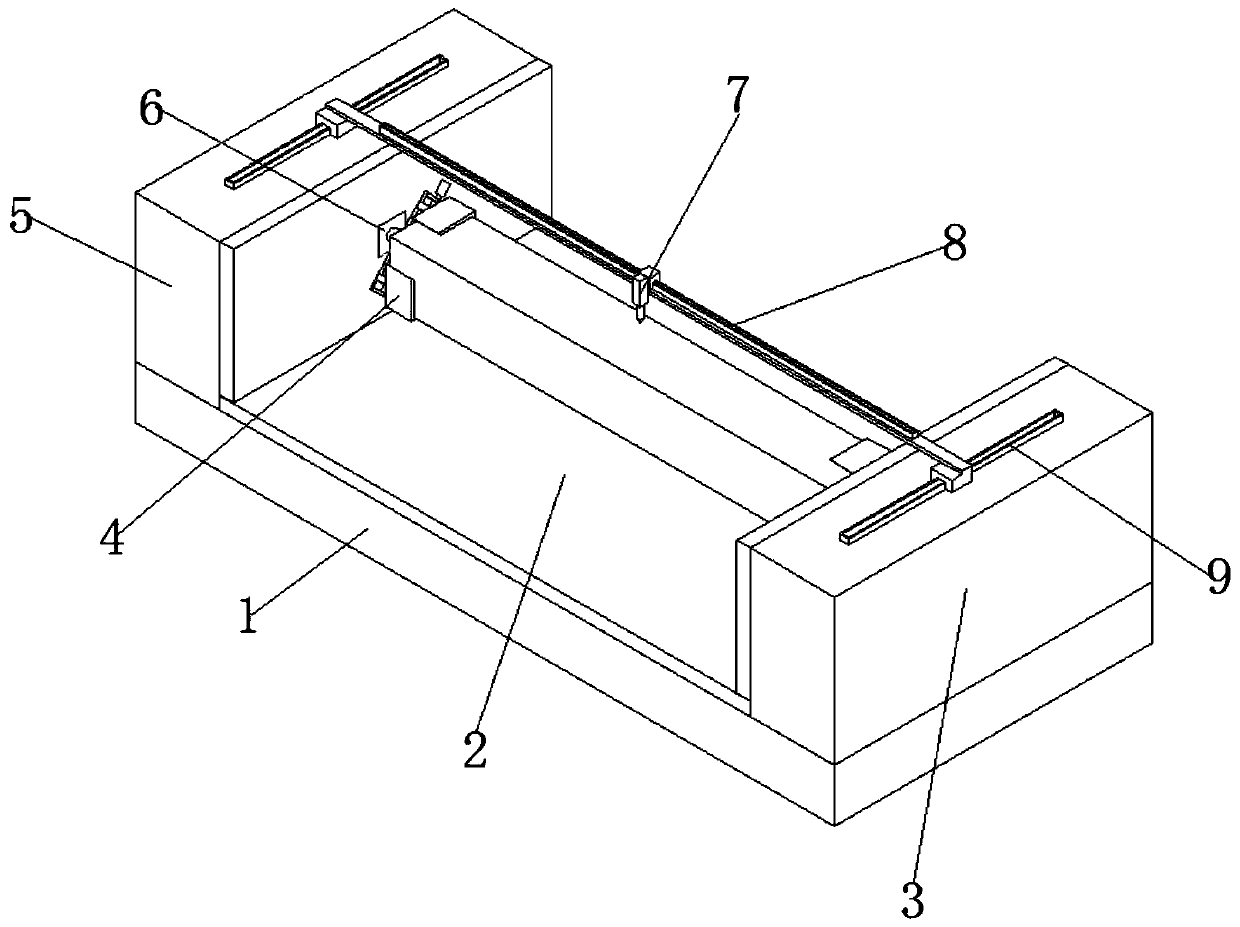

Small laser engraving machine for cubic column wood block

The invention provides a small laser engraving machine for a cubic column wood block and relates to the field of laser equipment. The small laser engraving machine comprises a base, an operation tablefixedly connected to the top of the base, a first case fixedly connected to one side of the operation table, a second case fixedly connected to the other side of the operation table, a Y-direction guide rail fixedly connected to the top of the first case and the top of the second case, an X-direction guide rail in sliding fit with the Y-direction guide rail, and a laser head in sliding fit with the X-direction guide rail. According to the small laser engraving machine for the cubic column wood block, when a workpiece in a cubic column shape is machined, at first, the workpiece in the cubic column shape is arranged between two clamping mechanisms, then an electric pushing rod is started, the electric pushing rod extends to enable the position of one clamping mechanism to get close to the other clamping mechanism, thus the distance between the two clamping assemblies is matched with the workpiece in the cubic column shape, then rotating handles on the two clamping mechanisms are rotated, and the rotating handles drive a first screw rod and a second screw rod to rotate synchronously.

Owner:SUZHOU MIKE LASER TECH SERVICE CO LTD

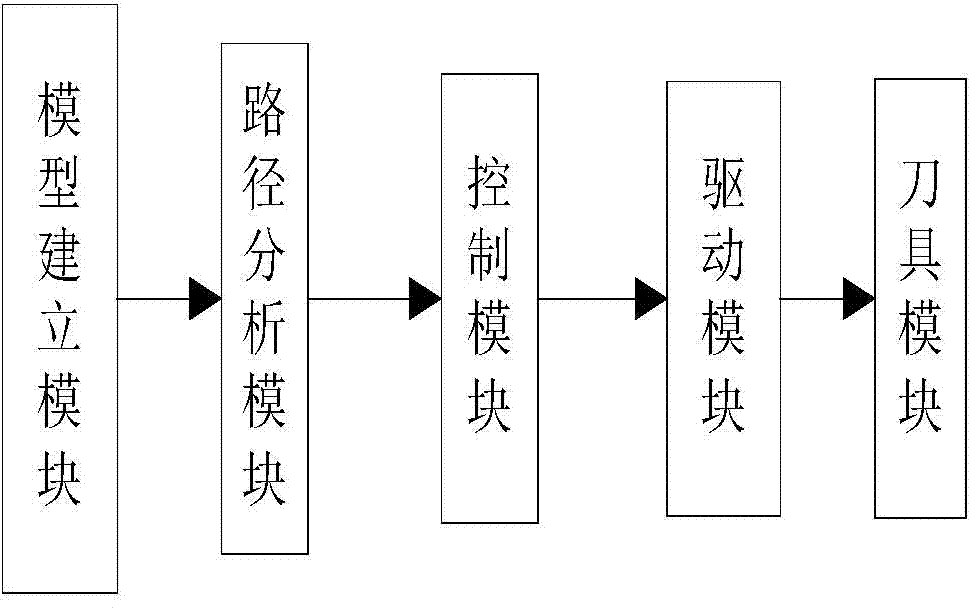

Layered carving system

ActiveCN104842699AReal-time detection of qualityImprove work efficiencyDecorative surface effectsSpecial data processing applicationsReference modelComputer module

The invention discloses a layered carving system. The layered carving system comprises a model establishing module, a path analysis module, a control module, a driving module and a tool module, wherein the tool module comprises more than one movable tool for carving a blank body; the driving module is connected with the tool module, and is used for driving the tool to move; the model establishing module is used for establishing a carving model; the path analysis module is connected with the model establishing module, and is used for generating a plurality of carving paths according to the carving model; the feeding depth of each point on each carving path relative to a preset reference model is the same; the control module is connected with the path analysis module and the driving module respectively, and is used for generating a control command according to the carving path in order to control the driving module to drive the tool module to work. Through adoption of the layered carving system, layered carving of the blank body can be realized, so that the problem of missing of carving or excessive carving due to different feeding depths and untimely response in the carving process of the tool is solved, and the rejection rate of the blank body is lowered.

