Patents

Literature

197results about "Alkali metal nitrates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-melting point inorganic nitrate salt heat transfer fluid

A low-melting point, heat transfer fluid made of a mixture of four inorganic nitrate salts: 9-18 wt % NaNO3, 40-52 wt % KNO3, 13-21 wt % LiNO3, and 20-27 wt % Ca(NO3)2. These compositions can have liquidus temperatures less than 100 C; thermal stability limits greater than 500 C; and viscosity in the range of 5-6 cP at 300 C; and 2-3 cP at 400 C.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

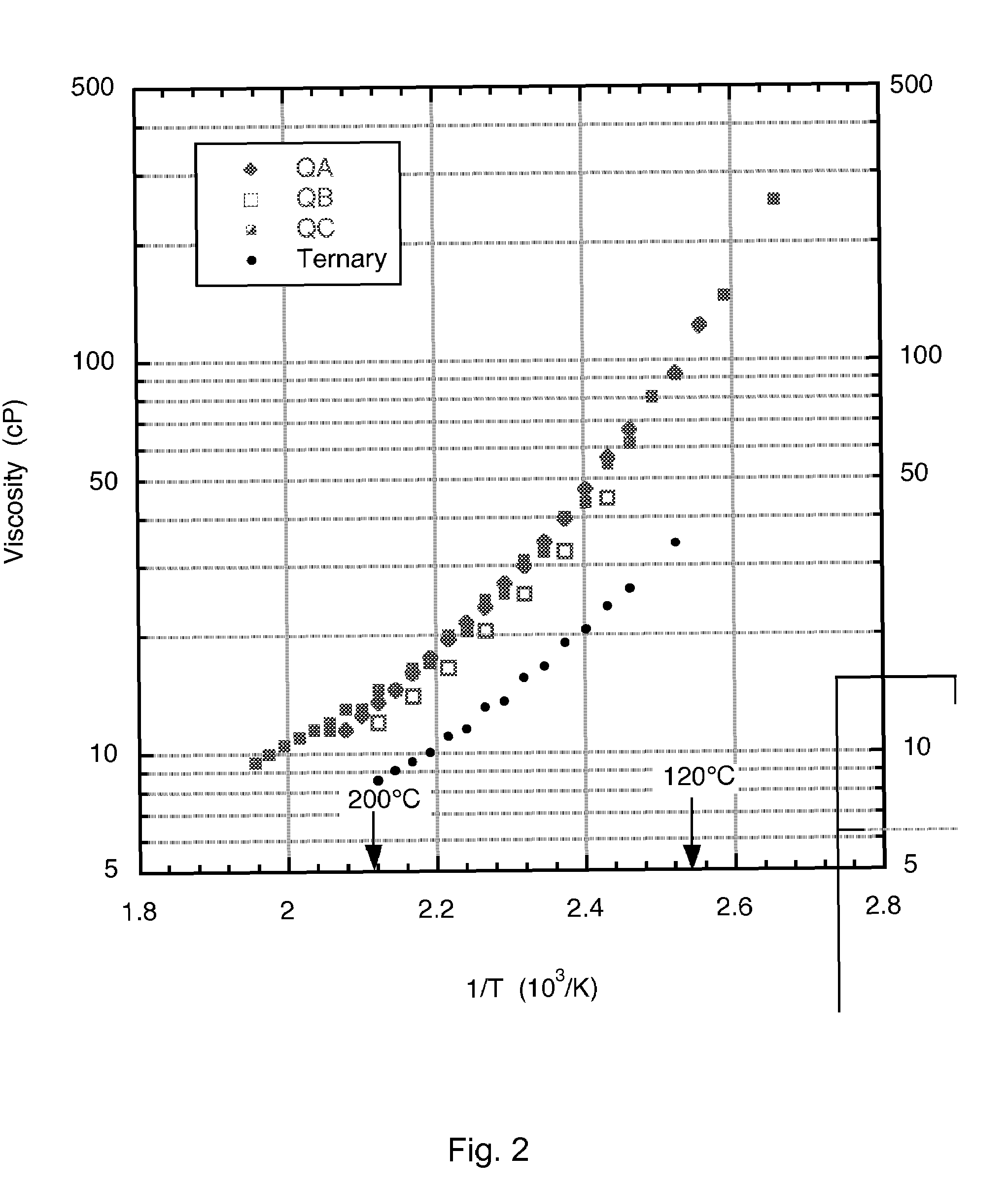

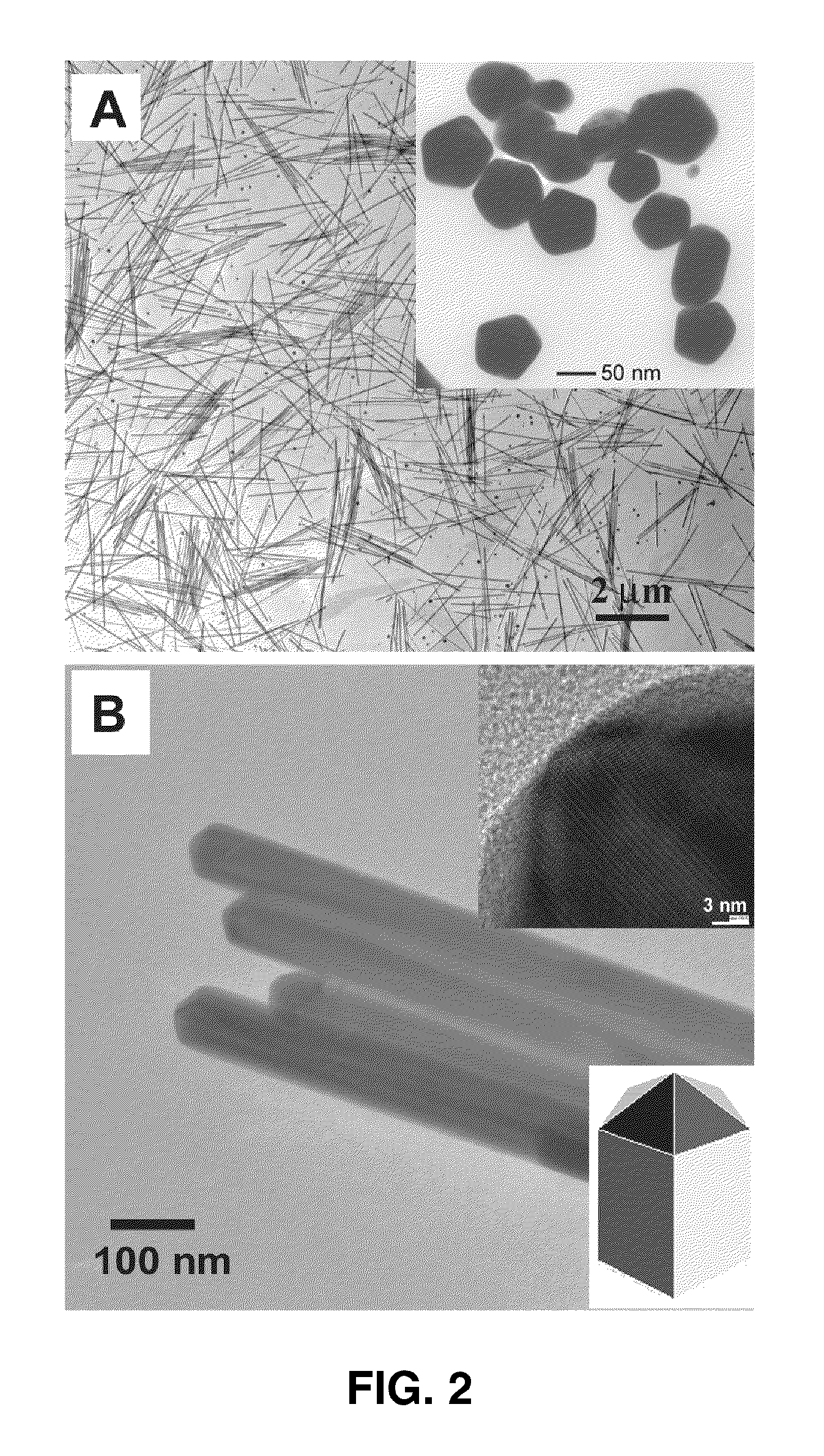

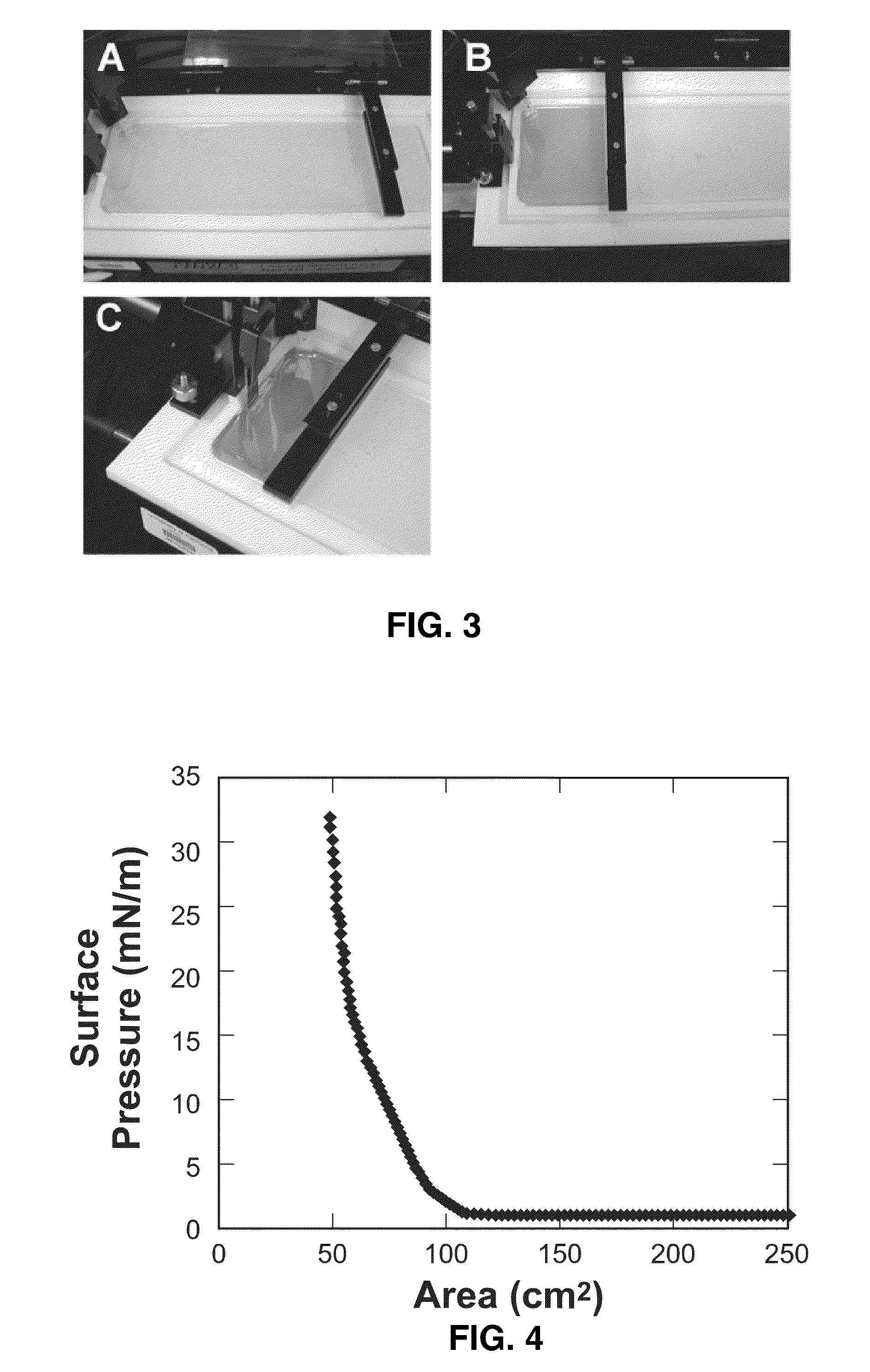

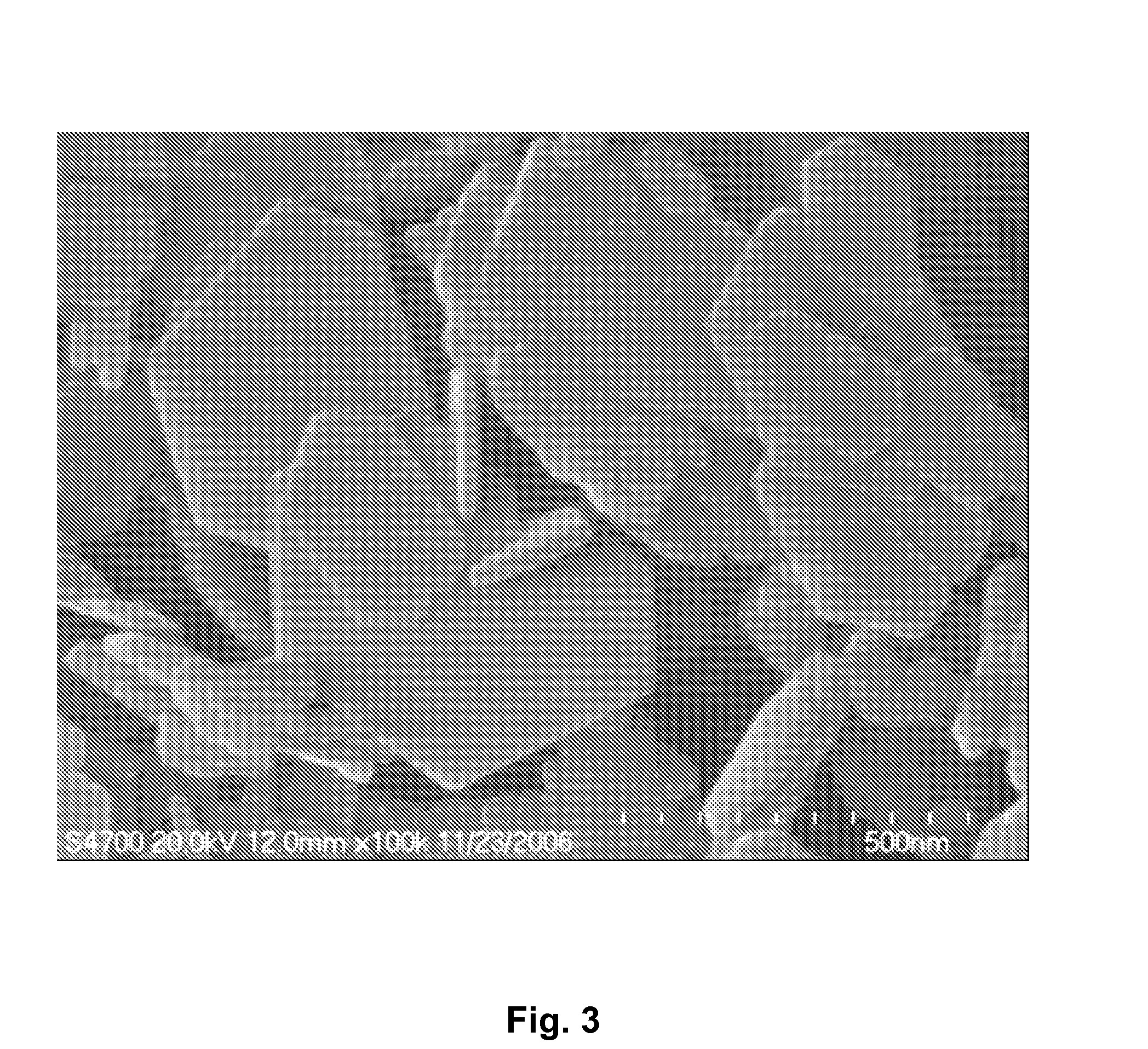

Langmuir-blodgett nanostructure monolayers

InactiveUS20090169807A1Easy to useLarge field enhancementLiquid surface applicatorsNanostructure manufactureNanoparticleEngineering

Methods for assembly of monolayers of nanoparticles using the Langmuir-Blodgett technique, as well as monolayers, assemblies, and devices are described. The surface properties of these monolayers are highly reproducible and well-defined as compared to other systems. These monolayers can readily be used for molecular detection in either an air-borne or a solution environment, and sensors using the monolayer could have significant implications in chemical and biological warfare detection, national and global security, as well as in medical detection applications.

