Process for recycling NaNO3 multilevel leaching liquid prepared by saltier ore

A technology of leaching liquid and nitrate ore, which is applied in the direction of alkali metal nitrate, alkali metal compound, inorganic chemistry, etc., can solve the problems of water consumption, low product quality, high production cost, etc., to reduce investment, reduce construction area, The effect of less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

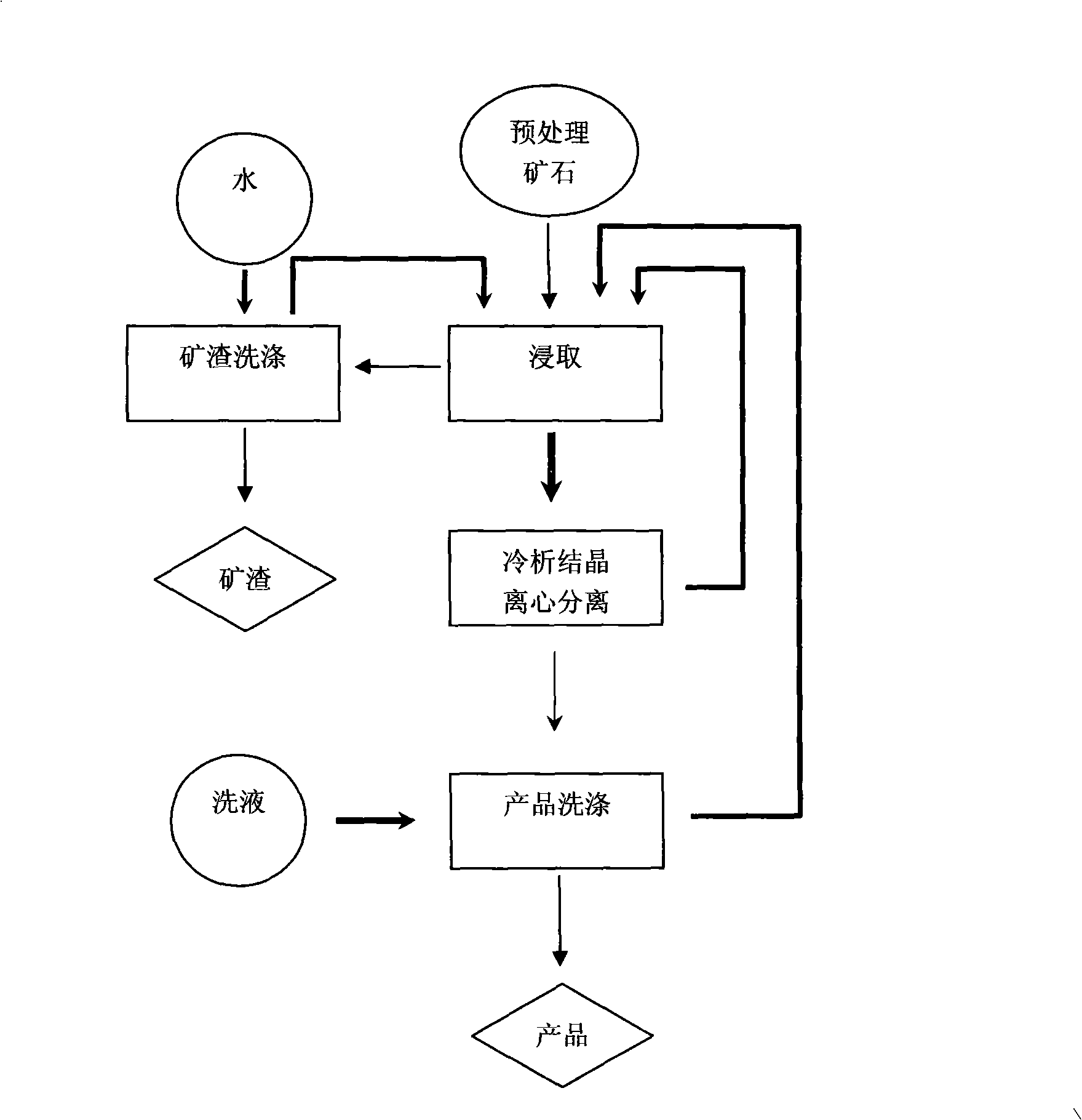

[0007] Example 1: After washing the slag, the lotion is used for leaching the pretreated ore, and the leaching solution is returned to the next level of leaching after being cooled and crystallized. The solid precipitate after cold crystallization is centrifuged to obtain the primary product, which is washed with lotion to improve the purity, and the washed liquid is used for leaching.

[0008] After the saltpeter ore is crushed to a certain particle size (below 2cm in particle size), the solid ore and fine ore are loaded into the leaching and washing tower together, and the NaNO-containing 3 The 350g / l leaching solution is leached in a leaching scrubber at 50°C in multi-stage countercurrent leaching to obtain NaNO-containing 3 The 470g / l leaching liquid is sent to the low-temperature separation section for cooling to 5°C for salt precipitation, separation, washing, and drying to produce sodium nitrate products. The single-pass yield of cold analysis is 25-32%, and the product...

Embodiment 2

[0010] Embodiment 2: Containing NaNO from mining 3 20.754 tons of sodium saltpeter with about 6% is transported by truck to the mine crushing site and crushed-screened-crushed to a particle size of ≤20mm by a truck, and 0.042 tons of ore dust is lost. The final crushed ore 20.712 tons is transported to the mobile bucket elevator, and the crushed ore is added to the top of the leaching tank through the elevator, and then leached with the leaching solution. Each tank is leached 5 times and washed three times. The first washing solution is used as the fifth leaching solution in the next tank, and the last washing is washed with clean water. Take fresh water 3.512m 3 , washing slag, slag washing liquid 3.65m 3 , used as a leaching solution, 19.474 tons of slag was discharged after washing, 9.073 tons of the leaching completed liquid was subjected to cold crystallization, and 6.831 tons of the liquid after cold analysis was brought back for the next level of leaching, and the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com