Owner:ANHUI YIWEI TRADE CO LTD

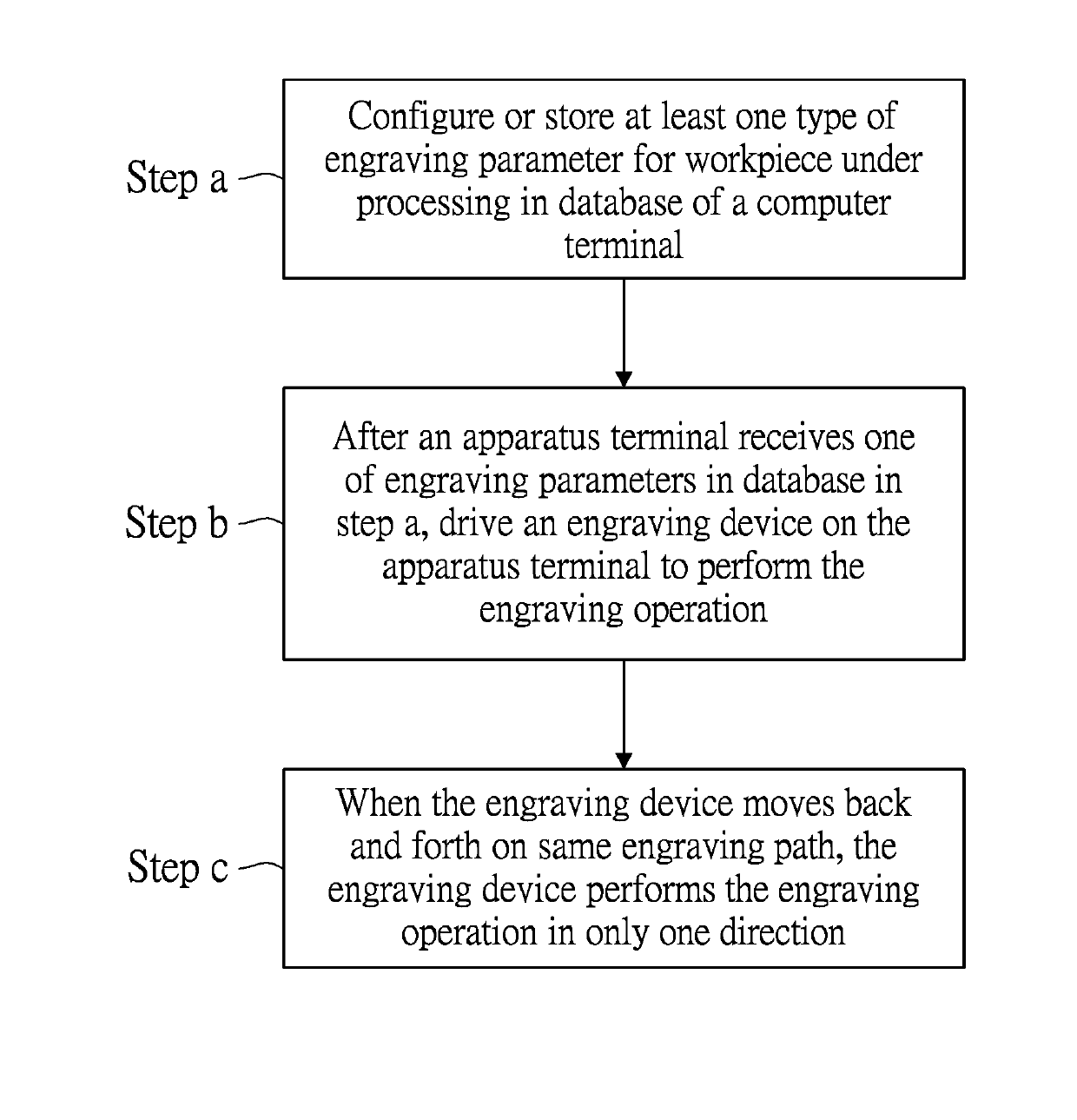

Method for improving engraving quality of laser engraving machine

InactiveUS20190337096A1Low costImprove precisionLaser beam welding apparatusEngravingLaser engravingComputer terminal

A method for improving engraving quality of a laser engraving machine is provided. At least one type of engraving parameter for a workpiece under processing is configured or stored in a database of a computer terminal. After an apparatus terminal receives one of the engraving parameters in the database, an engraving device on the apparatus terminal is driven to perform an engraving operation. When the engraving device moves back and forth on the same engraving path, the engraving device performs the engraving operation in only one direction.

