Patents

Literature

219results about How to "Meet mass production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

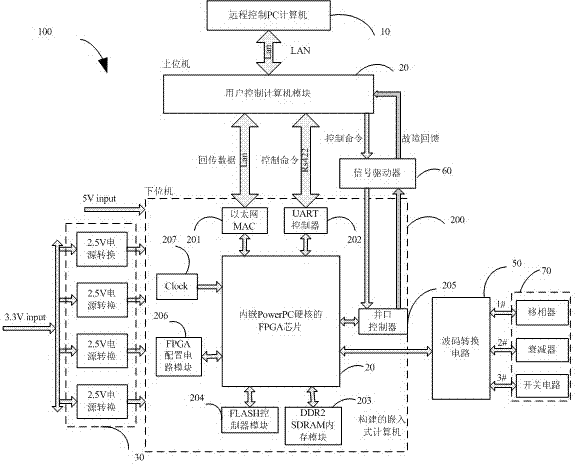

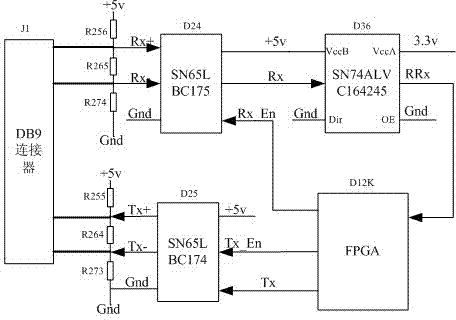

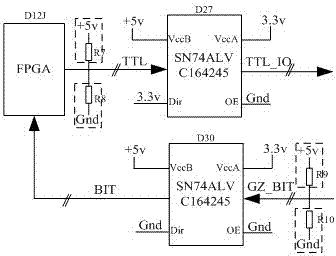

Phased array radar antenna beam control device

ActiveCN102495565AImprove reliabilityMeet developmentProgramme controlWave based measurement systemsDouble data rateUniversal asynchronous receiver/transmitter

The invention relates to a phased array radar antenna beam control device. The phased array radar antenna beam control device comprises a remote control PC (Personal Computer) computer, a user control computer module, a power supply management module, a FPGA (Field Programmable Gate Array) chip, a signal driver, a wave control conversion circuit and a controlled device which is electrically connected with the wave control conversion circuit, wherein the user control computer module remotely communicates with the remote control PC computer and are electrically connected with the FPGA chip, thepower supply management module and the wave control conversion circuit, respectively. The FPGA chip is embedded with a PowerPC hardcore and used for constructing an embedded computer; the embedded computer also comprises an Ethernet (Media Access Control), a UART (Universal Asynchronous Receiver Transmitter) controller, a DDR2SDRAM (Double Data Rate 2 Synchronous Dynamic Random Access Memory) memory module, a FLASH controller module, a parallel controller, a FPGA configuration circuit module and a clock generating circuit module. The phased array radar antenna beam control device provided by the invention has the advantage of high reliability.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

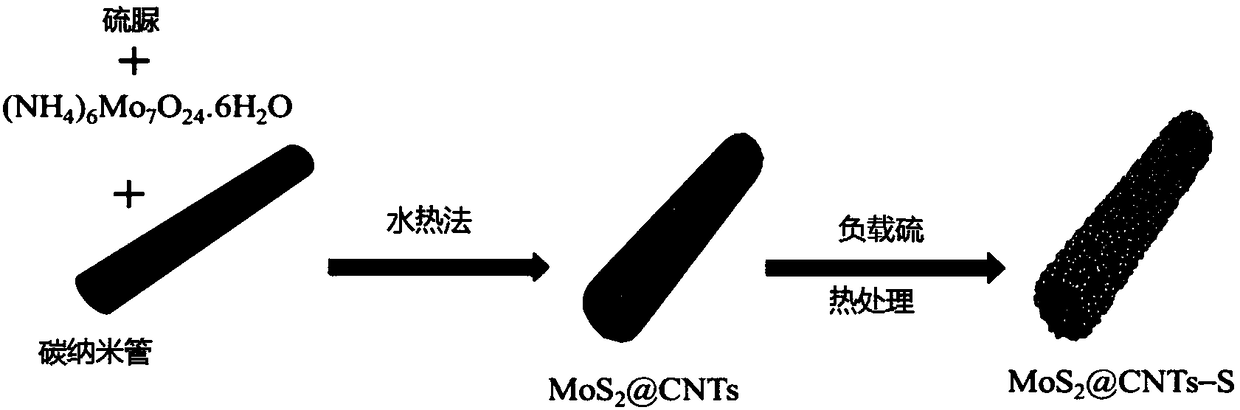

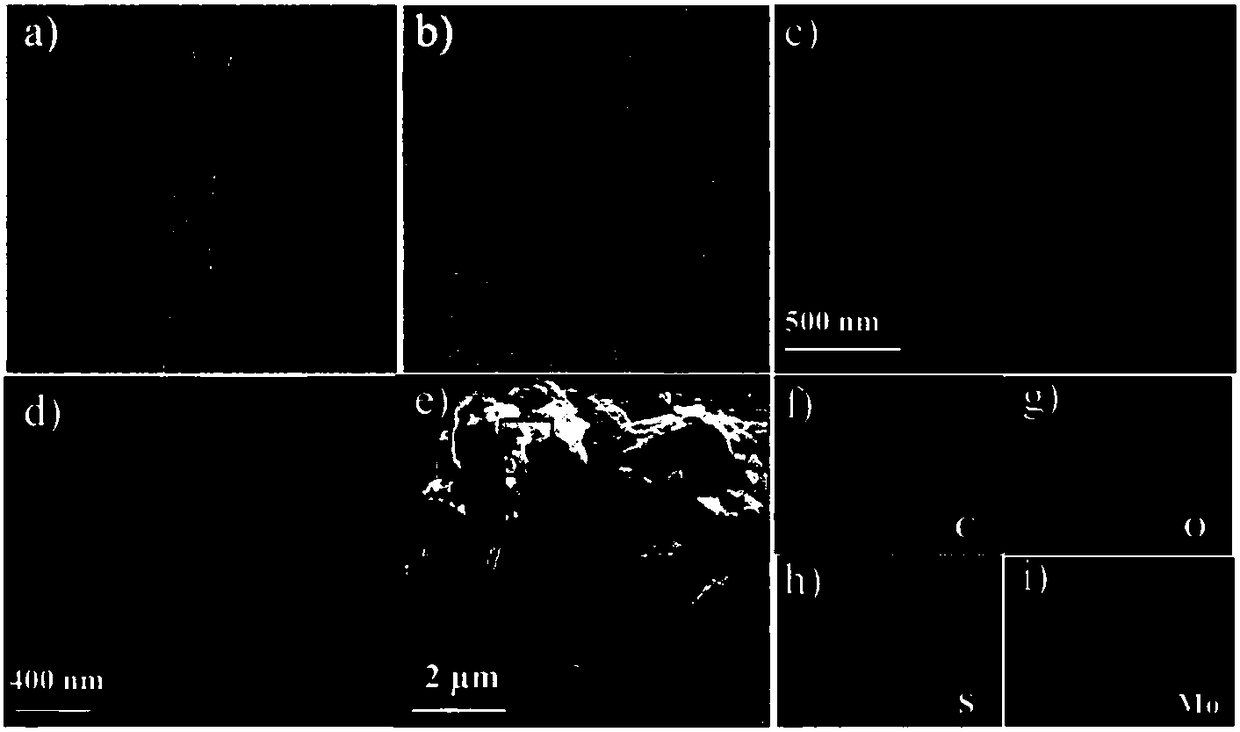

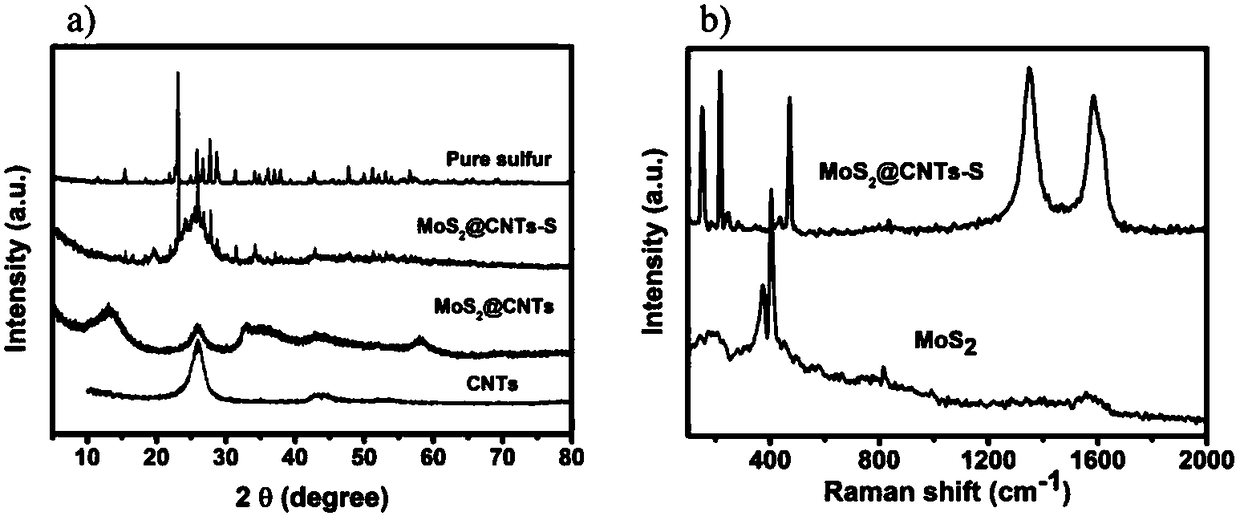

Lithium sulfur battery positive electrode material and preparation method thereof

InactiveCN108232164AFacilitate the transfer of electronsImprove charge and discharge propertiesPositive electrodesLi-accumulatorsChemistryHigh rate

The invention belongs to the field of lithium sulfur battery material, and in particular, relates to a lithium sulfur battery positive electrode material including a host material and elemental sulfurloaded on the host material; the host material includes carbon nanotubes and a transition metal sulfide compounded on the carbon nanotubes. The invention also discloses a preparation method and an application of the positive electrode material. According to the lithium sulfur battery positive electrode material, a strategy of adding the transition metal sulfide is adopted for reducing a back-and-forth shuttling effect; secondly, the carbon nanotubes are added to prevent the collapse of an electrode structure; the positive electrode material has excellent electrochemical performance, and is applied to a lithium sulfur battery to show high initial discharge capacity, high coulombic efficiency and high rate performance.

Owner:CENT SOUTH UNIV

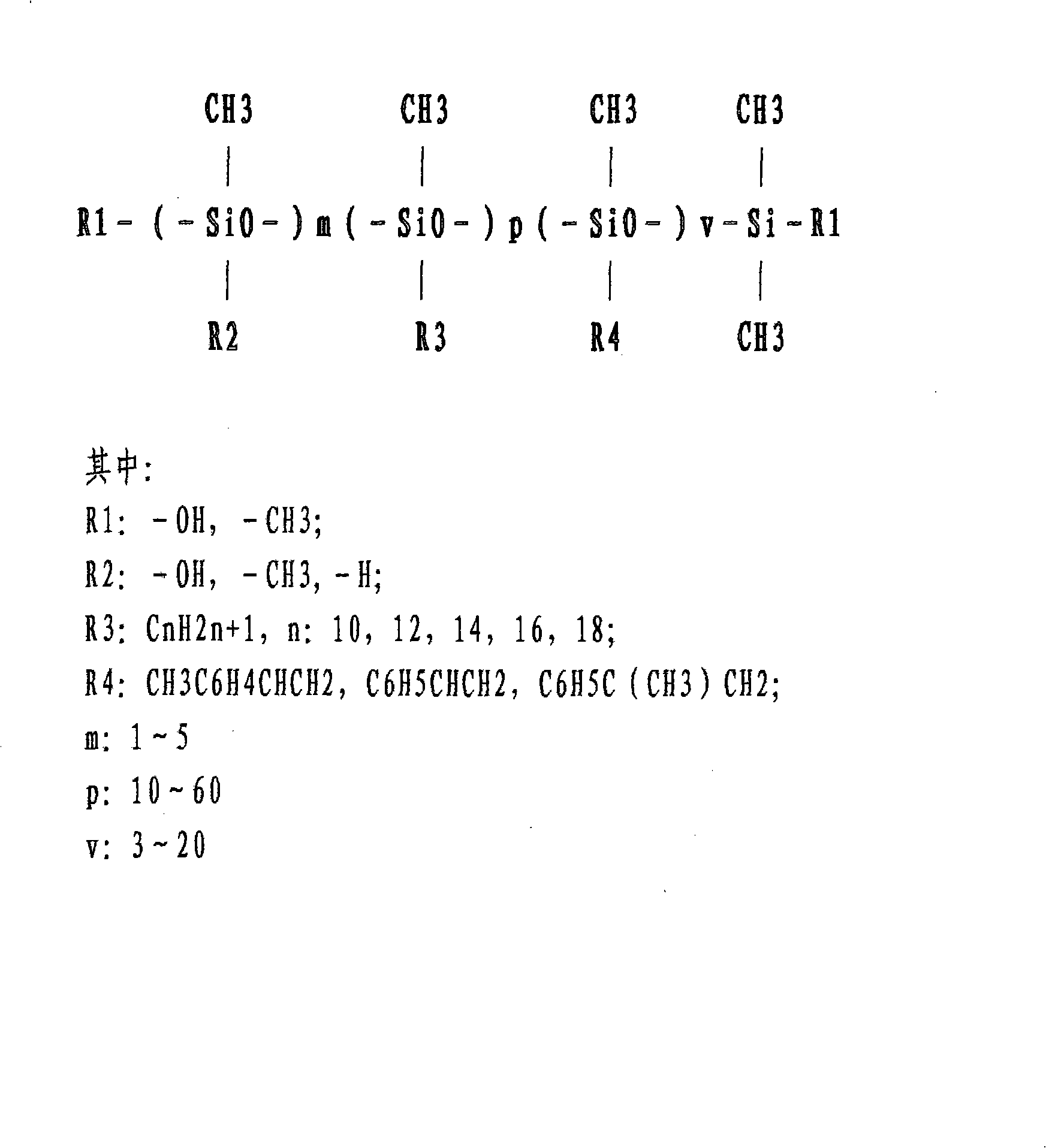

Long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent preparation method

InactiveCN104497312AImprove utilization efficiencyImprove conversion rateSilicon organic compoundsNitrogen gasAlpha-olefin

The invention discloses a long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent preparation method. The method includes the steps of subjecting tetramethyl tetra-hydrogen cyclotetrasiloxane and a catalyst of chloroplatinic acid to reaction, dropping styrene for reaction for some time, dropping long-chain alpha-olefin and a chloroplatinic acid isopropyl propanol solution to obtain an intermediate product of tetramethyl alkyl phenyl cyclotetrasiloxane, subjecting the obtained intermediate product of tetramethyl alkyl phenyl cyclotetrasiloxane, octamethylcyclotetrasiloxane, hexamethyldisiloxane and an acid catalyst to full reaction, fully cooling the obtained liquid, slowly adding calcium hydroxide to adjusting the PH value to 6-7, filtering out solids produced in neutralization with a vacuum pump, adding anhydrous magnesium sulfate to adsorb water produced in neutralization, and filtering to obtain a long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent. The long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent prepared through the preparation method has the advantages of being simple in process, high in efficiency, low in cost, short in cycle and the like.

Owner:仪征市新源新材料科技有限公司

Low temperature sintered (Ca, Mg) SiO3 microwave dielectric ceramic and its prepn process

InactiveCN1673174AMeet the design requirementsLower sintering temperatureCeramicsDielectricCommunications system

The present invention relates to low temperature sintered microwave dielectric ceramic for dielectric antenna, filter and other RF elements and devices in mobile communication system and its preparation process. The low temperature sintered microwave dielectric ceramic has (Ca, Mg)SiO3 as main component, CaTiO3 for regulating the temperature coefficient of frequency, and Li2CO3 and V2O5 as sintering assistant. The present invention features Li2CO3 and V2O5 lowering the sintering temperature of the ceramic system to below 900 deg.c, special technological process improving the characteristic of powder and slurry matching with silver electrode, the dielectric constant of 8-10, quality factor higher than 25000 GHz, the temperature coefficient of resonant frequency approaching zero, low cost, etc.

Owner:ZHEJIANG UNIV +1

Process for producing long-chain alkyl-phenyl modified silicone oil

The invention discloses a preparation method of long-chain alkyl phenyl modified silicone oil including a catalyst, raw materials, technological conditions and an addition reaction technology. In the preparation method, Pt is taken as the catalyst, the technical proposal that hydrogen siloxane, long-chain carbon olefin and styryl hydrocarbon are taken as raw materials for the addition reaction is adopted, and the problems and defects existing in the preparation method in the prior art such as numerous steps, complex process, low efficiency, high cost, long period and unsuitability for mass production are overcome. The preparation method of long-chain alkyl phenyl modified silicone oil realizes the simplification of steps and process for preparing long-chain alkyl phenyl modified silicone oil and achieves the improvement of efficiency, reduction of cost and shortening of period, thus meeting the objective required for mass production.

