Rolling bearing fault feature extraction method based on signal sparse representation theory

A rolling bearing and fault feature technology, which is applied in the field of rolling bearing fault feature extraction, can solve the problems of reducing the signal-to-noise ratio of fault feature components, increasing the difficulty of constructing an over-complete dictionary, the accuracy of sparse coefficient solution, and the lack of shock vibration response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

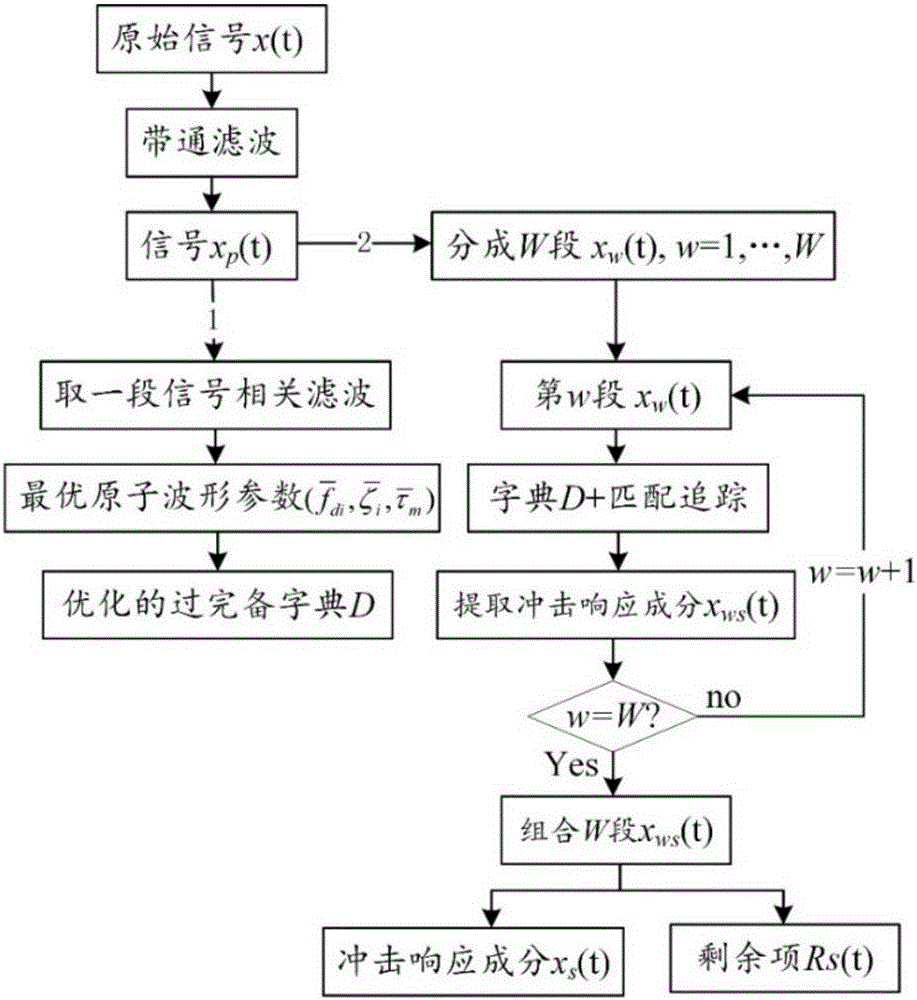

Method used

Image

Examples

Embodiment 1

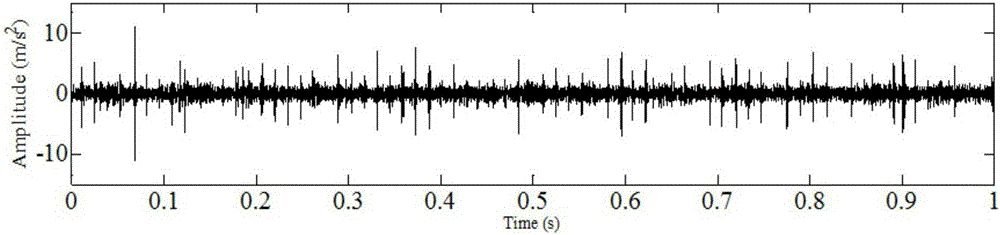

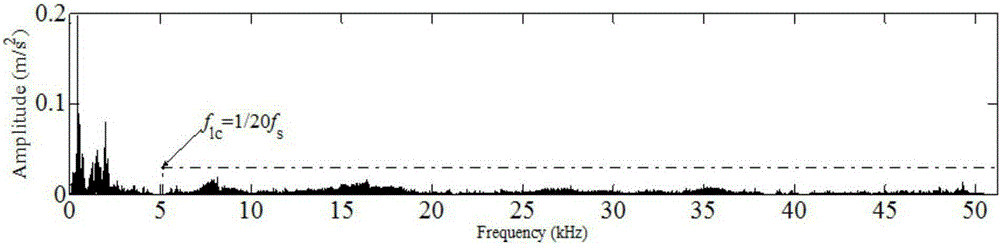

[0129] Example 1: Local damage to the outer ring of a pure rolling bearing

[0130] In the pure rolling bearing test bench, according to the rolling bearing with outer ring fault, the fault size is 0.2mm wide, 0.5mm deep, and the structural parameters of the bearing model N205M are listed in Table 1.

[0131] Table 1 N205M type rolling bearing structural parameters

[0132] outer diameter

the inside diameter of

Rolling element diameter

Number of rollers

52mm

25mm

38mm

6.5mm

13

0°

[0133] This embodiment is realized through the following specific steps:

[0134] Step S1:

[0135] S11. Coordinate system establishment: establish a spatial coordinate system XYZ, the positive direction of the X-axis points to the axial direction of the rolling bearing, the positive direction of the Z-axis is vertically upward, and the positive direction of the Y-axis is determined by the right-hand rule...

Embodiment 2

[0171] Example 2: Partial damage to the inner ring of rolling bearings in automobile transmissions

[0172] According to the rolling bearing with local faults in the inner ring at the output shaft of the automobile transmission, the fault size is 0.2mm wide and 1mm deep, and the structural parameters of the model NUP311EN are listed in Table 2.

[0173] Table 2 NUP311EN type rolling bearing structural parameters

[0174] outer diameter

the inside diameter of

Pitch diameter

Rolling element diameter

Number of rollers

120mm

55mm

85mm

18mm

13

0°

[0175] This embodiment is realized through the following specific steps:

[0176] Step S1:

[0177] S11. Coordinate system establishment: establish a spatial coordinate system XYZ, the positive direction of the X-axis points to the axial direction of the rolling bearing, the positive direction of the Z-axis is vertically upward, and the positive direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com