Making process for lacquer painting with gold wires embedded in surface

A kind of production process and technology of gold wire, applied in the direction of decorative art, art painting, etc., can solve the problems that are not suitable for mass production, standardized production, uncertainty, etc., to ensure the consistency of texture, easy to master, and craftsmanship convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

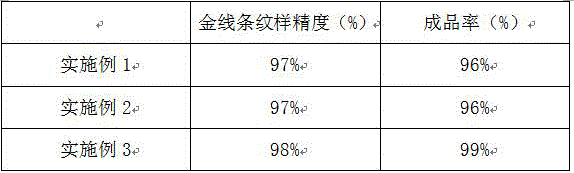

Examples

Embodiment 1

[0022] A lacquer painting production process of inlaid gold wires on the surface, after preparing the paint body, preparing the primer, applying the primer, rendering the draft, applying vegetable glue, filigree, painting, polishing, covering with transparent paint, polishing and wiping Clear the steps to complete the lacquer painting process of surface inlaid with gold wire; the specific steps are as follows:

[0023] (1) Prepare the paint tire: select imported five-plywood as the base plate, sand it with water sandpaper, and then mount a layer of gauze cloth on the base plate through latex, cut off the excess gauze cloth after drying, and set aside, the thickness of the gauze cloth 0.11mm;

[0024] (2) Preparation of primer: take raw lacquer and fine tile ash and mix evenly to prepare a primer. The mixing mass ratio of raw lacquer and fine tile ash is 1:1;

[0025] (3) Apply the primer: brush the primer evenly on the paint tire, and apply it 3 times with an interval of 24 h...

Embodiment 2

[0035] A lacquer painting production process of inlaid gold wires on the surface, after preparing the paint body, preparing the primer, applying the primer, rendering the draft, applying vegetable glue, filigree, painting, polishing, covering with transparent paint, polishing and wiping Clear the steps to complete the lacquer painting process of surface inlaid with gold wire; the specific steps are as follows:

[0036] (1) Prepare the paint tire: select imported five-plywood as the base plate, sand it with water sandpaper, and then mount a layer of gauze cloth on the base plate through latex, cut off the excess gauze cloth after drying, and set aside, the thickness of the gauze cloth 0.16mm;

[0037] (2) Preparation of primer: take raw lacquer and fine tile ash and mix evenly to prepare primer. The mixing mass ratio of raw lacquer and fine tile ash is 1:2;

[0038] (3) Apply the primer: brush the primer evenly on the paint tire, and apply it 5 times with an interval of 36 hou...

Embodiment 3

[0048] A lacquer painting production process of inlaid gold wires on the surface, after preparing the paint body, preparing the primer, applying the primer, rendering the draft, applying vegetable glue, filigree, painting, polishing, covering with transparent paint, polishing and wiping Clear the steps to complete the lacquer painting process of surface inlaid with gold wire; the specific steps are as follows:

[0049] (1) Prepare the paint tire: select imported five-plywood as the base plate, sand it with water sandpaper, and then mount a layer of gauze cloth on the base plate through latex, cut off the excess gauze cloth after drying, and set aside, the thickness of the gauze cloth 0.15mm;

[0050] (2) Preparation of primer: take raw lacquer and fine tile ash and mix evenly to prepare a primer. The mixing mass ratio of raw lacquer and fine tile ash is 1:1.5;

[0051] (3) Apply the primer: brush the primer evenly on the paint tire, and apply it 4 times with an interval of 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com