Owner:RGT UNIV OF CALIFORNIA

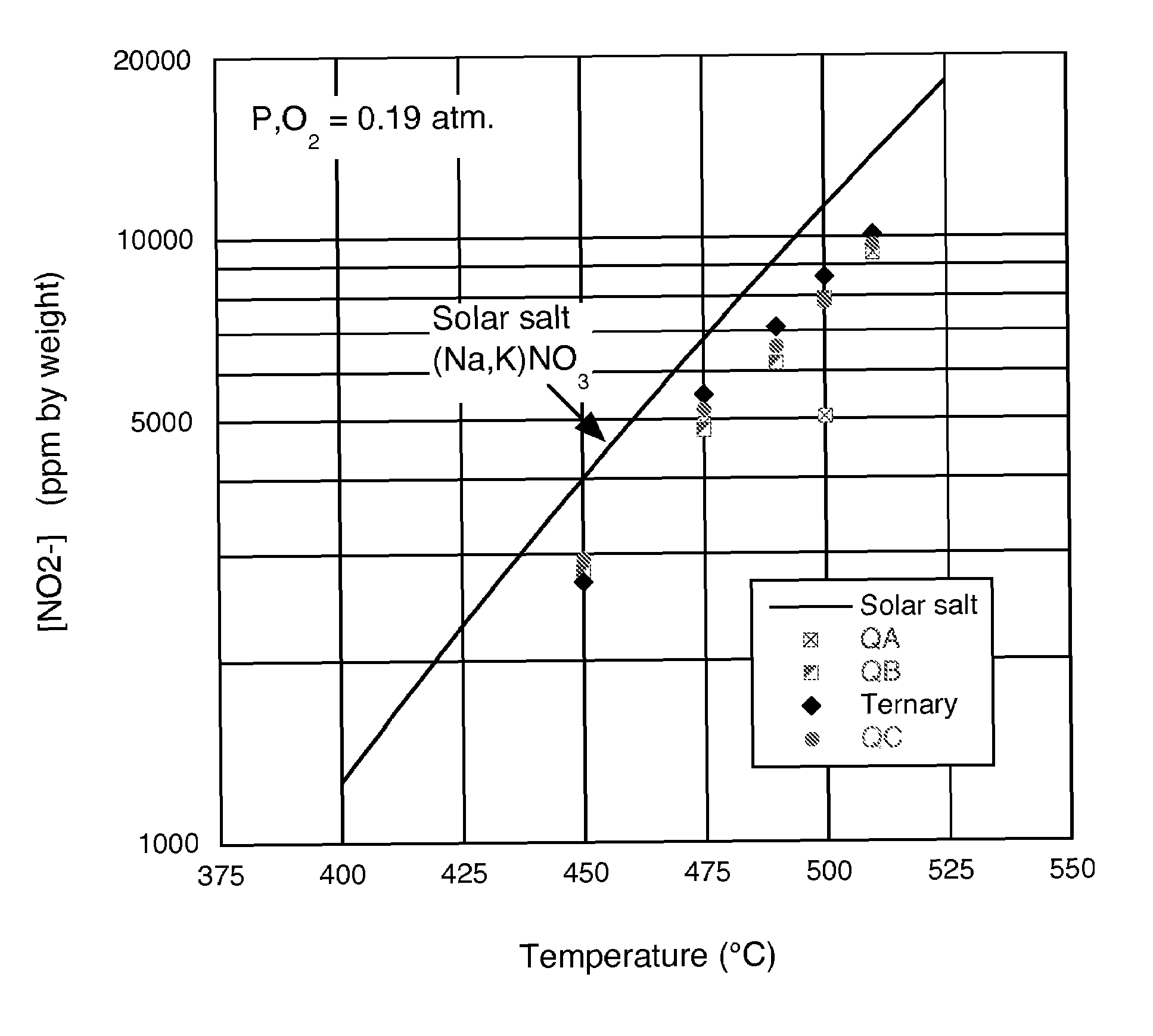

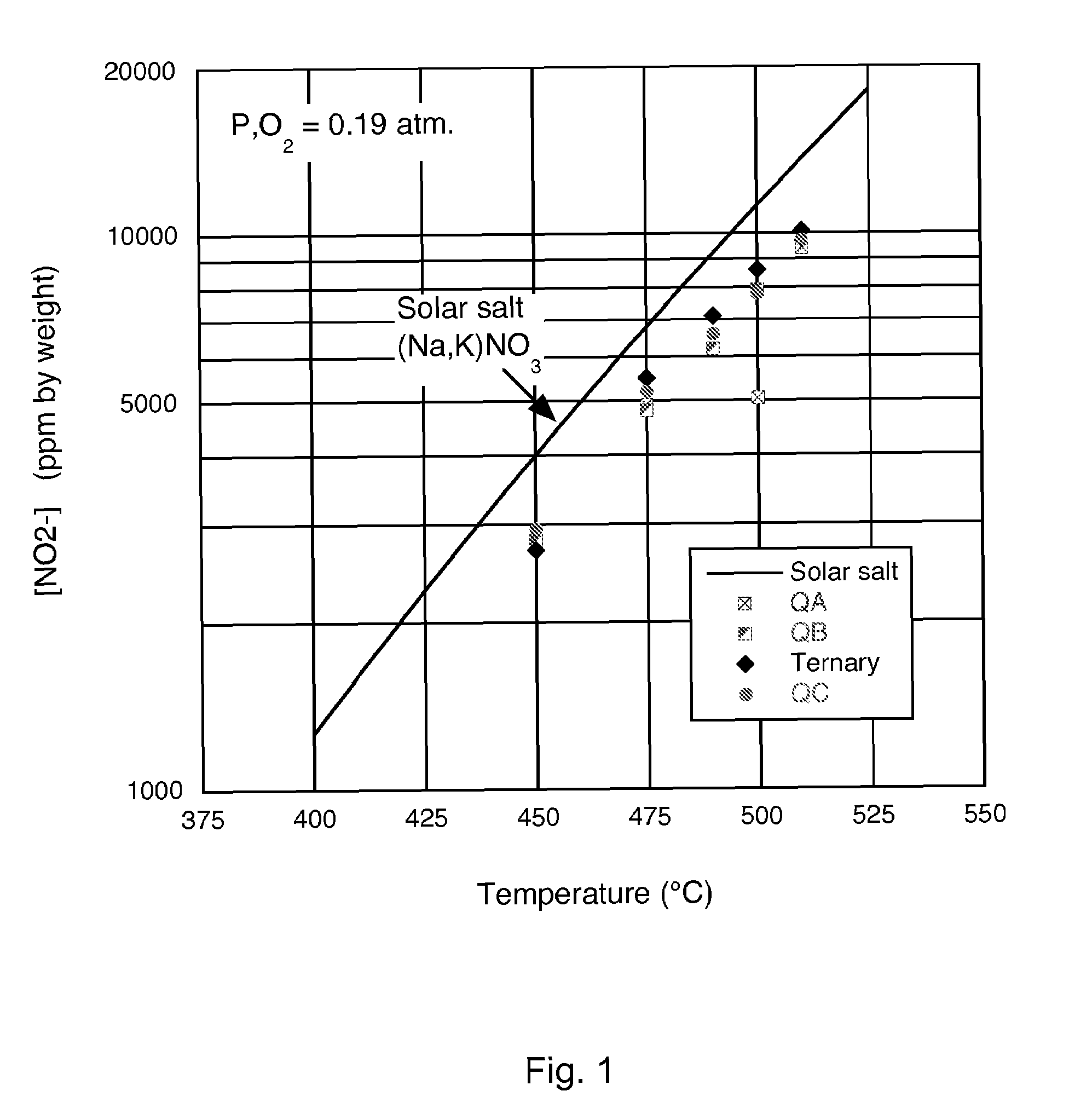

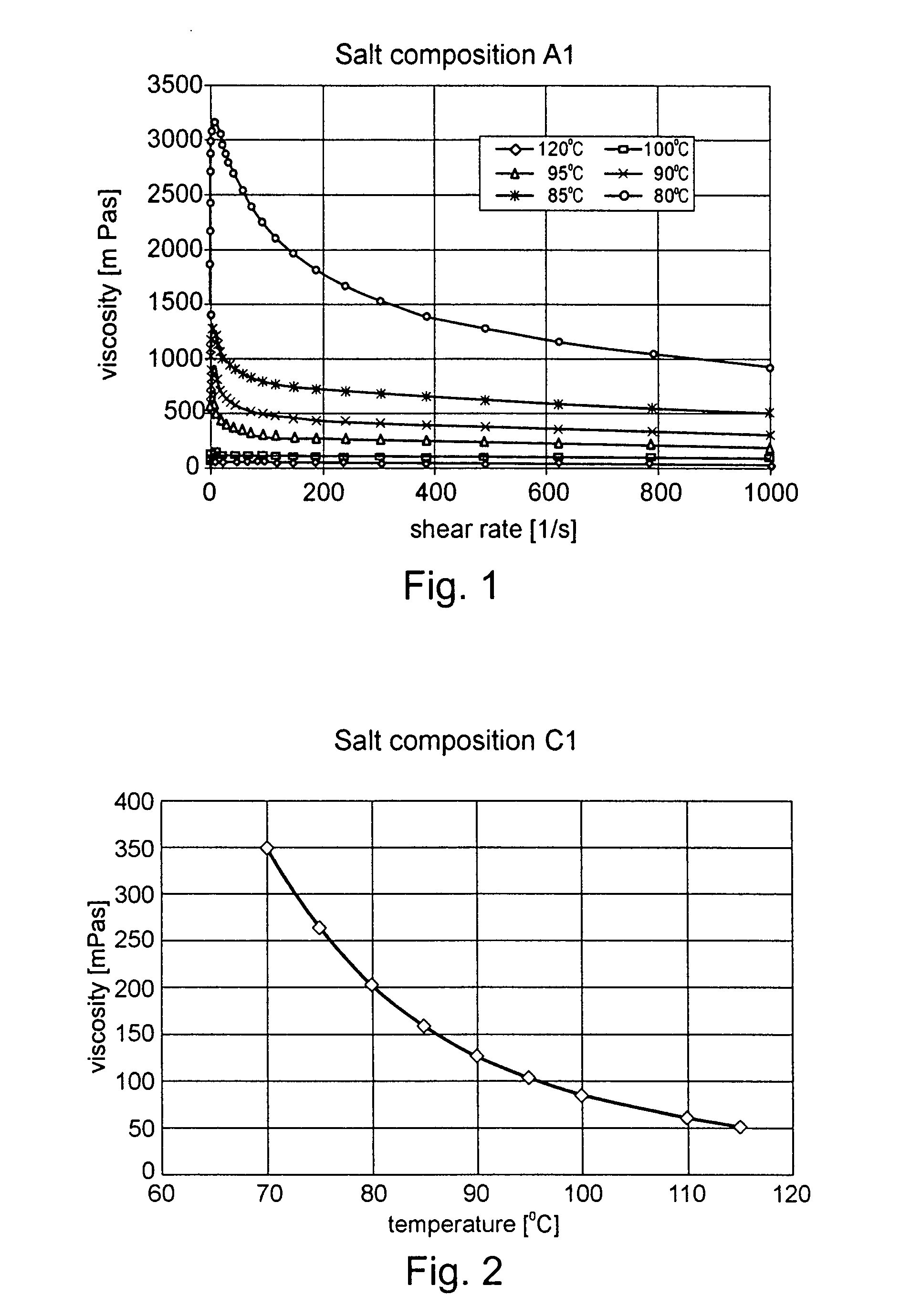

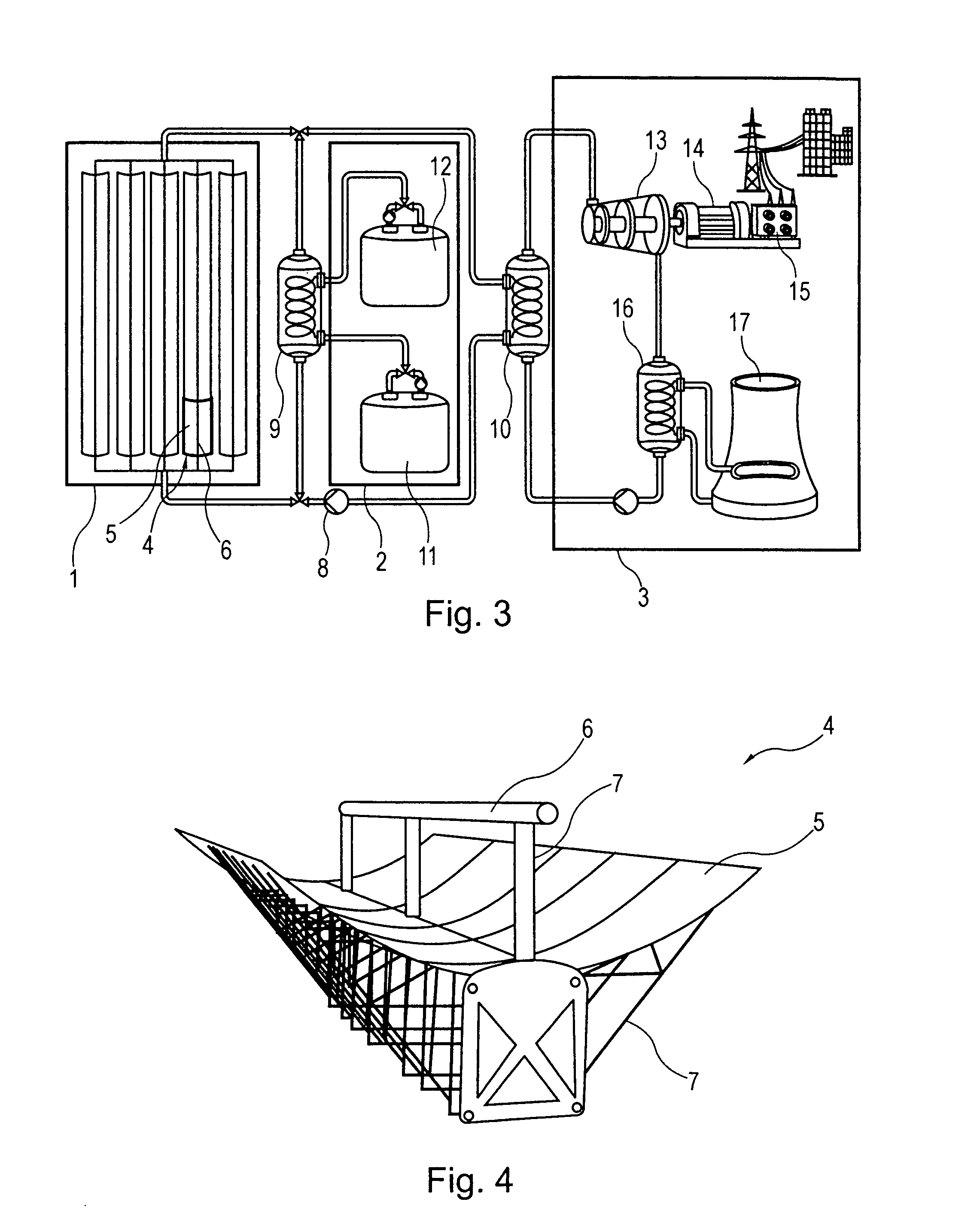

Multinary salt system for storing and transferring thermal energy

InactiveUS20100038581A1Low melting pointImprove stabilityAlkali metal nitratesEnergy inputThermal energyInorganic chemistry

Salt composition containing an amount of at least 10% by weight KNO2, an amount of at least 15% by weight NaNO2, and an amount of at least 10% by weight LiNO3. Salt aqueous liquid solution containing the salt composition. Use of a salt composition or salt aqueous liquid solution for storing and / or transferring thermal energy.