Owner:NINGBO RUNHE HIGH TECH MATERIAL CO LTD

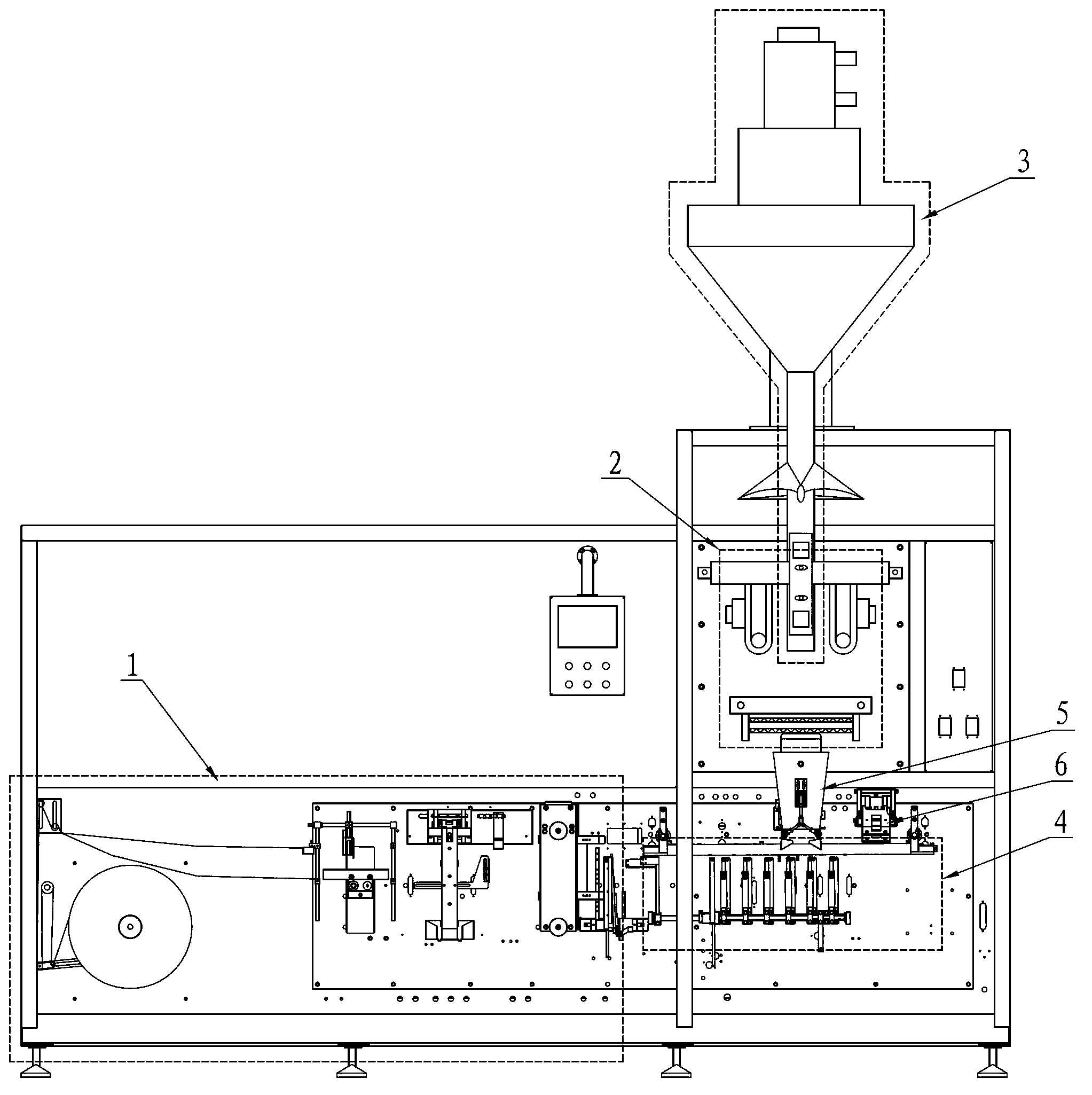

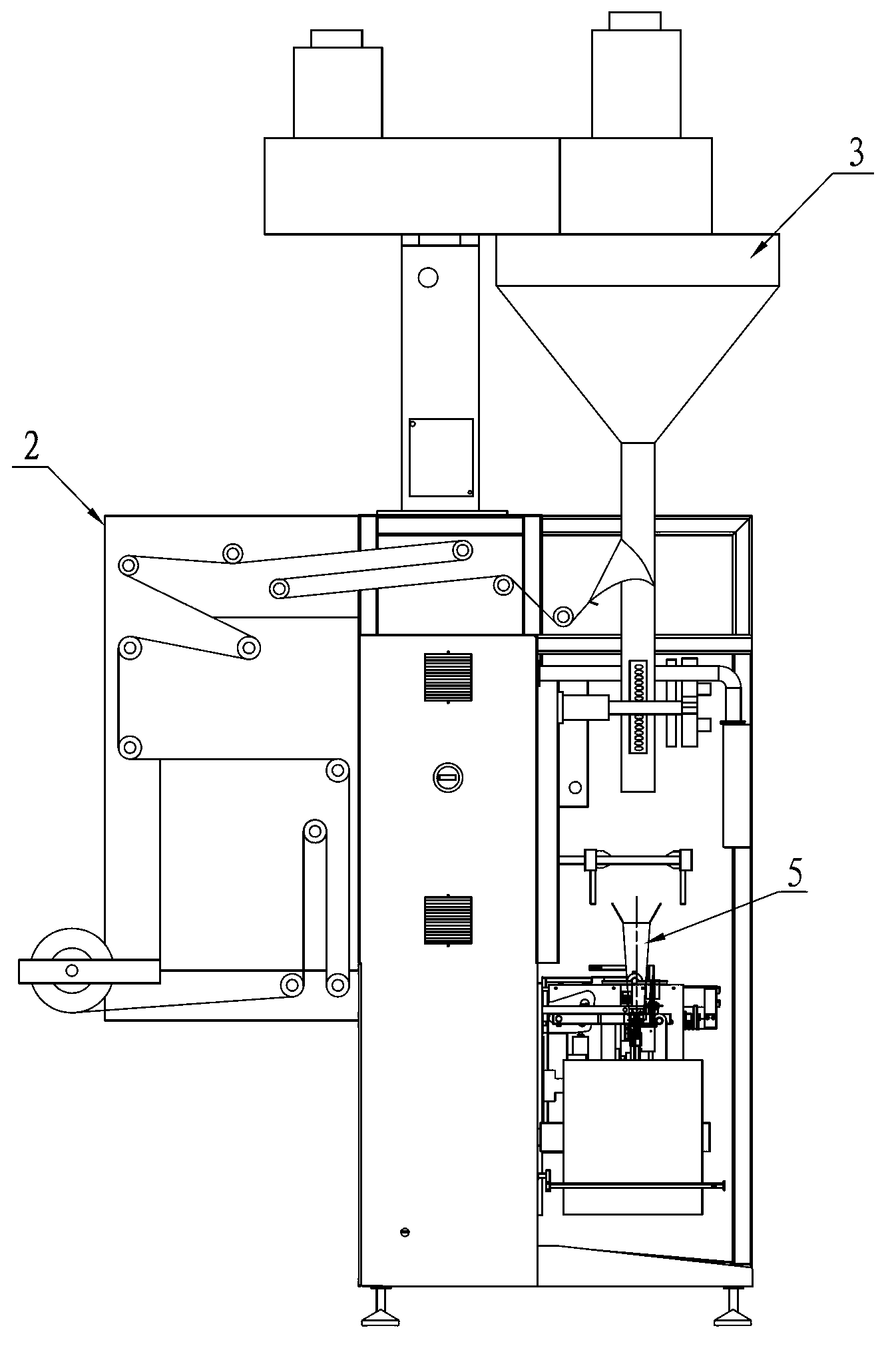

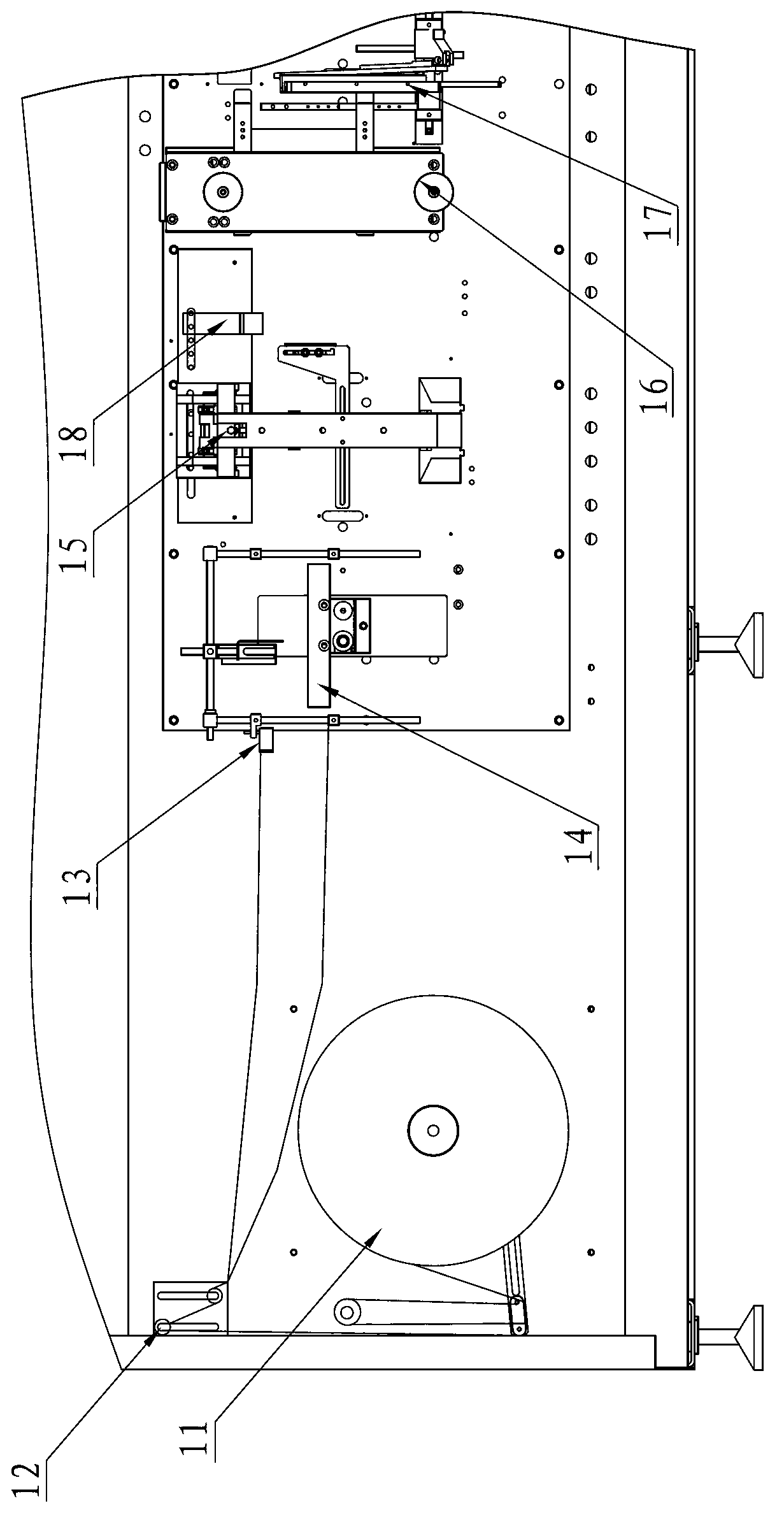

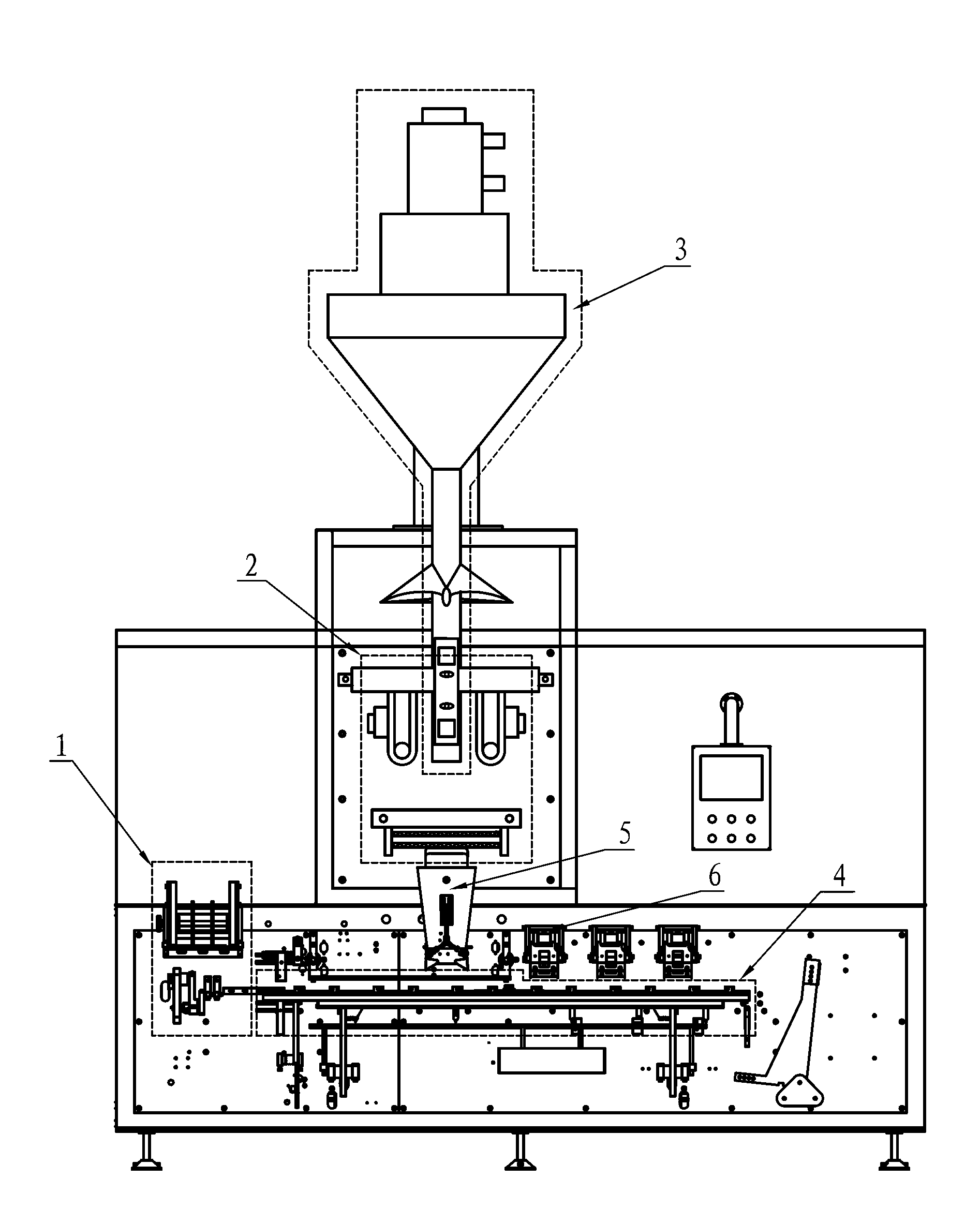

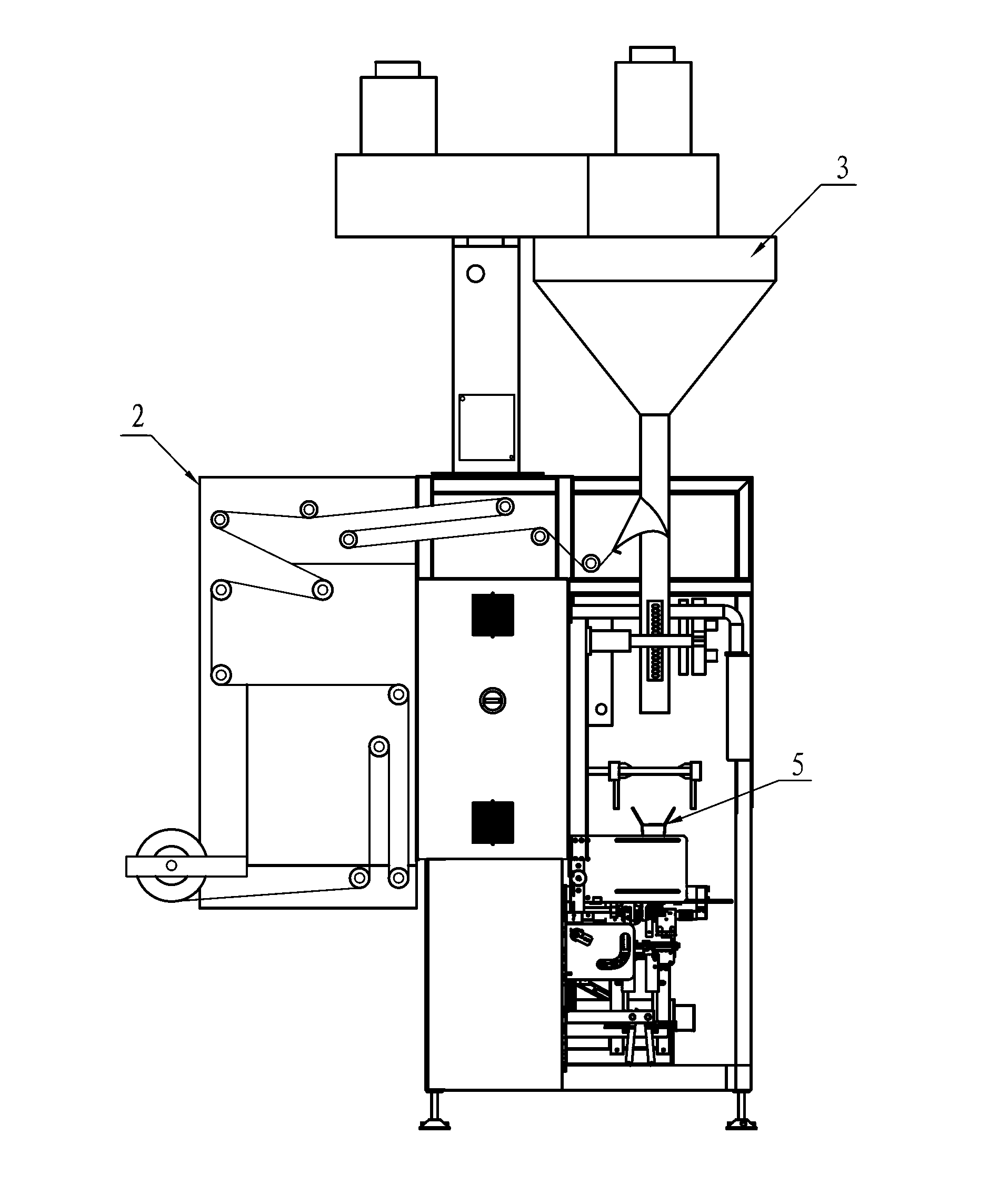

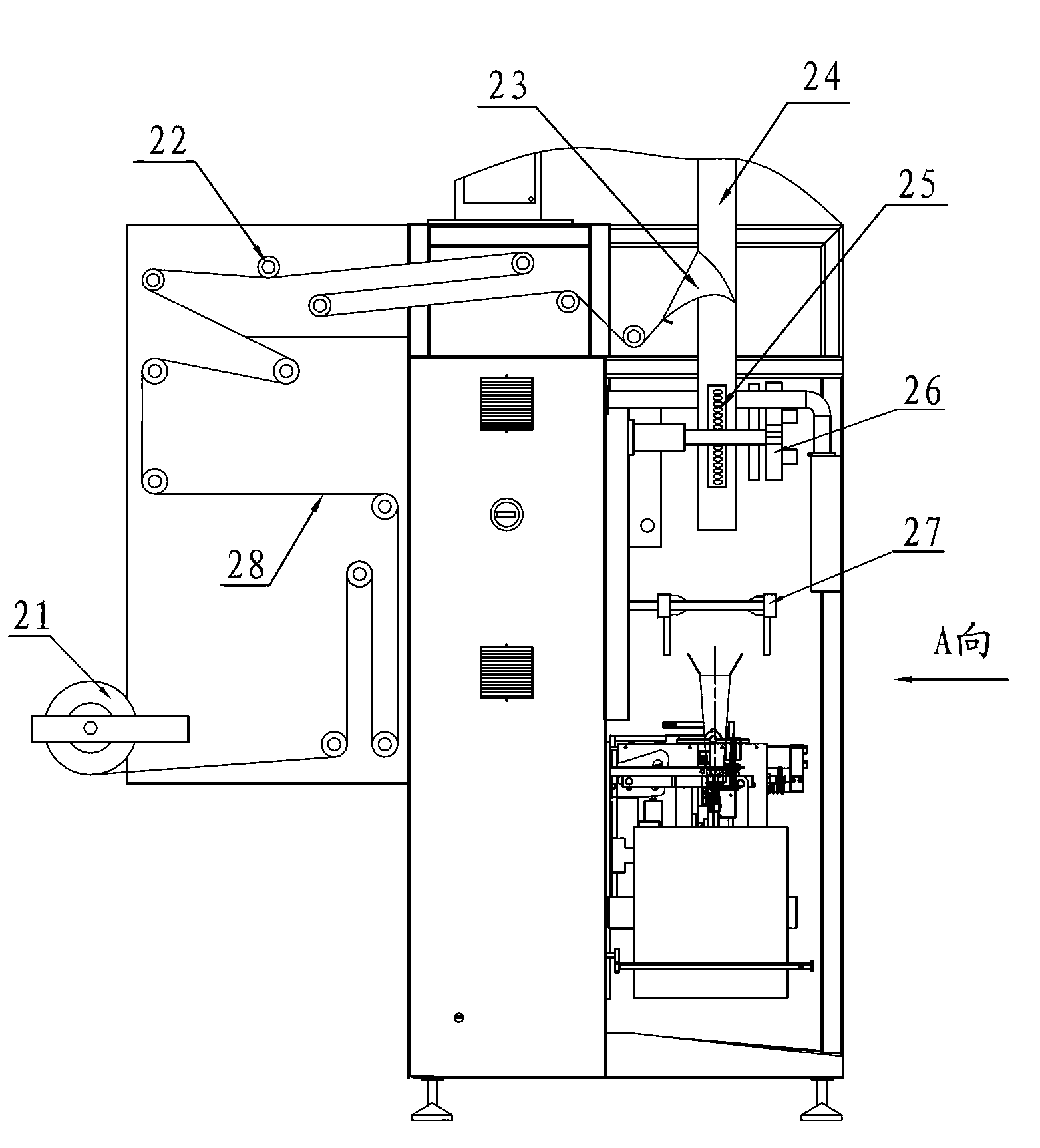

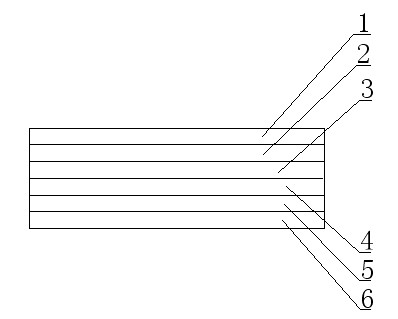

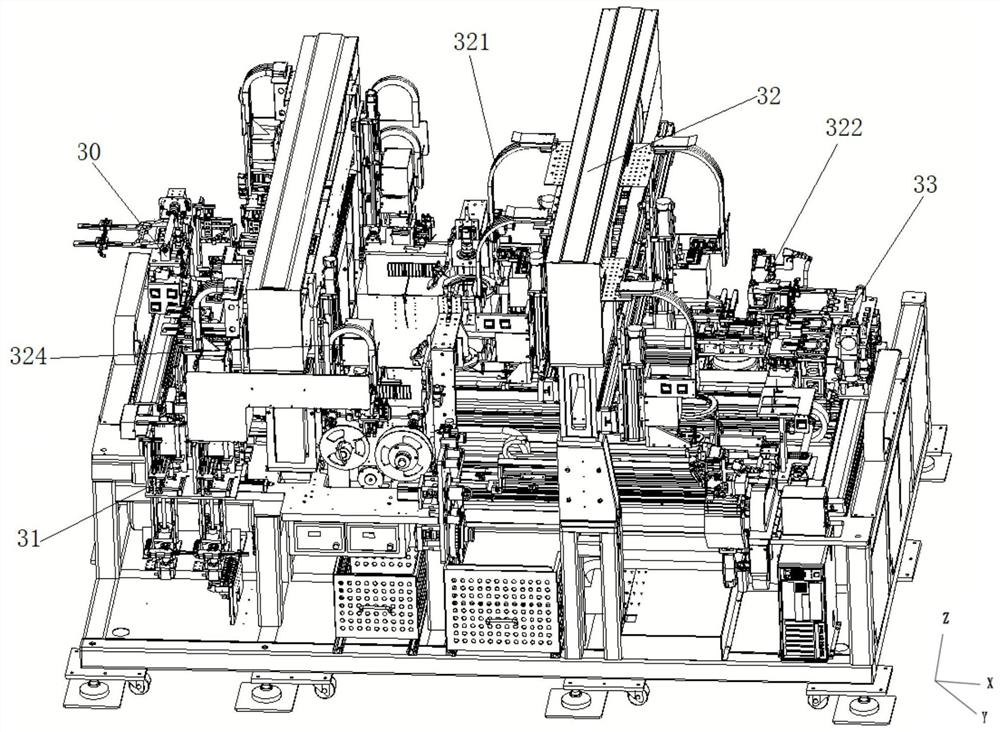

Full-automatic inner and outer bag packing machine capable of making outer bags for pesticides

InactiveCN103287591AImprove ergonomicsImprove packaging qualitySolid materialControl systemMechanical engineering

A full-automatic inner and outer bag packing machine capable of making outer bags for pesticides comprises a horizontal outer bag making device, an upright inner bag making device, an inner bag material metering and filling device, a reciprocating outer bag drawing and clamping device, a device for accurately feeding inner bags into the outer bags and a top sealing device for upper openings of the outer bags. The outer packing bags are made by the horizontal outer bag making device, the inner bags are made, vertically sealed, horizontally sealed and shorn by the upright inner bag making device, pesticide materials are metered and filled into the inner bags by the inner bag material metering and filling device, the outer bags are clamped, conveyed, opened and wiped in a linear reciprocating manner by the reciprocating outer bag drawing and clamping device, each conveyed outer bag is required to be accurately positioned under the device for accurately feeding the inner bags into the outer bags in a corresponding conveying procedure, the device for accurately feeding the inner bags into the outer bags completes secondarily poking edges of the upper openings of the outer bags and accurately feeding the inner bags into the outer bags, and top seals on the outer bags fed with the inner bags are sealed at a high temperature by the top sealing device for the upper openings of the outer bags. The full-automatic inner and outer bag packing machine has the advantages that various components act under a coordination effect of a control system, and accordingly mechanical bag-in-bag packing can be performed on the pesticide materials.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

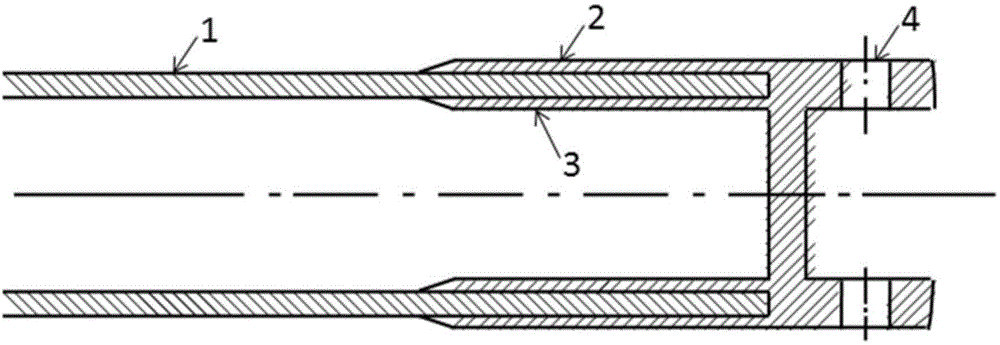

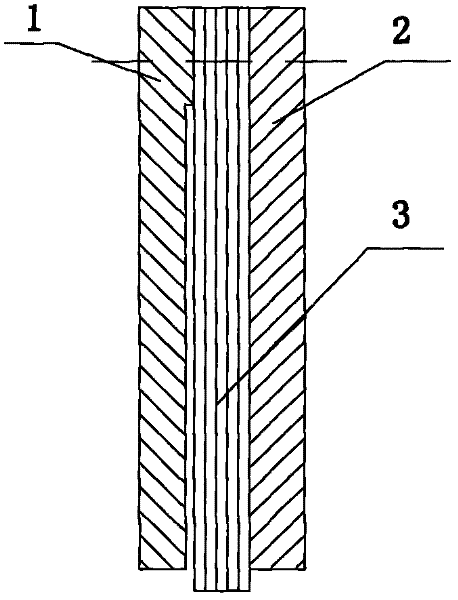

Manufacture method of fiber composite material automobile transmission shaft

The invention discloses a manufacture method of a fiber composite material automobile transmission shaft. Fibers and resin are wound on a core mold by means of winding, and are molded by high-temperature curing. As the thermal expansion coefficient of a fiber composite material is far lower than the thermal expansion coefficient of metal, demoulding can be carried out at a relatively low temperature by adopting the principle of thermal expansion and cold shrinkage by utilizing different thermal expansion properties of the fiber composite material and the metal under relatively large temperature difference, and finally a sleeve is bonded to a universal joint fork which is redesigned in structure by using structure adhesive to finally obtain the FRP automobile transmission shaft with the light mass and the good performance and meeting the requirements.

