Environment-friendly and pollution-free laser engraving machine

A laser engraving machine, pollution-free technology, applied in the field of laser engraving machines, can solve problems such as waste products, operator and environmental hazards, and material slippage, and achieve the effects of easy use, guaranteed engraving quality, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

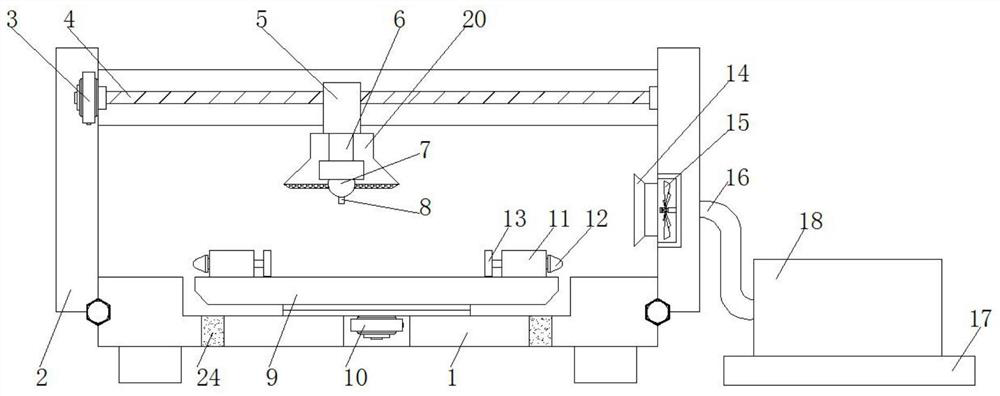

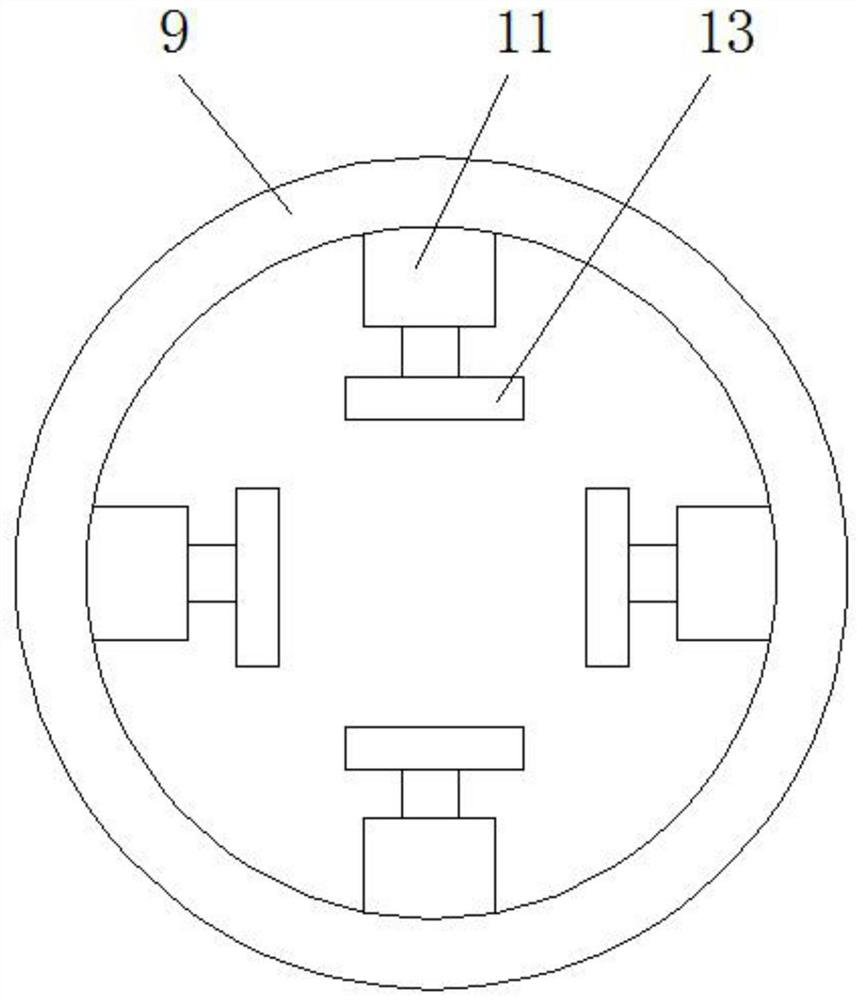

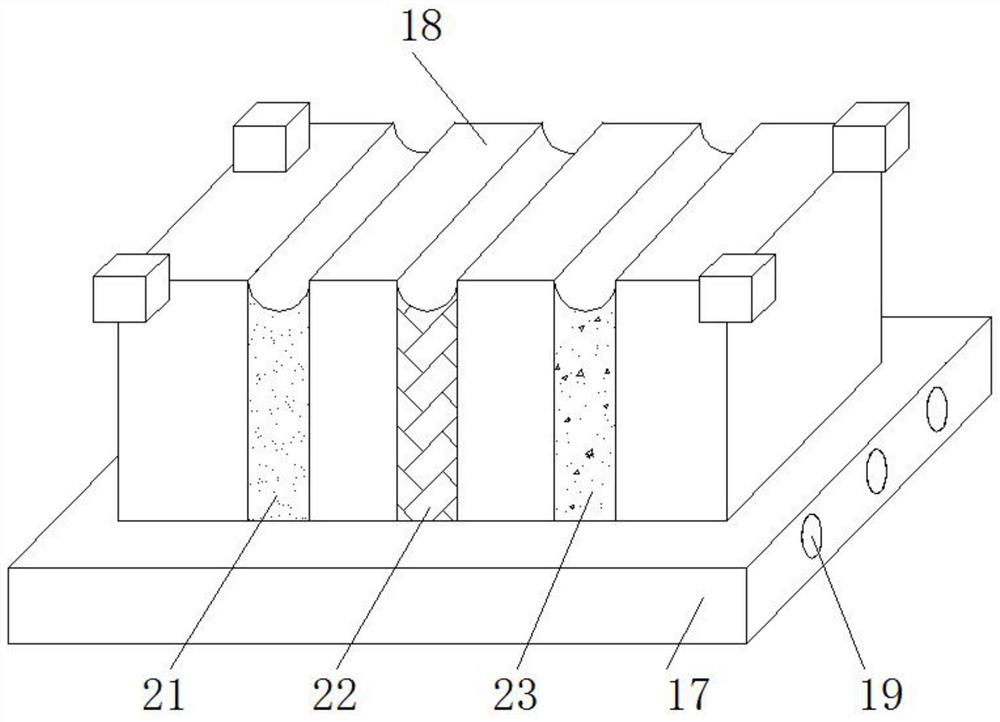

[0024] see Figure 1 to Figure 4 , the embodiment of the present invention discloses an environmentally friendly and pollution-free laser engraving machine, including a working base 1, an engraving component, a fixing component and an environmental protection component. An engraving assembly is provided, and an environmental protection assembly is provided on one side of the engraving assembly, and a vertical support 2 is provided on both sides of the top of the working base 1 by placing the item to be engraved on the fixing assembly, and the two groups of An engraving assembly is arranged between the vertical supports 2, and the engraving assembly includes a first motor 3, a screw mandrel 4, a sliding sleeve 5, a telescopic column 6, a laser generator 7 and a laser head 8, and the output end of the first motor 3 Connected with a screw rod 4, the motor model is Y90S-2, the surface of the screw rod 4 is sleeved with a sliding sleeve 5, the bottom of the sliding sleeve 5 is prov...

Embodiment 2

[0032] One side of the vertical support 2 is provided with a water tank 25, and the below of the water tank 25 is provided with a rotary nozzle 26, and the rotary nozzle 26 drives the water in the water tank 25 to spray out the laser head 8 while cooling down the temperature. The dust on the working base 1 is washed and finally discharged through the through hole 24 .

[0033] When this kind of environmentally friendly and pollution-free laser engraving machine is used, the items to be engraved are placed on the fixed component for stable fixation, and the engraving process is carried out through the engraving component. The air is absorbed and filtered, the first motor 3 drives the screw 4, the screw 4 drives the sliding sleeve 5, the sliding sleeve 5 drives the laser head 8 to move left and right, the telescopic column 6 drives the laser head 8 to move up and down for engraving, and through the second The motor 10 drives the rotating disk 9 to rotate, and adjusts the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com