6082S aluminum alloy sheet for stamping and processing technology thereof

A processing technology, aluminum alloy technology, applied in the field of aluminum alloy processing, can solve problems such as easy to become crack source, difficult to dissolve aluminum matrix, stamping cracking, etc., achieve the effect of improving organizational coordination ability, improving mechanical properties, and reducing the possibility of stamping cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

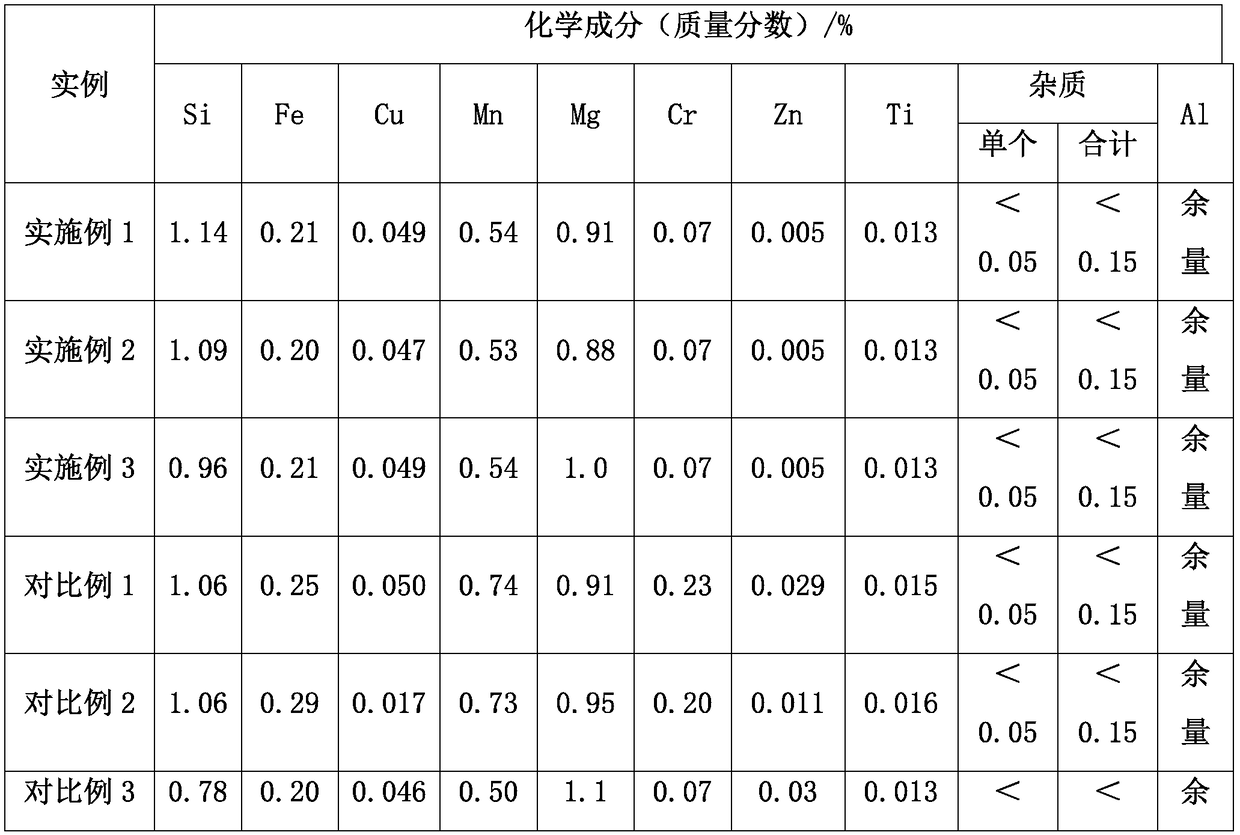

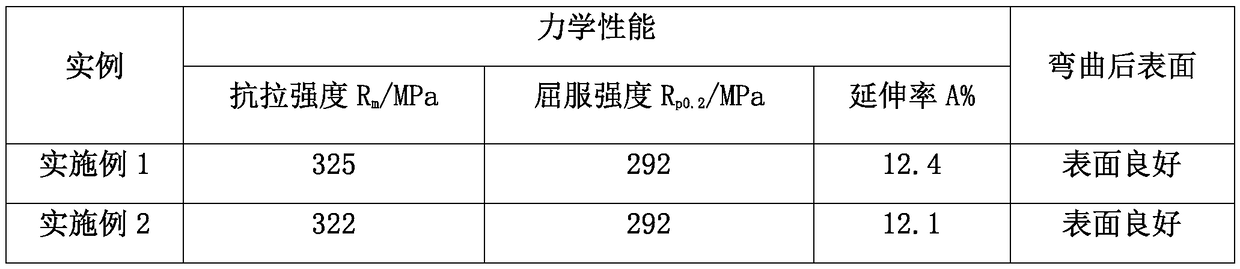

Examples

Embodiment 1

[0031] A processing technology of 6082S aluminum alloy thin plate for stamping, comprising the following steps:

[0032] A. According to the predetermined weight percentage, the ingredients of the above-mentioned 6082S aluminum alloy sheet are put into a melting furnace for melting, and after slag removal and filtration, the molten aluminum is cast into an aluminum alloy ingot;

[0033] B. Cut off the head and tail of the aluminum alloy ingot after melting and casting, perform face milling, and then use a milling machine to mill out the solidified shell layer on the surface of the aluminum alloy ingot;

[0034] C. Place the milled aluminum alloy ingot in a heating furnace for homogenization heat treatment. The process of homogenization heat treatment is: the aluminum alloy ingot is heated to 560 ° C, kept for 8 hours, then cooled to 500 ° C, kept for 2 hours, after heating Immediately after the ingot is released from the furnace, it is hot-rolled into a coil, and the thickness...

Embodiment 2

[0040] A processing technology of 6082S aluminum alloy thin plate for stamping, comprising the following steps:

[0041] A. According to the predetermined weight percentage, the ingredients of the above-mentioned 6082S aluminum alloy sheet are put into a melting furnace for melting, and after slag removal and filtration, the molten aluminum is cast into an aluminum alloy ingot;

[0042] B. Place the melted aluminum alloy ingot in a heating furnace for homogenization heat treatment and cut off the head and tail for face milling. The homogenization heat treatment process is that the melted aluminum alloy ingot is heated to 530°C, kept for 8 hours, and then cooled To 500 ℃, keep warm for 2 hours, and take out;

[0043] C. The aluminum alloy ingot after face milling is hot-rolled into a coil after being released from the furnace, and the thickness of the coil is 7mm;

[0044] D. Cold-roll the hot-rolled coil to the intermediate annealing thickness, wherein the annealing temperatu...

Embodiment 3

[0049] A processing technology of 6082S aluminum alloy thin plate for stamping, comprising the following steps:

[0050] A. According to the predetermined weight percentage, the ingredients of the above-mentioned 6082S aluminum alloy sheet are put into a melting furnace for melting, and after slag removal and filtration, the molten aluminum is cast into an aluminum alloy ingot;

[0051] B. Cut off the head and tail of the aluminum alloy ingot after melting and casting, perform face milling, and then use a milling machine to mill out the solidified shell layer on the surface of the aluminum alloy ingot;

[0052] C. Place the milled aluminum alloy ingot in a heating furnace for homogenization heat treatment. The process of homogenization heat treatment is: the aluminum alloy ingot is heated to 560 ° C, kept for 10 hours, then cooled to 500 ° C, kept for 4 hours, after heating Immediately after the ingot is released from the furnace, it is hot-rolled into a coil, and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com