Laser engraving machine engraving method

A laser engraving machine, random number technology, applied in engraving, decorative arts and other directions, can solve problems such as uneven visual perception of light and shade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

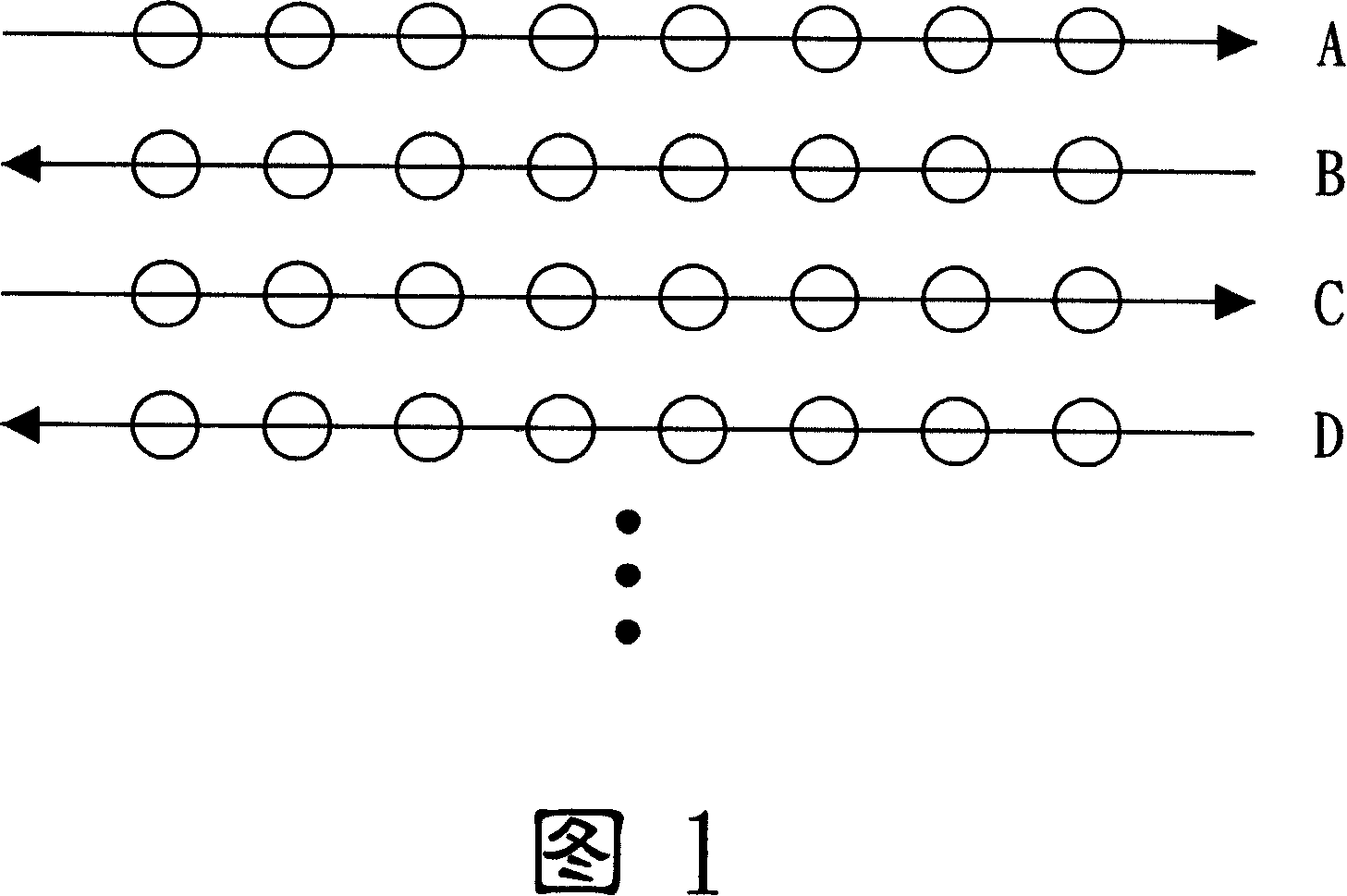

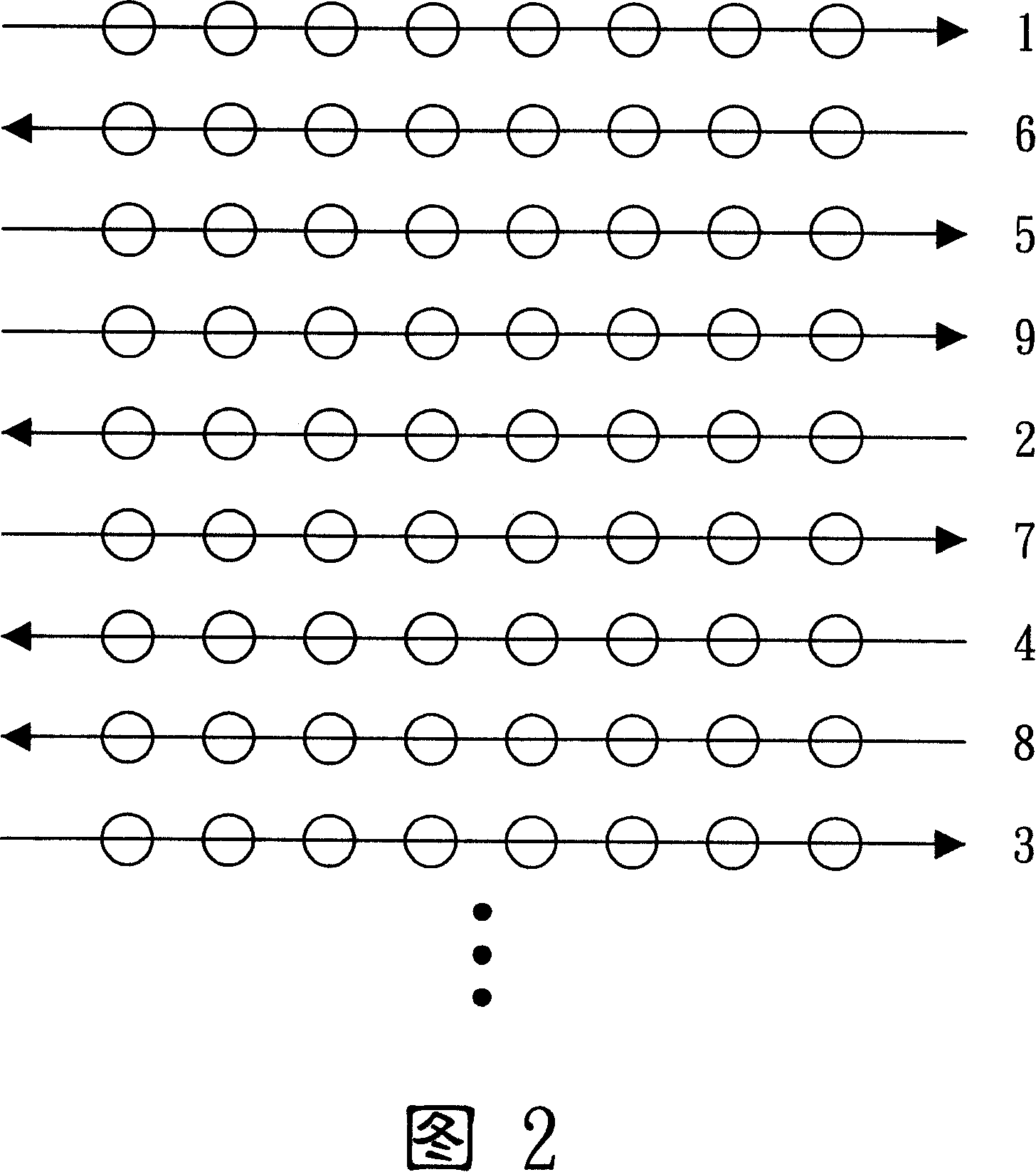

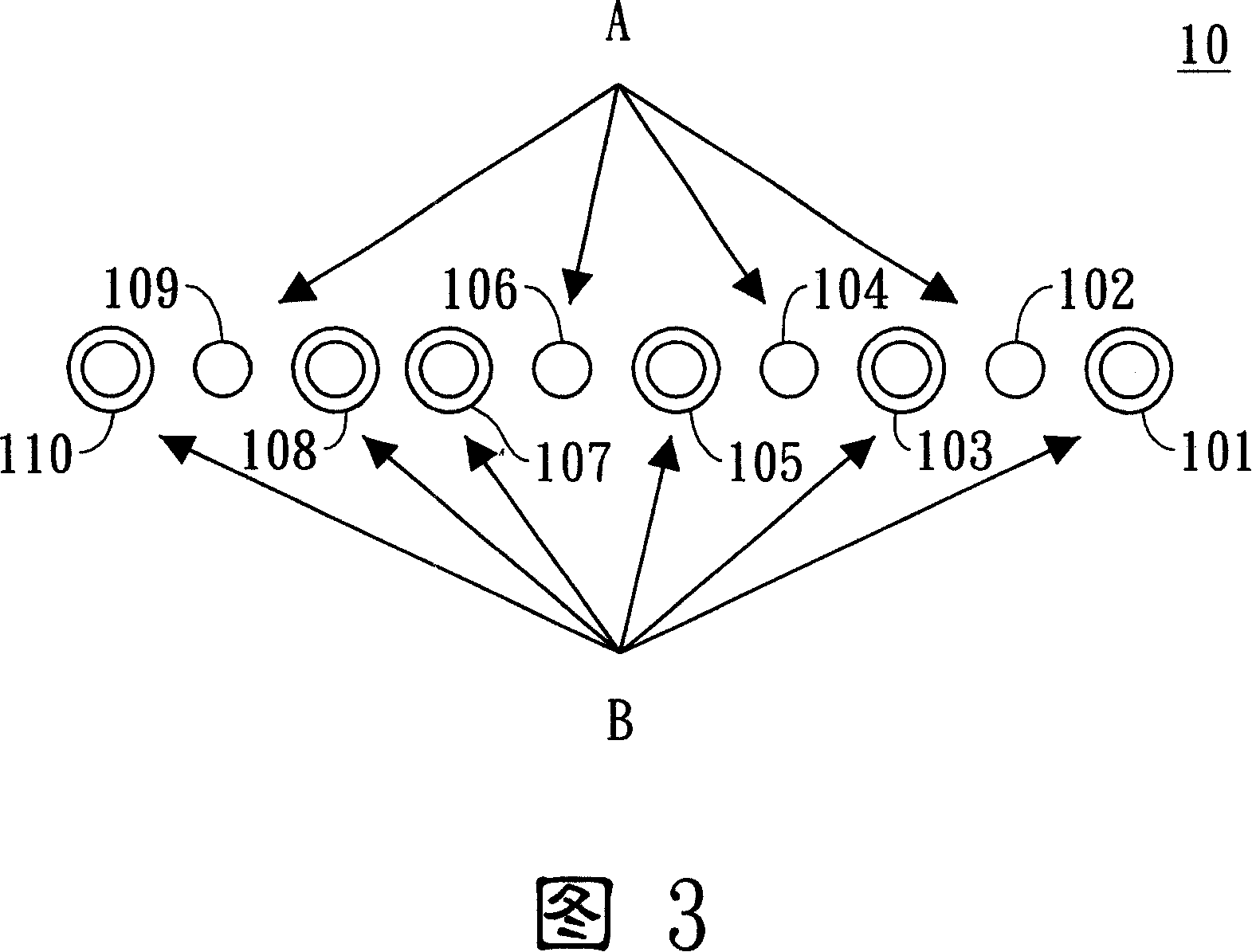

[0012] Please refer to Fig. 2, the content of the diagram is an embodiment of the engraving method of the laser engraving machine of the present invention, and it is characterized in that after the engraving device of the laser engraving machine carries out the data engraving of a horizontal engraving line 1, it proceeds in the skip mode. Data engraving of a horizontal engraving line 2.

[0013] The jumping mode mentioned above is one of jumping engraving of odd-numbered horizontal engraving lines, jumping engraving of even-numbered horizontal engraving lines or random number of horizontal engraving lines. As shown in Figure 2, the engraving device is carried out by jumping and engraving with a random number of rows of horizontal engraving lines, such as the first to ninth horizontal engraving lines in the drawing. After the data engraving of the horizontal engraving line 1 is completed, the The engraving device jumps to the horizontal engraving line 2 for data engraving, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com