Grease high-pressure hydrolysis production method and production device by recycling sweet water

A production method and technology of a production device, which are applied in the production of fatty acids, preparation/refining of fatty acids, separation of immiscible liquids, etc., can solve the problems of high COD content, high treatment costs, environmental pollution, etc., so as to protect the environment and reduce waste water discharge. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

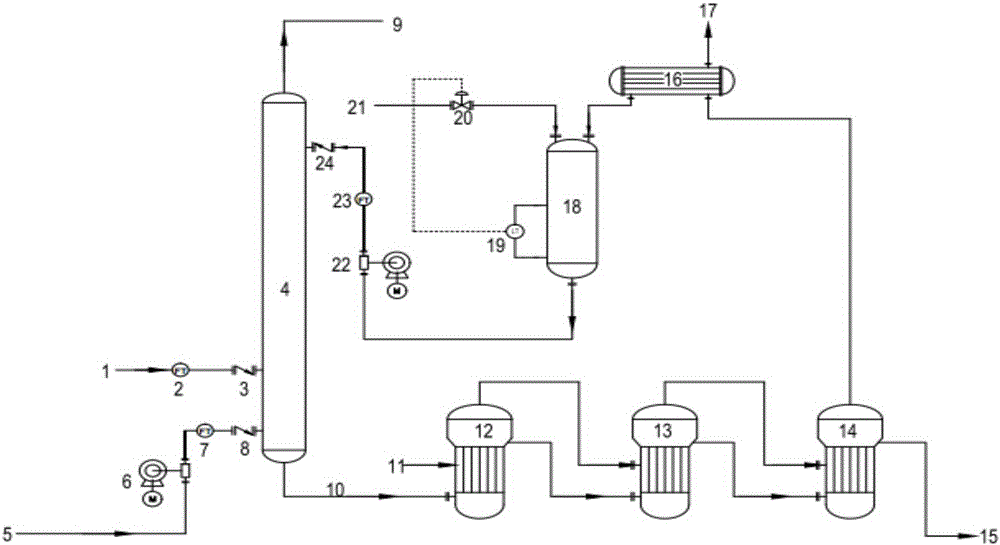

[0027] A production device for high-pressure hydrolysis of fats and oils for recycling sweet water, comprising successively connected hydrolysis towers 4 and three-effect evaporators; high-pressure steam 1 enters the steam inlet of the hydrolysis tower through a pipeline and the pipeline is provided with a steam flow meter 2, The steam check valve 3; the grease 5 is input into the grease inlet of the hydrolysis tower through a pipeline, and the pipeline is provided with a grease high-pressure pump 6, a grease flow meter 7, and a grease check valve 8.

[0028] The fatty acid 9 (the density is less) that hydrolysis reaction produces is discharged from hydrolysis tower 4 tops and carries out heat exchange with the process water 21 that enters hydrolysis tower; The bottom discharges and exchanges heat with the oil 5 entering the hydrolysis tower; the sweet water outlet at the bottom of the hydrolysis tower is connected to the feed port of the three-effect evaporator through a pipel...

Embodiment 2

[0032] A production method for high-pressure hydrolysis of fats and oils that recycles sweet water:

[0033] The lard from the external storage tank enters the hydrolysis tower 4 with a flow rate of 8 tons / hour after being pressurized by the grease high-pressure pump 6, and the process water 21 enters the hydrolysis tower with a flow rate of 5.5 tons / hour after being pressurized by the process water high-pressure pump 22. The high-pressure steam 1 of 6.0MPa enters the hydrolysis tower with the speed of 1 ton / hour, and lard and process water carry out hydrolysis reaction when temperature 260 ℃, pressure 6.0MPa, produce the fatty acid of 7.925 tons and the sweet water of 6.575 tons (glycerol in sweet water Concentration is 13%); The fatty acid 9 that hydrolysis reaction produces is discharged from hydrolysis tower 4 tops and carries out heat exchange with process water 21, and the sweet water 10 that hydrolysis reaction produces is discharged from hydrolysis tower bottom and carr...

Embodiment 3

[0036] A production method for high-pressure hydrolysis of fats and oils that recycles sweet water:

[0037] The palm oil from the external storage tank enters the hydrolysis tower 4 at a rate of 10 tons / hour after being pressurized by the grease high-pressure pump 6, and the process water 21 enters the hydrolysis tower with a flow rate of 6.2 tons / hour after being pressurized by the process water high-pressure pump 22. The high-pressure steam 1 of 6.0MPa enters the hydrolysis tower at a speed of 1.3 tons / hour, and the palm oil and the process water are hydrolyzed at a temperature of 260°C and a pressure of 6.0MPa to generate 9.85 tons of fatty acids and 7.65 tons of sweet water (glycerin in sweet water). Concentration is 14.3%); The fatty acid 9 that hydrolysis reaction produces is discharged from hydrolysis tower 4 tops and carries out heat exchange with process water 21, and the sweet water 10 that hydrolysis reaction produces is discharged from hydrolysis tower bottom and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com