Owner:WUHU LION AUTOMOTIVE TECH CO LTD

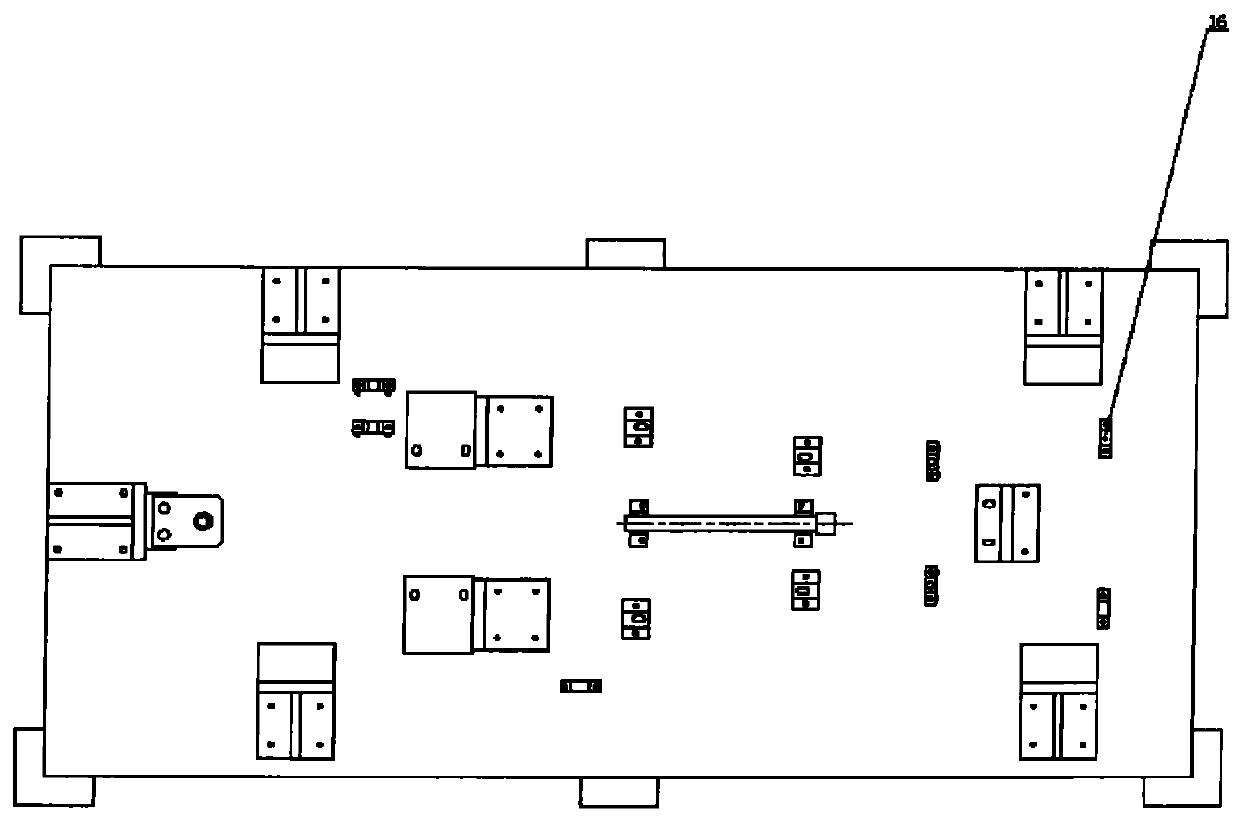

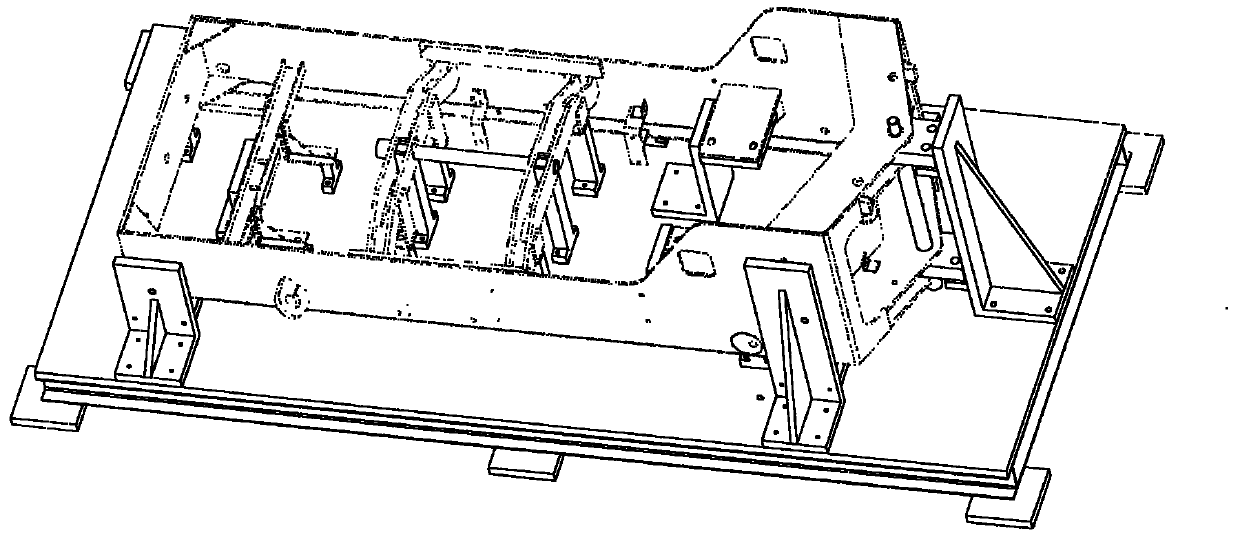

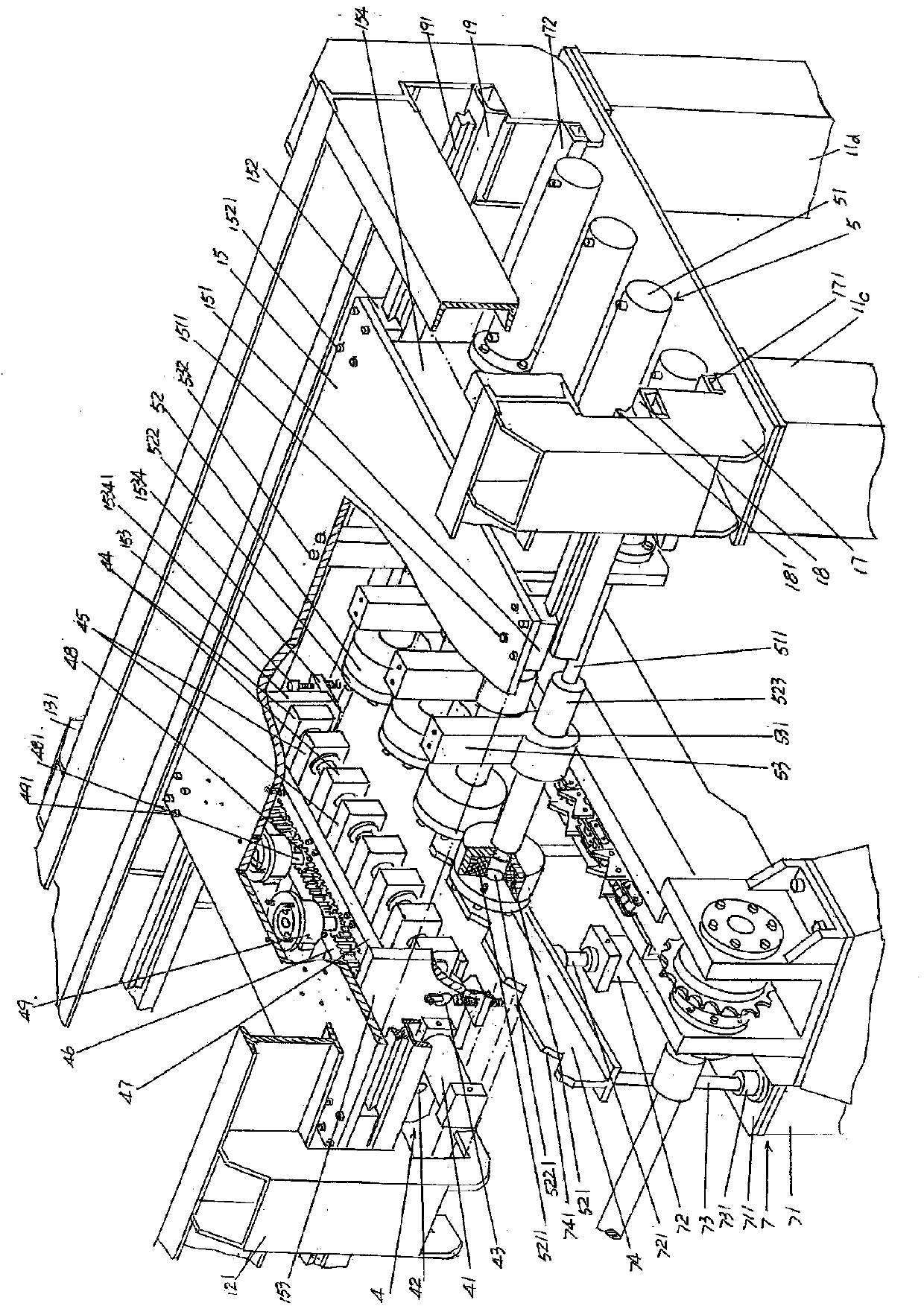

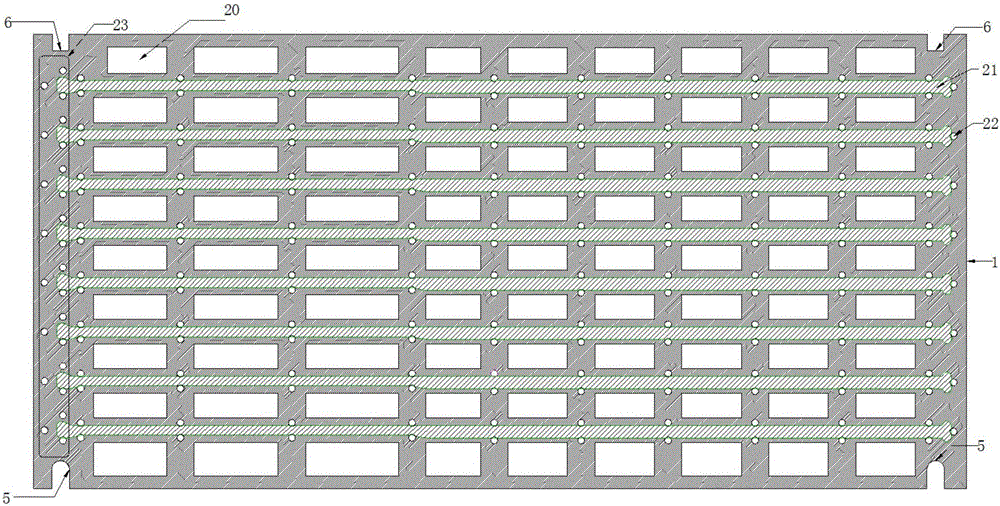

Integrated welding-die mechanism for rear frames of small-sized wheel loaders and medium-sized wheel loaders

InactiveCN103273242AGuaranteed accuracyMeet mass production requirementsWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention discloses an integrated welding-die mechanism for rear frames of small-sized wheel loaders and medium-sized wheel loaders. The integrated welding-die mechanism for the rear frames of the small-sized wheel loaders and the medium-sized wheel loaders comprises a welding-die base, wherein a hinged plate support, a pair of front fixing plates, a pair of gearbox installing locating plates, a pair of front engine installing hole fixing plates, a pair of rear engine installing hole fixing plates, two front-and-back swing frame hole blocks, a front-and-back swing frame hole locating pin roll, a gear pump installing base limiting plate, a pair of left-and-right longitudinal beam locating bases and a pair of rear tail plate limiting blocks are arranged on the welding-die base in sequence, the front-and-back swing frame hole locating pin roll is arranged between the front-and-back swing frame hole blocks, two vertically-arranged middle limiting plates are arranged on the hinged plate support, and a hinged plate hole locating core rod is arranged on the two middle limiting plates. The integrated welding-die mechanism for the rear frames of the small-sized wheel loaders and the medium-sized wheel loaders can ensure accuracy of assembled and welded assemblies, prevent welding deformation, meet requirement for mass production of the loaders, greatly improve efficiency of assembly, and ensure strength of welding, and meanwhile stress deformation of components cannot happen after the components are welded.

Owner:ANHUI ZHONGDING FEICAI VEHICLE

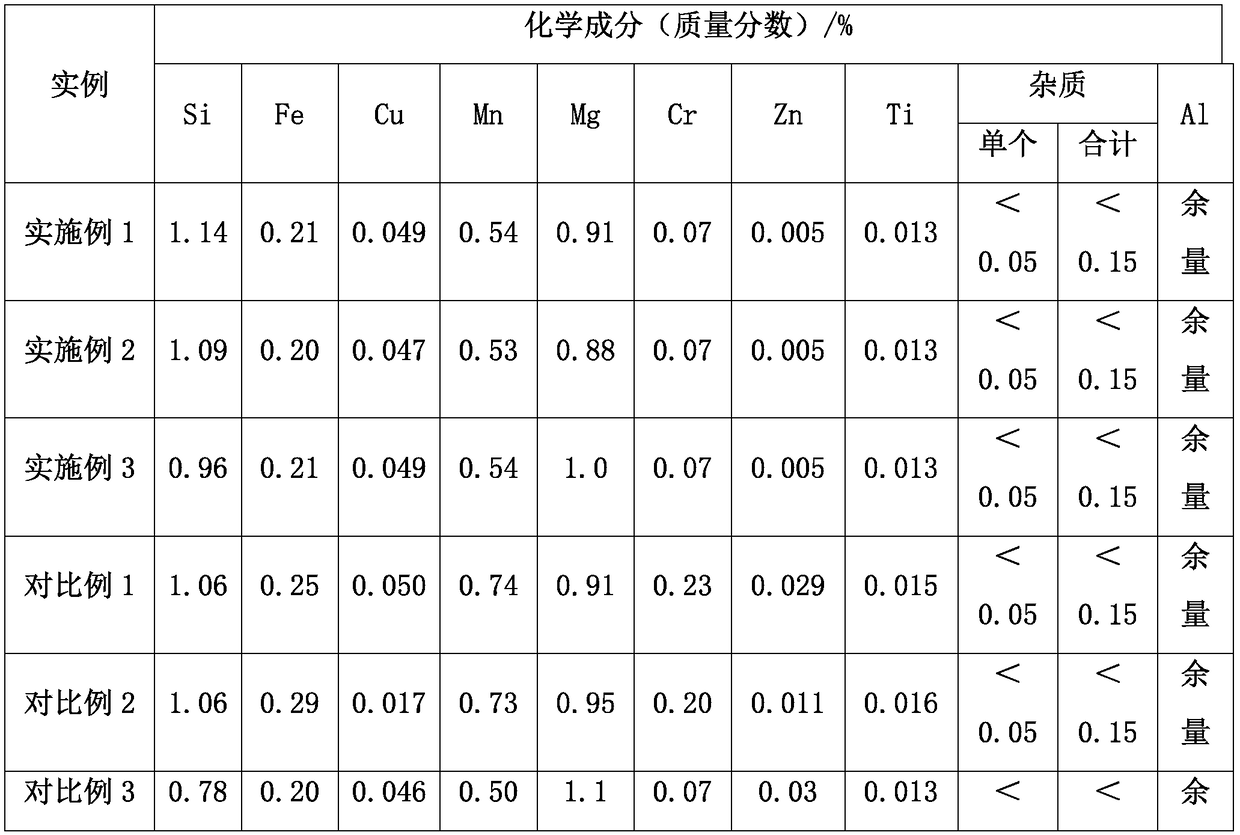

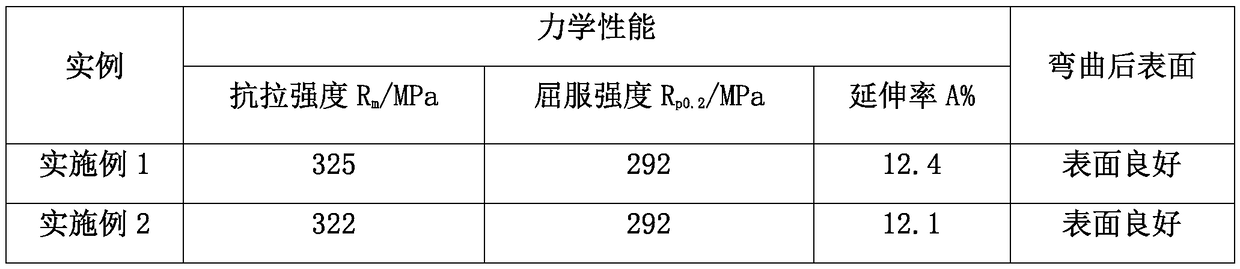

6082S aluminum alloy sheet for stamping and processing technology thereof

The invention belongs to the technical field of aluminum alloy processing, and relates to a 6082S aluminum alloy sheet for stamping and a processing technology thereof. The 6082S aluminum alloy sheetis prepared from the following elements of, in percentage by weight, 0.9-1.2% of Si, 0.1-0.25% of Fe, less than or equal to 0.1% of Cu, 0. 5-0.6% of Mn, 0.8-1.1% of Mg, less than or equal to 0.1%of Cr, less than or equal to 0.1% of Zn, 0.01-0.02% of Ti, less than or equal to 0.05% of a single impurity, less than or equal to 0.15% of total impurities, and the balance Al. The defect that the existing 6082 aluminum alloy is wide in range is solved, due to the existence of Fe and Mn elements in the alloy, micron-scale AlFeSi, AlMnSiFe and Al6Mn phases are often separated out in the solidificationprocess, the coarse one-time solidification phases is hard and brittle, is difficult to dissolve in an aluminum matrix in subsequent homogenization and solid solution treatment, in the stamping process, a crack source can be easily formed, so that stamping cracking is caused; by controlling the component range of 6082 aluminum alloy, a thin plate with good stamping performance is obtained.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

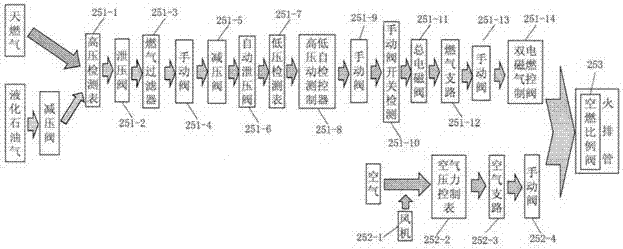

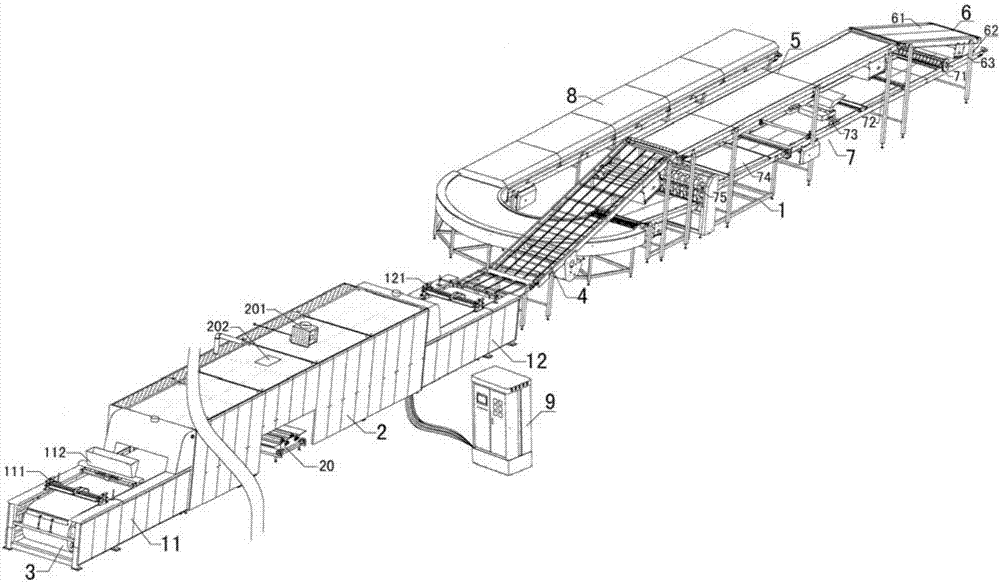

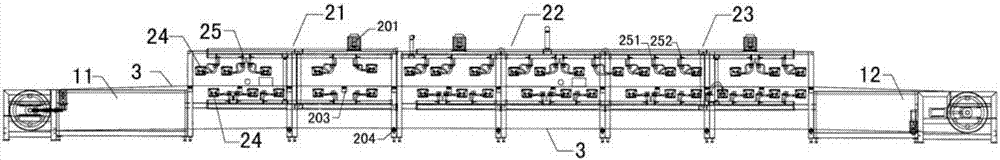

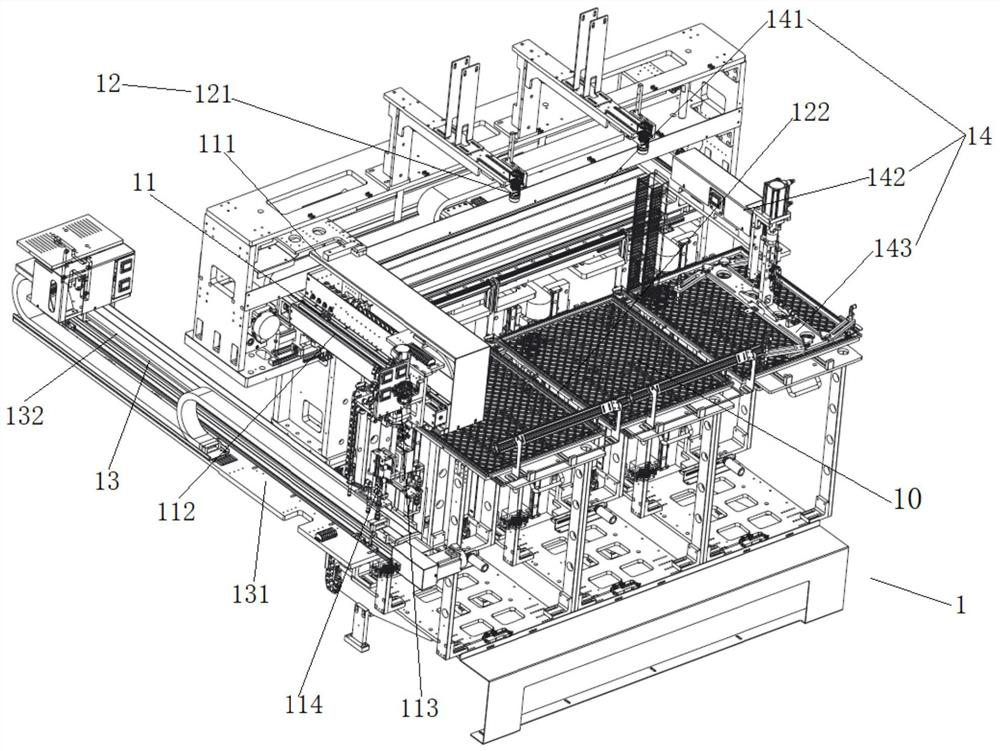

Full-automatic pocket cake baking production line and production processing method

InactiveCN107212037AGood conditionGreat tasteBaked article fillingBaking surface cleaning/greasingProgrammable logic controllerMolding machine

The invention discloses a full-automatic pocket cake baking production line and production processing method. The full-automatic pocket cake baking production line comprises a furnace inlet platform, a furnace outlet platform, a tunnel oven, a steel belt, a net chain conveying belt, a cooling transmission belt, a turning and rolling mechanism, a sandwich forming mechanism, a sterilization mechanism, a frame and a PLC (programmable logic controller) control box, the cooling transmission belt and the sandwich forming mechanism are arranged on the upper layer and the lower layer of the frame, the turning and rolling mechanism is connected with the cooling transmission belt and the sandwich forming mechanism, the tunnel oven is provided with a preheating area, a baking coloring area and a moisture control area, so that baking quality is controlled, a first pneumatic oil spray machine, a grouting machine, a second pneumatic oil spray machine, an automatic steel belt cleaning mechanism, an arc-shaped turning plate, a cutting slitting machine, a turnover mechanism, a paste machine, a laminating mechanism, a continuous forming separation mechanism and the sterilization mechanism are sequentially arranged on the production line, the PLC control box is connected with devices of the production line in a controlled manner, and intelligent control is achieved.

Owner:福建省亿焙机械有限公司

Bag-in-bag pesticide packing machine with preliminarily made outer bags

InactiveCN103287607AImprove ergonomicsImprove packaging qualityWrapping material feeding apparatusWrapper twisting/gatheringControl systemEngineering

A bag-in-bag pesticide packing machine with preliminarily made outer bags comprises an outer preliminarily made outer bag collecting device, an upright inner bag making device, an inner bag material metering and filling device, a reciprocating outer bag drawing and clamping device, a device for accurately feeding inner bags into the outer bags and a top sealing device for upper openings of the outer bags. The inner bags are made, vertically sealed, horizontally sealed and shorn by the upright inner bag making device, pesticide materials are metered and filled into the inner bags by the inner bag material metering and filling device, the outer bags are clamped, conveyed, opened and wiped in a linear reciprocating manner by the reciprocating outer bag drawing and clamping device, each conveyed outer bag is required to be accurately positioned under the device for accurately feeding the inner bags into the outer bags in a corresponding conveying procedure, and the device for accurately feeding the inner bags into the outer bags secondarily poking edges of the upper openings of the outer bags and accurately feeding the inner bags into the outer bags; top seals on the outer bags fed with the inner bags are sealed at a high temperature by the top sealing device for the upper openings of the outer bags. The bag-in-bag pesticide packing machine has the advantages that various components act under a coordination effect of a control system, and accordingly mechanical bag-in-bag packing is performed on the pesticide materials.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

Weatherproof flexible veneer and manufacturing method thereof

InactiveCN102602085AGood flexibilityIncrease profitSynthetic resin layered productsLaminationSolid woodHot melt

The invention provides a weatherproof flexible veneer, which comprises a nonwoven fabric layer, a polyurethane (PUR) hot melt adhesive layer, a wood solid veneer layer, a water-based coloring layer, a PUR hot melt adhesive paint layer and an ultraviolet (UV) finish paint layer, wherein the nonwoven fabric layer is bonded with the solid wood veneer layer through the PUR hot melt adhesive layer, and the water-based coloring layer, the PUR hot melt adhesive paint layer and the UV-side paint layer are sequentially coated on the upper surface of the solid wood veneer layer. The weatherproof flexible veneer has good flexibility and does not crack and prevents the paint from peeling off after being bent for multiple times, the adopted synthesized materials can meet the international environment-friendly requirement, a traditional paint technical is changed, no pollution is led to an application environment, the utilization rate of the paint is high, the weatherproof flexible veneer is free from being delaminated at a high temperature and being embrittled at a low temperature, has excellent properties such as ultraviolet resistance, aging resistance and water resistance and can be made into a veneer synthesized material which can be continuously coiled, and the requirement on elongation and mass production of the material can be met.

