Lithium-air battery positive electrode employing hydroxyl cobalt oxide as catalyst and preparation method of positive electrode

A technology for cobalt oxyhydroxide and lithium-air batteries, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor battery cycle stability, high charging potential, poor cycle performance, etc., to promote electron transfer and reduce charging voltage. platform, the effect of reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of the positive electrode of the lithium-air battery:

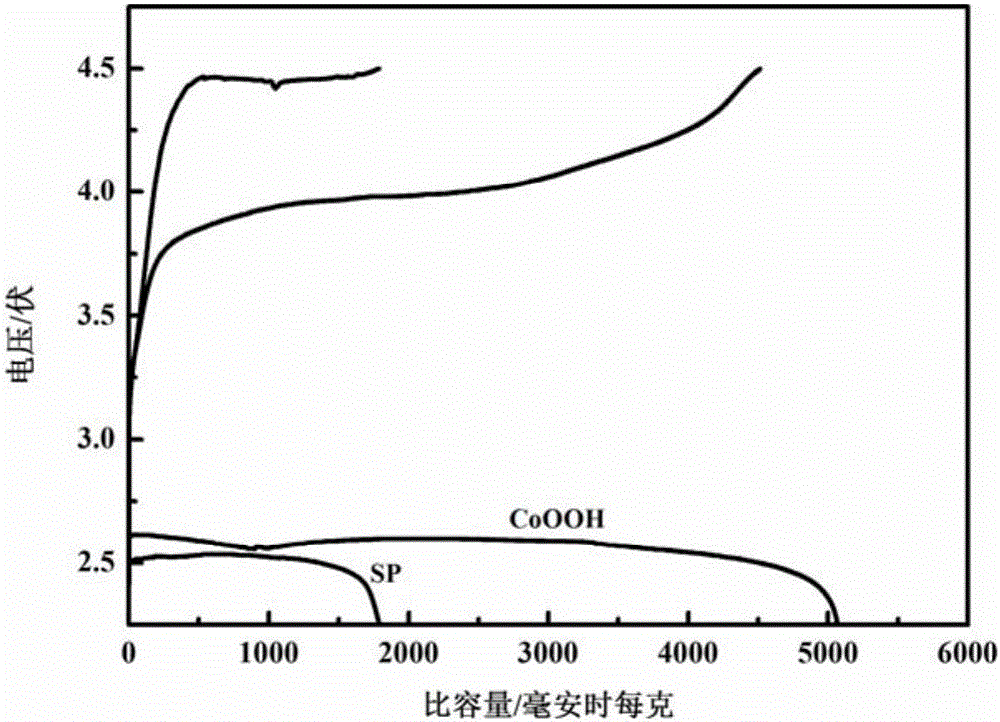

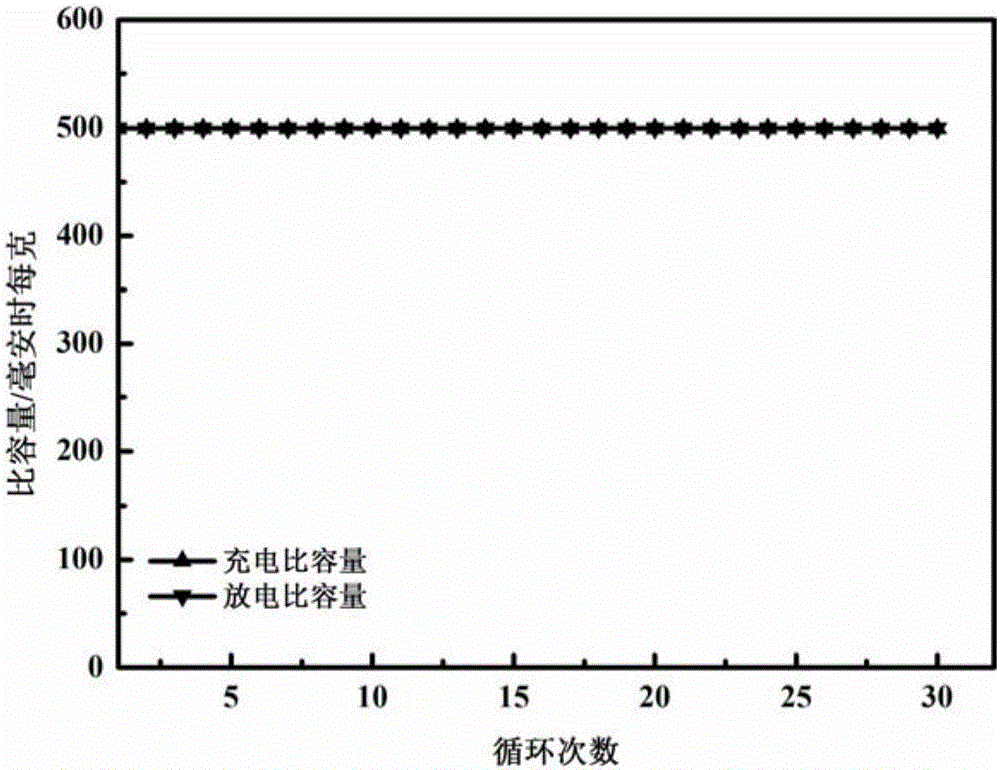

[0027] Weigh CoOOH, polyvinylidene fluoride, and conductive carbon black (SP) according to the percentages of 30%, 20%, and 50%, respectively, mix and grind CoOOH and SP in an agate mortar for 20 minutes to obtain a mixture, and polyvinylidene fluoride Dissolve in N-methylpyrrolidone, and add it dropwise to the mixture to obtain a slurry. The amount of N-methylpyrrolidone can completely dissolve polyvinylidene fluoride, and make the SP and The cobalt oxyhydroxide is uniformly dispersed to obtain a slurry, and the obtained slurry is ultrasonically dispersed for 30 minutes, and then the ultrasonically dispersed slurry is coated on the nickel foam, and vacuum-dried at 120°C for 12 hours, cooled to room temperature, and then used in a hydraulic press at a pressure of 12MPa Press down to form an electrode sheet to obtain a lithium-air battery positive electrode with CoOOH as a catalyst. The carbon material c...

Embodiment 2

[0036] Preparation of the positive electrode of the lithium-air battery:

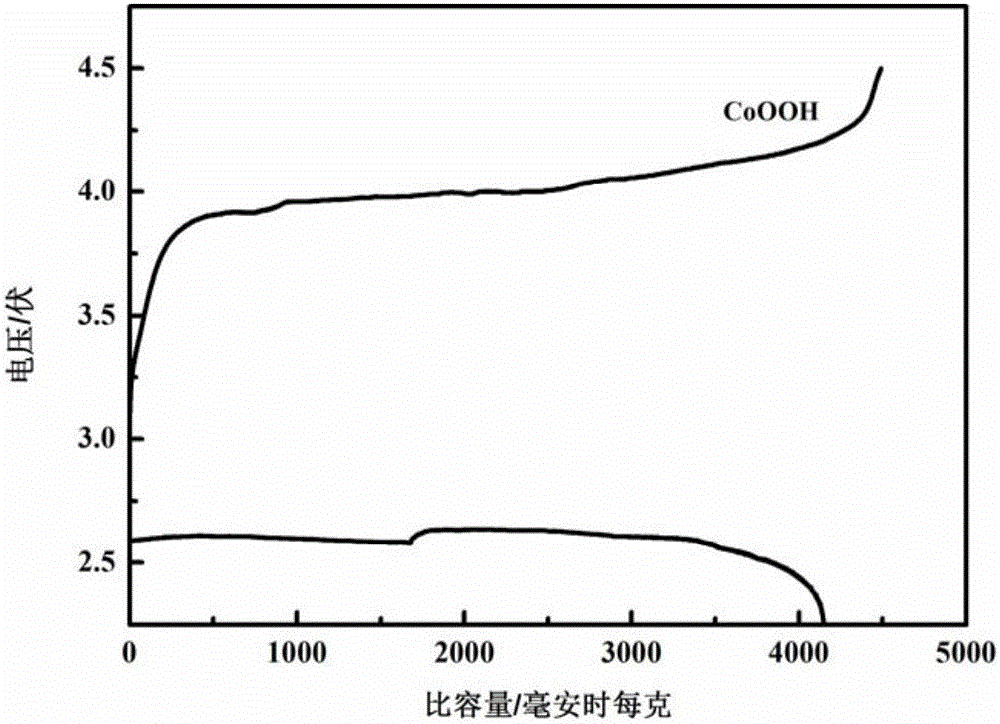