Owner:XINGYUN COMP

Environment-friendly and pollution-free laser engraving machine

PendingCN113681169AQuality assuranceKeep healthyGas treatmentDispersed particle filtrationLaser engravingElectric machinery

The invention provides an environment-friendly and pollution-free laser engraving machine. The environment-friendly and pollution-free laser engraving machine comprises a working base, an engraving assembly, a fixing assembly and an environment-friendly assembly, the fixing assembly is arranged above the working base, the engraving assembly is arranged right above the fixing assembly, the environment-friendly assembly is arranged on one side of the engraving assembly, stable fixing is carried out on an object needing to be engraved is placed on the fixing assembly, vertical supports are arranged on the two sides of the top of the working base, the engraving assembly is arranged between the two vertical supports, the engraving assembly comprises a first motor, a lead screw, a sliding sleeve, a telescopic column, a laser generator and a laser head, the output end of the first motor is connected with the lead screw, the output end of the first motor is connected with the sliding sleeve, the surface of the lead screw is sleeved with the sliding sleeve, and the telescopic column is arranged at the bottom of the sliding sleeve. According to the environment-friendly and pollution-free laser engraving machine, the first motor, the lead screw, the sliding sleeve, the telescopic column, the laser generator and the laser head are used in cooperation, stable engraving is carried out on the object needing to be engraved, and the engraving position can be adjusted.

Owner:江苏觅科激光设备有限公司

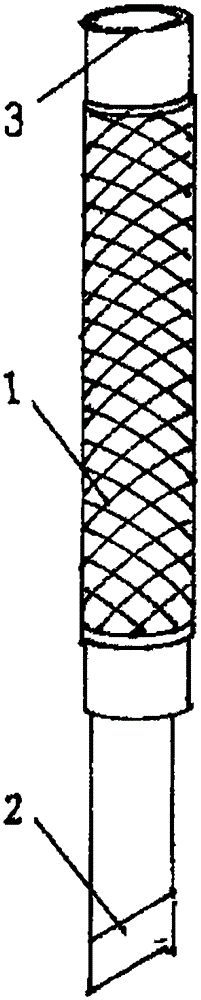

Electric carving knife with shockproof structure

The invention discloses an electric carving knife with a shockproof structure. The electric carving knife with the shockproof structure comprises a coil body and a shell body, and shock absorption devices are arranged on the upper side and the lower side of the coil body in the direction of an iron core separately. Each shock absorption device comprises a first elastic shock absorption body, an arched shock absorption elastic piece and a second elastic shock absorption body, wherein the arched shock absorption elastic piece is arranged between the first elastic shock absorption body and the second elastic shock absorption body, the first elastic shock absorption body is attached to the inner sidewall of the shell body, and the second elastic shock absorption body is attached to the coil body. Limiting fixation blocks are arranged at the two ends of each shock absorption device. The vibration of the electric carving knife with the shockproof structure is minimized through multiple shockabsorption, the hand feeling of an operator using the carving knife is improved, the stability is good, the carving quality can be improved, and the electric carving knife is simple in structure, good in shock absorption effect and suitable for practical use.

Owner:中江县圣泉菊花石艺术有限公司

Carving knife provided with pencil for use and used for carpenter

The invention provides a carving knife provided with a pencil for use and used for a carpenter. The tail portion of a handle of a carving knife body is provided with a handle sleeve in which the pencil can be inserted. In this way, the wood carving knife can be provided with the pencil at the same time, and use is more convenient when the carpenter performs carving.