Owner:ZHEJIANG LINYA

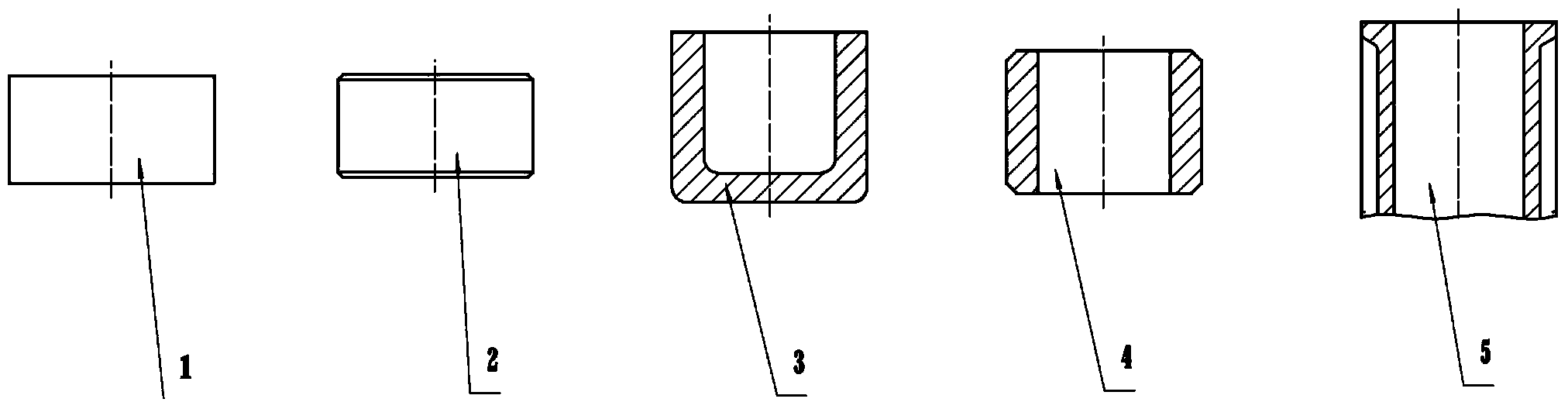

Precision external spline pipe forming method

ActiveCN103934638ASolve the problem of batch processingImprove the finishExtrusion diesEngineeringHardness

The invention provides a precision external spline pipe forming method. The method comprises the steps that hot rolling bars are sawn, spheroidizing annealing is conducted, and bars are formed through cylindrical turning; shot blasting is conducted on the bars, the bars are processed through phosphorus saponification, and workblank is formed; reverse extrusion, radial facing, chamfering, phosphorus saponification processing and external spline forward extrusion are conducted on the workblank, and the external spline pipe is obtained. According to the precision external spline pipe forming method, the precision external spline pipe can be produced through the common hot rolling bars, and the problem that external spline batch machining is difficult for multiple enterprises is solved. The precision external spline pipe formed by the method is compact in internal structure and stable in hardness number, and the surface smooth finish of the external splines is high and can be smaller than or equal to Ra1.6; in addition, the machining cost is low, machining efficiency is high, follow-up cutting machining amount is small, the requirement for batch production can be met, labor loss is saved, and the enterprise cost is reduced.

Owner:JIANGSU SUNWAY PRECISION FORGING

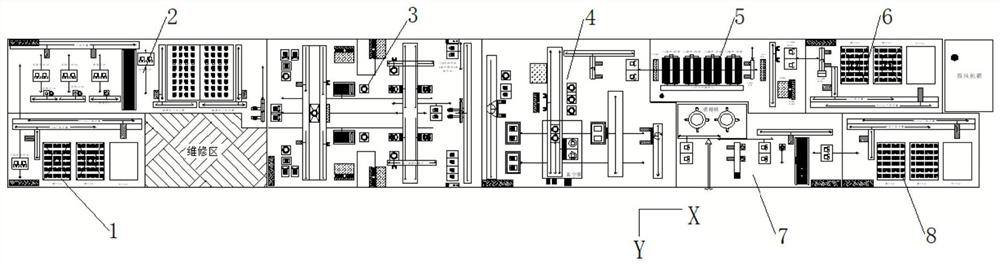

Laminating machine and laminating method

ActiveCN112731695AReduce labor intensityMeet mass production requirementsNon-linear opticsConveyor partsGlass coverMechanical equipment

The invention relates to the technical field of automatic mechanical equipment, in particular to a laminating machine and a laminating method. The laminating machine comprises a first feeding module, a dispensing module, a soft-to-hard laminating module, a hard-to-hard laminating module, a film tearing and cleaning module, a second feeding module, a finished product detection module and a finished product discharging module, wherein the first feeding module is used for feeding a display module; the second feeding module is used for feeding a glass cover plate; the dispensing module is located between the first feeding module and the soft-to-hard laminating module, and the display module is sequentially conveyed to the first feeding end of the hard-to-hard laminating module along the first feeding module, the dispensing module and the soft-to-hard laminating module; the film tearing and cleaning module is located between the second feeding module and the hard-to-hard laminating module, and the glass cover plate is sequentially conveyed to the second feeding end of the hard-to-hard laminating module along the second feeding module and the film tearing and cleaning module; and the finished product detection module and the finished product discharging module are sequentially arranged at the discharging end of the hard-to-hard attaching module. According to the laminating machine, the production efficiency can be improved, and the labor intensity of workers can be reduced.

Owner:东莞市鼎力自动化科技有限公司

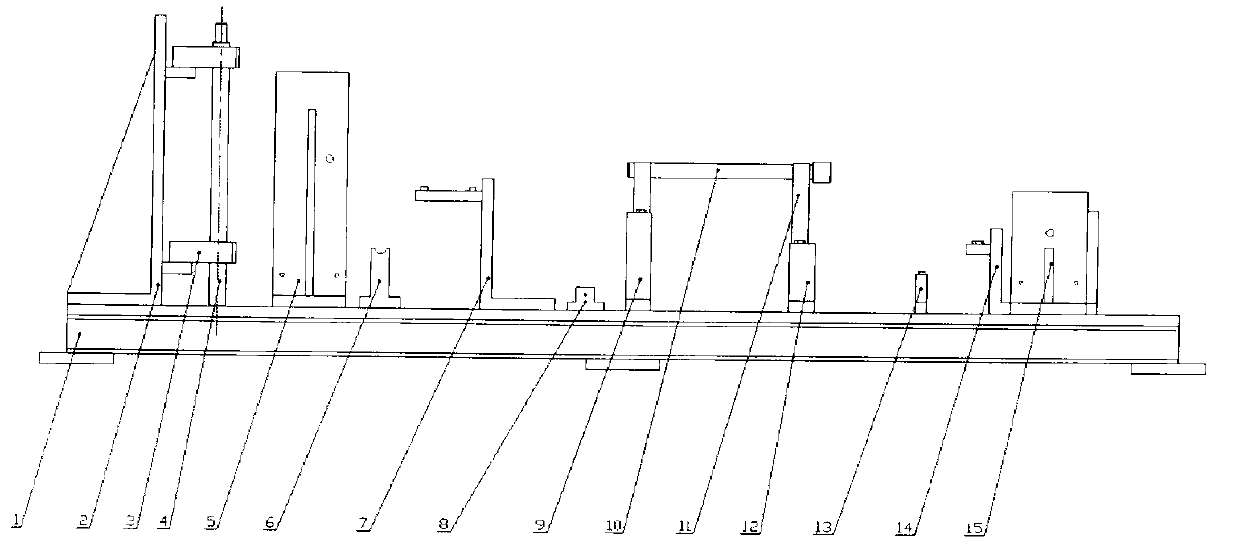

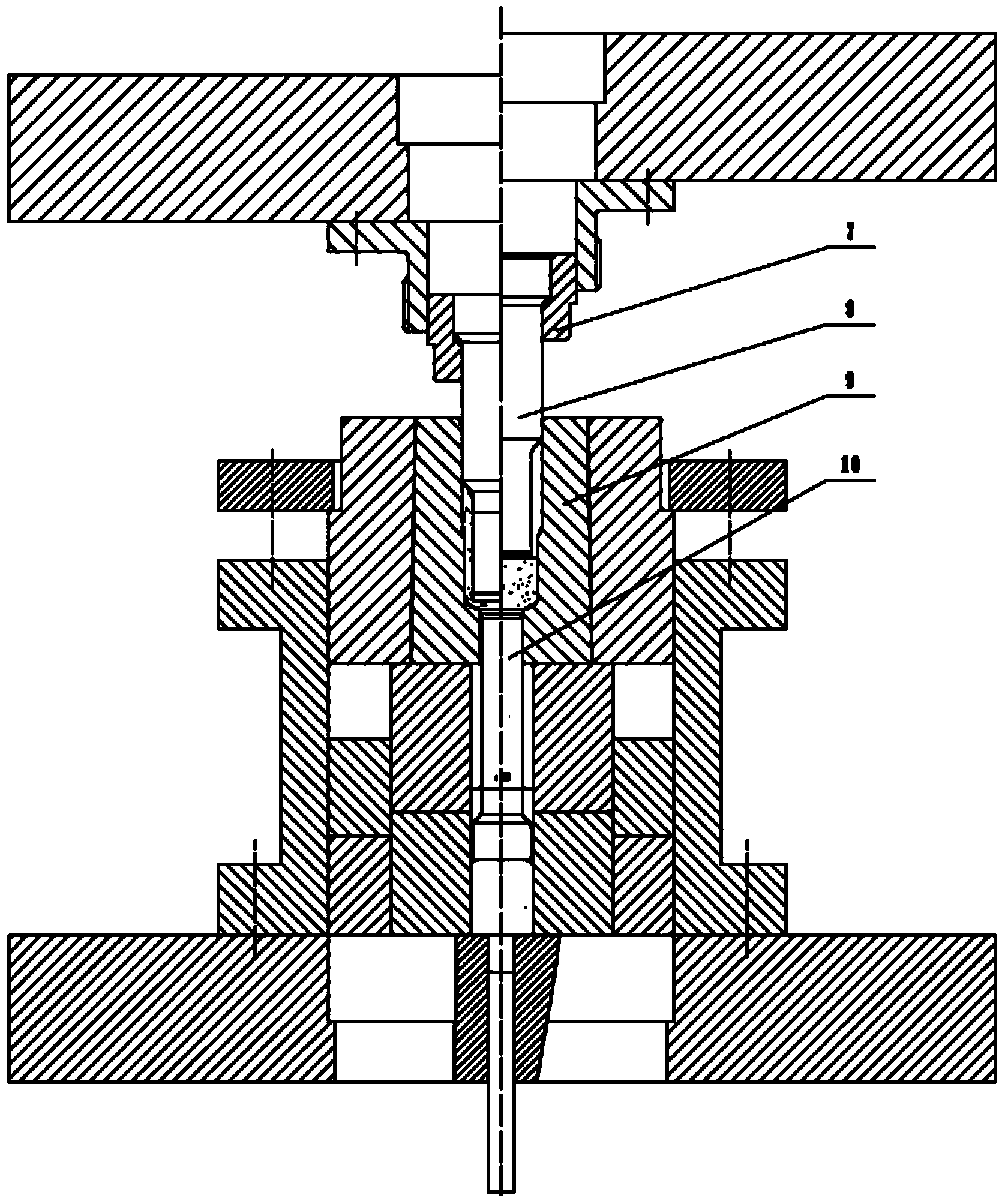

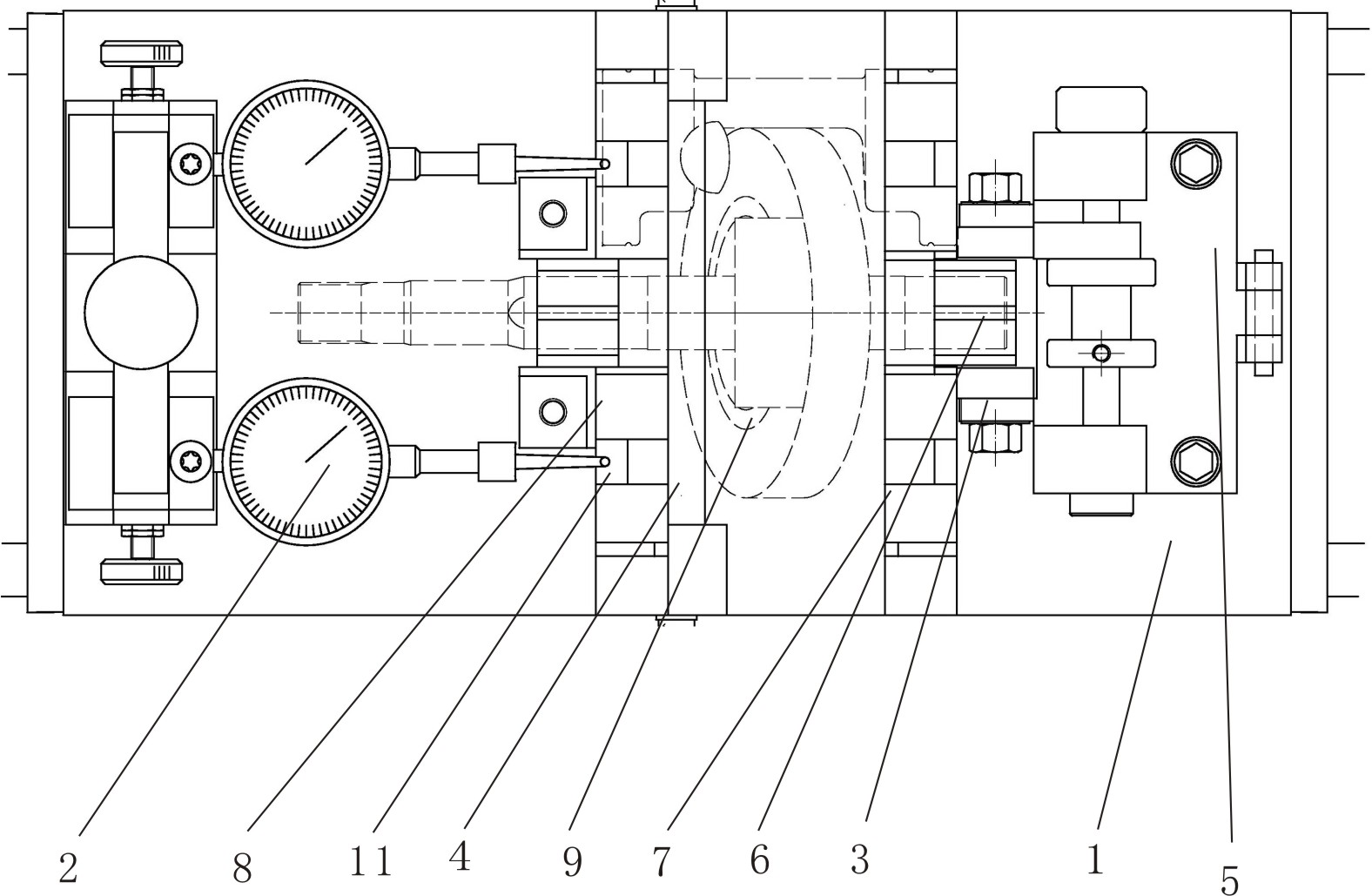

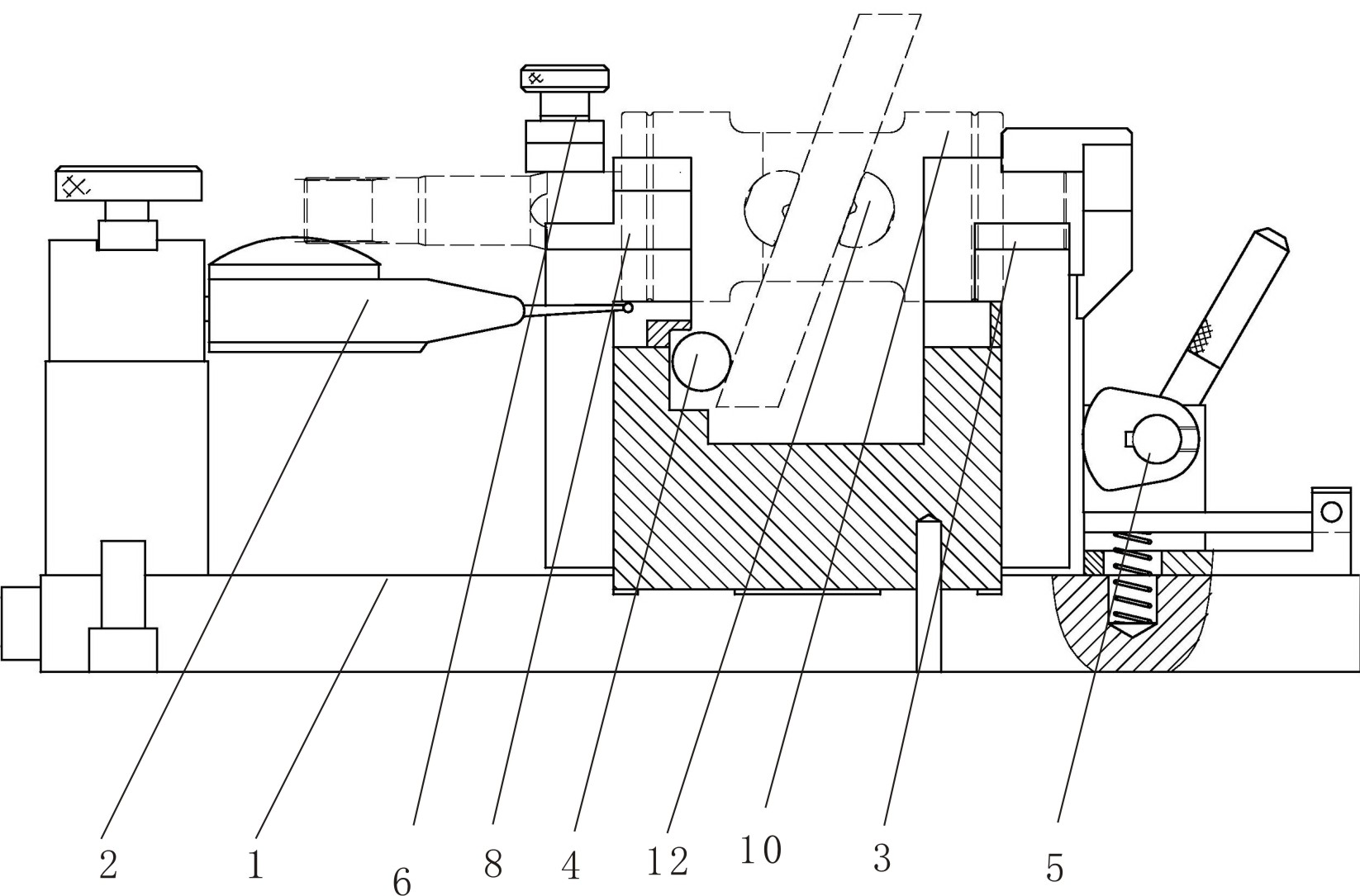

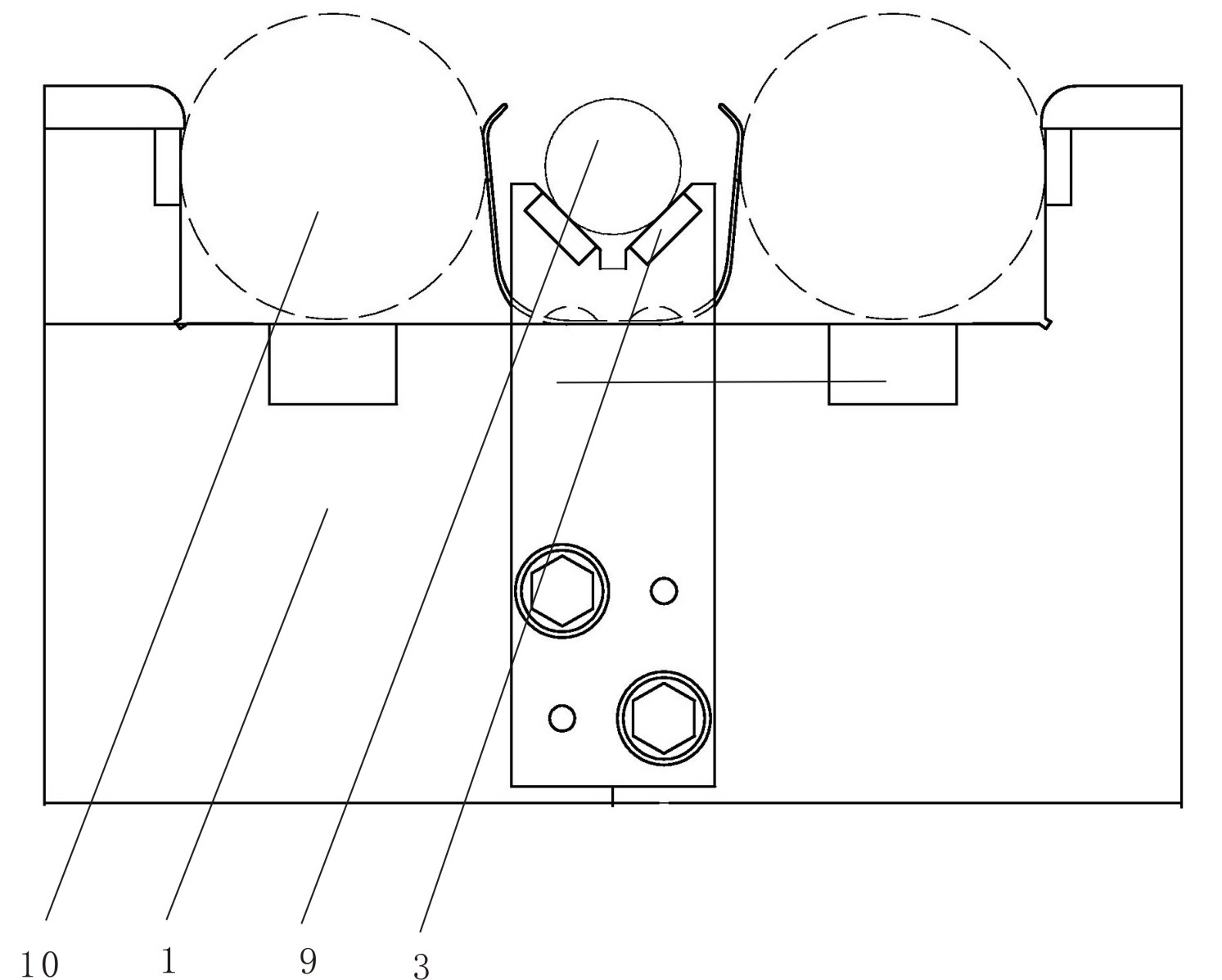

Detection device of swash plate and piston axial matched gap and using method thereof

ActiveCN102589394AImprove matching accuracyMeet mass production requirementsMechanical clearance measurementsEngineeringStructural engineering

The invention discloses a detection device of a swash plate and piston axial matched gap and a using method thereof. The detection device comprises an operating platform, and a swash plate fixed structure, a piston support and a displacement measurement mechanism are arranged on the operating platform. The piston support comprises two piston placing blocks provided with grooves and fixed on the operating platform, and a pit is arranged in the middle position at the bottom of the groove of one piston placing block. The positions of the piston placing blocks are that when two ends of a piston are placed in the grooves of the piston placing blocks, a swash disc fixed on the swash plate fixed structure is right inserted in a swash disc socket of the piston, an axis of the piston and an axis of the swash disc fixed on the swash plate fixed structure are in a same horizontal height, and measure points of the displacement measurement mechanism is placed at the bottom of one end of the piston on the groove with the pit. The detection device of the swash plate and piston axial matched gap can improve selection and matching accuracy to meet requirements of volume production, and the using method has the advantages of being simple and convenient in operation.

