Lithium sulfur battery positive electrode material and preparation method thereof

A lithium-sulfur battery and cathode material technology, which is applied in battery electrodes, lithium storage batteries, positive electrodes, etc., can solve the problems of unsatisfactory electrical properties of cathode materials, reduce shuttle effect, high Coulomb efficiency, and ensure electrical conductivity and mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

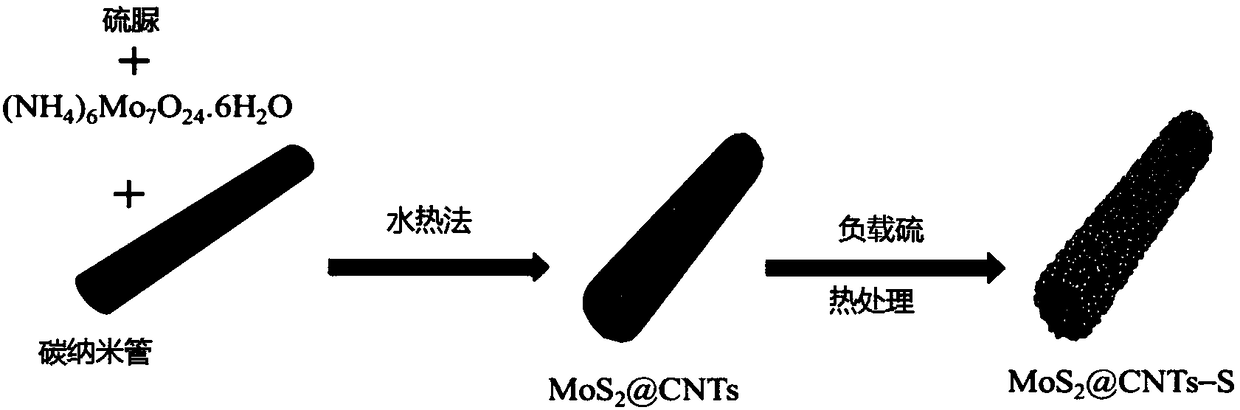

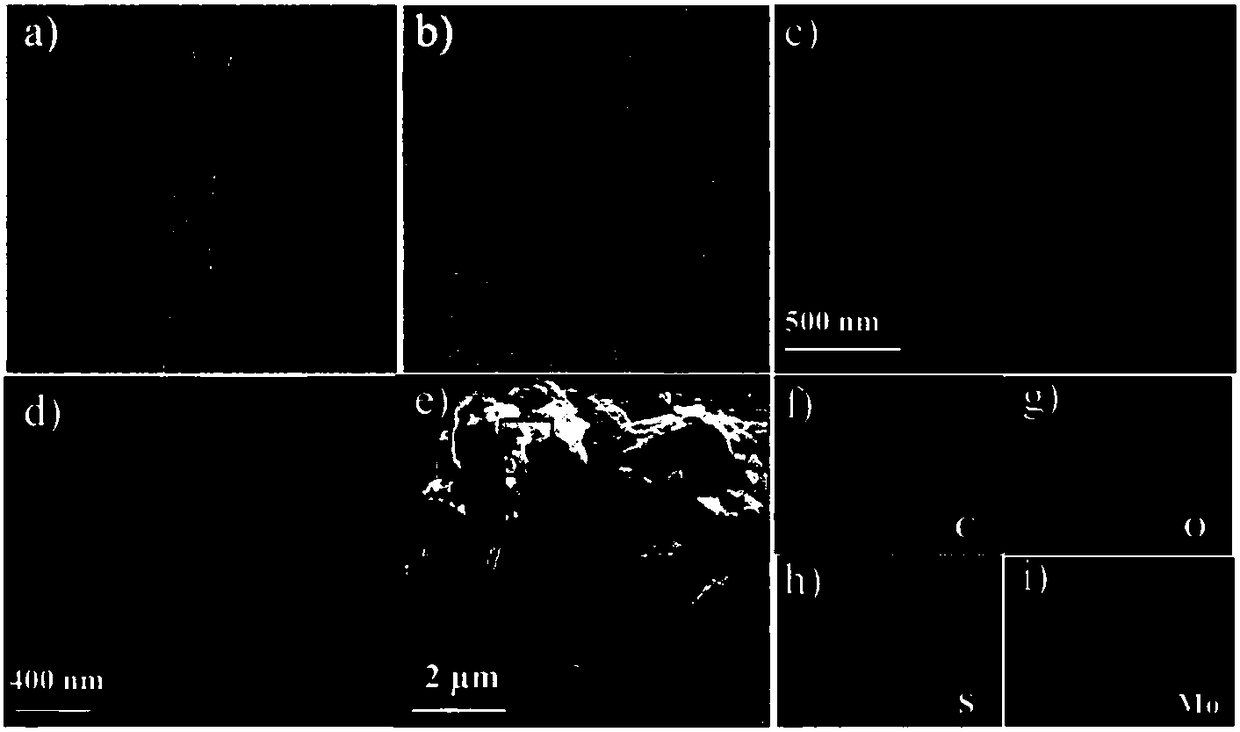

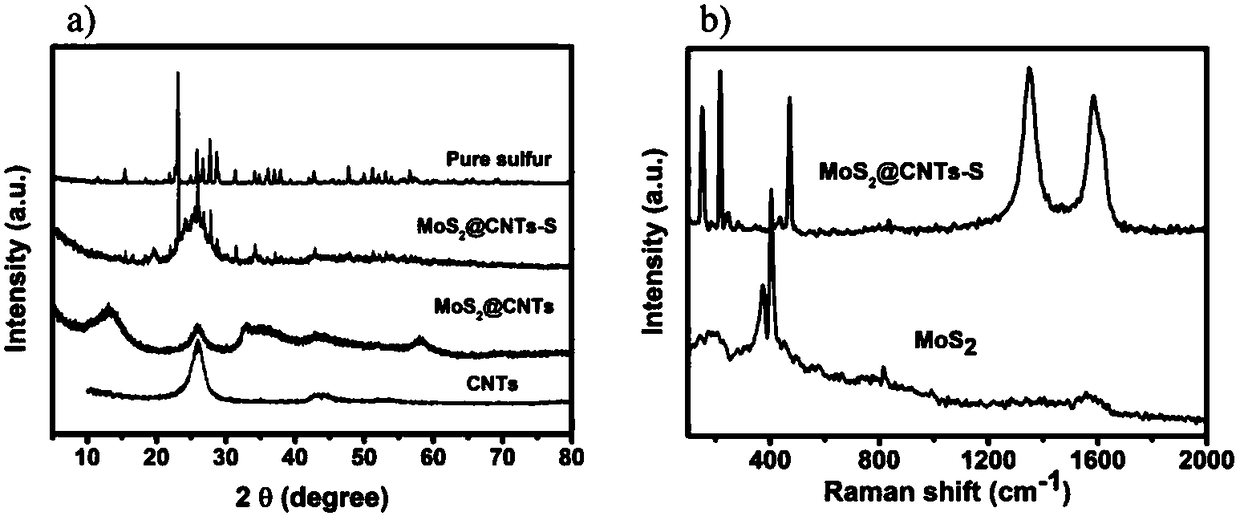

[0055] MoS 2 Preparation of @CNTs-S and Performance Test of Li-S Batteries Assembled

[0056] Step (1): Spongy molybdenum disulfide-modified carbon nanotubes (MoS 2 Preparation of @CNTs)

[0057] S1, 12mg (NH 4 ) 6 Mo 7 o 24 4H 2 O (0.068mmoL; 1eqv.) and 12.9mg of thiourea (2.5eqv.) were dissolved in 25ml of pure water, and the two were mixed while stirring;

[0058] S2. Add 100 mg of carbon nanotubes to the mixed solution obtained in step S1, and stir for 12 hours;

[0059] S3. Transfer the solution obtained in step S2 to a 100ml stainless steel reaction kettle, place the stainless steel reaction kettle in an oven, and keep it at 180°C for 12h;

