Fingertip sealing device

A fingertip seal and assembly hole technology, which is applied in the direction of leakage prevention, engine components, machines/engines, etc., can solve the problems of complex processing, poor sealing performance of fingertip seal structure, high production cost, etc., and achieve simple processing technology, Meet the requirements of mass production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

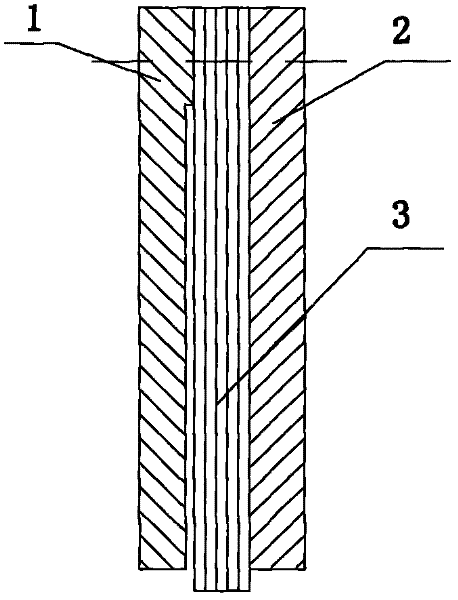

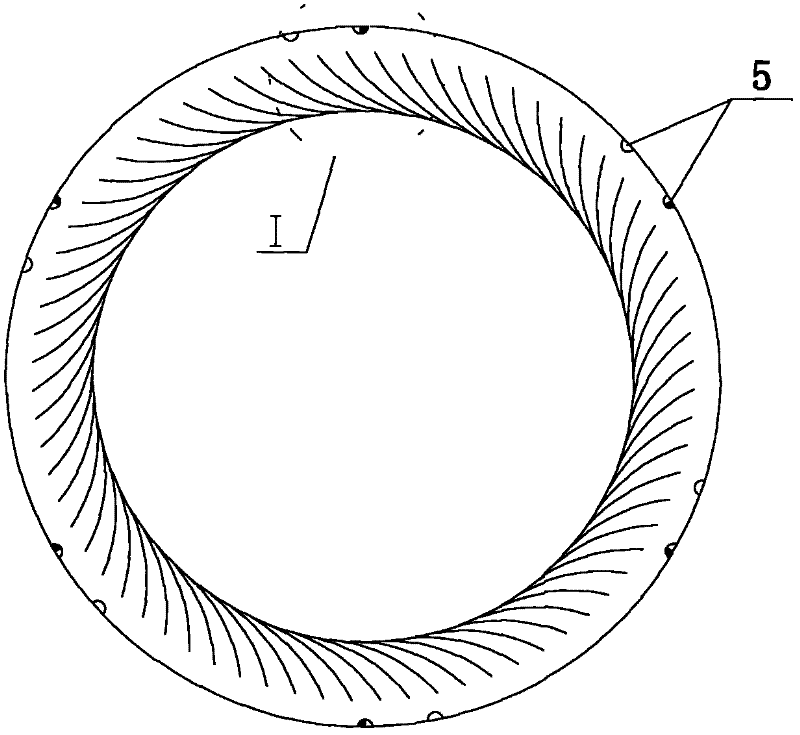

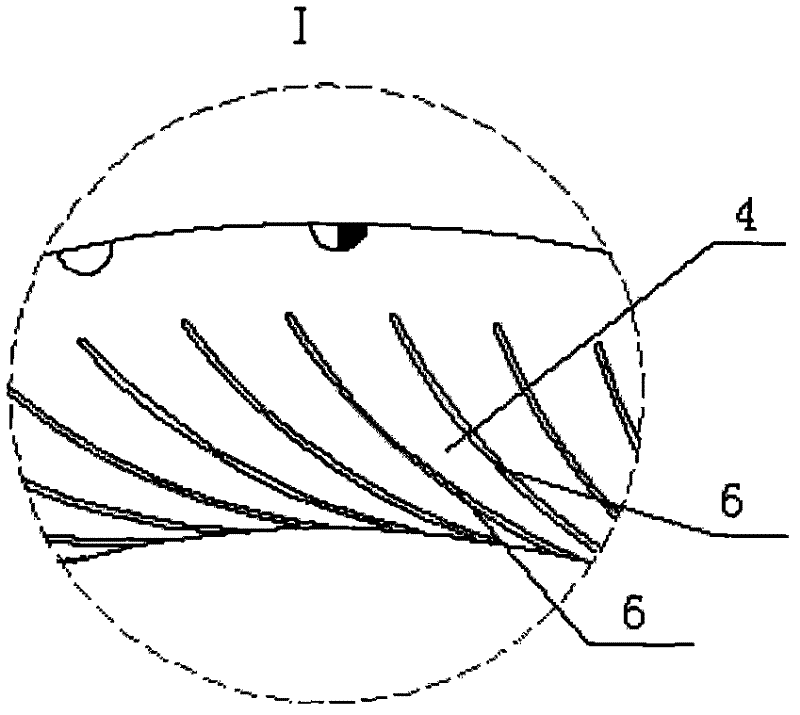

[0013] see figure 1 , which is a structural schematic diagram of the first embodiment of the fingertip sealing device of the present invention. The fingertip sealing device is composed of a front baffle 1, a rear baffle 2 and five layers of fingertip sheets 3 arranged between the two, and the front baffle 1, the rear baffle 2 and the fingertip sheets 3 are made of Riveted or welded connection. Wherein, the front baffle 1 is an annular plate-like structure, and its main function is to support and protect the fingertip sheet 3. This structure is similar to the front lining ring of the hydrostatic pressure fingertip seal structure, but has the The function of the backing ring and front spacer. The tailgate 2 is also an annular plate-shaped structure, and its main function is to support and protect the fingertip sheet 3. This struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com