An engraving fixture for ceramic processing

A ceramic processing and fixing device technology, which is applied in the field of ceramic processing, can solve the problems of poor fixing effect of magnetic tires, poor treatment effect of porcelain clay slag, and influence of magnetic tire engraving, so as to avoid scattering around and facilitate engraving operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

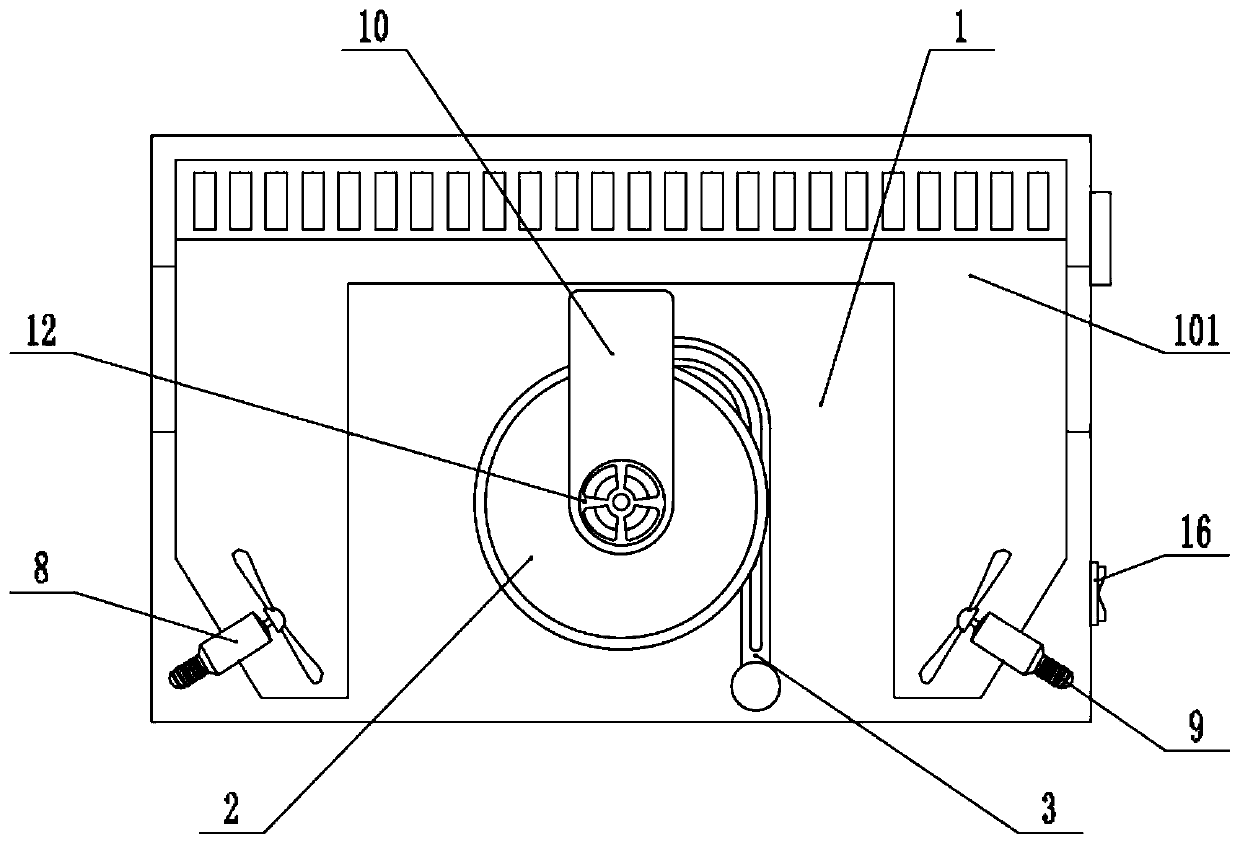

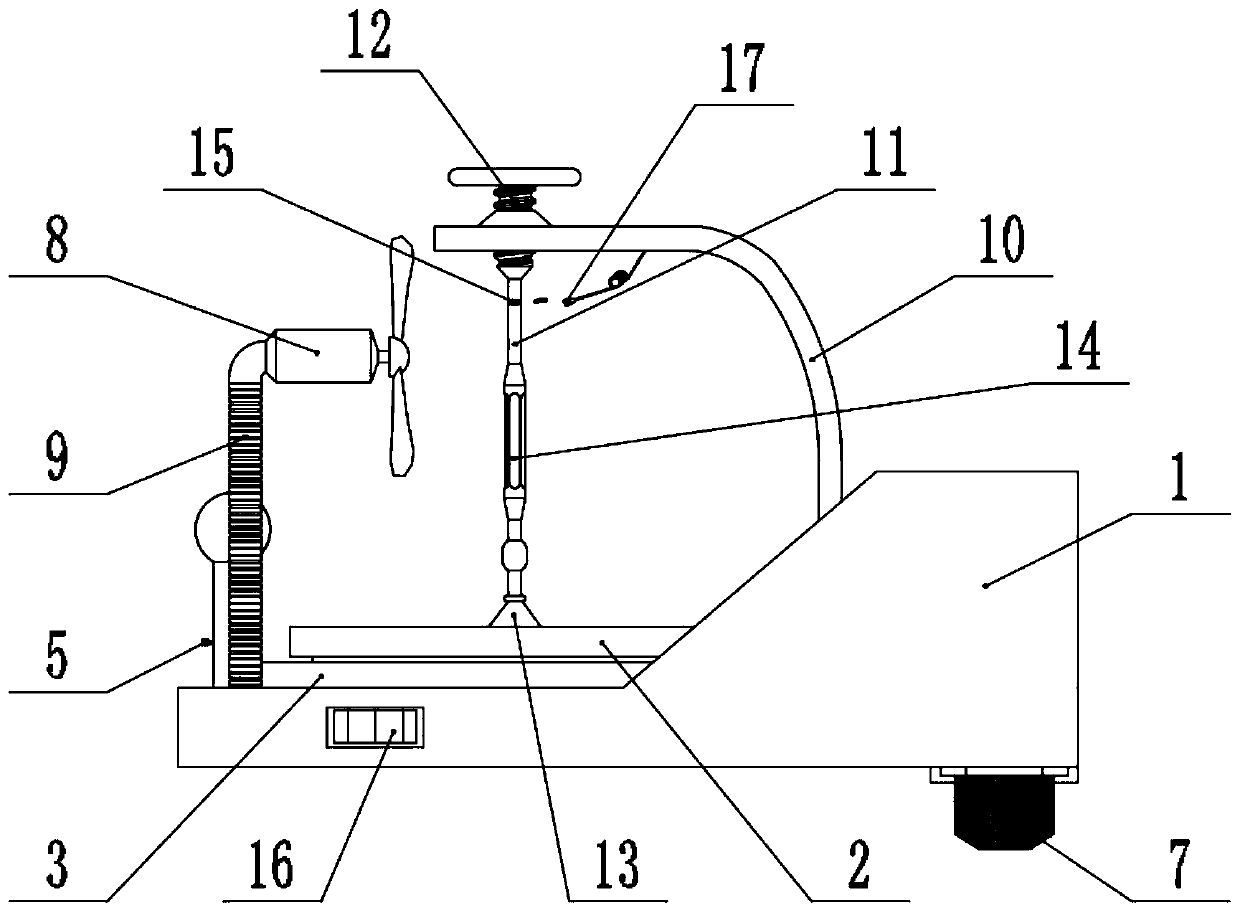

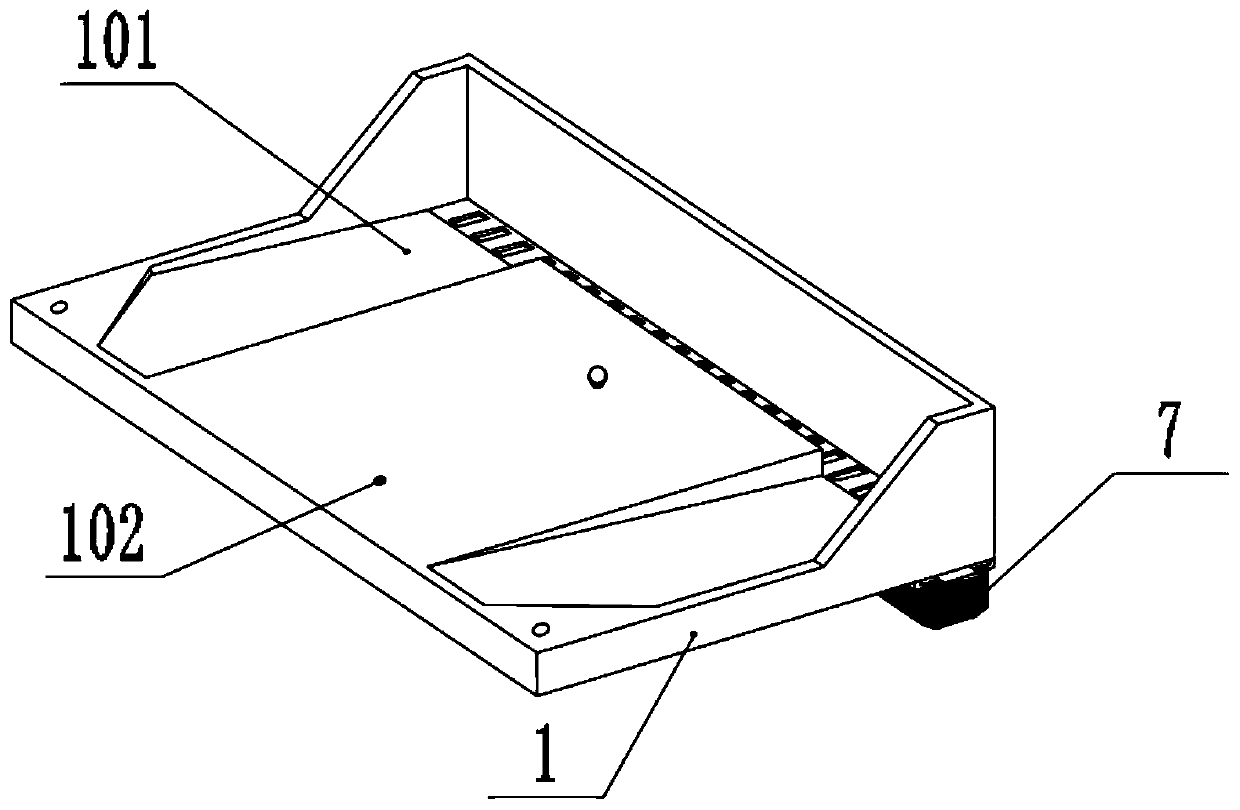

[0036] as attached figure 1 to the attached Figure 9 shown:

[0037]The invention provides an engraving and fixing device for ceramic processing, which includes an engraving table 1, a material leakage groove 101, a positioning groove 102, a turntable 2, a handle 3, a rubber pad 4, a latch 5, a spring 6, a net bag 7, a fan 8, Flexible support rod 9, support column 10, fixed rod 11, threaded connecting rod 12, latex block 13, lamp tube 14, small power jack 15, power switch 16 and small power plug 17; Leakage groove 101, and the bottom of leakage groove 101 is hollow shape; The front end of the top end face of the engraving table 1 is provided with a positioning groove 102, and the bottom of the latch 5 is slidably connected in the positioning groove 102; The top of the turntable 2 is circular Plate-shaped structure, and the turntable 2 is located on the top end surface of the engraving table 1; the turn handle 3 is an "L" strip structure, and the bottom of the turn handle 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com