Bag-in-bag pesticide packing machine with preliminarily made outer bags

A bag-in-bag and packaging machine technology, applied in packaging, transportation packaging, multiple packages, etc., can solve problems such as high cost, inability to meet mass production requirements, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

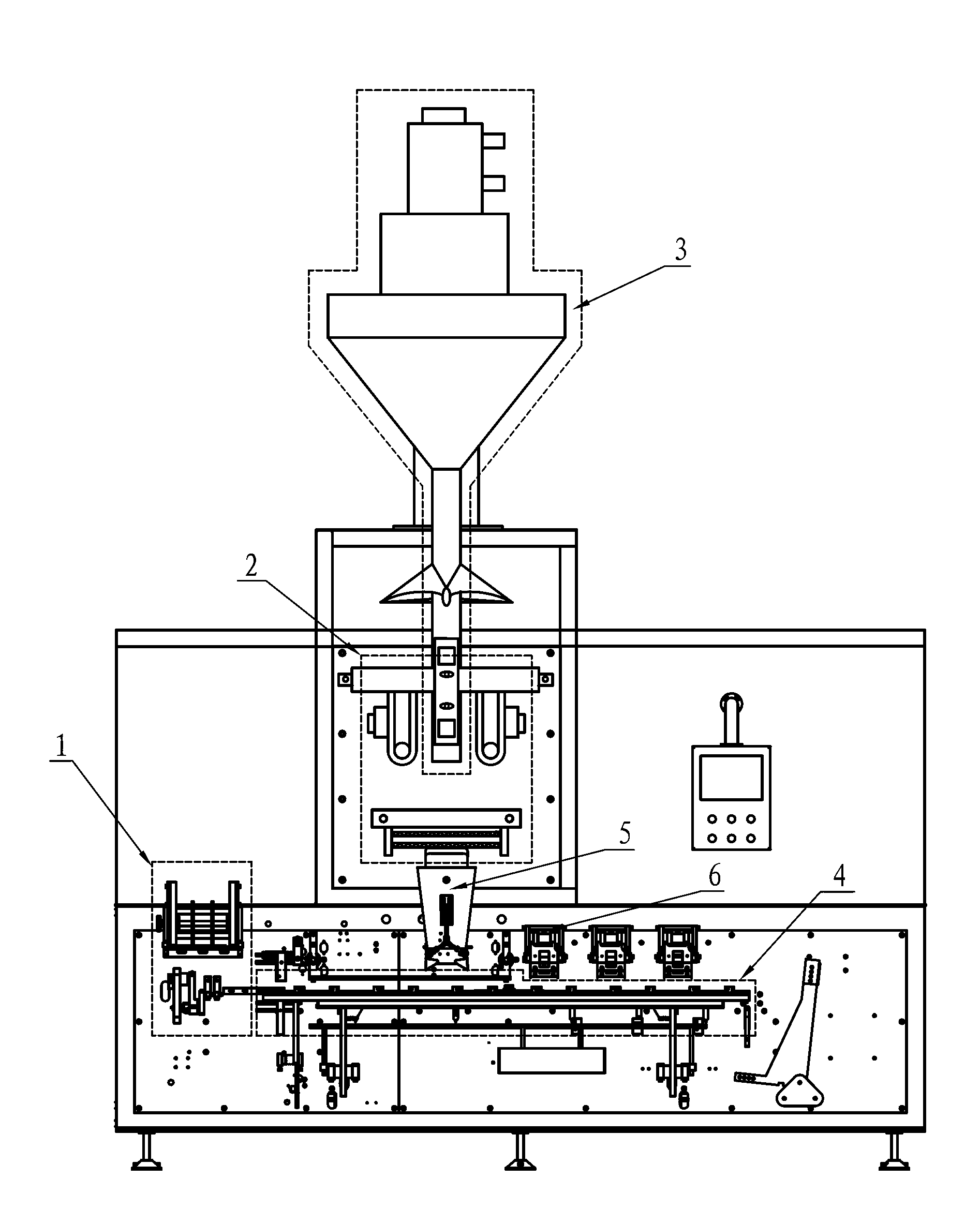

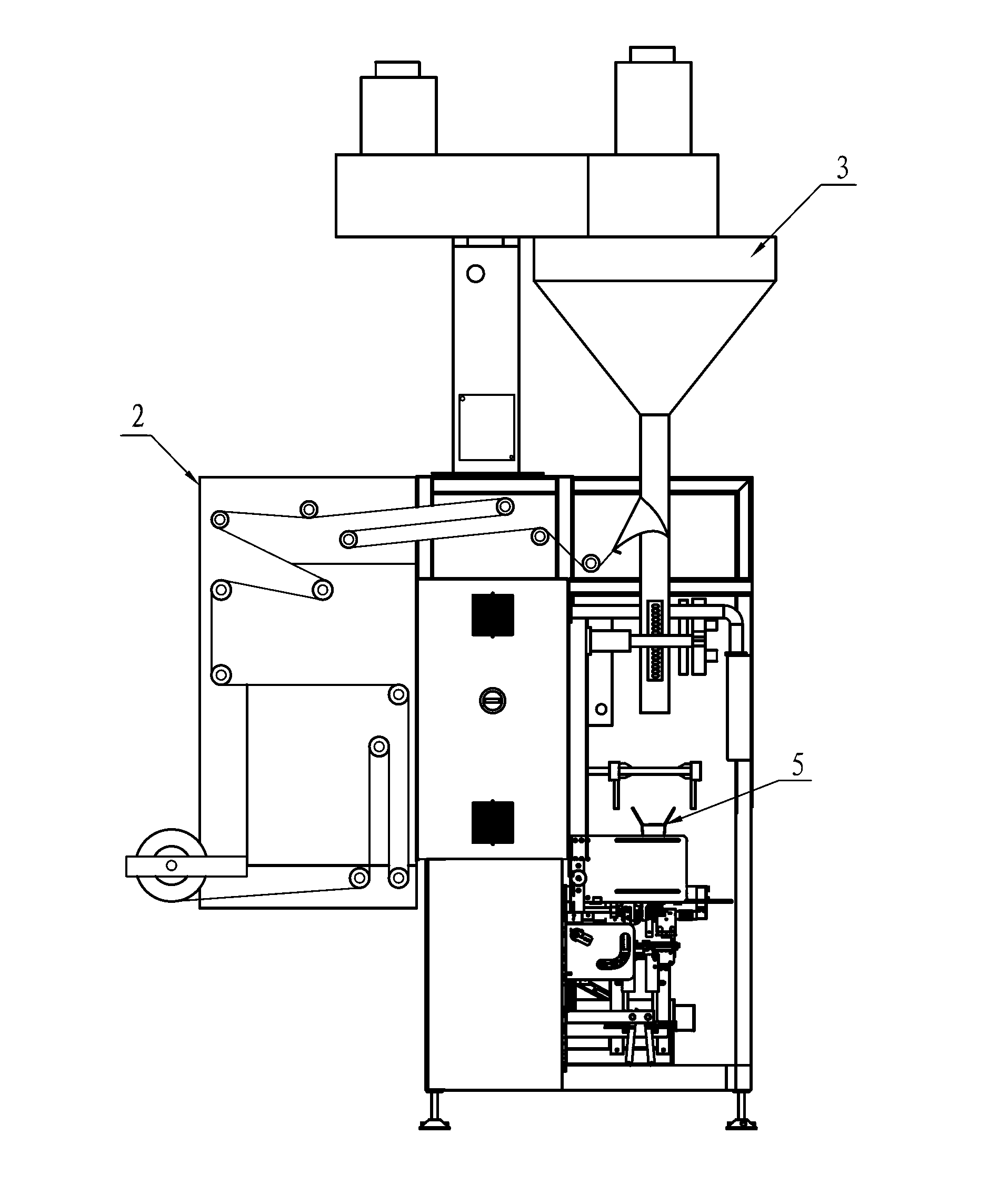

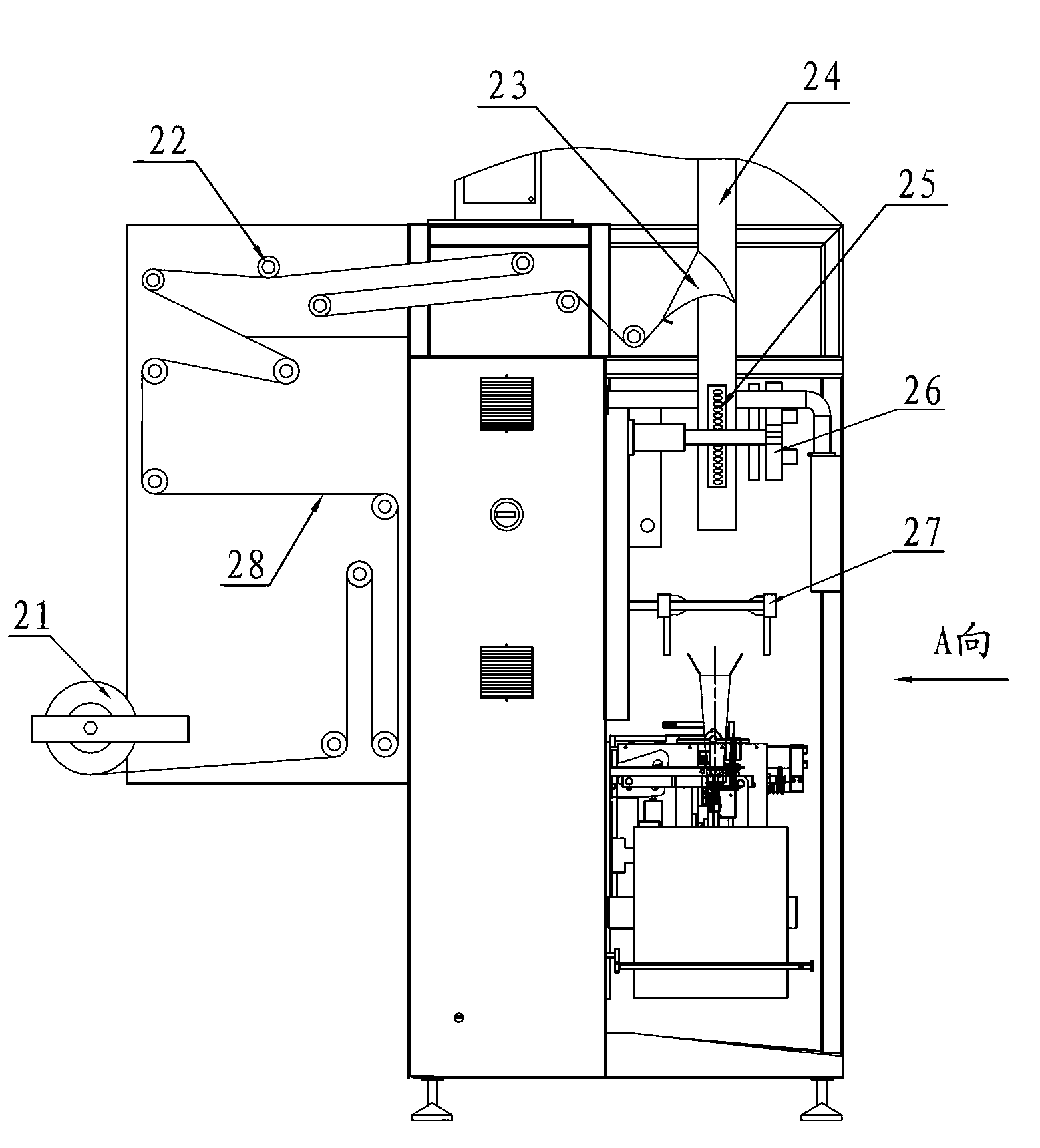

[0031]Example 1: A prefabricated outer bag-type pesticide bag-in-bag packaging machine, including a pre-bag pre-slicing device 1; a vertical inner bag bag making device 2; an inner bag material metering and filling device 3; a reciprocating outer bag traction bag Device 4, inner bag quasi-injecting outer bag device 5 and outer bag top sealing device 6; pre-bag pre-slicing device 1 and reciprocating outer bag traction and clamping device 4 are distributed linearly along the horizontal direction; inner bag material metering and filling device 3 and the vertical inner bag making device 2 are distributed collinearly along the vertical direction, and the inner bag material metering and filling device 3 is collinearly compounded with the vertical inner bag making device 2, and the inner bag accurate feeding outer bag device 5 is set inside Below the bag material metering and filling device 3; the pre-bag pre-slicing bag device 1 completes the input of prefabricated outer bags one by ...

Embodiment 2

[0032] Embodiment 2: The difference from Embodiment 1 is that the inner bag material metering filling device 3, in this example, the inner bag material metering filling device 3 is a single-head liquid filling unit, a single-head liquid filling unit The middle liquid filling nozzle is arranged in the inner bag mold core 24 in the vertical inner bag bag making device 2 .

[0033] There are many embodiments of the present invention, and the inner bag material metering and filling device 3 and the inner bag quasi-throwing outer bag device 5 also have many other functional substitution structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com