Carving robot system

A robot system and robot technology, applied in the field of robots, can solve the problems of untreated waste water and waste residue, low processing efficiency, and the inability of plane engraving machines to carve three-dimensional models, so as to reduce waste water discharge, protect the environment, improve product quality and engraving efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

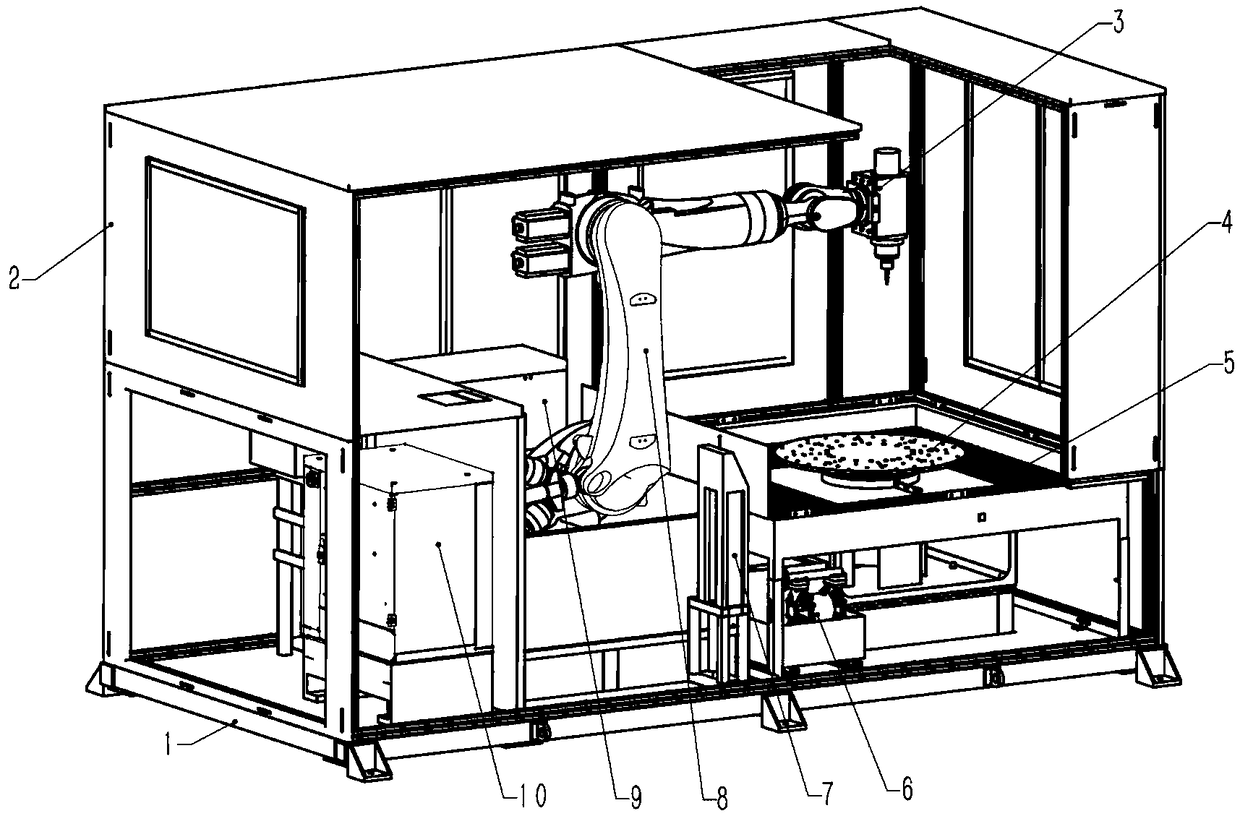

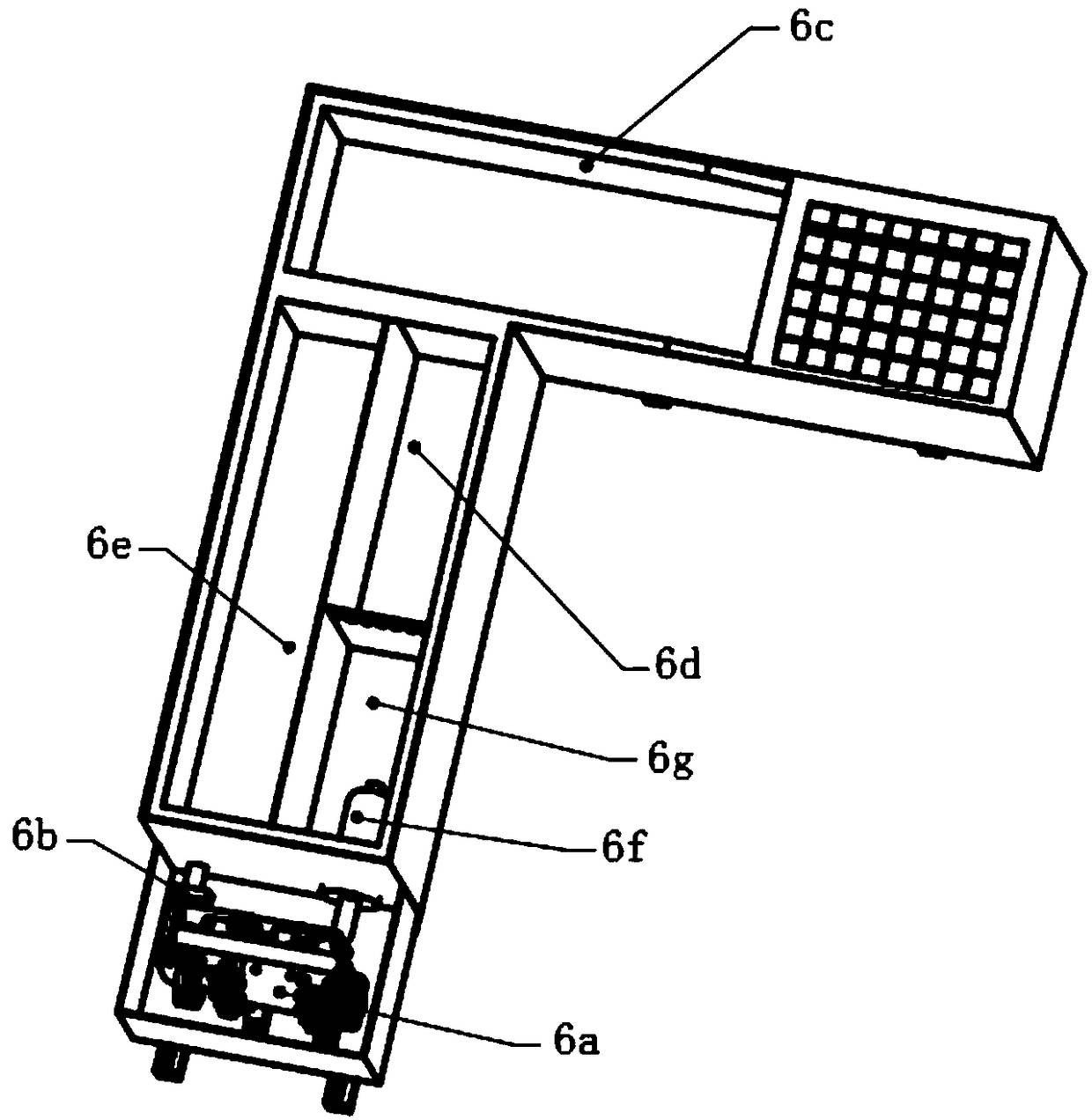

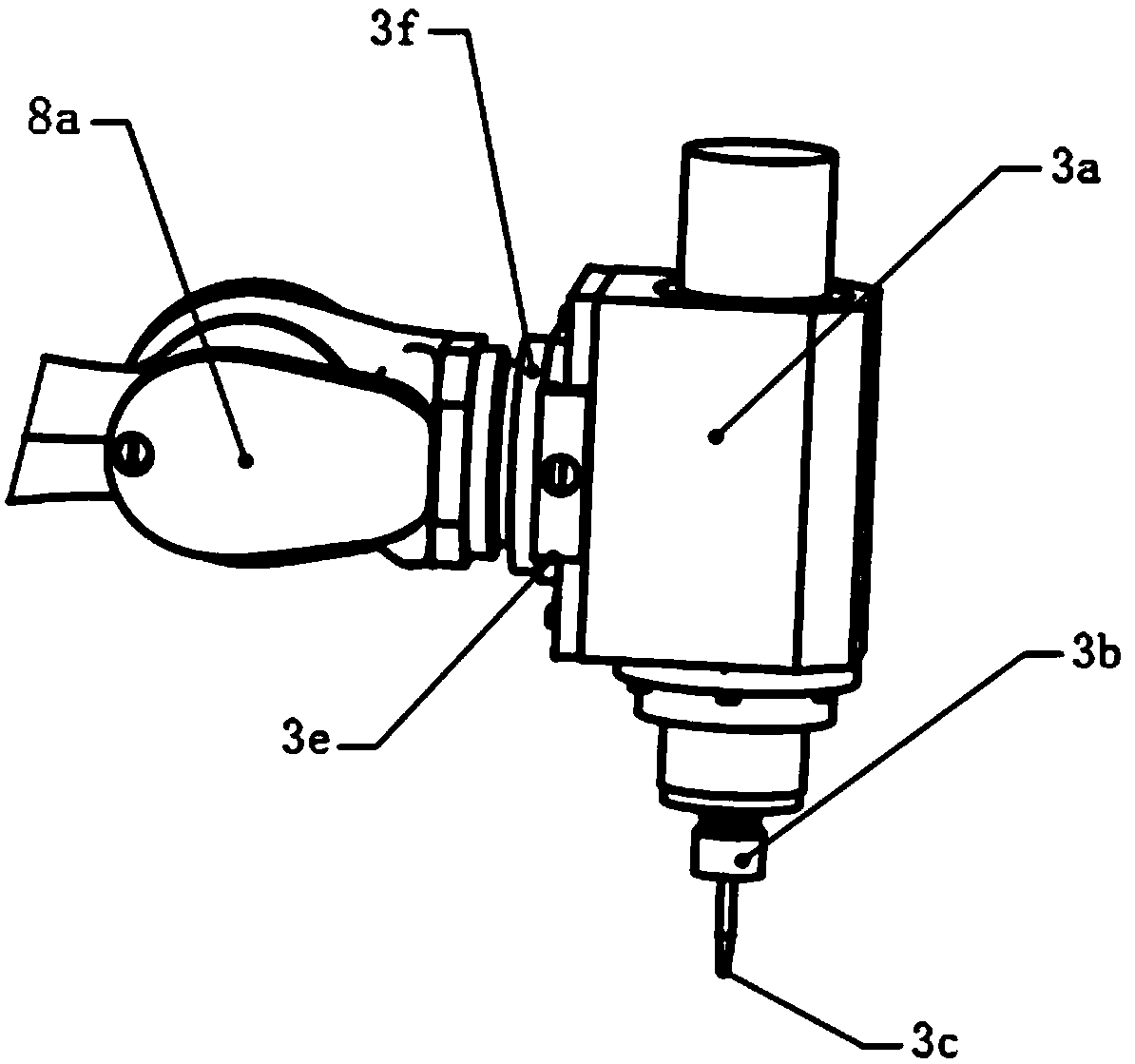

[0024] Such as figure 1 and 3 As shown, the engraving robot 8 system includes a robot base 1, and the robot base 1 is provided with a robot 8, a rotary platform 4 and a controller 10 for controlling the action of the robot 8. The robot 8 includes a mechanical arm 8a, and the end of the mechanical arm 8a is arranged There is a multifunctional engraving head 3, the robot base 1 is provided with a sump 5, and the rotary platform 4 is located above the sump 5. The carving robot 8 system also includes a filter system 6, and the filter system 6 communicates with the sump 5.

[0025] Such as Figure 6 For the working principle block diagram of the engraving robot 8 system, when the engraving robot 8 system is working, first pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com