Weatherproof flexible veneer and manufacturing method thereof

A flexible veneer, weather-resistant technology, applied in the field of wood processing, can solve the problems of easy peeling, easy delamination and easy cracking of paint, and achieve the effect of satisfying long material and mass production, high UV resistance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The weather-resistant flexible veneer of the present invention is made of the following materials: the solid wood veneer is made of Tianre solid wood veneer produced by Dehua Rabbit Baby Decoration New Material Co., Ltd.; Melt glue; PUR hot-melt adhesive paint layer adopts PUR hot-melt adhesive paint of German "Ke Libao" brand; water-based coloring layer uses American "DuPont" brand colorant; UV topcoat layer adopts Zhuhai Dongcheng Light Curing Material Co., Ltd. Production of UV topcoats.

[0023] The production process of this product is as follows:

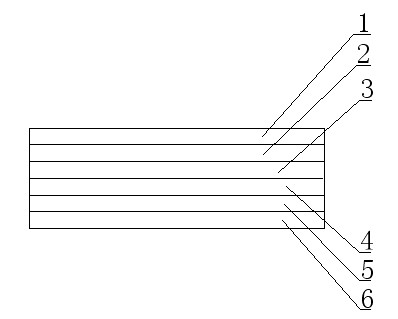

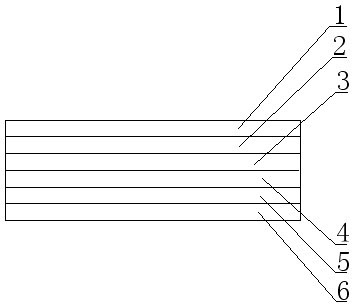

[0024] 1. Bond the natural solid wood veneer with a thickness of 0.3mm and the non-woven fabric with PUR hot melt adhesive, and then iron it with a hot roller to become the basic material. The amount of PUR hot melt adhesive is 55g / ㎡;

[0025] 2. Use water-based colorant to evenly color the surface of the veneer to highlight the natural and clear texture of the veneer, and then apply hot-melt adhesive paint and UV topc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com