Owner:SOLAR MILLENNIUM

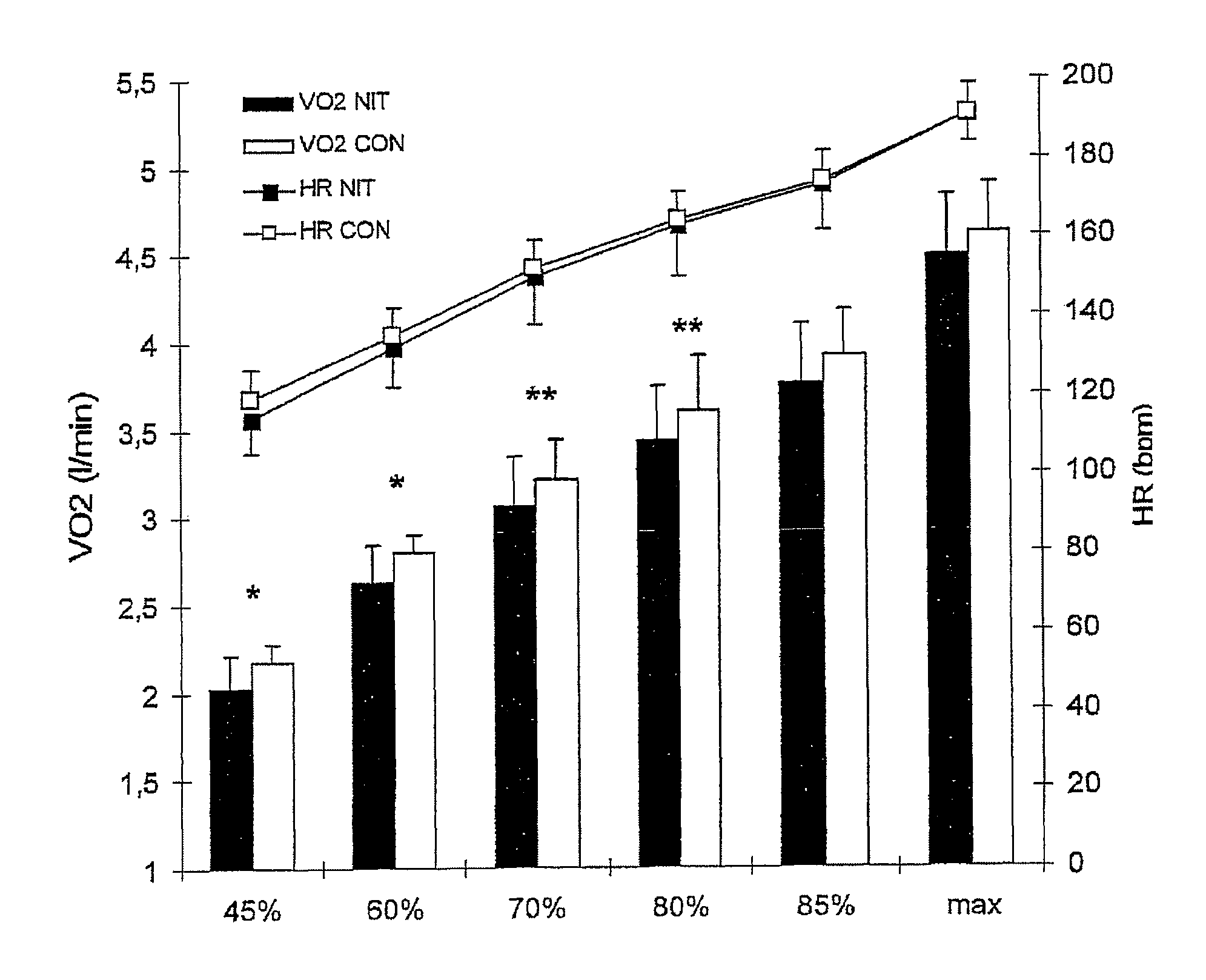

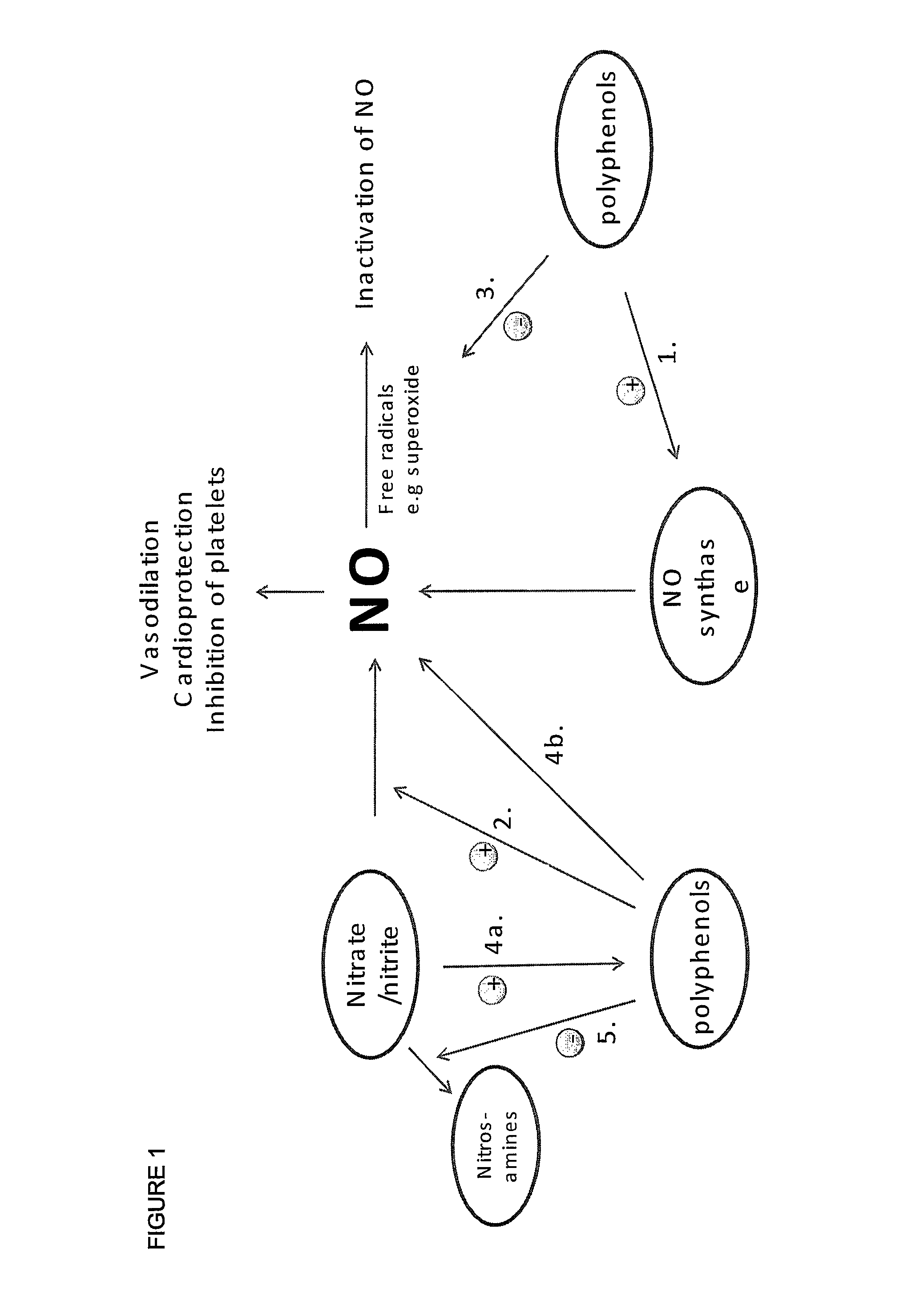

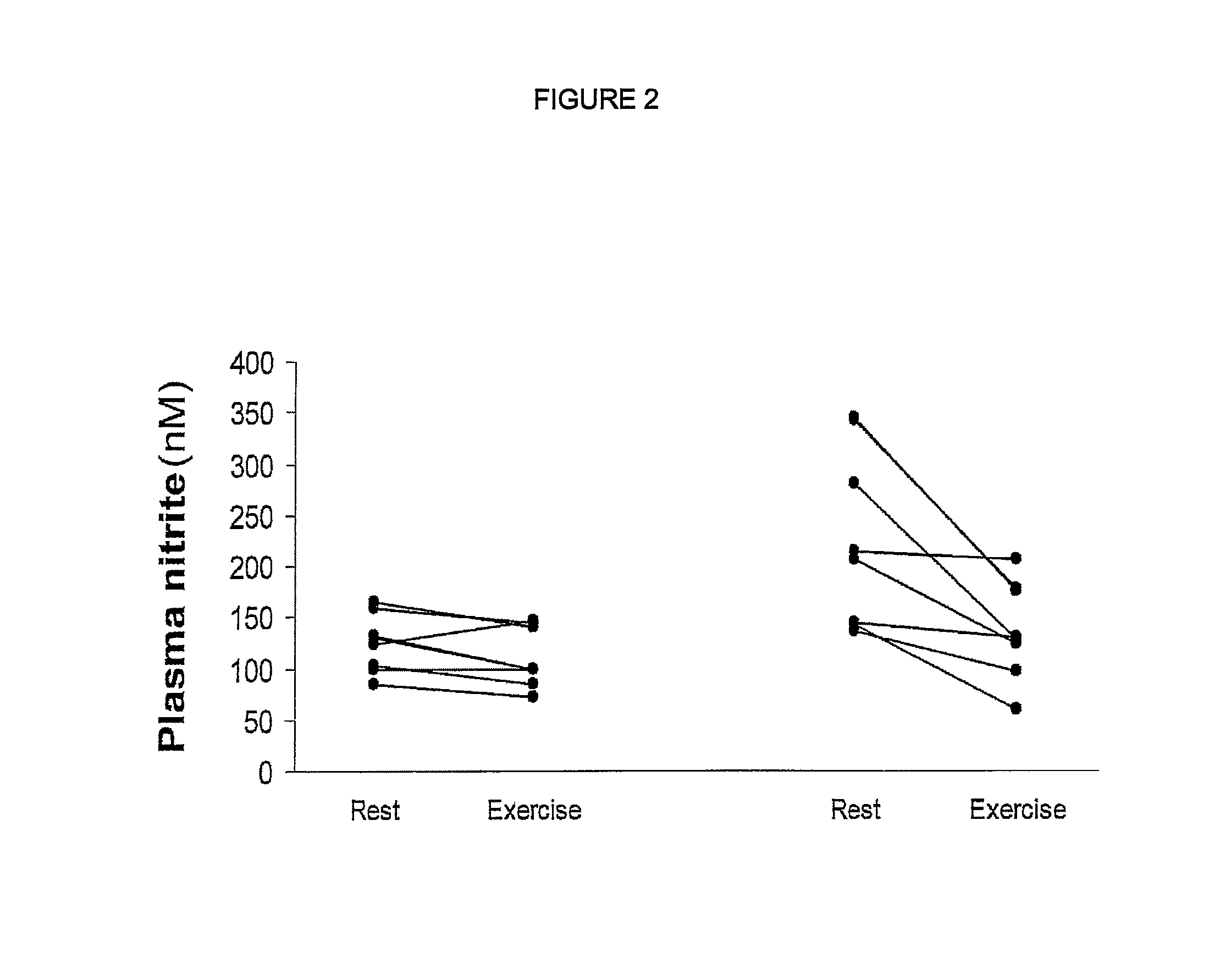

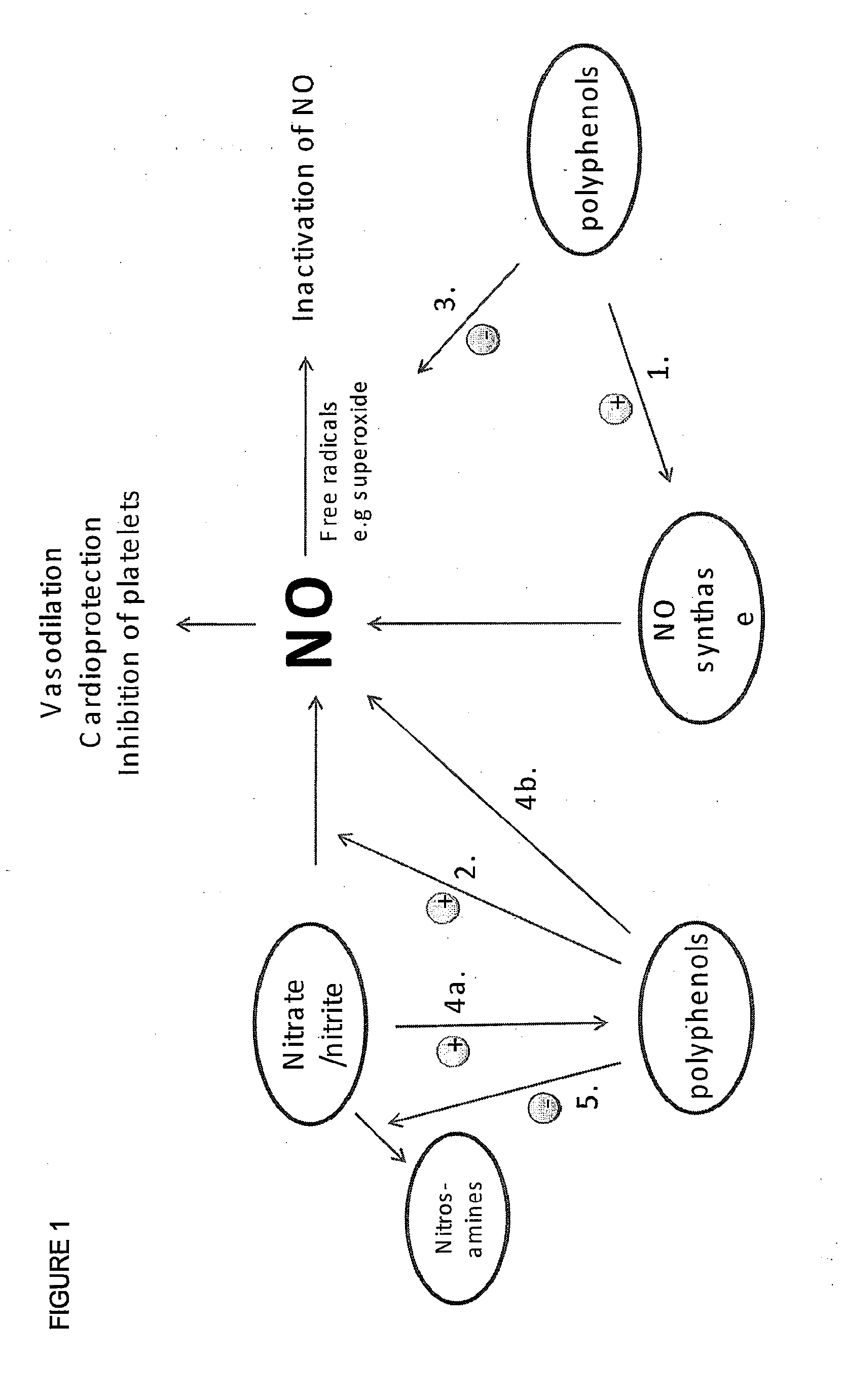

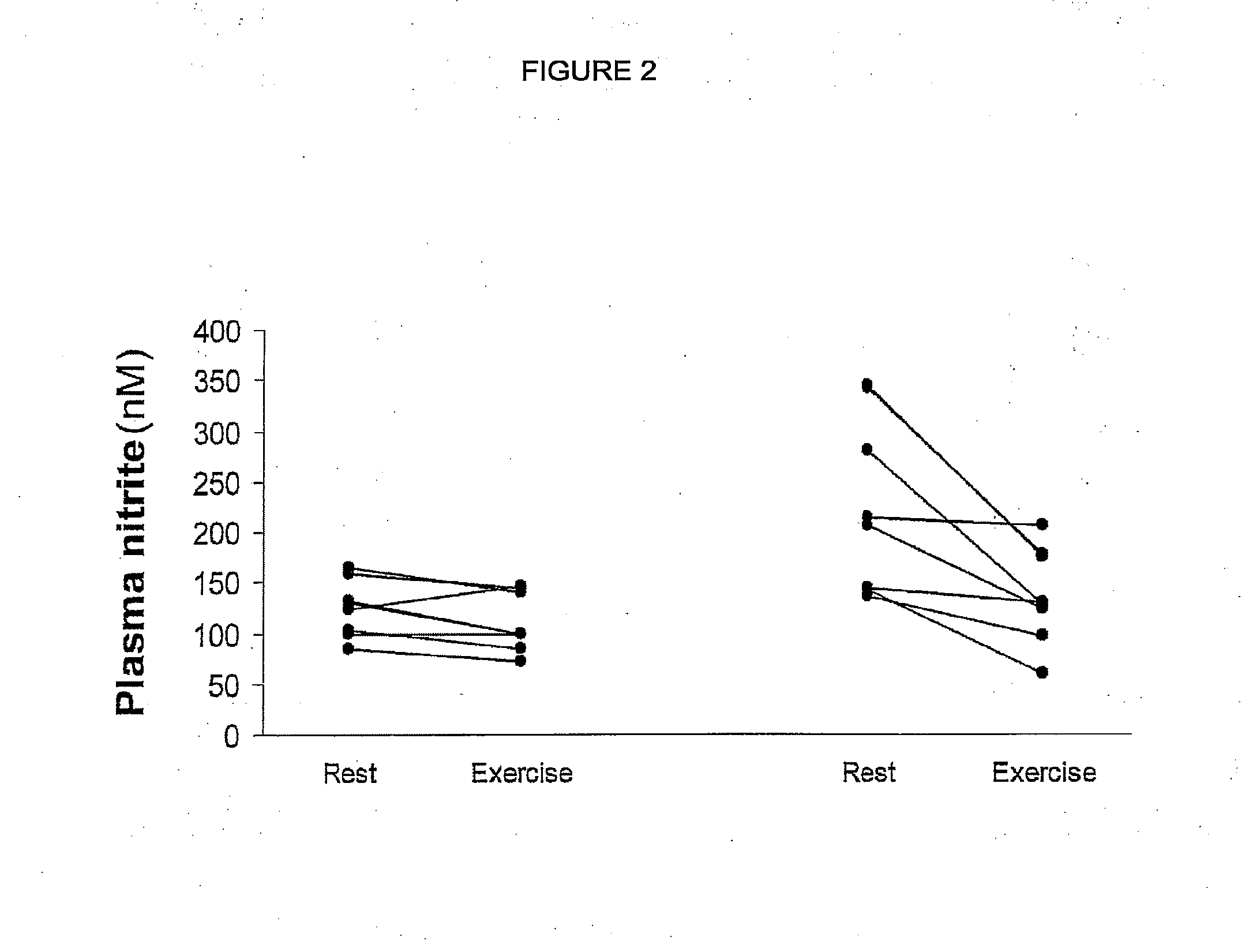