Owner:浙江春晖空调压缩机有限公司

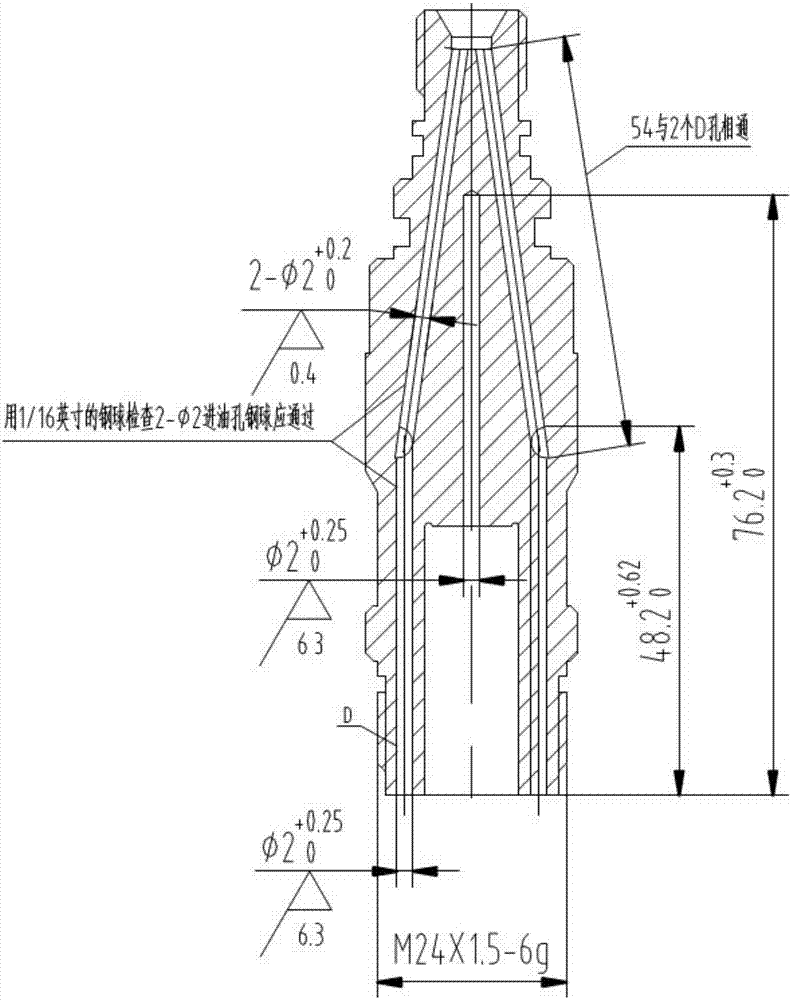

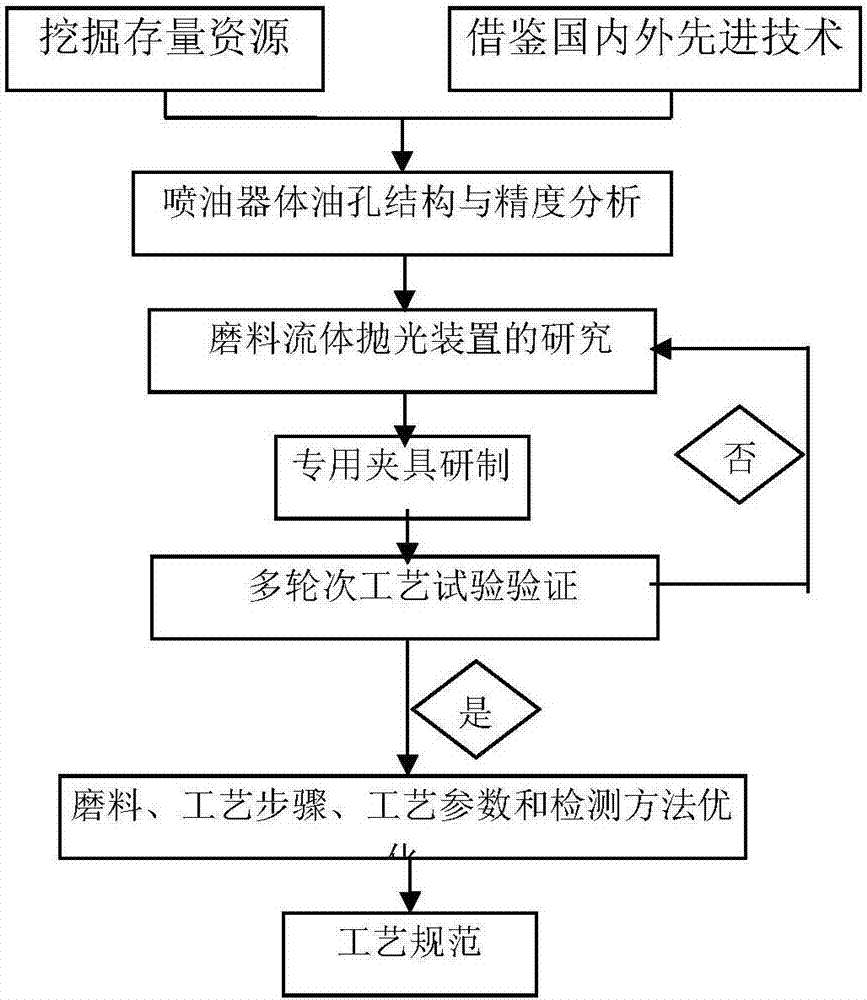

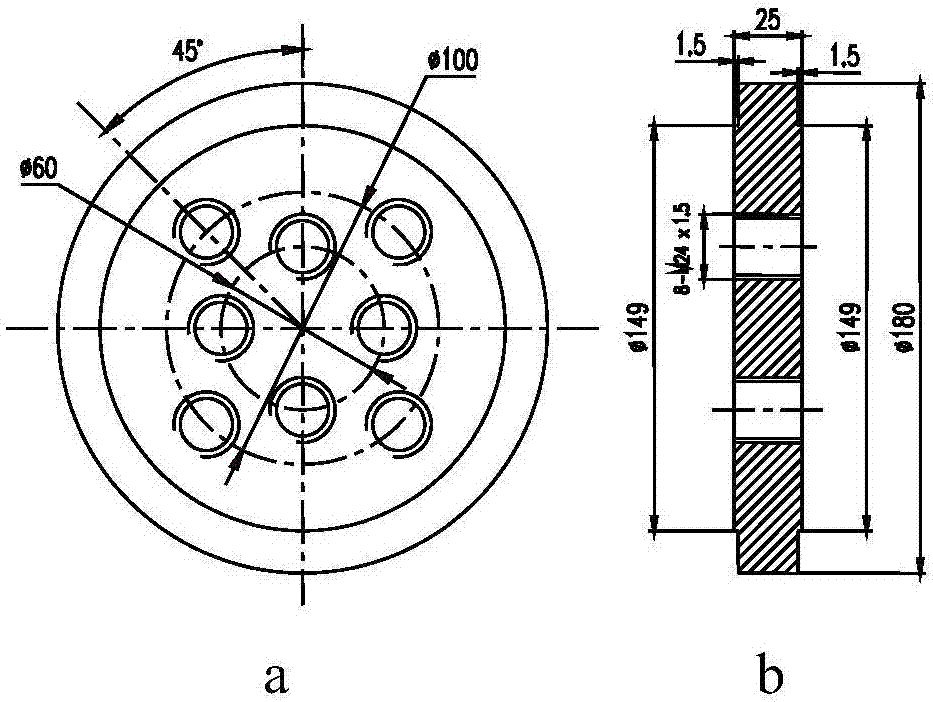

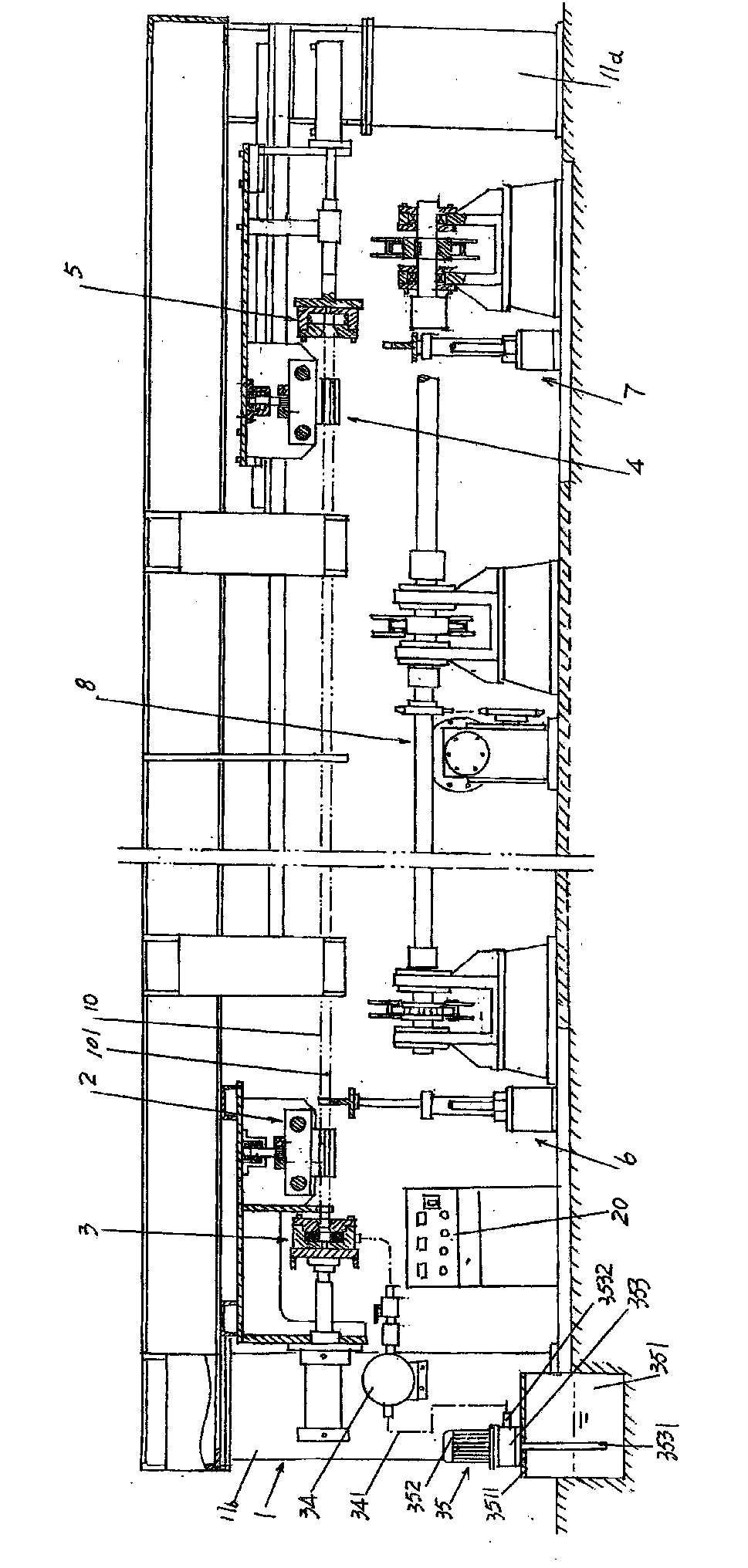

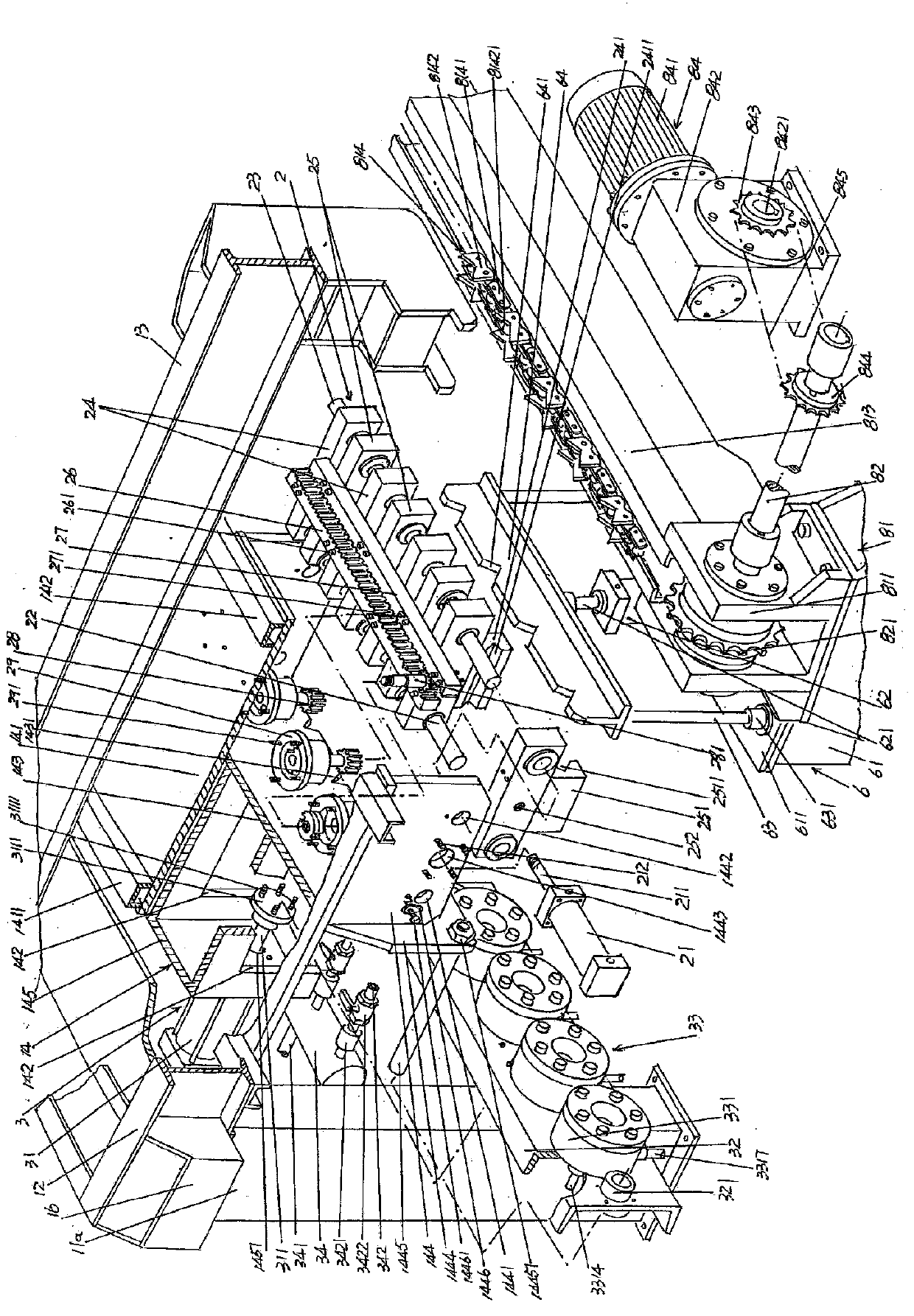

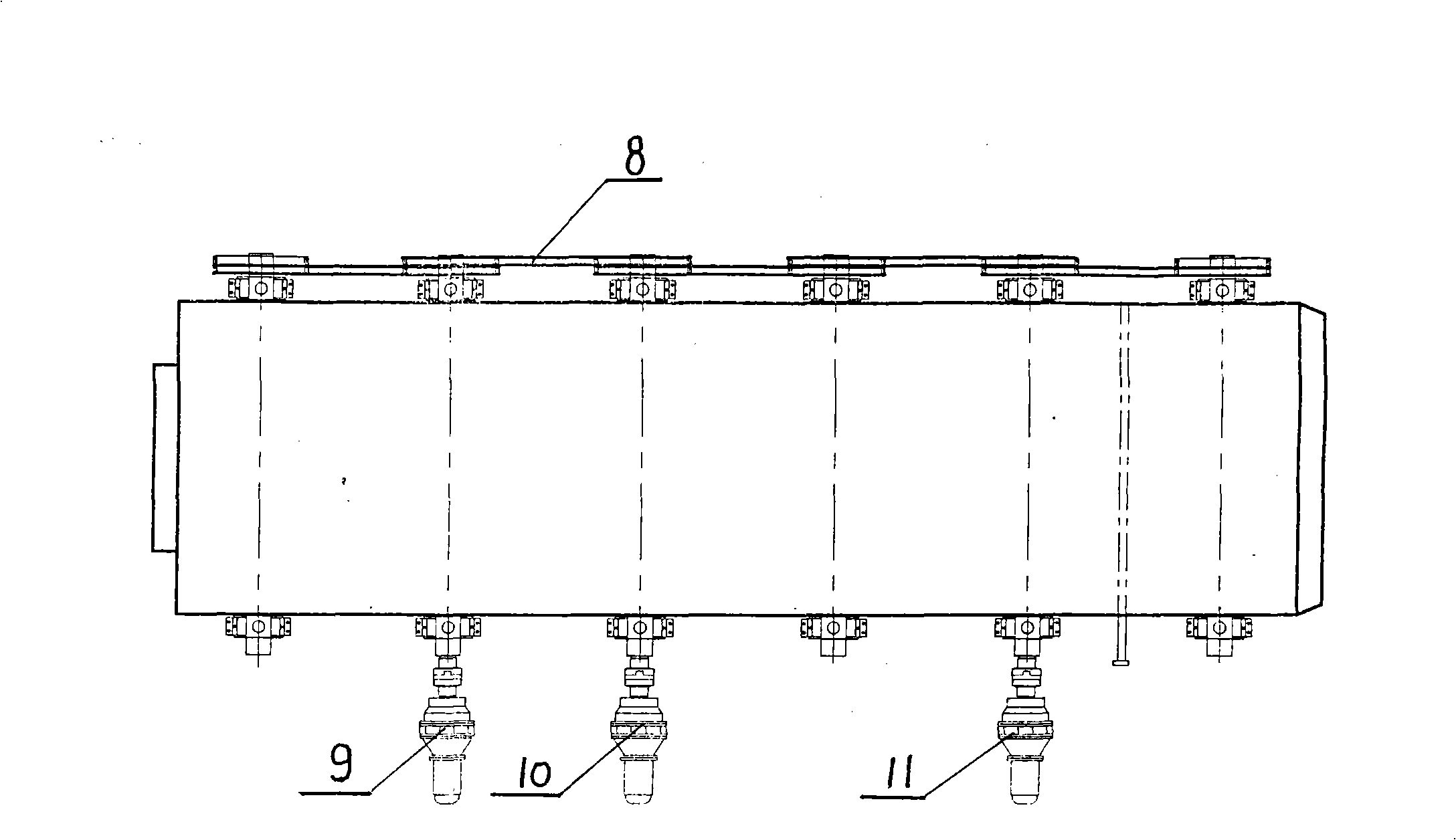

Burr removing device and method for cross deep oil hole with large ratio of length to diameter

InactiveCN106976008APracticalSimple structureEdge grinding machinesPolishing machinesPulp and paper industryInjector

The invention discloses a burr removing device for a cross deep oil hole with the large ratio of the length to the diameter. The burr removing device comprises a clamp and abrasive material cylinders. The abrasive material cylinders comprise the upper abrasive material cylinder and the lower abrasive material cylinder which are opposite. The clamp is clamped between the upper abrasive material cylinder and the lower abrasive material cylinder. An oil injector body to be subjected to burr removing is mounted on the clamp. Under the effect of extrusion force, abrasive materials are extruded from the lower abrasive material cylinder to the upper abrasive material cylinder and then extruded from the upper abrasive material cylinder to the lower abrasive material cylinder and move back and forth for a certain times. The oil hole of the oil injector body is polished through the abrasive materials, and burrs are removed. The structure is simple, using is convenient, and the manufacturing cost is low; and especially the serial clamp with multiple types and special for the oil injector body is high in practicability and can clamp a plurality of workpieces at a time, so that the production efficiency is improved by a large margin, and the requirement of batch production is met.

Owner:STATE RUN NO 616 FACTORY

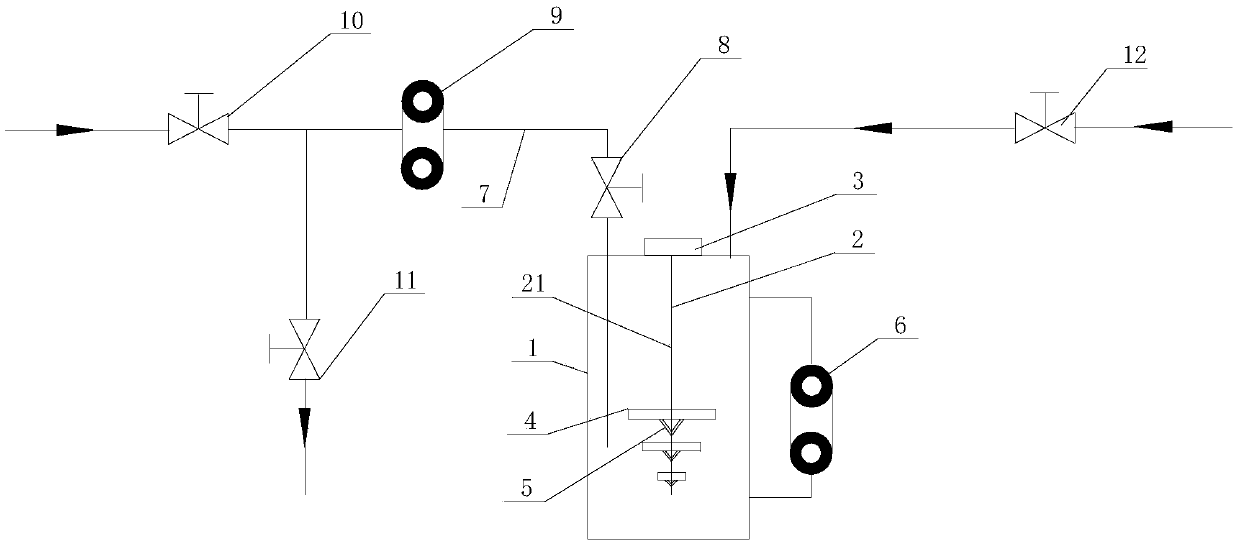

Steel pipe water pressure detecting device

ActiveCN104181047AMeet comprehensive testingQuality improvementMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumPipe waterUltimate tensile strength

The invention discloses a steel pipe water pressure detecting device and belongs to the technical field of steel pipe water pressure testing machines. The steel pipe water pressure detecting device comprises a rack, a left steel pipe clamping mechanism, a steel pipe water injecting mechanism, a right steel pipe clamping mechanism, a steel pipe opening sealing mechanism, a left steel pipe lifting mechanism, a right steel pipe lifting mechanism and a steel pipe dragging mechanism, wherein the left steel pipe clamping mechanism and the steel pipe water injecting mechanism are arranged at the left end of the rack; the right steel pipe clamping mechanism and the steel pipe opening sealing mechanism are arranged at the right end of the rack; the left steel pipe lifting mechanism is supported on a terrace and corresponds to the right side of the left steel pipe clamping mechanism, and the right steel pipe lifting mechanism is supported on the terrace and corresponds to the right side of the right steel pipe clamping mechanism; the steel pipe dragging mechanism is supported on the terrace and corresponds to the middle part of the rack. The steel pipe water pressure detecting device has high detection efficiency and allows a steel pipe manufacturer to carry out comprehensive detection on produced steel pipes, and the overstock of steel pipes to be detected can be avoided; the labor intensity of online detection workers is reduced, and the safety is ensured; the steel pipe manufacturer can conveniently control the quality of the produced steel pipes, and the phenomenon that unqualified defective steel pipes are mixed in qualified steel pipes is avoided.

