Vibration reduction testing device for chip type micro-gyroscope

A test device and gyroscope technology, which is applied in the direction of vibration test, measurement device, machine/structural component test, etc., can solve the problem of real-time application of micro gyroscopes that cannot meet the mass production, difficult adjustment of resonance frequency of vibration reduction system, and installation of vibration reduction test mechanism Complexity and other issues, to achieve the effect of simple structure, easy processing and assembly, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

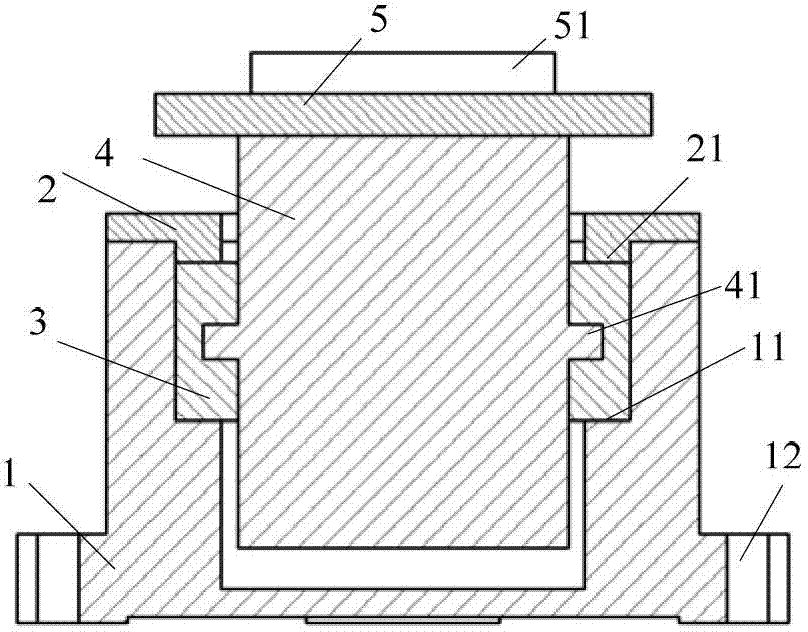

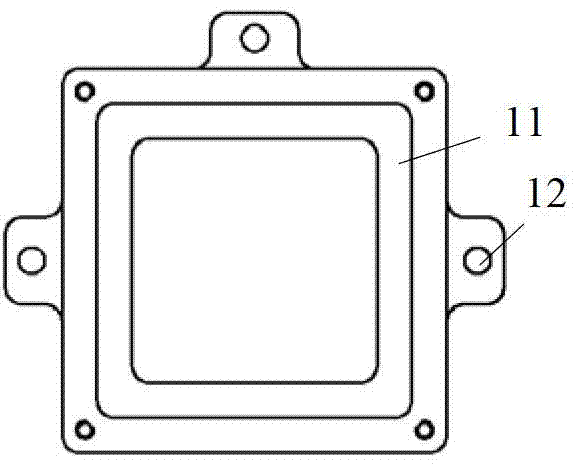

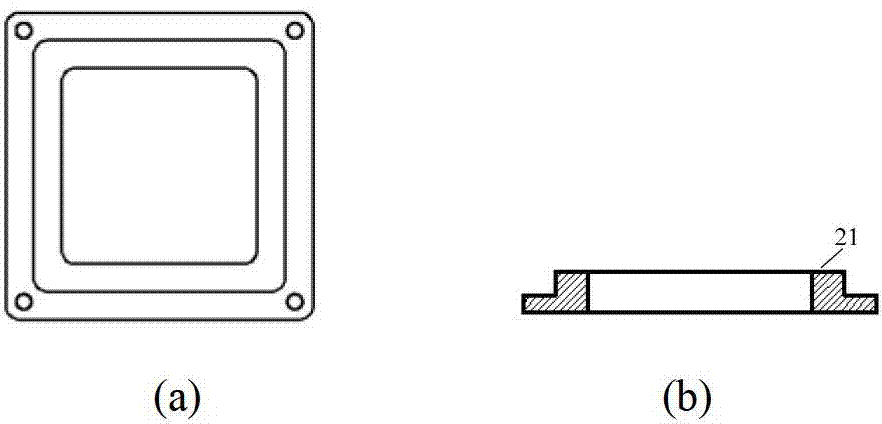

[0014] combine figure 1 , the vibration reduction test device of the chip type micro-gyroscope of the present invention is used to carry out the vibration reduction test of the chip type micro-gyroscope. It is fixed on the vibrating table through the installation hole 12 provided at the bottom. The inner wall of the cavity of the plastic box 1 is provided with a first boss 11 surrounding the inner wall, and the middle position of the outer wall of the mass block 4 is provided with a second boss 41 surrounding the outer wall to reduce vibration. The rubber 3 is provided with an assembly groove that matches the second boss 41. After the assembly of the mass block 4 and the damping rubber 3, it is placed on the first boss 11 in the cavity of the rubber box 1. The middle of the rubber cover 2 has a hole and Set up with the rubber box 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com