Workbench of 3D engraving machine

A technology of engraving machine and workbench, which is applied in painting tools, processing models, decorative arts, etc., can solve the problems of powerlessness and low efficiency, and achieve the effects of prolonging service life, high efficiency, and improving engraving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

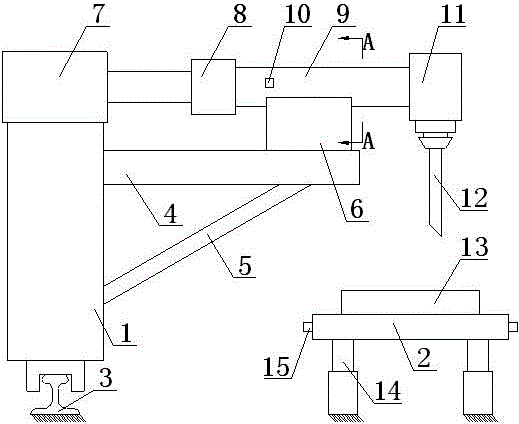

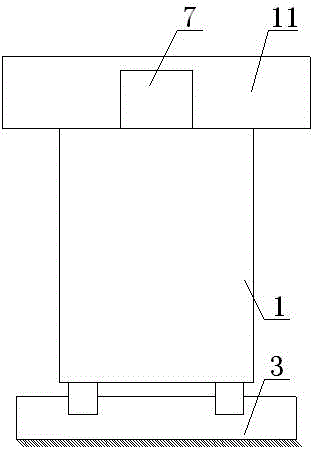

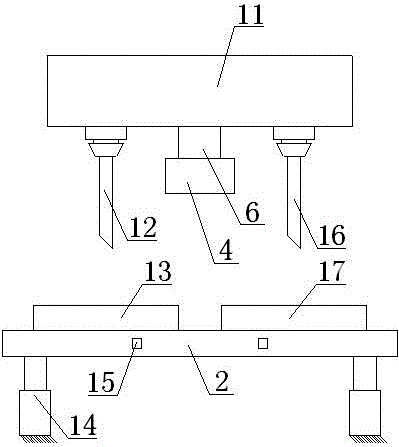

[0019] Such as figure 1 -shown in 4, a kind of workbench of 3D engraving machine, it comprises walking knife rest 1 and base plate 2, the bottom of described walking knife rest 1 is provided with guide rail 3, and the right upper part of described walking knife rest 1 is arranged There is a support plate 4, the top of the right side of the support plate 4 is provided with a fixed plate 6, the center of the top of the traveling tool rest 1 is provided with a hydraulic cylinder 7, and the telescopic end of the hydraulic cylinder 7 passes through the connecting block 8 Connected with movable rod 9, the right end of described movable rod 9 is provided with tool fixed plate 11, and the bottom of described tool fixed plate 11 is respectively provided with processing knife A12 and processing knife B16, and the bottom of described base plate 2 is provided with The telescopic device 14, the base plate 2 is respectively provided with a workpiece placing plate A13 and a workpiece placing...

Embodiment 2

[0022] Such as figure 1 -shown in 4, a kind of workbench of 3D engraving machine, it comprises walking knife rest 1 and base plate 2, the bottom of described walking knife rest 1 is provided with guide rail 3, and the right upper part of described walking knife rest 1 is arranged There is a support plate 4, the top of the right side of the support plate 4 is provided with a fixed plate 6, the center of the top of the traveling tool rest 1 is provided with a hydraulic cylinder 7, and the telescopic end of the hydraulic cylinder 7 passes through the connecting block 8 Connected with movable rod 9, the right end of described movable rod 9 is provided with tool fixed plate 11, and the bottom of described tool fixed plate 11 is respectively provided with processing knife A12 and processing knife B16, and the bottom of described base plate 2 is provided with Telescopic device 14, described base plate 2 is respectively provided with workpiece placing plate A13 and workpiece placing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com