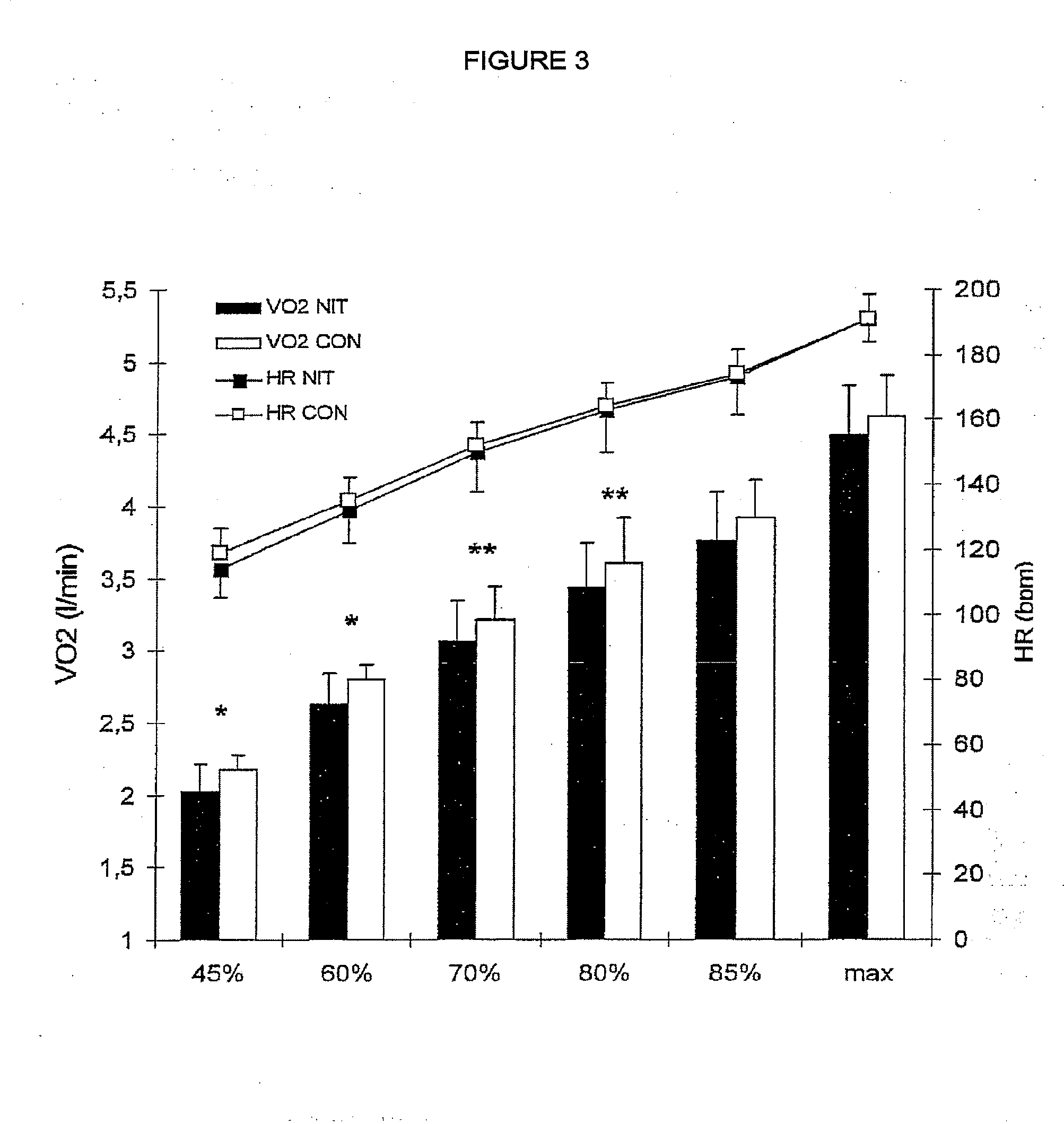

Performance enhancing composition and use thereof

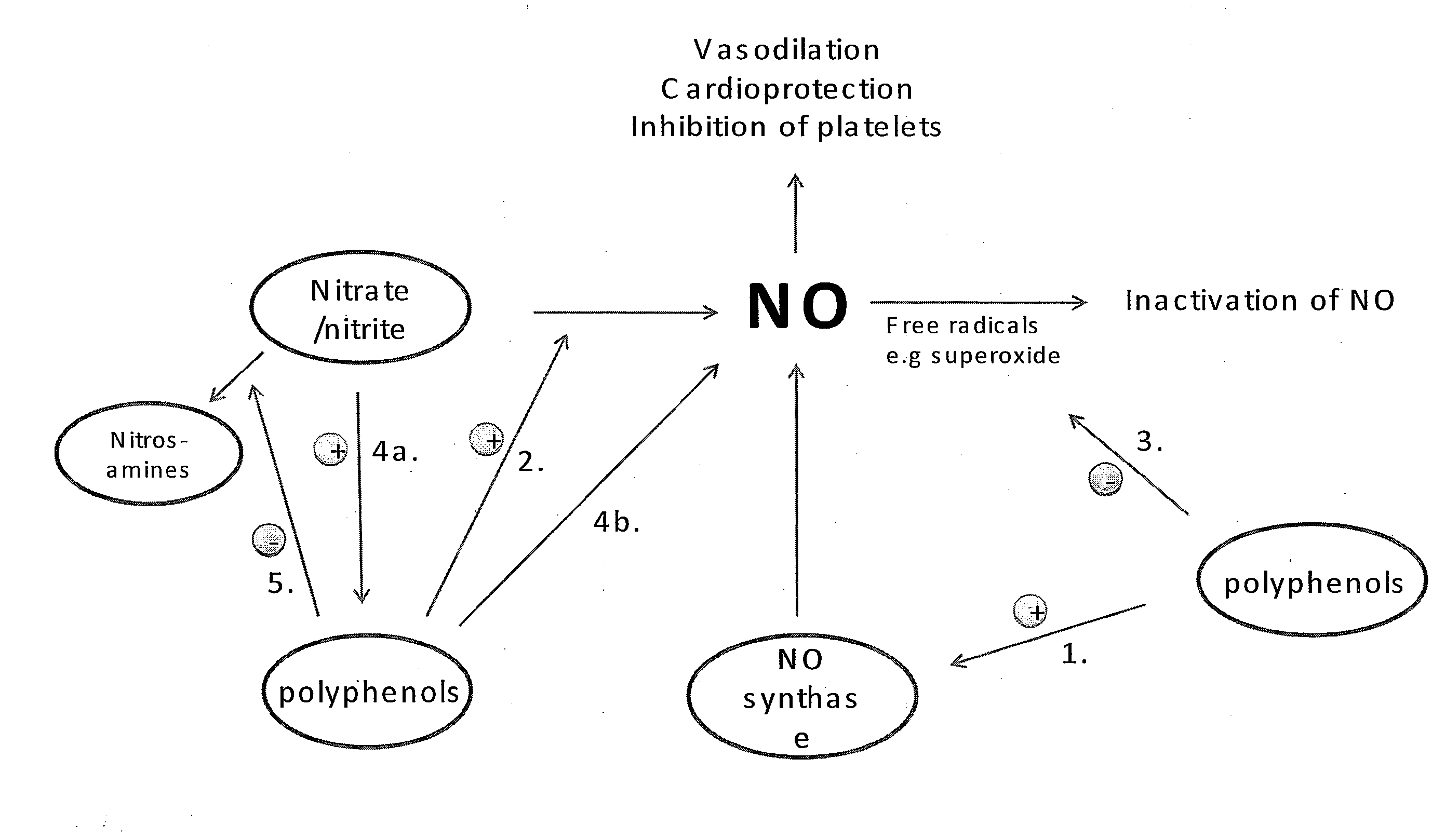

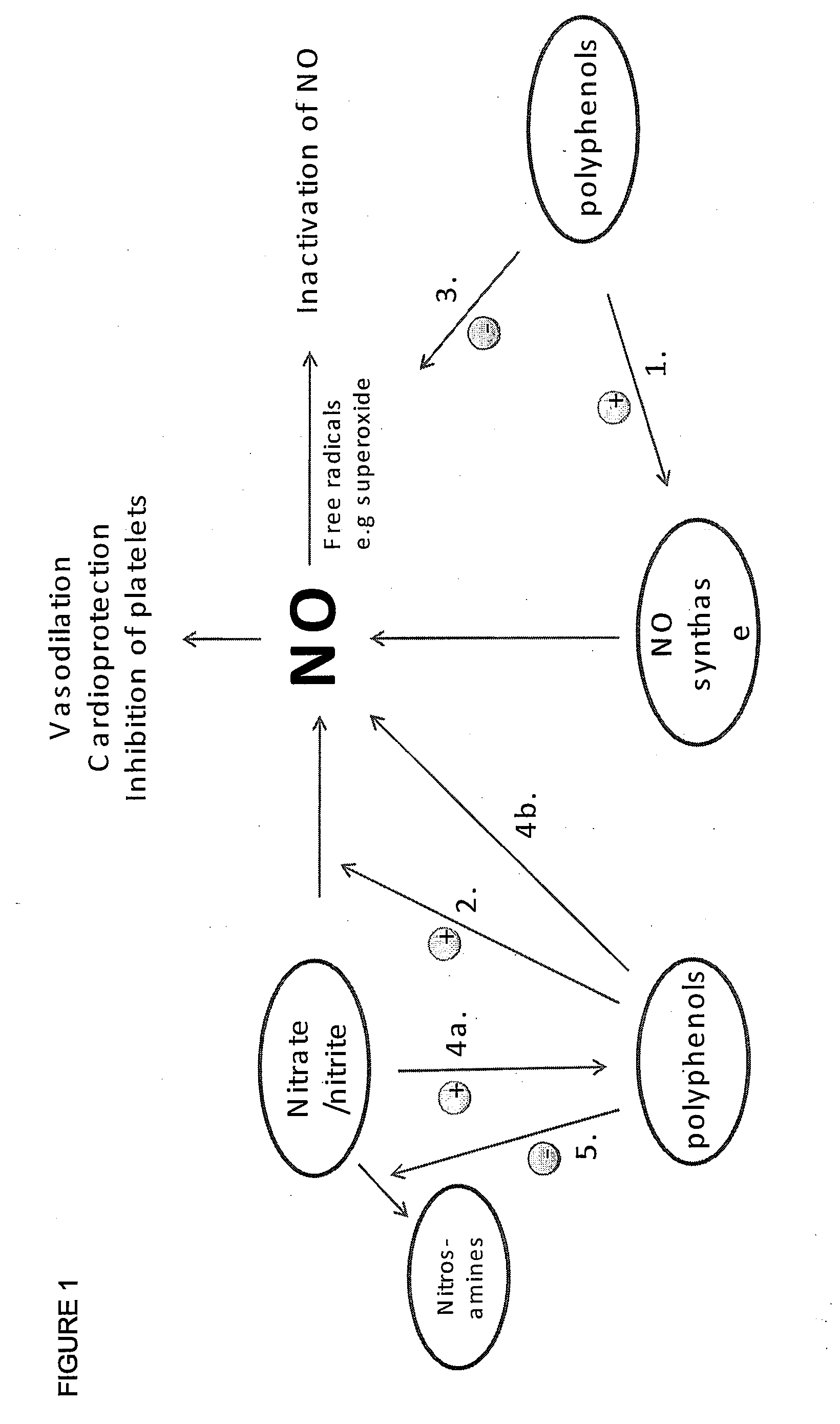

The performance of a mammal, manifested as a reduced oxygen uptake (VO2) during physical exercise, can be enhanced by administering to said mammal a non-toxic amount of nitrate and / or nitrite. Liquid, semi-solid and solid snack and food products and nutritional supplements, such as sport drinks are made available.