[0060] S4, filter the solution obtained in step S3, wash, and dry to obtain spongy molybdenum disulfide-modified carbon nanotubes (MoS 2 @CNTs);

[0061] Step (2): Sponge-like molybdenum disulfide-modified carbon nanotubes loaded with sulfur (MoS 2 @CNTs-S)

[0062] Sulfur powder and MoS 2 @CNTs were mixed and ground at ...

Embodiment 2

[0066] WS 2 Preparation of @CNTs-S and Performance Test of Li-S Batteries Assembled

[0067] Step (1): Tungsten disulfide modified carbon nanotubes (WS 2 Preparation of @CNTs)

[0068] S1, 21mg (NH 4 ) 10 W 12 o 41 ·xH 2 O (0.083mmoL; 1eqv.) and 15.7mg of thiourea (2.5eqv.) were dissolved in 50ml of pure water, and the two were mixed while stirring;

[0069] S2. Add 150 mg of carbon nanotubes to the mixed solution obtained in step S1, and stir for 8 hours;

[0070] S3. Transfer the solution obtained in step S2 to a 150ml stainless steel reaction kettle, place the stainless steel reaction kettle in an oven, and keep it at 160°C for 10h;

[0071] S4, the solution obtained in step S3 is filtered, washed, and dried to obtain tungsten disulfide-modified carbon nanotubes (WS 2 @CNTs);

[0072] Step (2): the molybdenum disulfide-modified carbon nanotubes loaded with sulfur (WS 2 @CNTs-S)

[0073] Combine sulfur powder with WS 2 @CNTs were mixed and ground at a mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com