Owner:李健

Wooden ashtray hand-carved frame

ActiveCN109334324ARaise the adjustment angleFacilitate the engraving processModel makingEngravingEngineering

The invention discloses a wooden ashtray hand-carved frame. The wooden ashtray hand-carved frame includes a engraving side frame, a bottom plate and a engraving fixing plate, wherein the engraving fixing plate is provided with a splint device; the inner top of the engraving side frame is provided with a rotating chute for the horizontal rotation of the engraving fixing frame; a clamping device isarranged on the bottom surface of a rotating slider; the rotating slider is clamped in the rotating chute; a jacking device for driving the clamping device to move up and down is arranged in a jackingcavity; and the driving end of the jacking device is connected with a pedal device arranged on the bottom plate. The engraving fixing frame can not only drive an ashtray to rotate vertically, but also drive the ashtray to rotate horizontally in the arc-shaped rotating chute through the rotating slider, so that the adjustment angle of the ashtray is greatly improved, and the engraving process of the ashtray is greatly facilitated; and the horizontal rotation can be quickly stopped through the arrangement of a foot pedal, so that the smoothness of the engraving process is ensured, the operationis quick, convenient and stable, and the engraving efficiency and quality of the ashtray are greatly improved.

Owner:安徽姜尚工艺品有限公司

Press plate device and application method thereof

InactiveCN110877156ASolve the needs of only one-sided engravingOnly applicable to single-sided engraving requirementsLaser beam welding apparatusLaser engravingElectric machinery

The invention relates to a press plate device and an application method thereof. The press plate device comprises a fixing assembly, a driving assembly and a positioning assembly. The fixing assemblycomprises a set of supporting plates, two left supports and two right supports. One left support and one right support are fixed to the two ends of each supporting plate respectively. The driving assembly comprises a set of driving motors, and two belts. The driving motors are fixed to the two left supports or the two right supports respectively. Each belt is driven by a roller assembly. The roller assemblies are fixed to the supporting plates. The positioning assembly is used for positioning engraving steel. The application method is easy to operate and convenient to apply. The press plate device and the application method thereof overcome the defect that a driving assembly in an engraver in the prior art can just meet the requirements on single-sided engraving but double-sided engraving.The press plate device and the application method can meet the requirement of a laser engraver for double-sided engraving and conveying, and are flexible in operation, convenient to use, accurate incontrol, and higher in engraving efficiency and engraving accuracy with improvement on the quality of a finished product as a result.

Owner:苏州威百斯特智能科技有限公司

Optical lenses for laser marking

ActiveUS10213870B2Improve engraving qualityFast engravingLaser beam welding apparatusOptical elementsEngravingOptoelectronics

An optical lens for laser marking includes a first lens (L1), a second lens (L2), and a third lens (L3), which are successively coaxially arranged along a transmission direction of incident light, wherein the first lens (L1) and the second lens (L2) are meniscus lenses, and the third lens (L3) is a biconvex lens; wherein the first lens (L1) has a first surface (S1) and a second surface (S2), the second lens (L2) has a third surface (S3) and a fourth surface (S4), the third lens (L3) has a fifth surface (S5) and a sixth surface (S6); the first surface (S1) to the sixth surface (S6) are successively arranged along the transmission direction of the incident light; wherein radii of curvature of the first surface to the sixth surface are −47±5% mm, ∞, −218±5% mm, −81±5% mm, 778±5% mm, and −142±5% mm, respectively; wherein central thicknesses of the first lens, the second lens, and the third lens are 4±5% mm, 15±5% mm, and 18±5% mm, respectively. The optical lens for laser marking not only has high engraving quality, but also has a high engraving speed with a higher efficiency than conventional engraving lens.

