Integrated welding-die mechanism for rear frames of small-sized wheel loaders and medium-sized wheel loaders

A wheel loader, small and medium-sized technology, applied in the field of forklifts, can solve problems such as damage, structural failure, crack strength, etc., to achieve the effects of ensuring accuracy, preventing welding deformation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

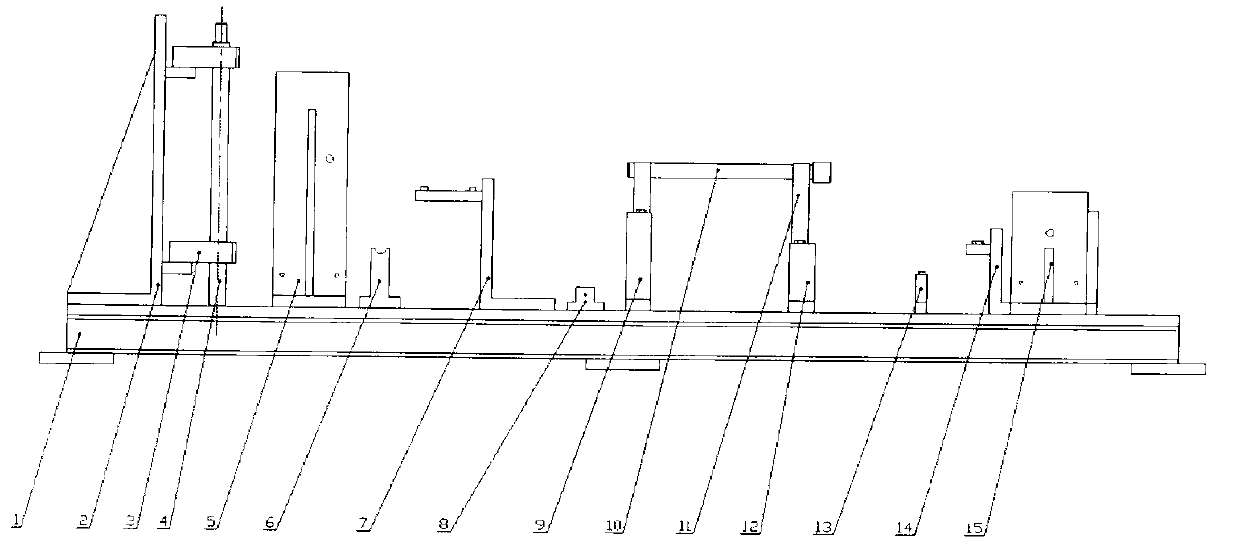

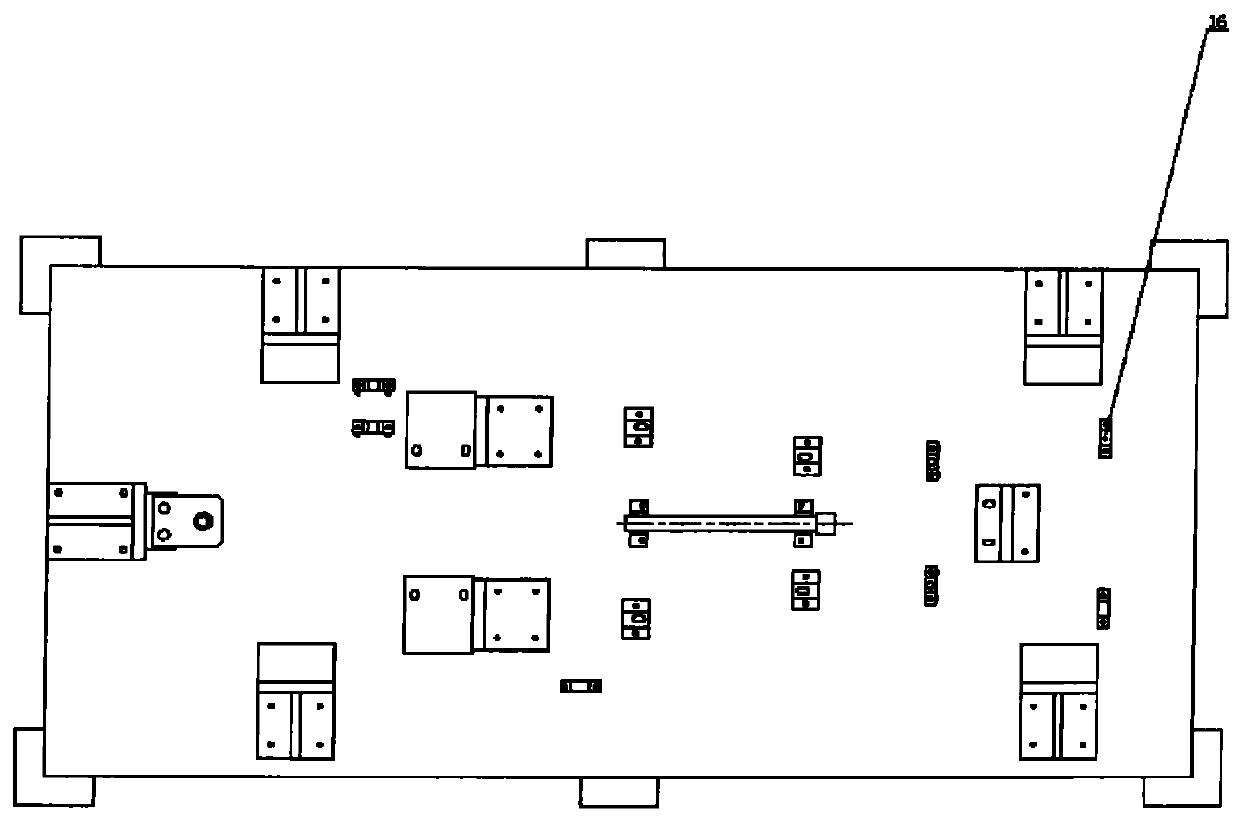

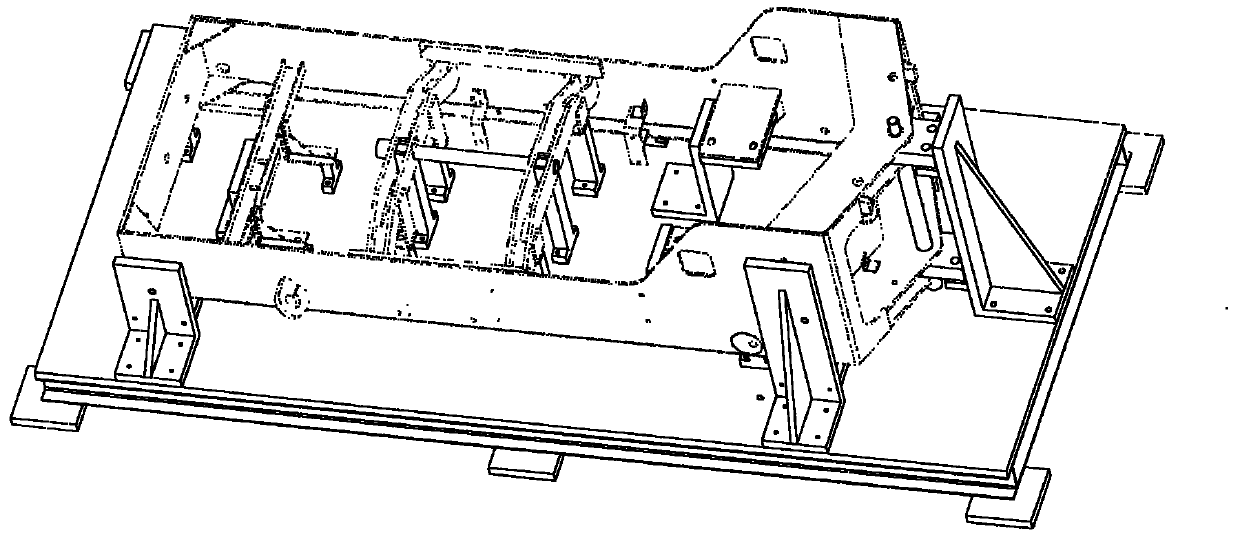

[0018] Examples, see attached figure 1 , 2 , 3, small and medium-sized wheel loader rear frame integrated welding mold mechanism, including welding mold base 1, on which welding mold base 1 is sequentially provided with hinged plate support 2, a pair of front fixing plates 5, a pair of transmission Box installation positioning plate 7, a pair of front engine mounting hole fixing plates 9, a pair of rear engine mounting hole fixing plates 12, two front and rear swing frame hole blocks 10, and front and rear swing frame hole blocks 10 arranged between the front and rear swing frame holes Frame hole positioning pin shaft 11, gear pump mounting seat limiting plate 14, a pair of left and right longitudinal beam positioning seats 15 and a pair of rear tail plate limiting blocks 16, the hinge plate support 2 is provided with two middle Li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com