Owner:HEARTBEET LTD

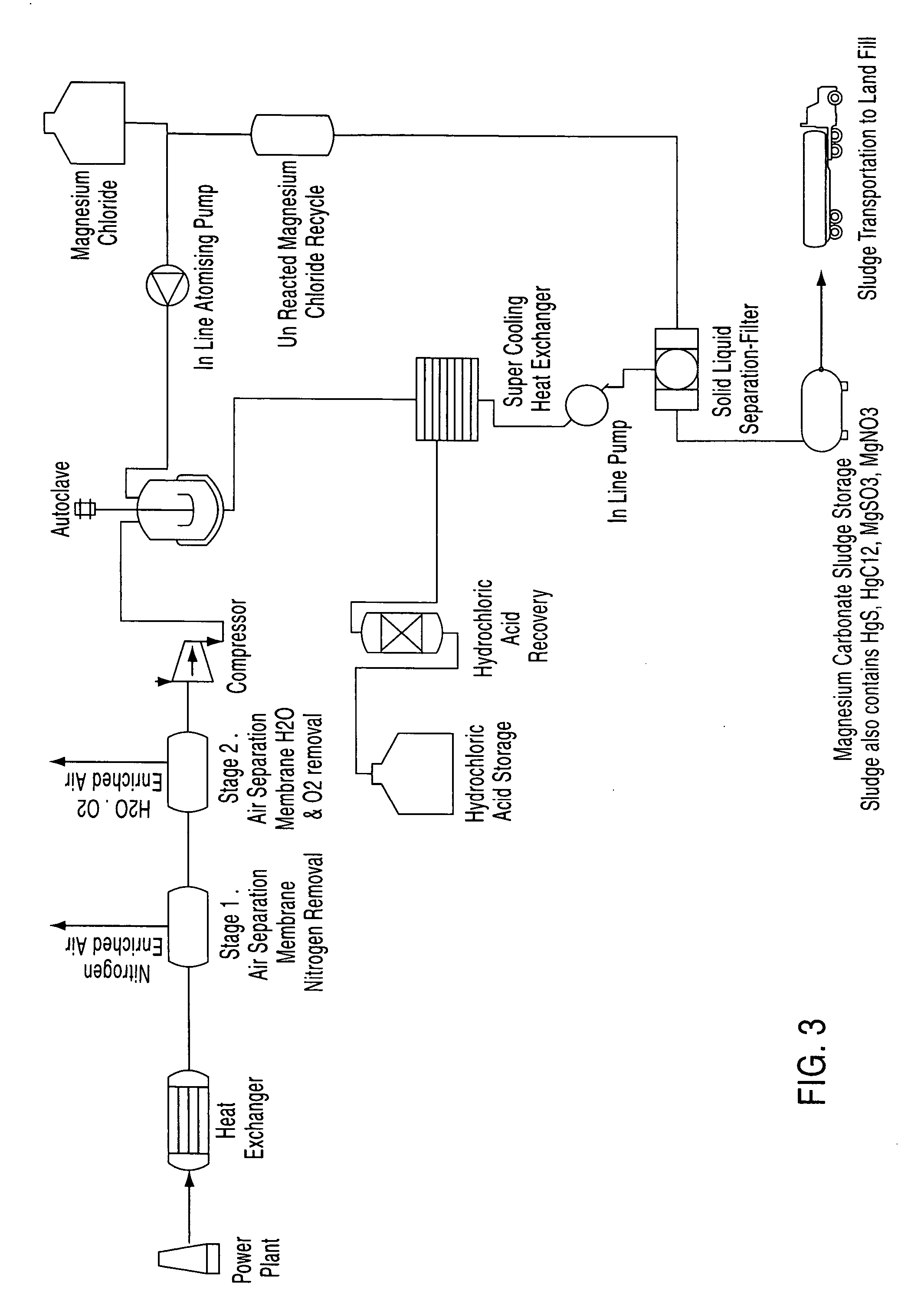

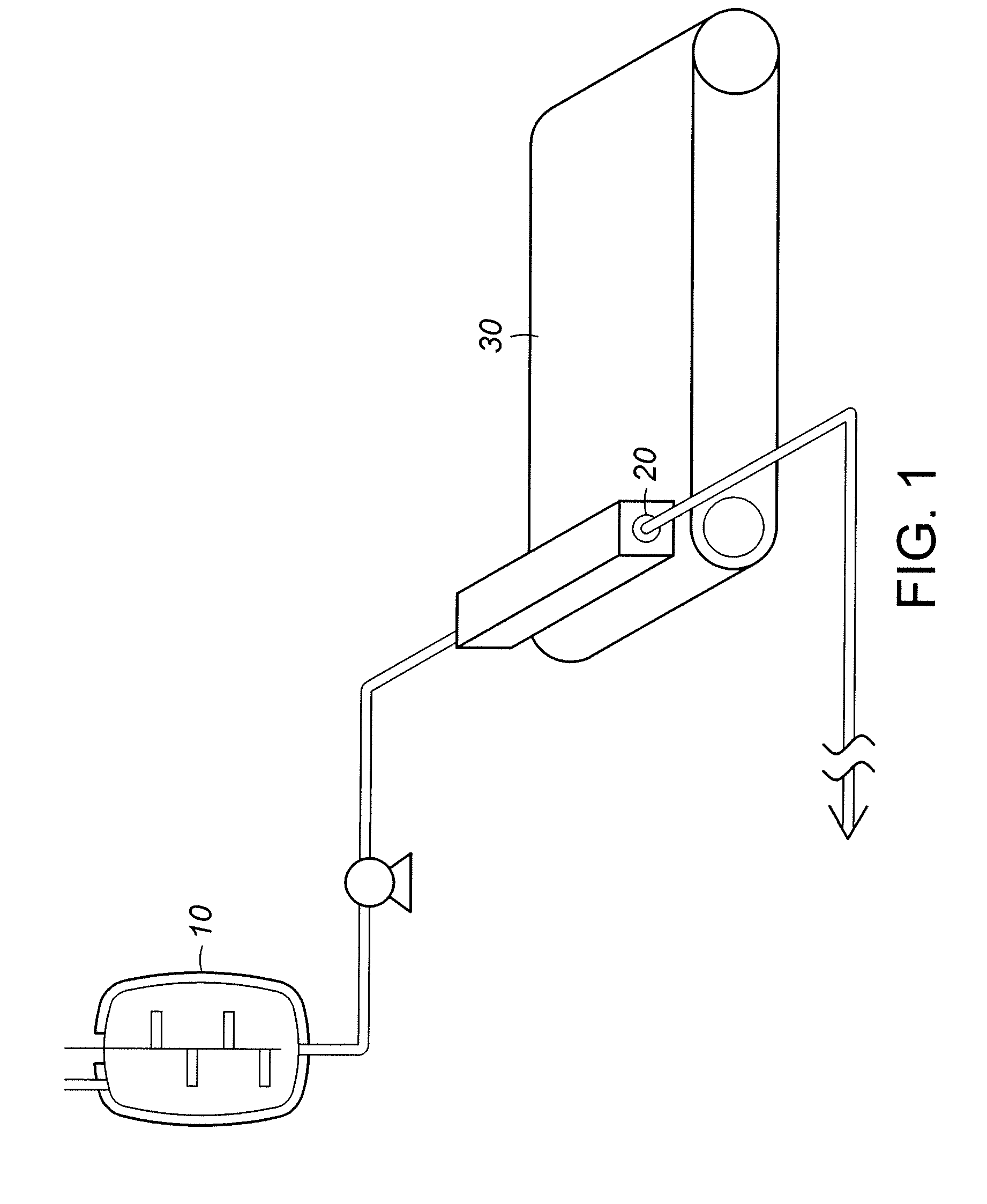

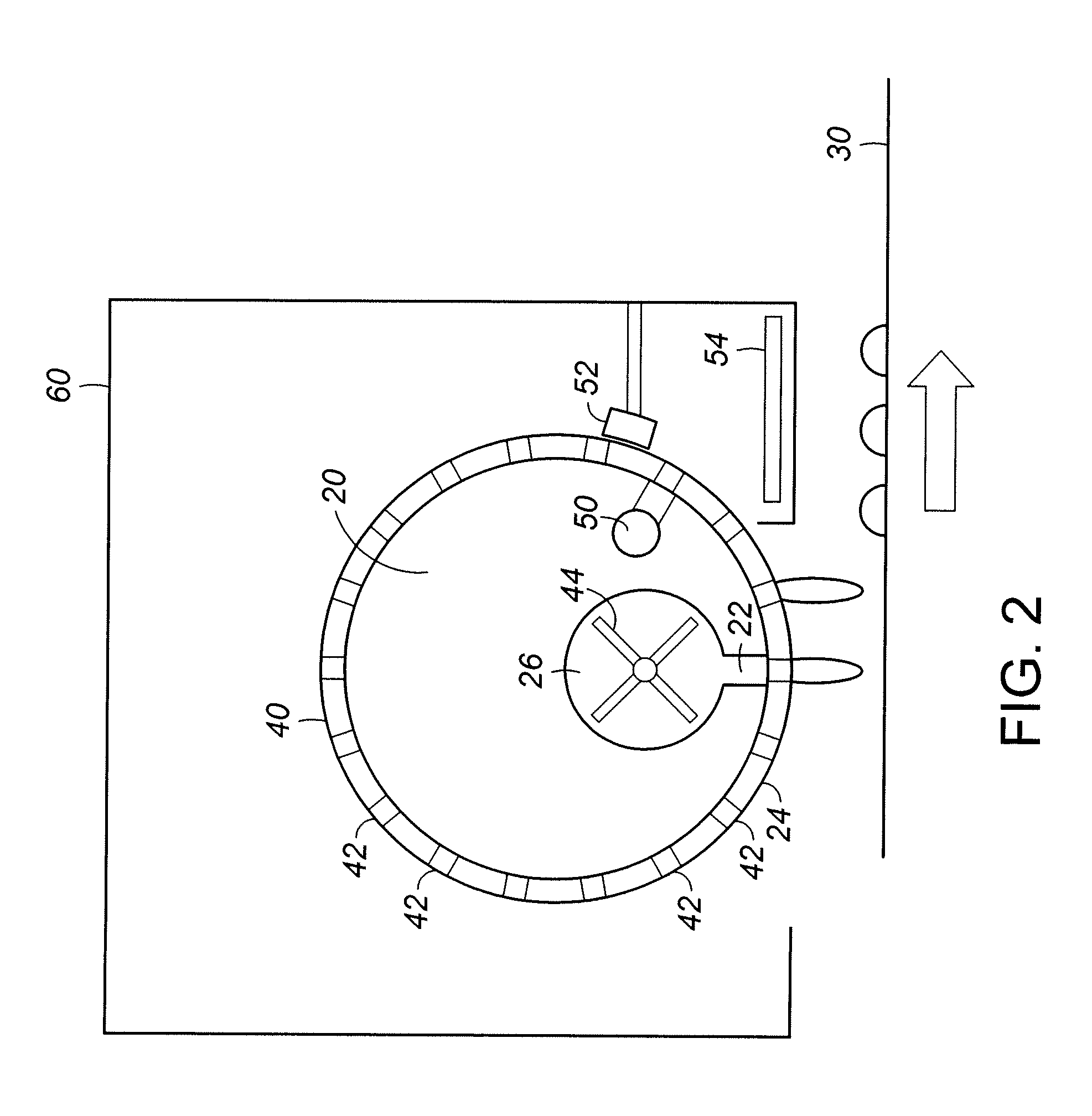

Process for removal of pollutants

A process for the removal of pollutants from a combustion process and, more particularly, a process for removing pollutants such as carbon dioxide, mercury, sulphur dioxide, nitrogen compounds and oxygen compounds from a combustion process. The process includes the removal of pollutants from a combustion process that produces an emission comprising: cooling the emission to a temperature of about 200° C.; removing nitrogen, water and oxygen from the emission to produce a gas containing a concentration of pollutants; contacting the gas with an aqueous magnesium chloride solution, wherein a slurry mixture is formed; and cooling the gas and the slurry mixture, wherein hydrochloric acid vapour and a sludge are formed.

