Non-contact extreme value method inner diameter detection method and device

A non-contact detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to meet simple and fast detection requirements, inaccurate evaluation of inner diameter size, and few detection sampling points, etc., to achieve Improve the core competitiveness of products, the calculation principle is simple and easy to understand, and the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

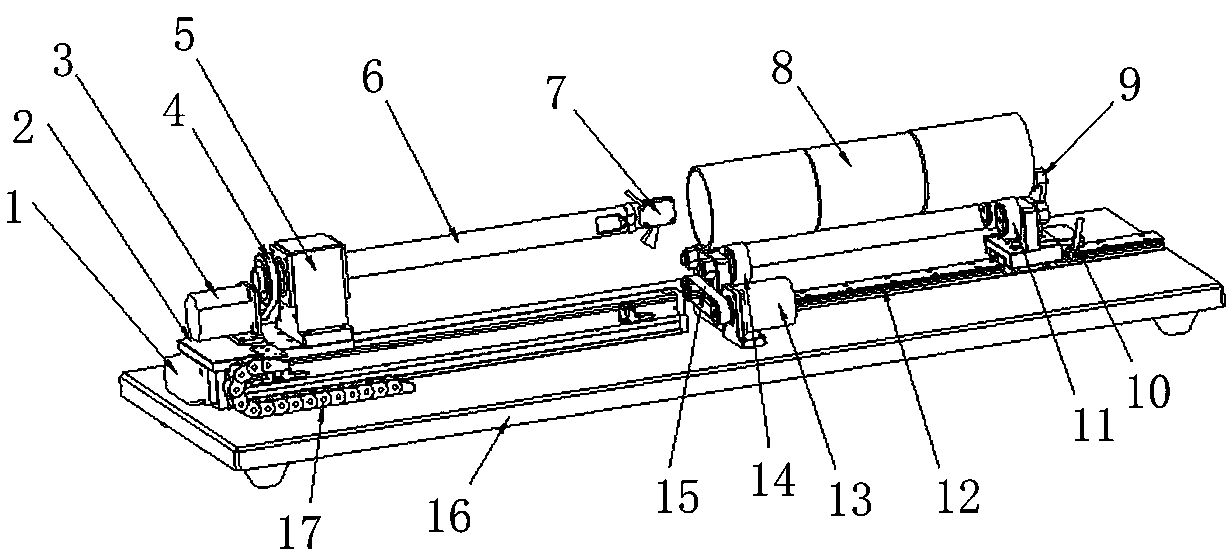

[0024] Such as figure 1 As shown, a non-contact extreme value method inner diameter detection device includes a measuring device and a bracket to be tested. The measuring device and the bracket to be tested are respectively installed at both ends of the base 16. The measuring device is installed on the On the electric module 1, the electric module 1 is installed on the base 16. The electric module belongs to the prior art, including a motor, a lead screw, and a guide rail, and belongs to a technology that can be obtained by those skilled in the art. The direction is moved axially, and the electric module 1 located on the base 16 drives the measuring device to reciprocate along the axis direction of the sensor mounting rod 6; the measuring device includes a laser displacement sensor 7, which is fixedly installed on the end of the sensor mounting rod 6 The oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com