Owner:CHANGSHUSMLESS STEEL TUBE

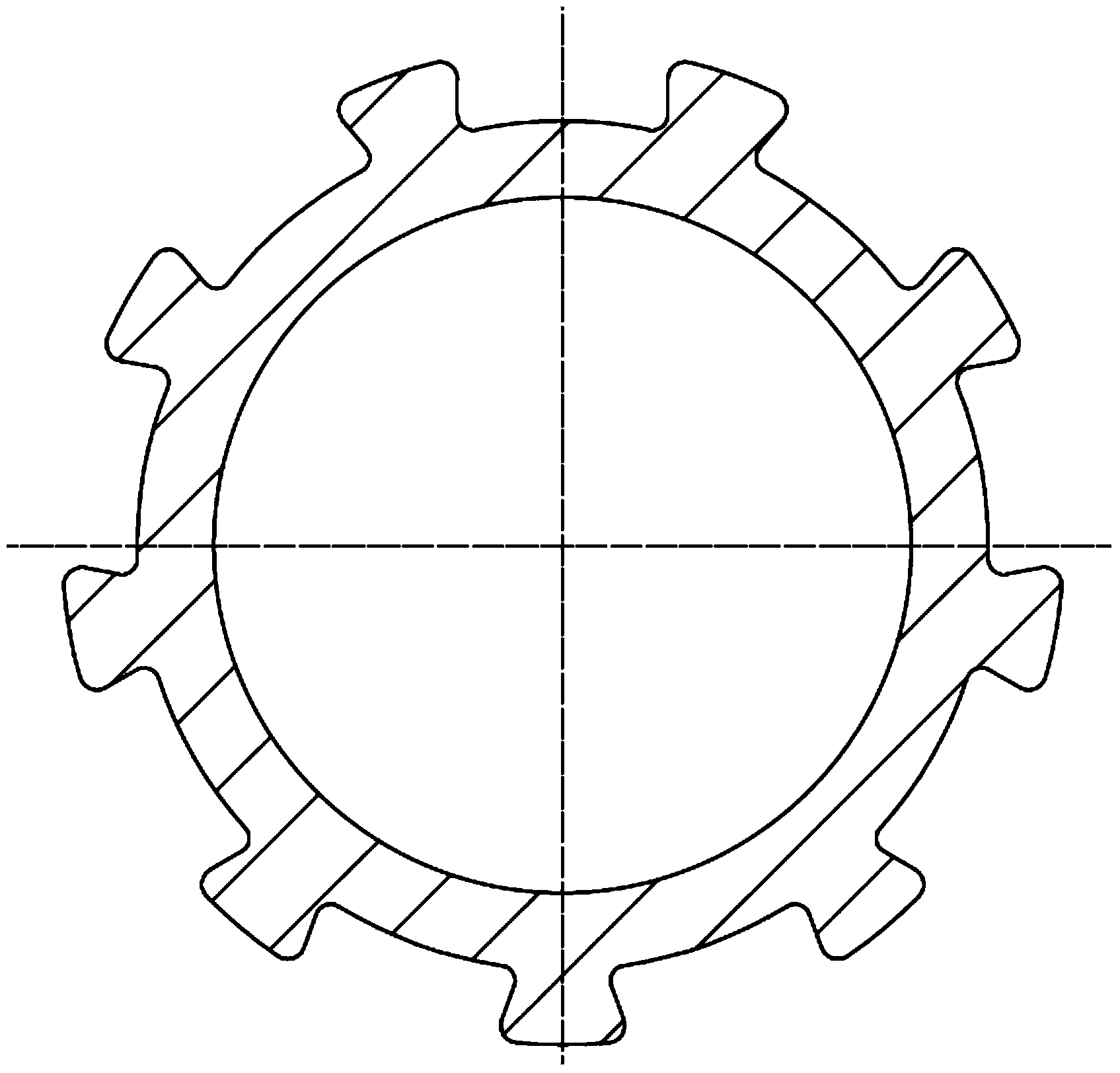

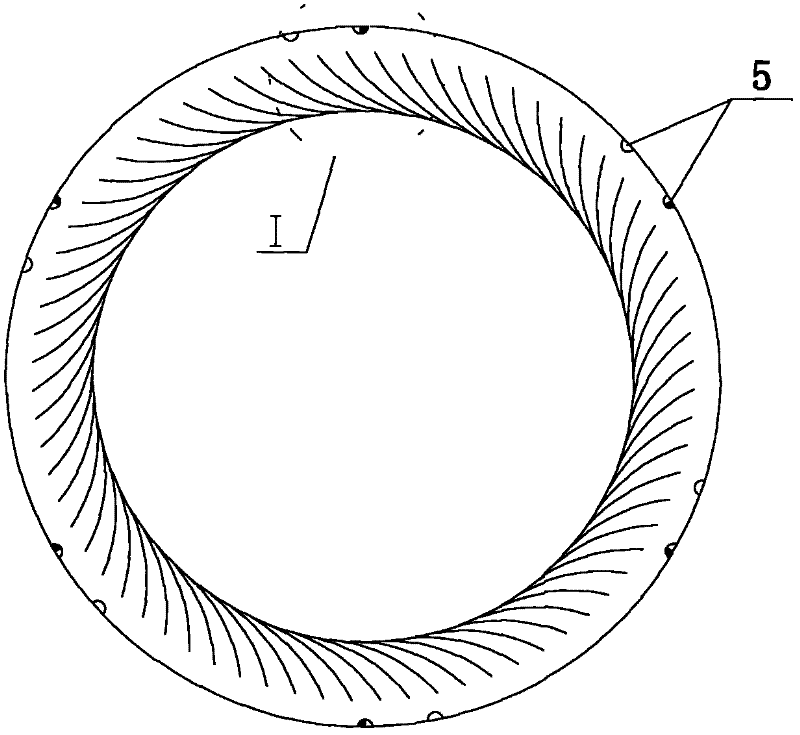

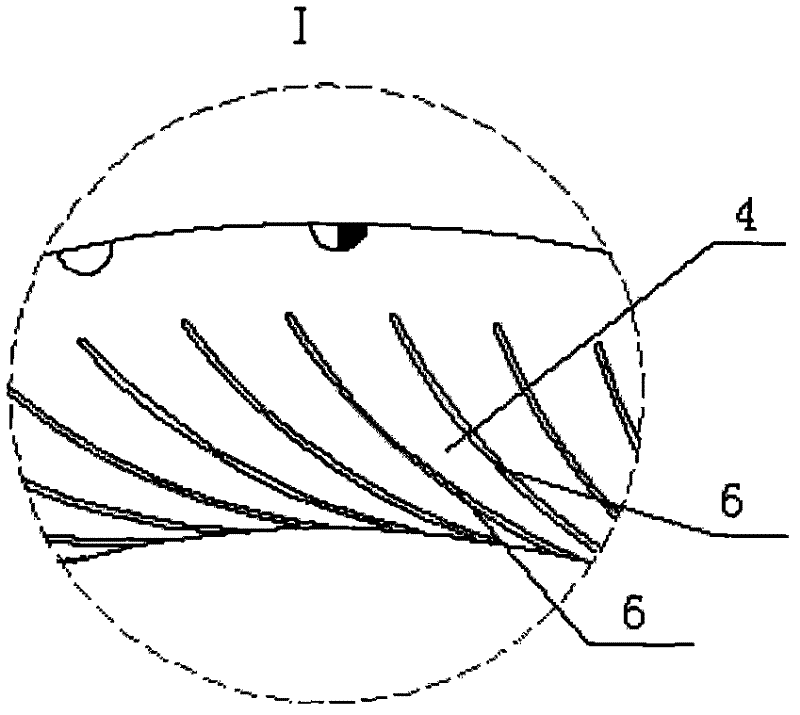

Fingertip sealing device

ActiveCN102418568ALow calorific valueGood sealingLeakage preventionMachines/enginesAxial displacementRelative displacement

The invention relates to a sealing device, in particular to a fingertip sealing device for controlling secondary flow leakage in a gas turbine engine. The fingertip sealing device consists of a front baffle plate, a rear baffle plate and a plurality of fingertip sheets arranged between the front baffle plate and the rear baffle plate, wherein both the front baffle plate and the rear baffle plate have annular platy structures; downwards sunken finger bodies which are arranged linearly are formed on the inner diameters of the fingertip sheets; the finger bodies between two adjacent layers of fingertip sheets are staggered; a plurality of pairs of assembly holes are formed in the fingertip sheets; and the front baffle plate, the rear baffle plate and the fingertip sheets are connected with one another through rivets in a riveting or welding mode. The fingertip sealing device can adapt to vibration of a shaft, relative displacement, which is produced by a centrifugal force and thermal deformation, between a rotor and the sealing device, and larger axial displacement of the rotor, so that aims of improving the sealing property and reducing leakage are fulfilled, and the service life is prolonged. The fingertip sealing device has the characteristics of being suitable for manufacturing sealing devices in various sizes and meeting requirements for batch production, along with simple structure and low cost.

Owner:AECC SICHUAN GAS TURBINE RES INST

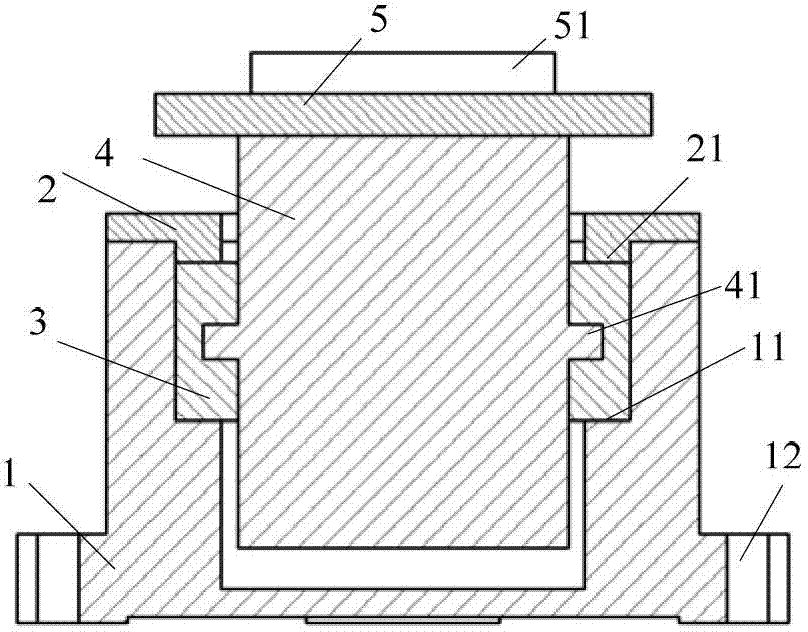

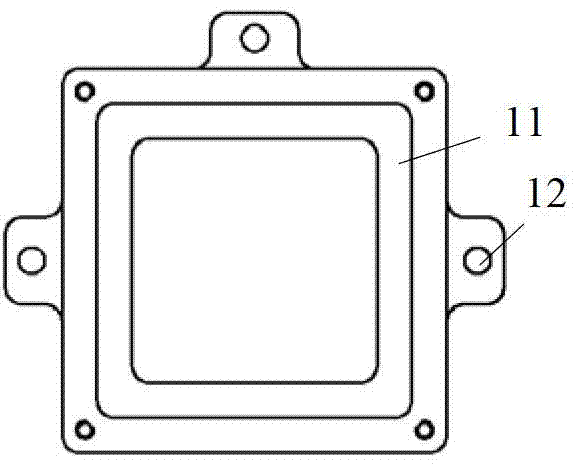

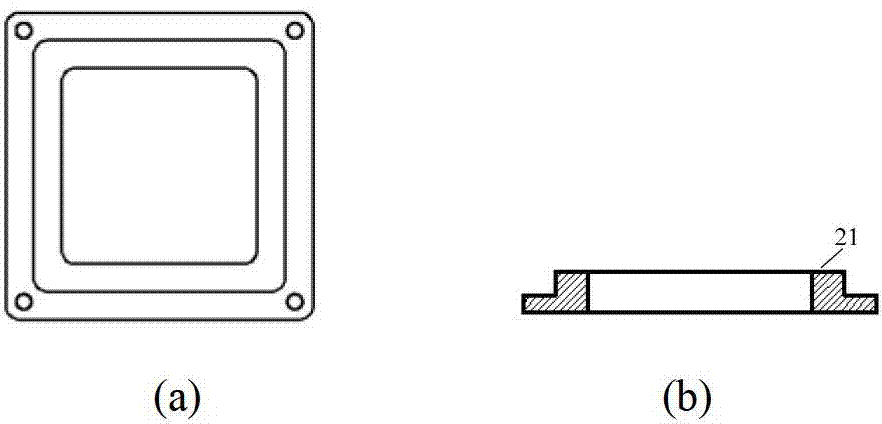

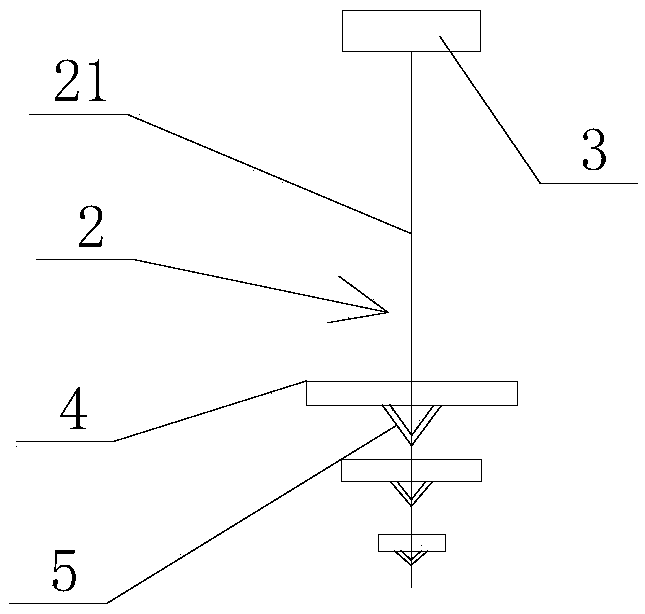

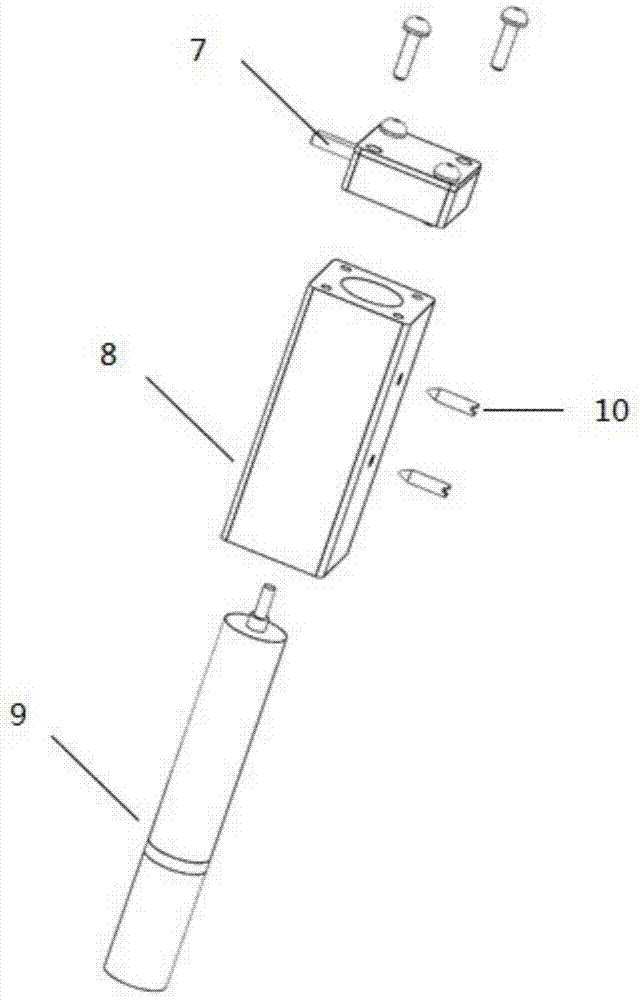

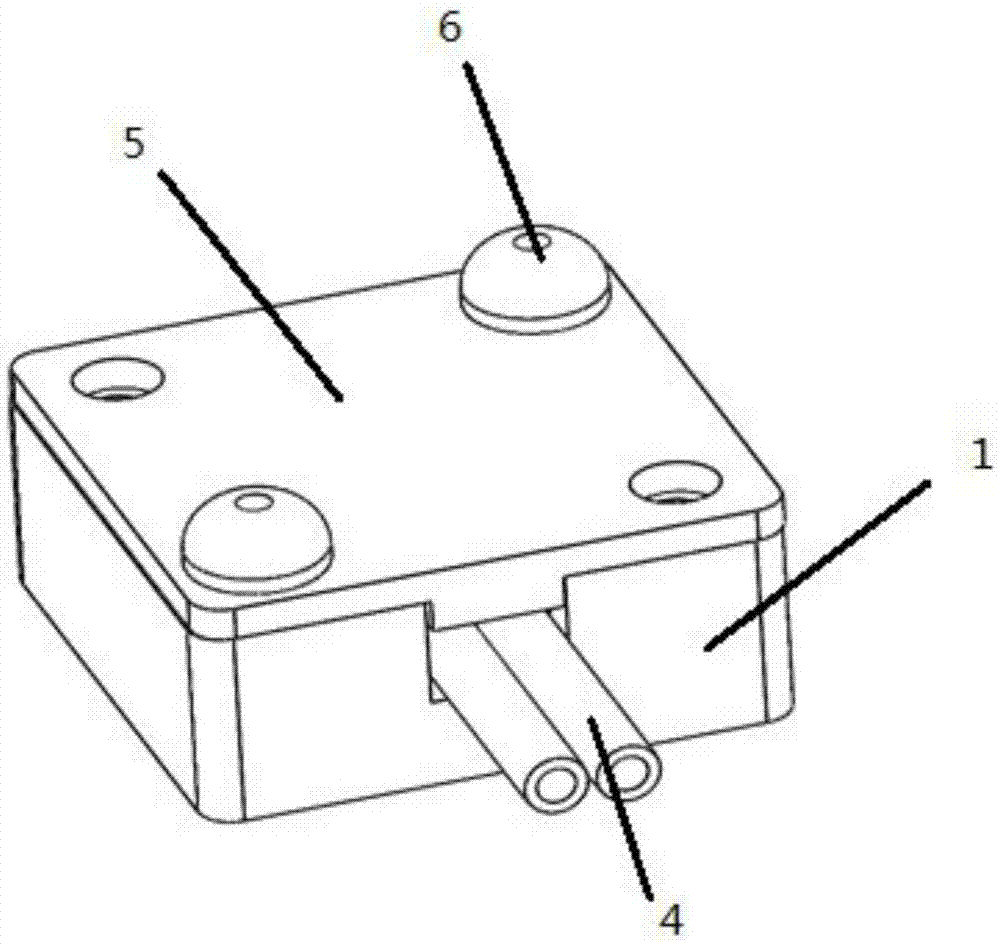

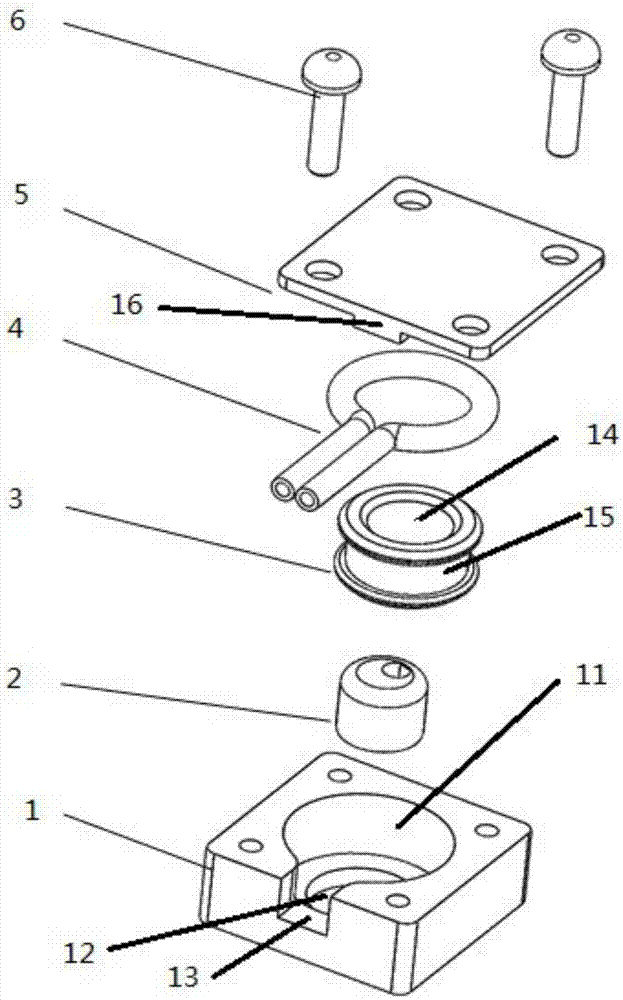

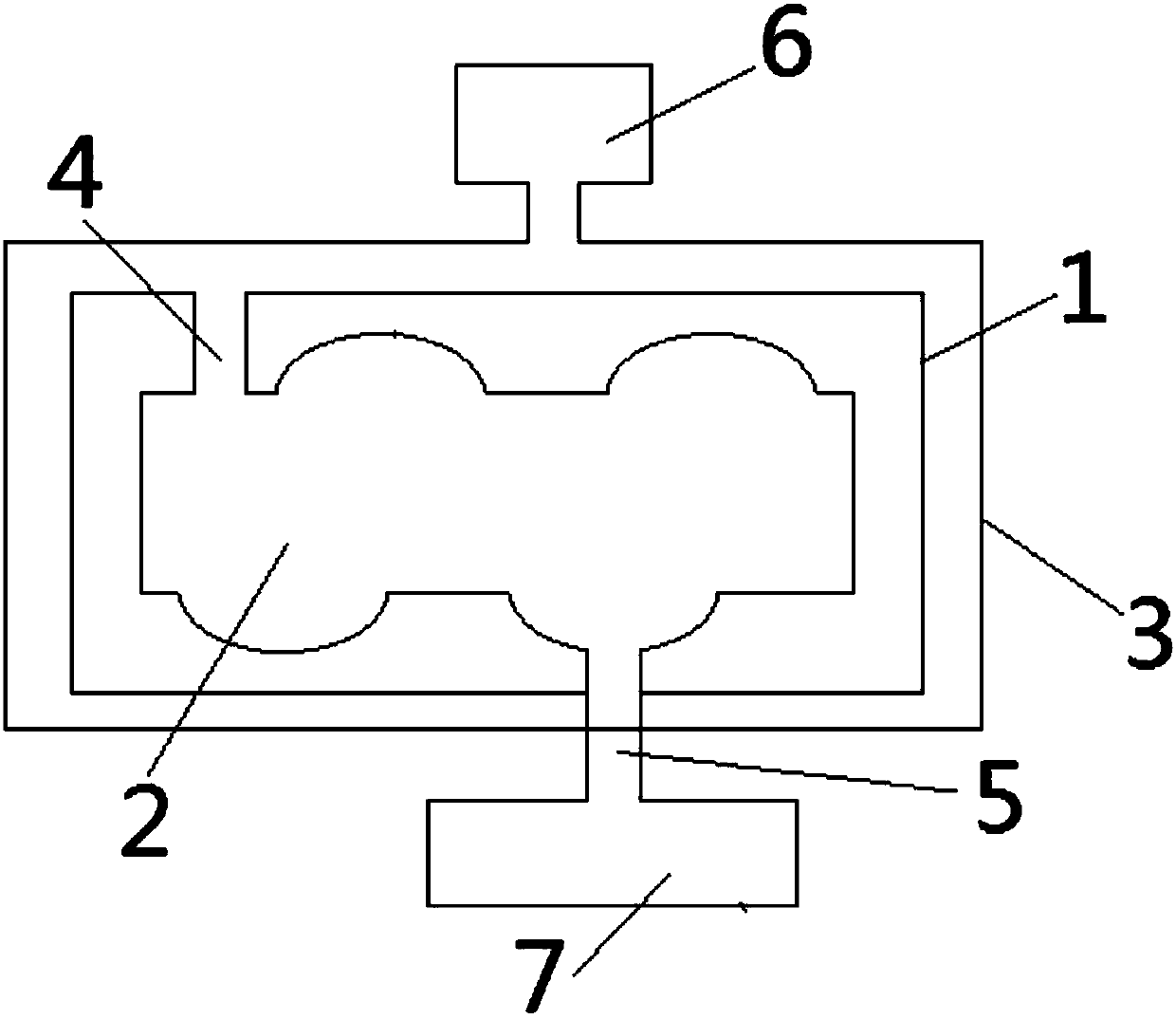

Vibration reduction testing device for chip type micro-gyroscope

The invention discloses a vibration reduction testing device for a chip type micro-gyroscope. The device comprises a rubber box, a rubber cover, a vibration reduction rubber, a mass block and a substrate, wherein the rubber box is fixed on a vibration table through installing holes arranged in the bottom of the rubber box, the inner wall of the cavity of the rubber box is provided with a first boss encircling the inner wall, a second boss encircling the outer wall of the mass block is arranged at a middle position of the outer wall, the vibration reduction rubber is provided with an assembling groove cooperating with the second boss, the mass block and the vibration reduction rubber are assembled together and then arranged in the cavity of the rubber box, the center of the rubber cover is perforated and arranged to be cooperative with the rubber box, the mass block passes through the central hole in the rubber cover, the interior surface of the rubber cover is provided with a third boss along the edge of the central hole, the third boss is pressed on the vibration reduction rubber, the substrate is fixedly arranged on the top of the mass block, and the upper surface of the substrate is provided with two fourth projecting blocks used for fixing the chip type micro-gyroscope. The vibration reduction testing device for the chip type micro-gyroscope has the advantages of a simple structure, convenient installation and adjustable frequency and meets requirements for batch production.