Owner:CLEAN WORLD STRATEGIES CORP

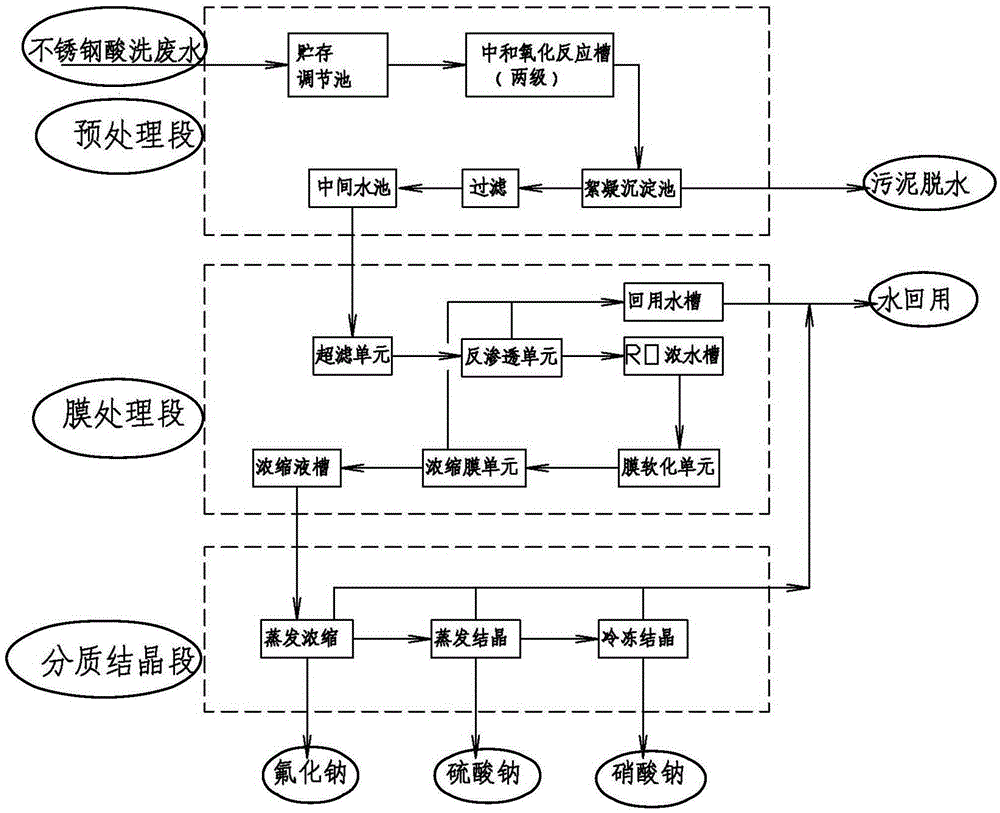

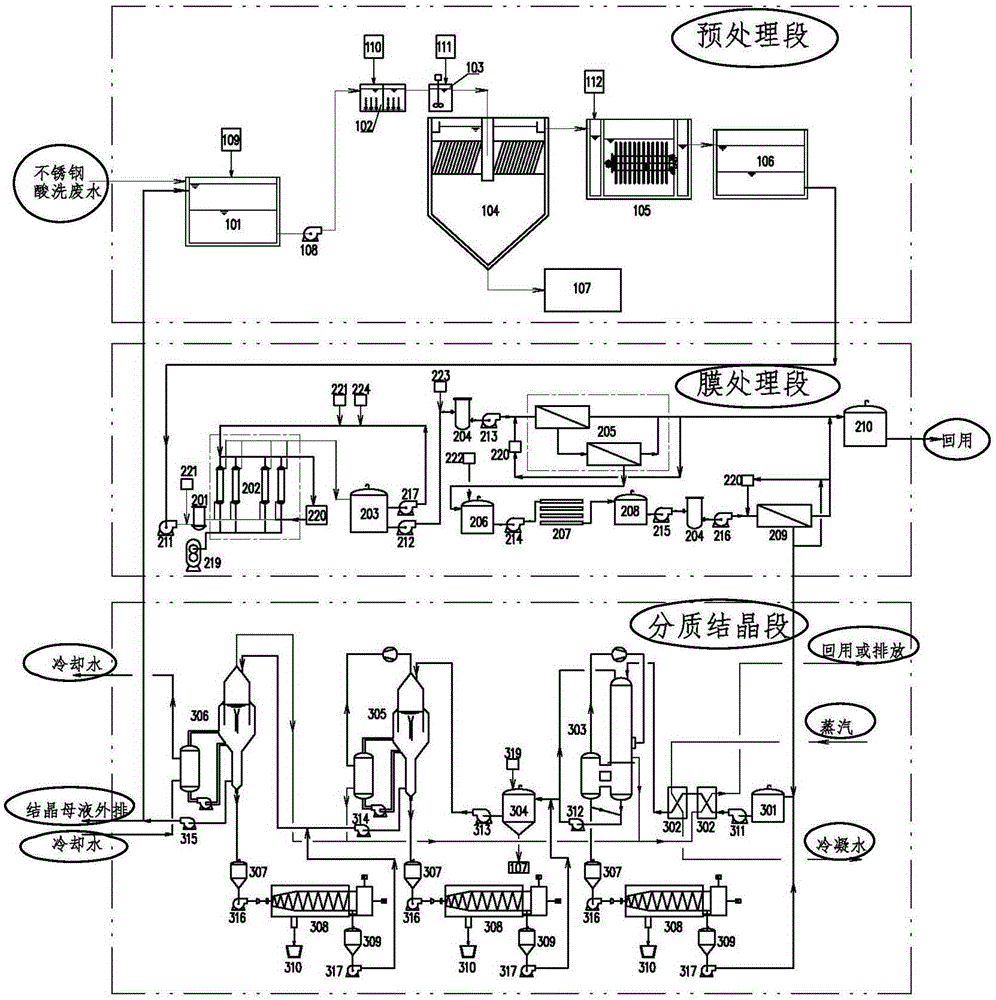

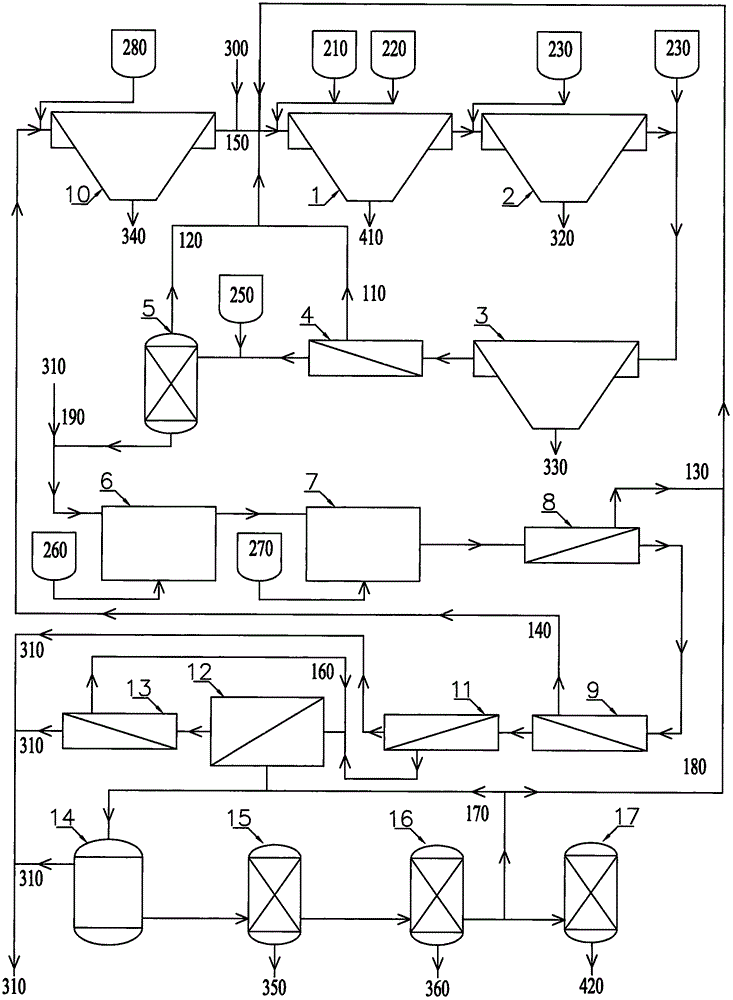

Complete equipment for stainless steel pickling wastewater treatment and resource recycling and treatment process

PendingCN106565045AAchieve reuseRealize zero-emission resource utilizationAlkali metal nitratesWaste water treatment from metallurgical processChemical reactionUltrafiltration

Complete equipment for stainless steel pickling wastewater treatment and resource recycling and a treatment process are disclosed. A pretreatment section, a membrane treatment section and a quality-based crystallization section are involved. The invention is characterized in that a storage regulating basin, a neutralization-oxidation reaction tank, a flocculent precipitation tank, a filter, an ultrafiltration and reverse osmosis system, a membrane concentration system and an evaporation and concentration and quality-based crystallization system are mutually connected end to end through pipelines. Each dosage device is respectively arranged on corresponding section. According to the order of the pretreatment section, the membrane treatment section and the quality-based crystallization section, thirteen steps are included for the operation. By the treatment process of chemical reactive precipitation, membrane separation concentration and evaporation and quality-based crystallization, various acid wastewaters mainly containing acid and inorganic salt can be treated to realize recycling of wastewater. After crystallization of salt, sodium sulfate (and sodium chloride), sodium nitrate, sodium fluoride and other products can be recycled, and zero-discharge resource utilization of stainless steel pickling wastewater is realized. Meanwhile, system sludge yield is greatly reduced such that the burden of sludge treatment is decreased.

Owner:MAIWANG INT BUSINESS SHANGHAI

Performance enhancing composition and use thereof

The performance of a mammal, manifested as a reduced oxygen uptake (VO2) during physical exercise, can be enhanced by administering to said mammal a non-toxic amount of nitrate and / or nitrite. Liquid, semi-solid and solid snack and food products and nutritional supplements, such as sport drinks are made available.

