Detection device of swash plate and piston axial matched gap and using method thereof

A technology for matching gaps and detection devices, applied to measuring devices, mechanical gap measurement, instruments, etc., can solve problems such as measurement errors, deviations, and large errors in matching results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

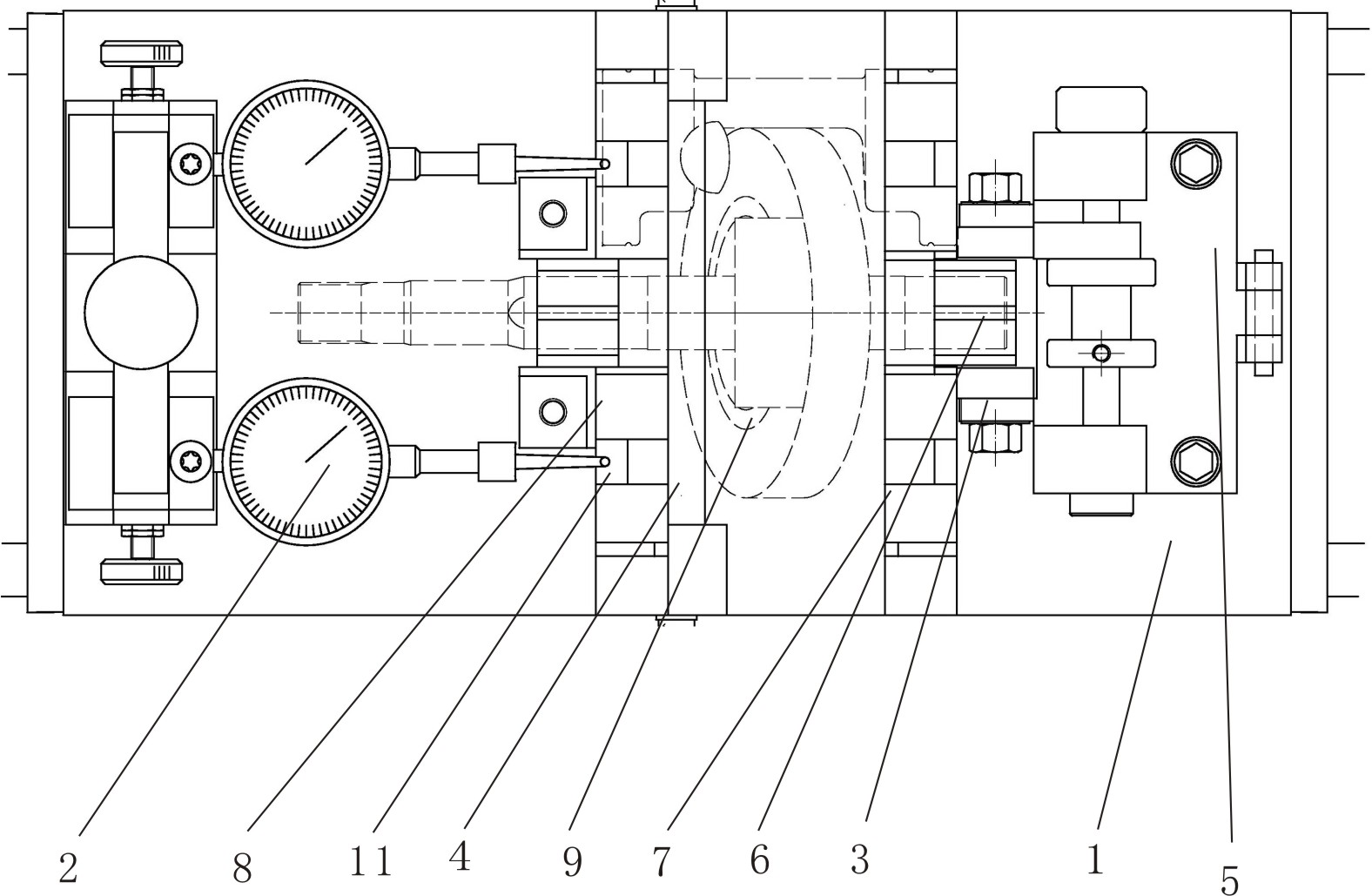

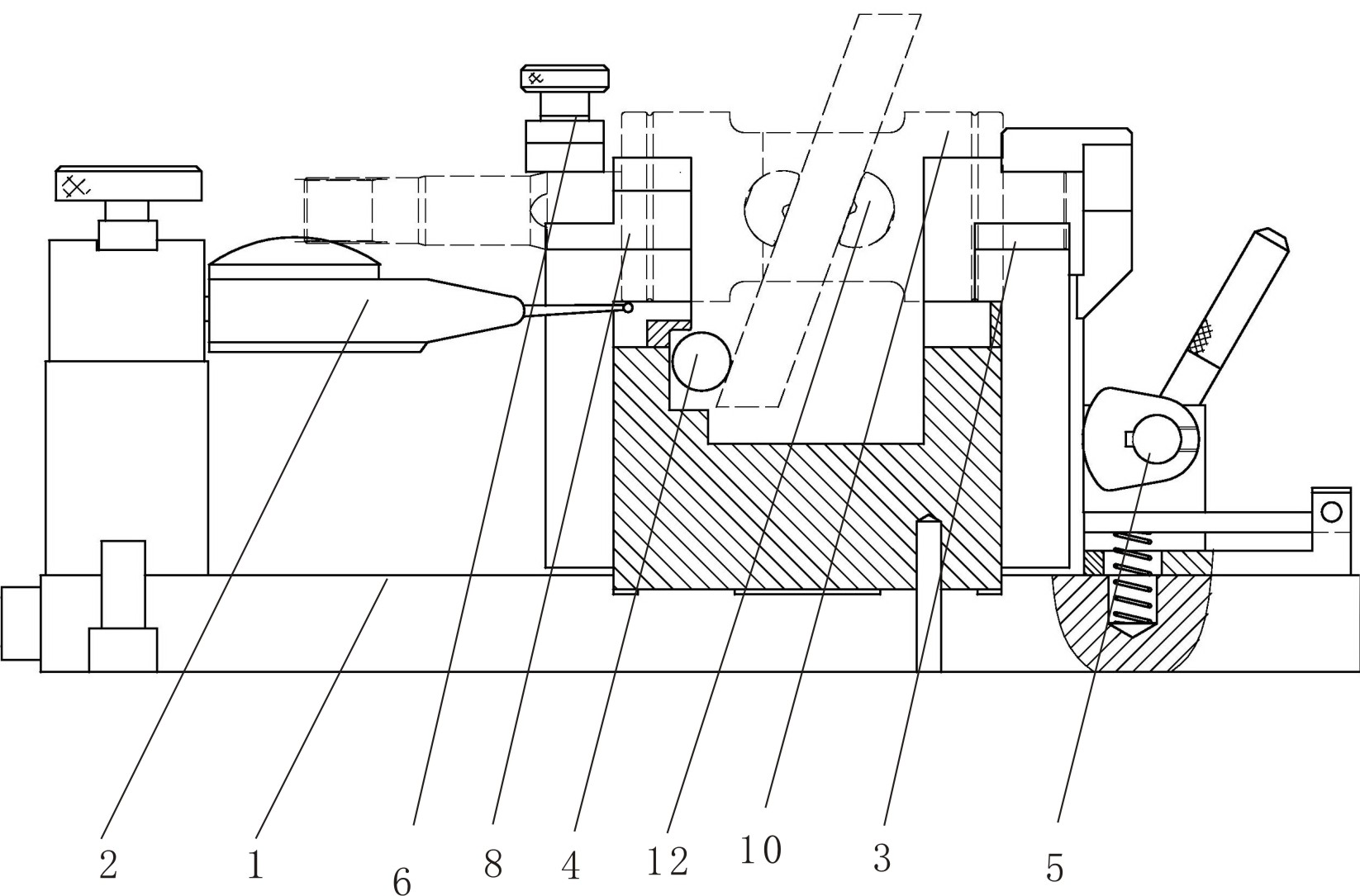

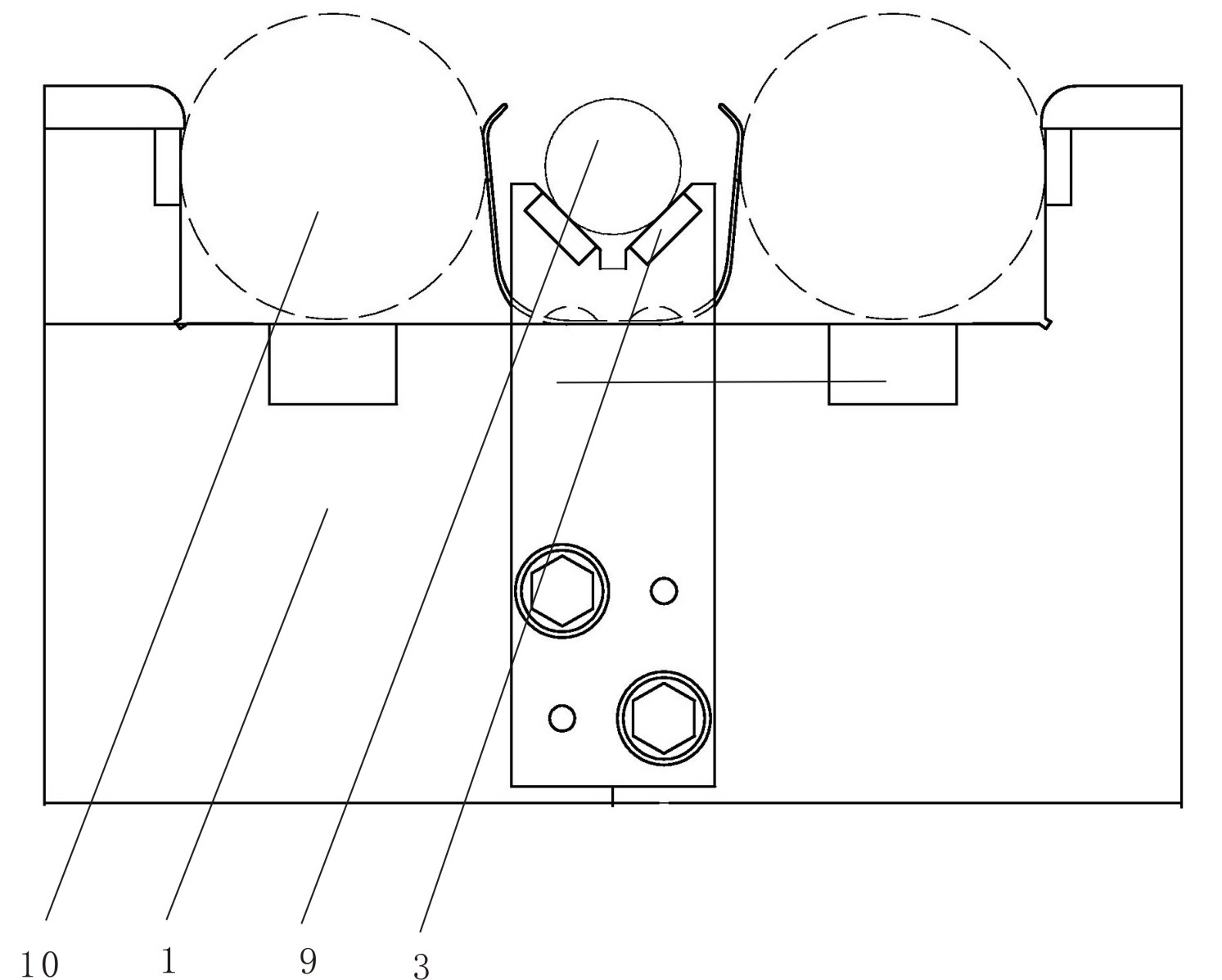

[0026] see figure 1 , image 3 , the fixed structure of the swash plate includes two V-shaped positioning seats 3, the heights of the two V-shaped positioning seats 3 are the same, and the two V-shaped positioning seats 3 are provided with a pressure block 6. The inner side of one of the V-shaped positioning seats 3 is provided with a swash plate axial positioning rod 4, and the outside of the other V-shaped positioning seat 3 is provided with a swash plate axial tightening member 5, and the axis of the axial positioning rod 4 is in line with the two The central line of the two V-shaped positioning seats is vertical, and the axial tightening member 5 of the swash plate can adopt some tightening structures in the existing mechanical field. To save space, it will not be described in detail here.

[0027] The piston support includes two piston rest blocks 8 with grooves 7 fixed on the workbench 1. In order to make the piston 10 have a better limit during the test, the two sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com