Owner:NANJING UNIV OF SCI & TECH

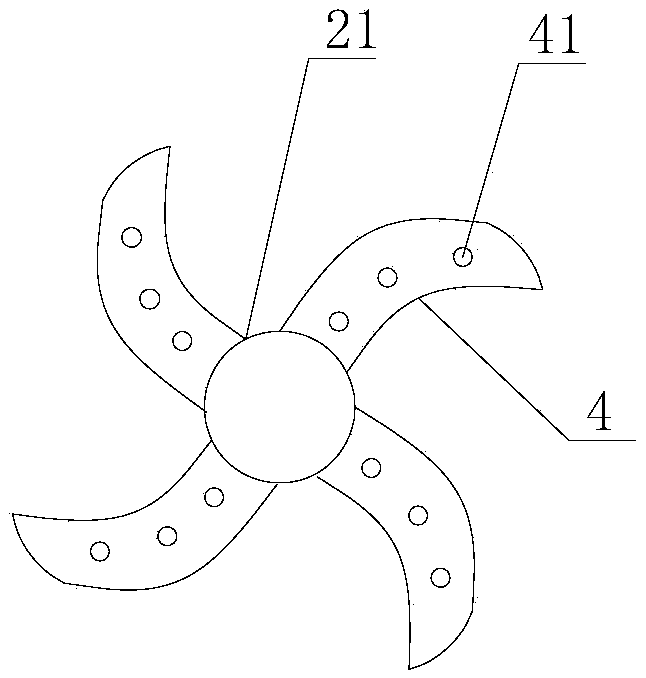

Automotive urea solution stirring device and production device with same

ActiveCN105498584AExtended service lifeStir wellTransportation and packagingRotary stirring mixersPulp and paper industryUrea

The invention discloses an automotive urea solution stirring device, and relates to the technical field of automobile engineering. The automotive urea solution stirring device comprises a stirring paddle arranged in a stirring tank and a motor, and the stirring paddle is connected with the motor and provided with blade sets with different lengths along a stirring shaft. The invention further discloses a production device comprising the automotive urea solution stirring device. The automotive urea solution is prepared in the stirring mode of driving the stirring paddle to rotate through the motor, and compared with an existing stirring mode for an automotive urea solution, the automotive urea solution stirring device is high in stirring efficiency and capable of meeting the requirement for mass production, and the stirring mode is uniform in stirring and greatly improves product quality. In addition, the stirring paddle is provided with the blade sets with different lengths along the stirring shaft and is better in stirring effect and long in service life compared with an existing stirring paddle provided with one blade set.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD

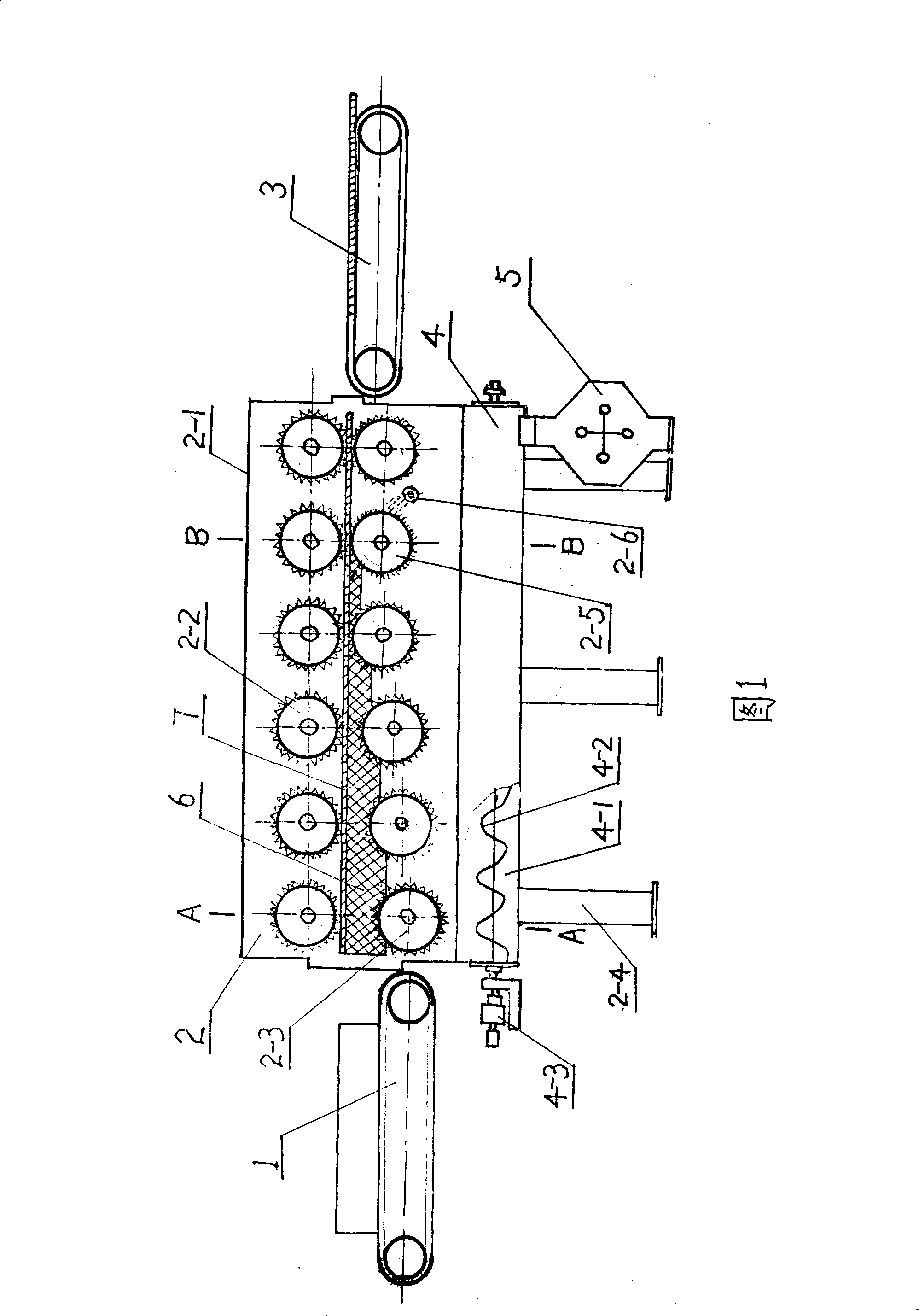

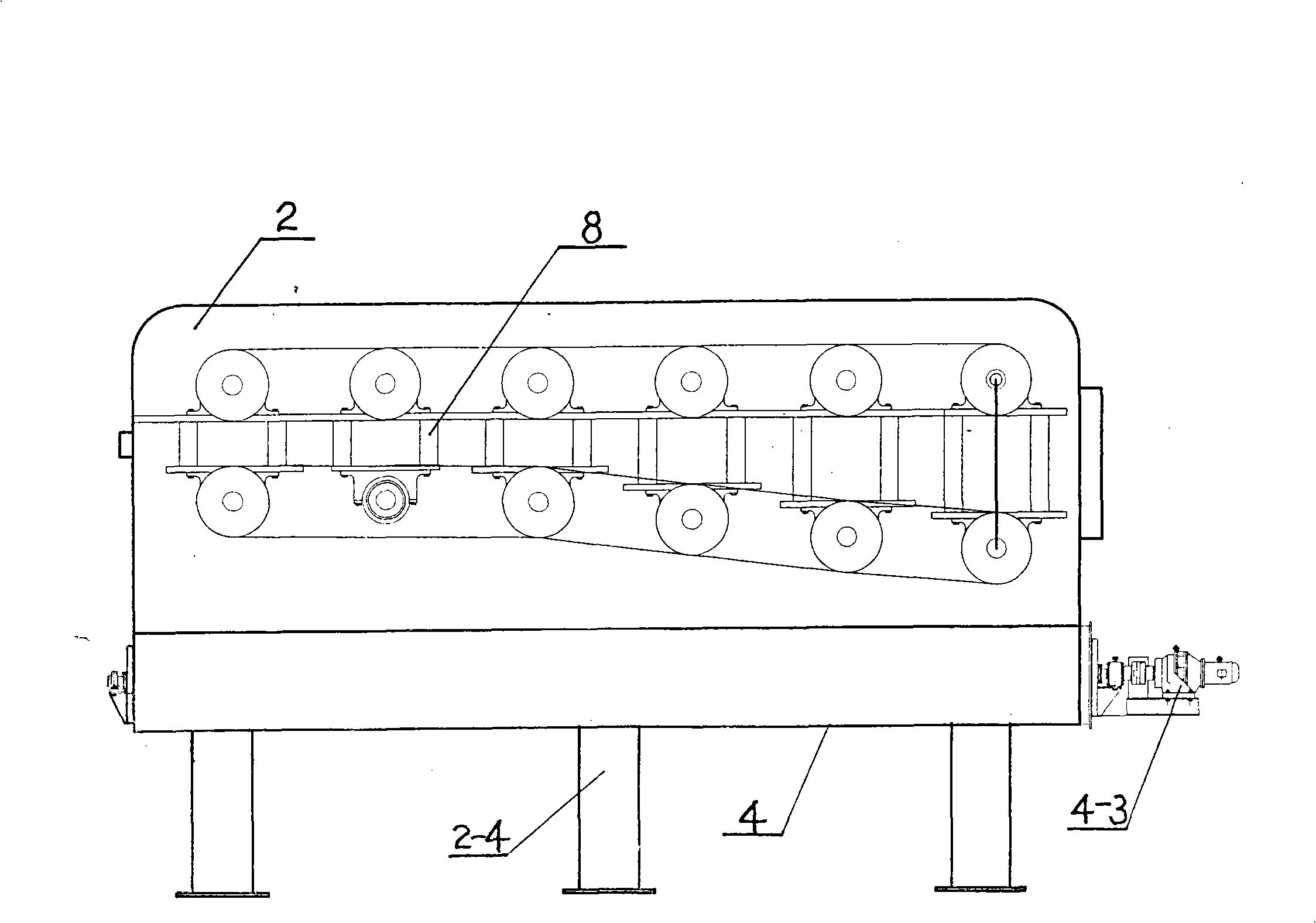

Extrusion type combined peeling machine and cornmill for Cycas revoluta

The invention relates to a crushing type Shagu tree combined peeling and milling machine, comprising a trunk conveyor, a peeling and core extracting machine, a bark conveyor, a tree core gathering and transportation mechanism and a crusher; the trunk conveyor and the bark conveyor are respectively arranged at the feed end and exit end of the peeling and core extracting machine; the tree core gathering and transportation mechanism is arranged at the bottom of the peeling and core extracting machine, and the tree core discharge end of the tree core gathering and transportation mechanism is connected with the crusher; the peeling and core extracting machine is provided with a box body arranged on a frame body; a pressing and feeding roll arranged on the upper row and a squeezing roll and a cleaning and scraping roll arranged on the lower row are respectively arranged in the box body; the pressing and feeding roll and the squeezing roll are respectively connected and interlocked by roll shafts, the chain driving parts arranged at both external sides of the box body and a motor; the cleaning and scraping roll is directly driven by the motor. The crushing type Shagu tree combined peeling and milling machine has the advantages that the machine can continuously perform peeling and tree core milling operation to the Shagu trees rapidly which have tough bark and soft core, and the machines has convenient operation, reliable performance, high productivity, low energy consumption, etc.

Owner:HENAN TIANGUAN GRP

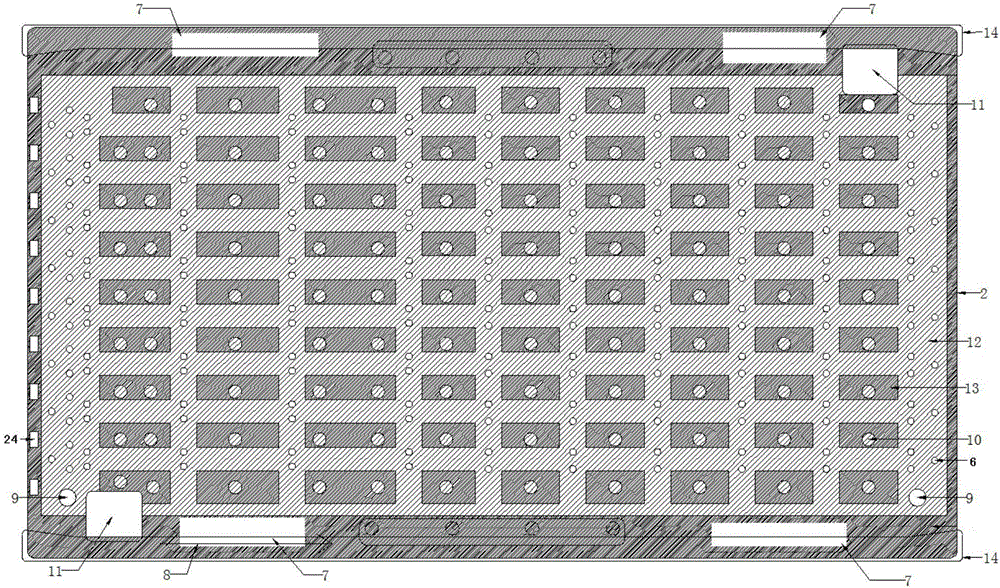

Multifunctional reflow jig for FPC lamp bar

ActiveCN106180956ANo soldering requiredEasy to usePrinted circuit assemblingWelding/cutting auxillary devicesReusabilityDie casting

The invention discloses a multifunctional reflow jig for an FPC lamp bar, and solves the technical problems that the influence of an existing jig for an FPC lamp bar on the temperature of a reflow welding furnace is excessive, and a steel cover piece and a magnetic structure of the jig both need welding, and have poor reusability. The following technical scheme is adopted: the multifunctional reflow jig for the FPC lamp bar comprises a carrying disc formed from a synthetic stone material in a die-casting manner, a location base matched and clamped with the carrying disc to form one piece and formed from an aluminium alloy material in a die-casting manner, a magnet embedded on the location base, and a steel cover piece closely attracted through the magnet, used for sealing the carrying disc on the location base and formed from a steel material in a die-casting manner. The multifunctional reflow jig has the following advantages: heat absorption influence is reduced through using the carrying disc formed from the synthetic stone material and a reflow fixing fixture, clip connection is used in the structure for many times, and a lighting fixture is designed, thus an assembly process is greatly simplified, and the production efficiency is increased.

Owner:NANJING CHINA ELECTRONICS PANDA LIGHTING

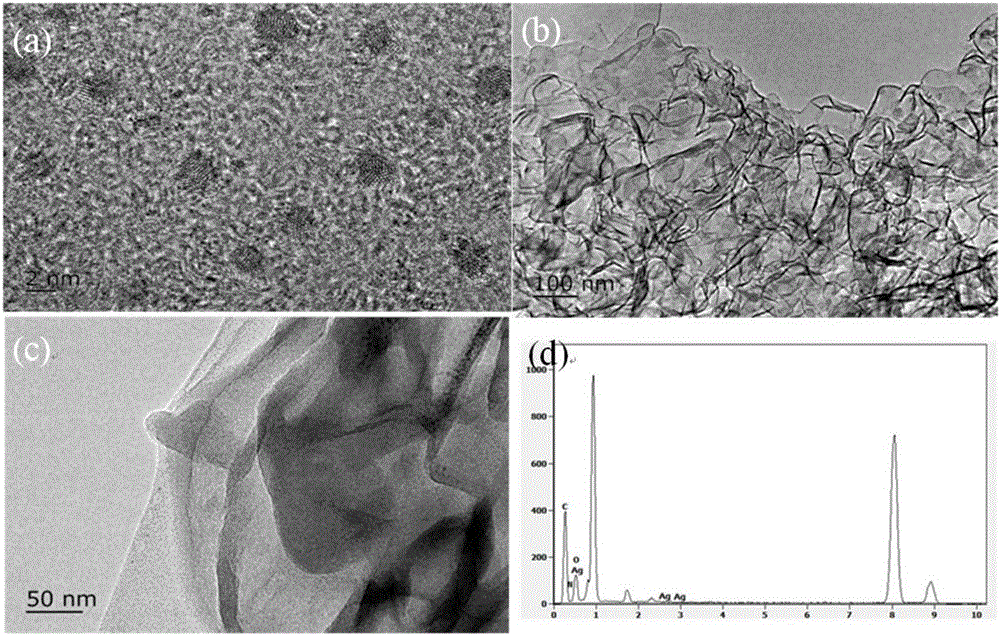

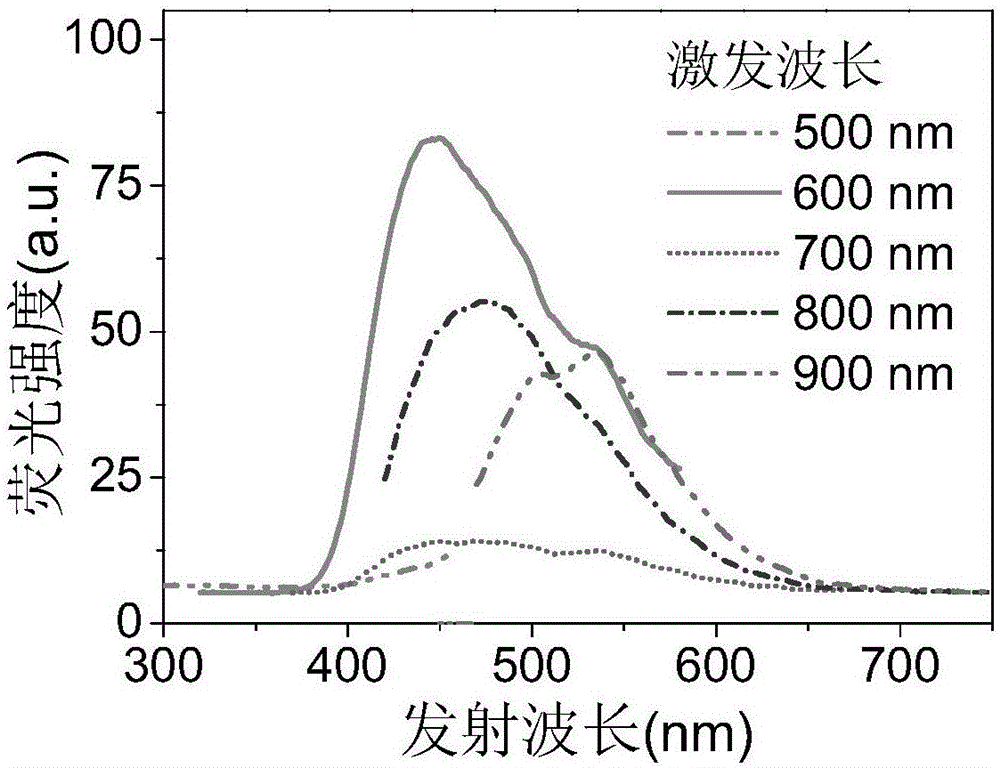

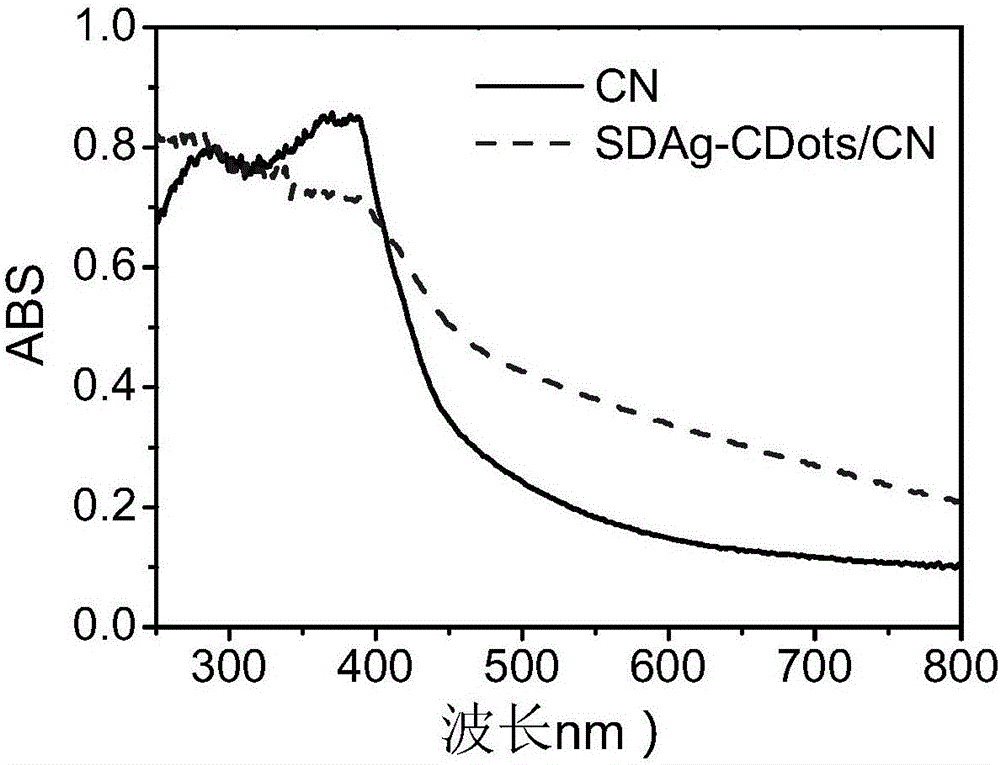

Monatomic silver-carbon point and carbon nitride composite catalyst, preparation method and application thereof

InactiveCN107519908AReduce recombination rateImprove utilization efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationEthylenediamineFiltration

The invention discloses a monatomic silver-carbon point and carbon nitride composite catalyst, a preparation method and an application thereof. The method comprises the following steps: respectively heating sodium tricyanohydrate aqueous solution and silver nitrate aqueous solution to 60-80 DEG C; dropwise adding the silver nitrate aqueous solution into the sodium tricyanohydrate aqueous solution under a stirring condition; stirring and staying overnight under room temperature; performing suction filtration and washing on the acquired flocculate and performing vacuum drying, thereby acquiring tricyanohydrate silver powder; adding glucose into quadrol and ultrapure water, reacting at 150-220 DEG C, cooling to room temperature, centrifuging, drying and grinding, thereby acquiring CDots powder; adding dicyandiamide, ammonium chloride, tricyanohydrate silver and CDots into ultrapure water, drying and calcining at 400-600 DEG C, cooling to room temperature and then grinding and sieving, thereby acquiring an SDAg-CDots / CN compound photocatalyst. The photocatalyst is capable of degrading a non-steroid anti-inflammatory agent under visible light.