[0037]Weigh CoOOH, polyvinylidene fluoride, and conductive carbon black (SP) according to the percentages of 15%, 25%, and 60%, respectively, mix and grind CoOOH and SP in an agate mortar for 20 minutes to obtain a mixture, and polyvinylidene fluoride Dissolve in N-methylpyrrolidone, and add it dropwise to the mixture to obtain a slurry. The amount of N-methylpyrrolidone can completely dissolve polyvinylidene fluoride, and make the SP and hydroxyl in the mixture Cobalt oxide is uniformly dispersed to obtain a slurry, and the slurry is ultrasonically dispersed for 30 minutes, and then the ultrasonically dispersed slurry is coated on carbon paper, and vacuum-dried at 120°C for 12 hours, cooled to room temperature, and pressed with a hydraulic press at a pressure of 12MPa Form an electrode sheet to obtain a lithium-air battery positive electrode with CoOOH as a catalyst, and the carbon material content on ...

Embodiment 3

[0041] Preparation of positive electrode for lithium air battery:

[0042] Weigh CoOOH, polyvinylidene fluoride, and porous carbon according to the percentages of 15%, 25%, and 60%, respectively, mix and grind CoOOH and porous carbon in an agate mortar for 20 minutes to obtain a mixture, and dissolve polyvinylidene fluoride in N -Methylpyrrolidone, and added dropwise to the mixture to obtain a slurry, the amount of N-methylpyrrolidone completely dissolves polyvinylidene fluoride, and makes the porous carbon and cobalt oxyhydroxide in the mixture Uniformly disperse the slurry, disperse the slurry ultrasonically for 30 minutes, then coat the uniformly dispersed slurry on the nickel foam, and dry it in vacuum at 120°C for 12h, cool to room temperature and press it with a hydraulic press at a pressure of 12MPa to form an electrode sheet, to obtain a lithium-air battery positive electrode with CoOOH as a catalyst, and the carbon material content on the electrode sheet is 0.8mg / cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com