Owner:HANS LASER TECH IND GRP CO LTD

Method for processing imitation wood carvings with waste materials

ActiveCN104875272BHigh hardnessImprove smoothnessWood working apparatusDomestic articlesEconomic benefitsPulp and paper industry

Owner:努尔买买提·吐松

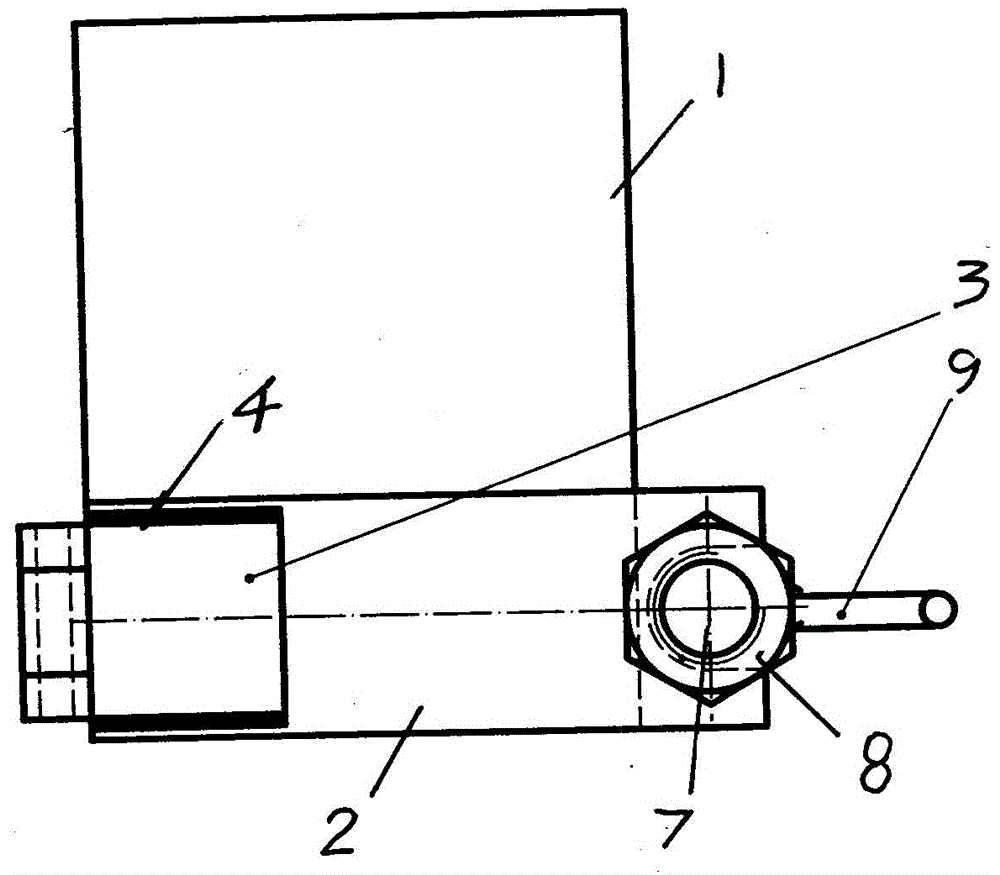

Mark engraving device

The invention provides a mark engraving device. A movable upper cover is arranged above a character head slot at one side of a base and is connected to one side face of the base through a hinge in a hinging manner, the other side face of the base is provided with a shaft seat which is connected to a flat lower end of a movable screw through a connecting shaft, the upper end of the movable screw is matched with a nut, the side face of the nut is welded with a right-angled rotating rod, the other end, opposite to the hinge hinged end, of the movable upper cover extends out of the character head slot, the end part of the end, extending out of the character head slot, of the movable upper cover is in a forked shape, and a groove in the middle of the forked-shape part is matched with the upper end of the movable screw. According to the mark engraving device, the connection manner of the original upper cover is changed into hinge connection, in such a way, fonts can be frequently replaced, and the detaching time is largely saved. Bolt and nut connection is adopted at the right side, and through screwing up a spanner on the nut, the upper cover can be tightly pressed, so that the phenomenon of font fuzz caused by looseness of character heads during marking can be avoided. The mark engraving device belongs to a mechanism suitable for engraving permanent marks after an end part of which the material diameter is greater than 30mm is forged to be flat.

Owner:TIANJIN JL RAILWAY TRANSPORT EQUIP

A wood engraving machine capable of automatic loading and unloading

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com