Owner:GUANGDONG UNIV OF TECH

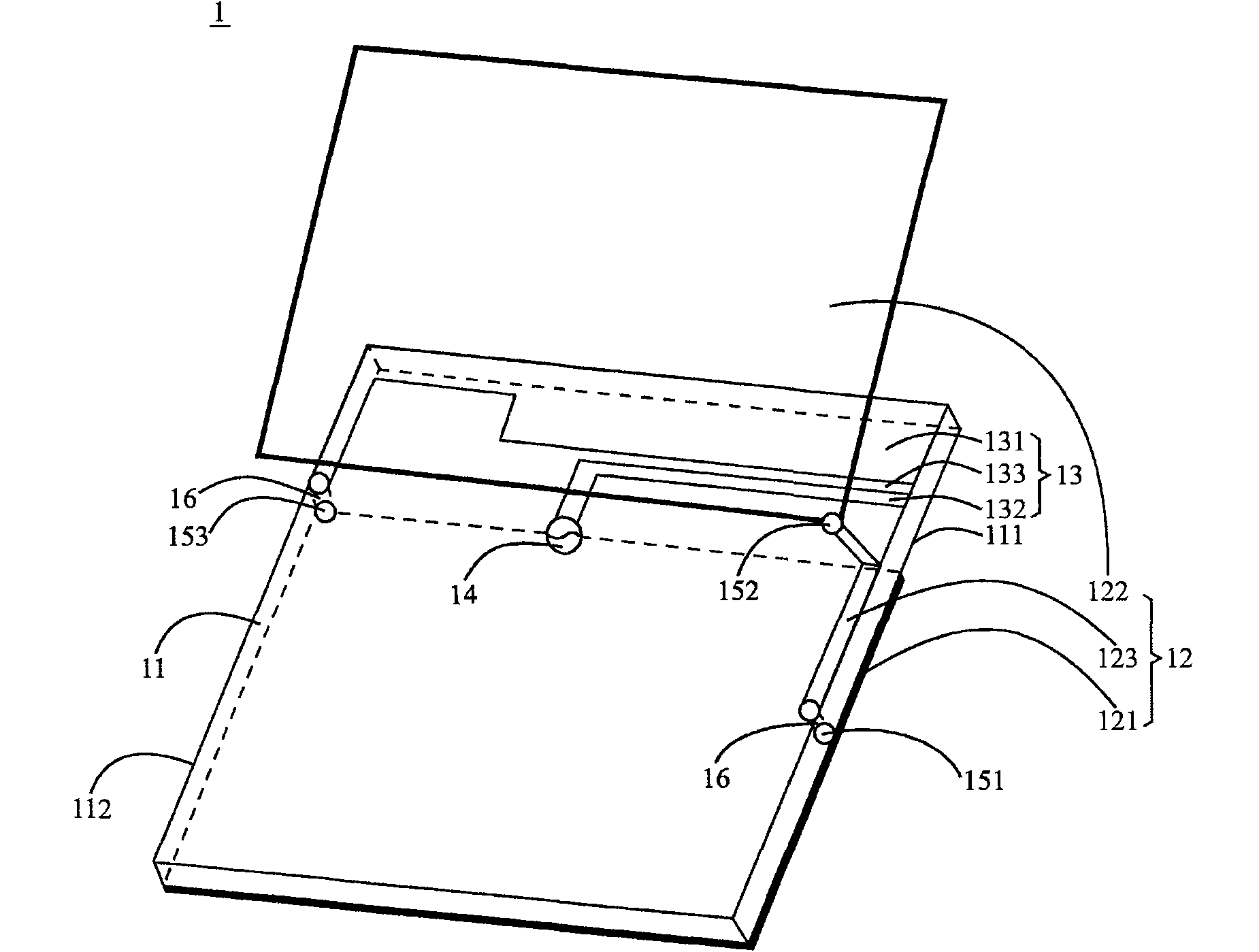

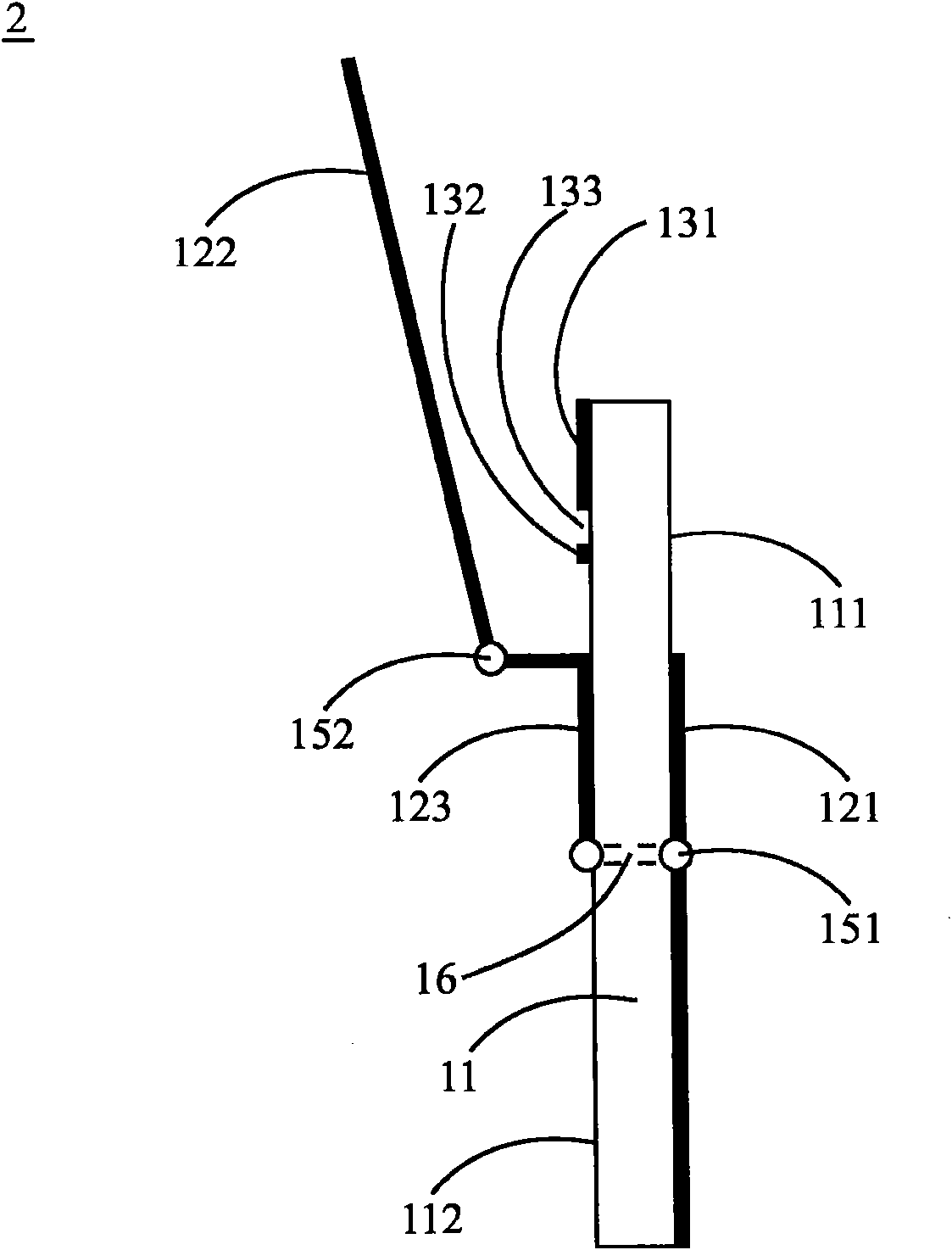

Multiband antenna and communication device with multiband antenna

ActiveCN101826651AAchieve the purpose of miniaturizationEasy to makeSimultaneous aerial operationsAntenna supports/mountingsEngineeringSignal source

The invention relates to a multiband antenna and a communication device with the multiband antenna. The multiband antenna is used for a communication device and comprises a medium substrate, a grounding part and a radiation metal part. The medium substrate comprises two surfaces. The grounding part comprises a first grounding surface, a second grounding surface and a connecting metal wire; the first grounding surface of the grounding part is positioned on one surface of the medium substrate and has a first connecting point and a short circuit point; the second grounding surface is close to the first grounding surface and has a second connecting point; one end of the connecting metal wire is connected with the first connecting point and the other end is connected with the second connecting point; and at least one part of the connecting metal wire is positioned on one surface of the medium substrate. The radiation metal part is positioned on one surface of the medium substrate and is not overlapped with the first grounding surface; and the radiation metal part comprises a radiation section and a feed-in section, wherein one end of the radiation section is connected to the short circuit point, and the other end is an open end; one end of the feed-in section is connected to a signal source, the other end is an open end, and the distance between the open end and the radiation section is less than 3mm.

Owner:ACER INC

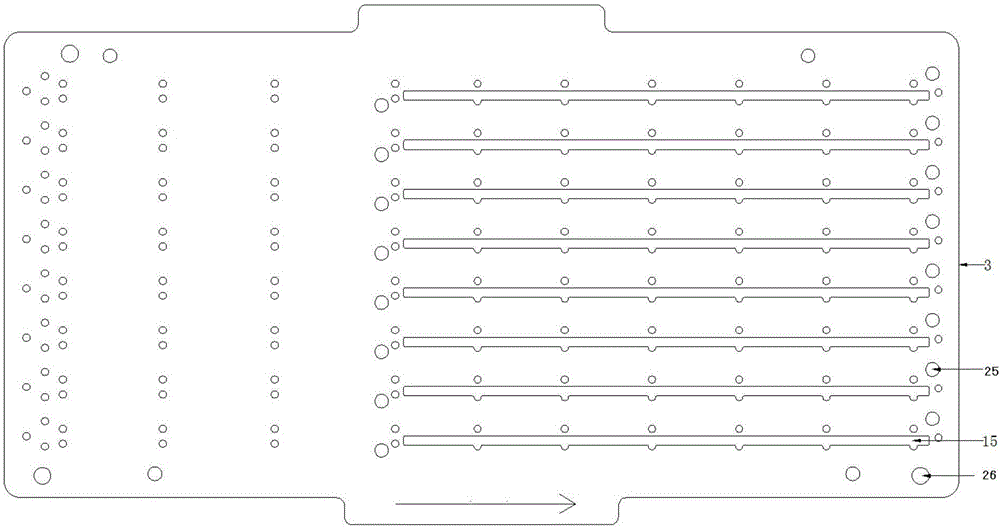

Single-use pipeline and pump head integrated split type micropump

ActiveCN105443363ACompact structureReduce volumeFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpMicropump

The invention relates to a split type miniature peristaltic pump, in particular to a miniature peristaltic pump, wherein a pipeline is integrated to a pump head, and both the pump head and the pipeline can be used for one time. The micropump comprises a pump body, a motor and a pump head and pipeline assembly. The pump head and pipeline assembly comprises a pump head seat, an eccentric wheel, a pump head roller and a circumferential pressing pipeline; a pump head seat center hole is formed in the pump head seat, a through hole is coaxially formed in the bottom of the pump head seat center hole, and a pipeline inlet / outlet groove is formed in one side of the pump head seat; the pump head roller is arranged in the pump head seat center hole, a pump head roller center hole is formed in the pump head roller, and the eccentric wheel is arranged in the pump head roller center hole and connected with an output shaft of the motor through an eccentric hole; and a pump head roller groove is formed in the outer wall of the pump head roller, and the circumferential pressing pipeline is sleeved with the pump head roller groove along the outer wall of the pump head roller. According to the micropump, the structure of the assembly formed by the pump head and the pipeline can guarantee that the pump is compact in structure and small in size; and the single-use purpose can be achieved, the pollution risk is lowered effectively, and the experiment success rate is increased to a great extent.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

Casting method for casting stainless steel workpiece through evanescent mold

InactiveCN107598087AImprove processing qualityComplex structureFoundry mouldsFoundry coresHigh volume manufacturingLiquid metal

The invention provides a casting method for casting a stainless steel workpiece through an evanescent mold applied to the technical field of evanescent mold casting. The casting method for casting thestainless steel workpiece through the evanescent mold comprises the casting steps that firstly, bake drying is carried out on a mold shell (2), and then the mold shell (2) is put into a sand mold (1); secondly, the sand mold (1) and the mold shell (2) are heated, and the mold shell (2) is disappeared in a liquidation manner; thirdly, the sand mold (1) is put into a sealed molding box (3), and airin the molding box (3) is extracted till the molding box (3) is extracted to a negative pressure state; and fourthly, a liquid metal raw material is poured into a workpiece cavity. By means of the casting method for casting the stainless steel workpiece through the evanescent mold, the machining quality of the stainless steel workpiece can be improved, the production efficiency of the stainless steel workpiece is improved, the large batch production requirement of the stainless steel product is met, meanwhile, the environmental friendly and energy saving effects can be obviously improved, andthe stainless steel workpiece with a complex structure and surface quality superior to that of a traditional process is manufactured.

Owner:ANHUI WEIGONG MACHINERY TECH

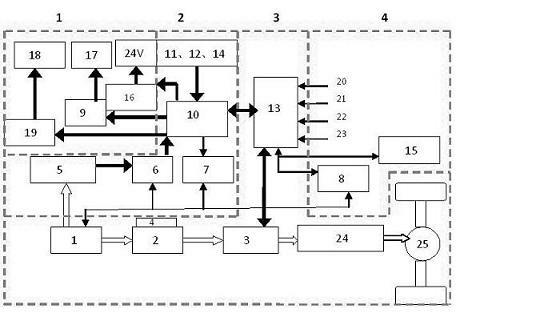

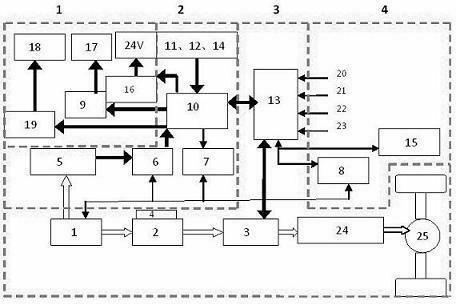

Plug-in hybrid electric bus electromechanical coupling system

ActiveCN102658773AImprove reliabilityReduce energy consumptionHybrid vehiclesGas pressure propulsion mountingElectric machineryDrive motor

The invention discloses a plug-in hybrid electric bus electromechanical coupling system which comprises an auxiliary power system region, an energy source region, a transmission system region and a control and signal region. On the basis of the characteristic that a series-parallel plug-in hybrid electromechanical coupling system integrates series hybrid power and parallel hybrid power, the plug-in hybrid electric bus electromechanical coupling system disclosed by the invention can ensure both an engine and a driving motor to work in a high efficiency region under any condition, has wider application range and has the advantages of fulfilling the aims of improving the reliability of a finished automobile and reducing the energy consumption by the high integration and integrated control of the system and meeting the requirement on the mass production.

Owner:ZHONGTONG BUS HLDG

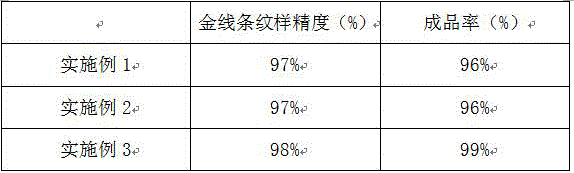

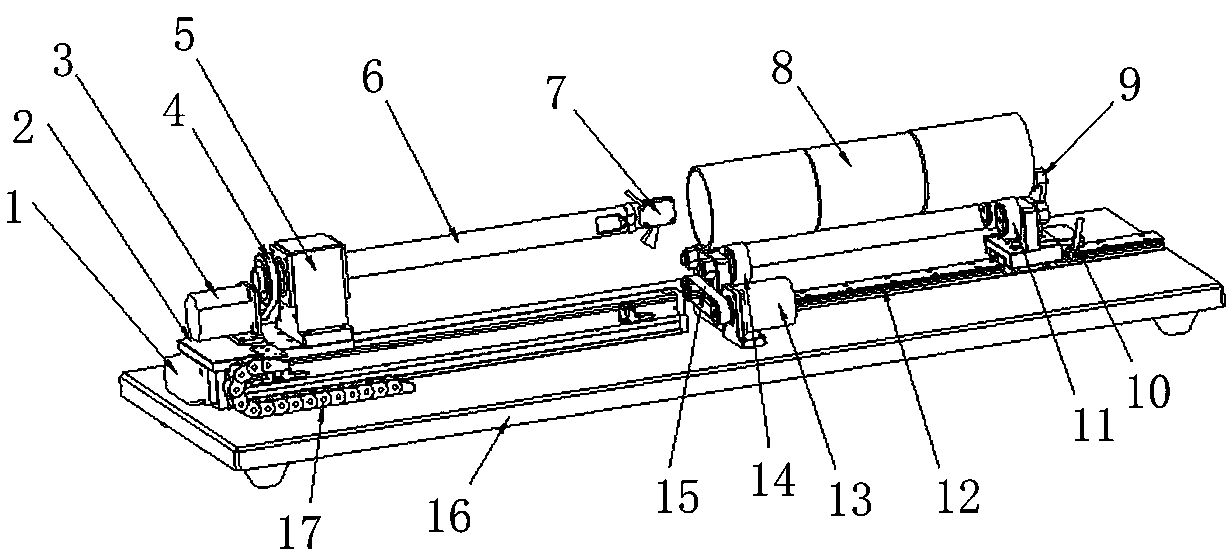

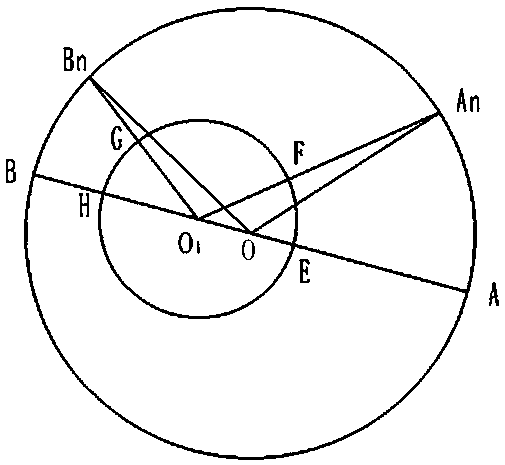

Making process for lacquer painting with gold wires embedded in surface

InactiveCN106696589AImprove effect controllabilityGuaranteed accuracySpecial artistic techniquesBatch productionLacquer

The invention discloses a making process for a lacquer painting with gold wires embedded in the surface. By means of the steps of lacquer body preparation, primer preparation, primer coating, manuscript making, plant gum coating, filigreeing, japanning, grinding for showing, clear lacquer covering, pushing for brightening and clean wiping, the making process for the lacquer painting with the gold wires embedded in the surface is completed. The making process for the lacquer painting with the gold wires embedded in the surface has the beneficial effects that the final effect controllability of the lacquer painting can be effectively improved, the precision of stripe patterns of gold lines is guaranteed, the texture consistency of a plurality of frames is guaranteed, the batch production requirement is met, the rate of finished products is increased, and the process is convenient and fast, and is easy to master.

Owner:IANGSU COLLEGE OF ENG & TECH

Non-contact extreme value method inner diameter detection method and device

InactiveCN110906876ALow rotational control accuracy requirementsRealize non-destructive testingUsing optical meansEngineeringComputational physics

The invention belongs to the technical field of high-precision non-contact detection. Only qualitative detection can be carried out by adopting contact detection; the surface of the part is possibly scratched during detection; sampling points are few, the detection efficiency and precision are low; by adopting a laser non-contact measurement three-point method, a least square method, normal and cosine laws and other methods, the calculation formula is tedious, the process is complex, the system operation is slow, and the efficiency is low. The invention provides a non-contact extreme value method inner diameter detection method and device. The rotation radius of the sensor is determined after the device is calibrated through a standard part; the sensor mounting rod extends into the inner cavity of the to-be-measured piece for measurement, and the inner diameter of the to-be-measured piece is calculated according to measured data and the rotation radius of the sensor. According to the method, nondestructive measurement is achieved, the detection precision is high, calculation is simple and efficient, large-batch offline or online detection can be met, and the requirement for the rotation control precision of the sensor is low.

Owner:SHANXI DIMAI WOKE PHOTOELECTRIC IND CO LTD

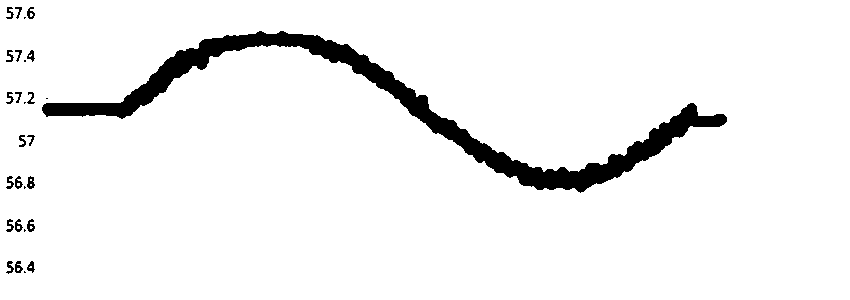

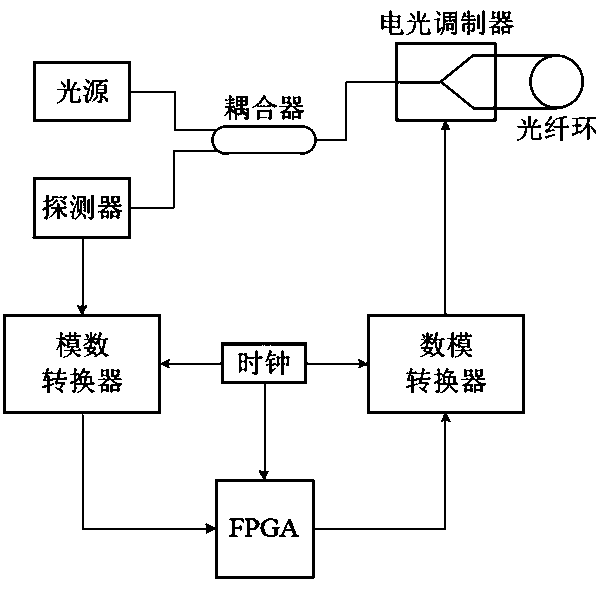

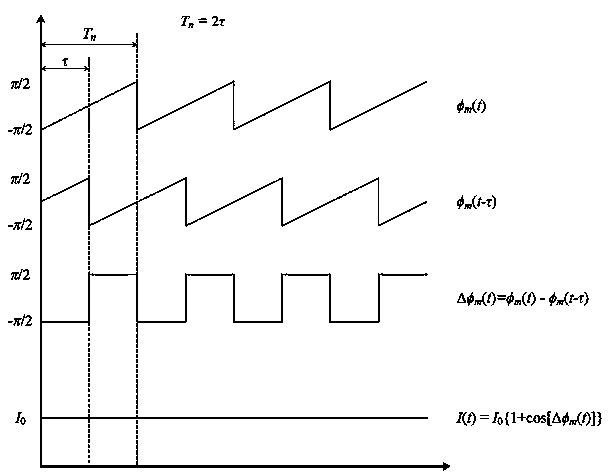

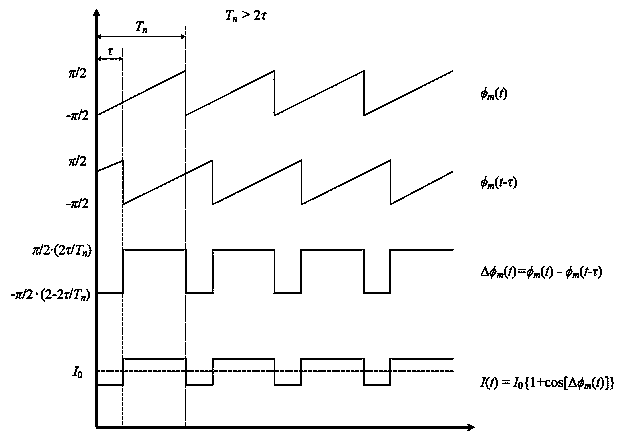

Quick measuring method for fiber-optic gyroscope transition time based on digital sawtooth wave

InactiveCN103940593ASatisfy engineeringMeet mass production requirementsSagnac effect gyrometersTesting optical propertiesFiberGyroscope

The invention discloses a quick measuring method for fiber-optic gyroscope transition time based on digital sawtooth wave. An electrooptical modulator is modulated by digital sawtooth wave signals, the sawtooth wave signals are traversed in a periodical value range one by one in a progressive increasing mode, modulation results of sawtooth wave signals in different periods are sampled and processed to form a result sequence, an initial measuring result is calculated out according to the period of the sawtooth wave signals corresponding to the minimum value in the result sequence, a second periodical value range is set according to the initial measuring result, the above steps are repeated to obtain a second measuring result sequence, and a second measuring result is calculated according to the period of the sawtooth wave signal corresponding to the minimum value of the second measuring result sequence to obtain a final fiber-optic gyroscope transition time. The quick measuring method can quickly test the fiber-optic gyroscope transition time without adding testing equipment or periods, solves the problem of transition time change caused by adjusting an optical system in a fiber-optic gyroscope producing process and flexibly meets engineering and batching production of fiber-optic gyroscopes.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com