Owner:HEARTBEET LTD

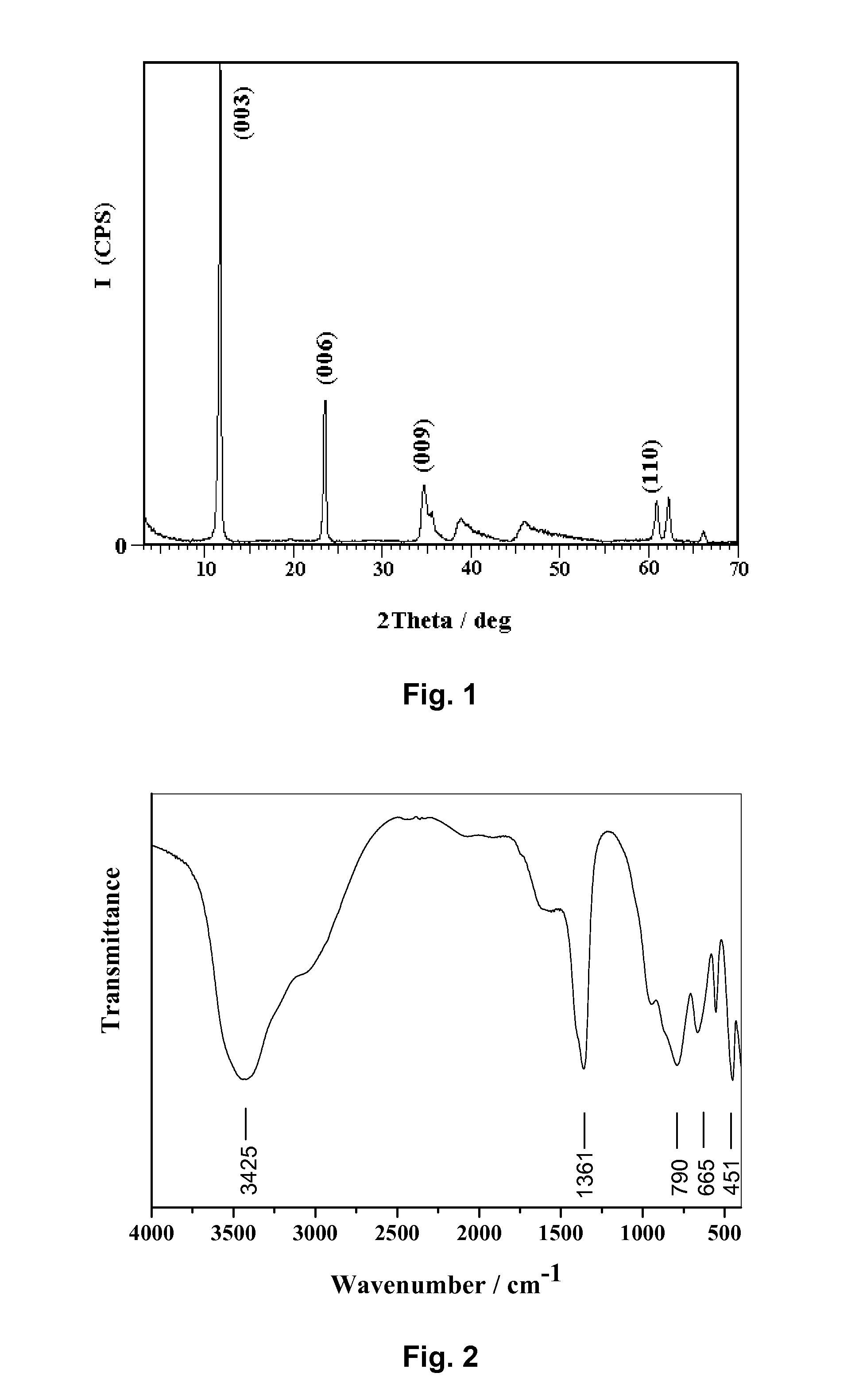

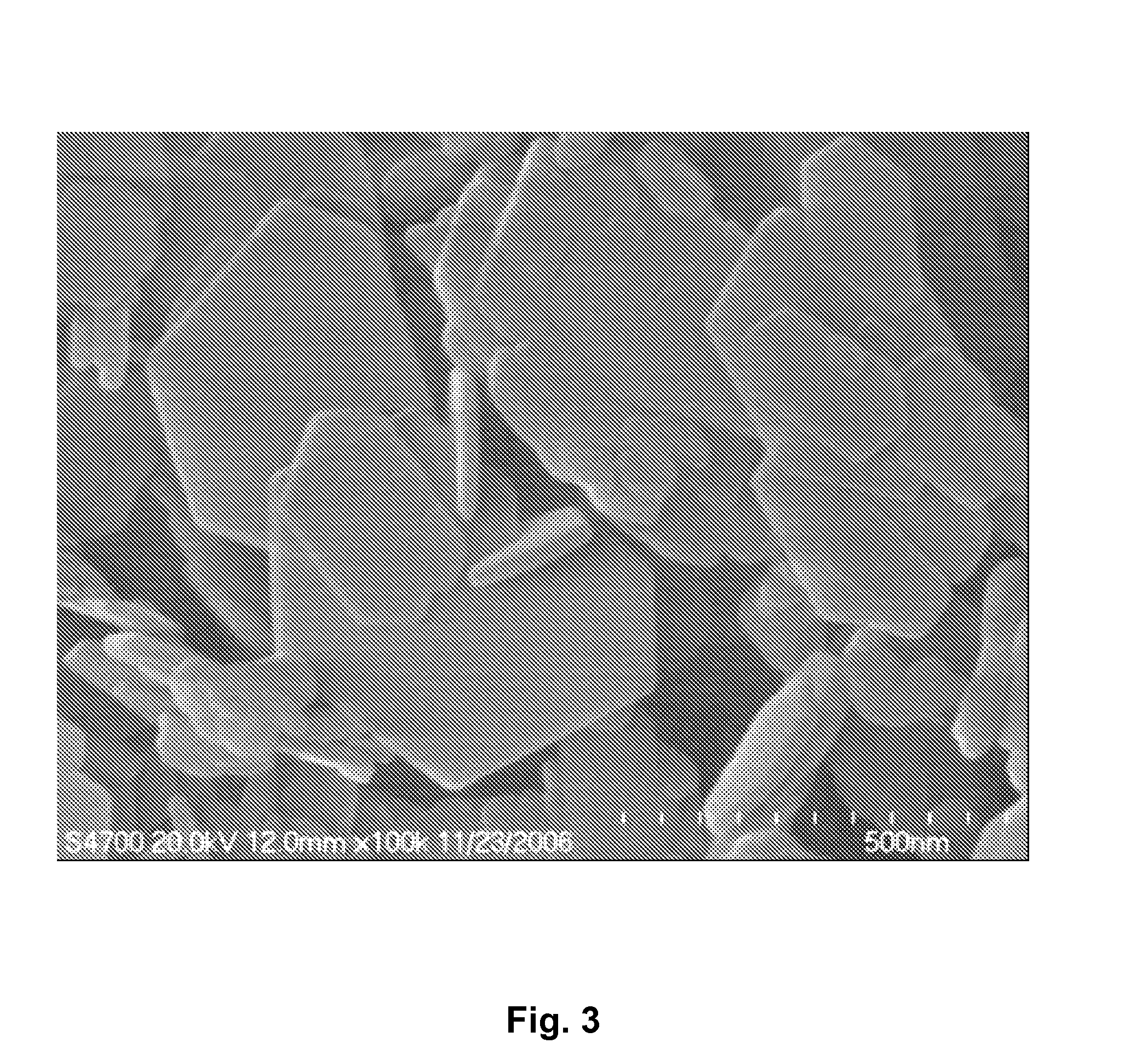

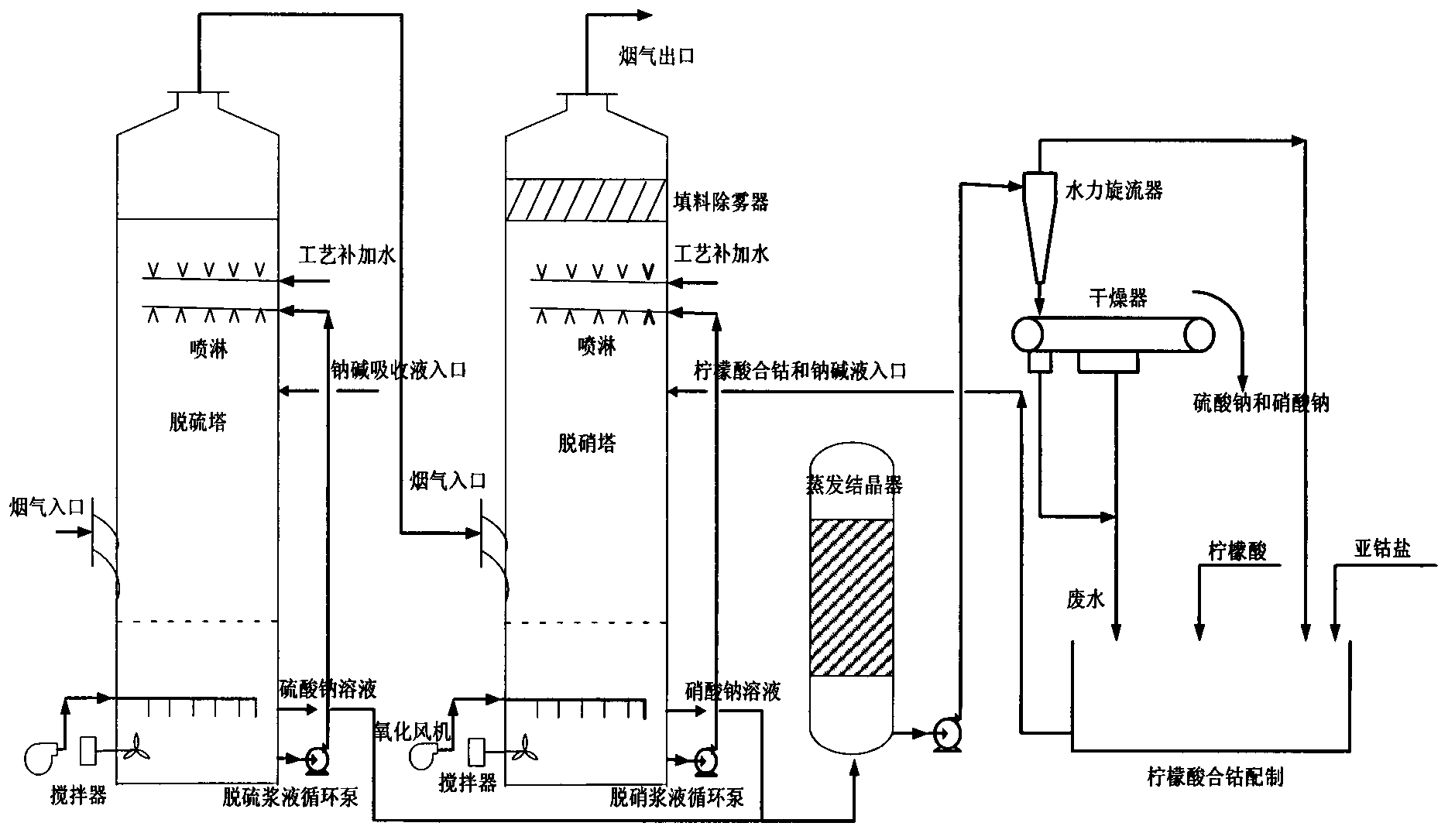

Clean method for preparing layered double hydroxides

ActiveUS20080170978A1Efficient responseProtect environmentLithium compoundsManganese oxides/hydroxidesFiltrationCleaning methods

Disclosed is a clean method for preparing layered double hydroxides (LDHs), in which hydroxides of different metals are used as starting materials for production of LDHs by atom-economical reactions. The atom efficiency of the reaction is 100% in each case because all the atoms of the reactants are converted into the target product since only M2+(OH)2, M3+(OH)3, and CO2 or HnAn− are used, without any NaOH or other materials. Since there is no by-product, filtration or washing process is unnecessary. The consequent reduction in water consumption is also beneficial to the environment.

Owner:BEIJING UNIV OF CHEM TECH

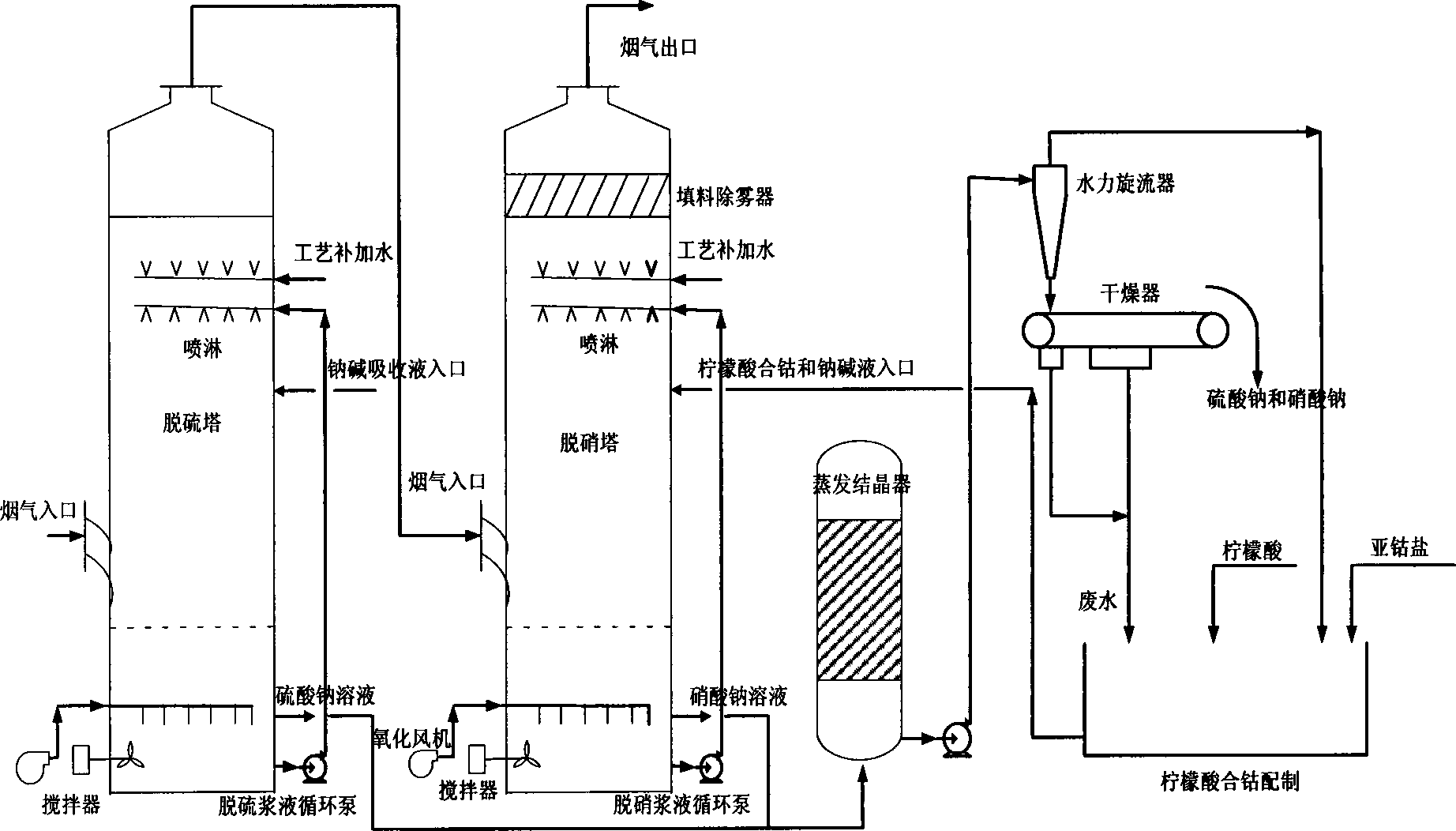

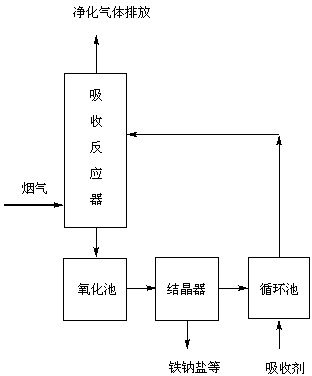

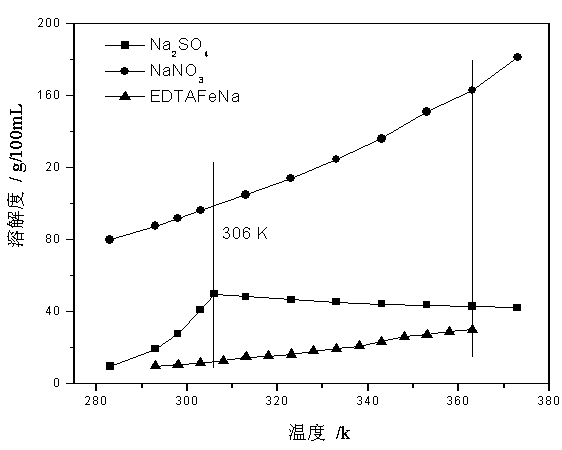

Method for producing sodium sulfate and sodium nitrate by simultaneous desulfurization and denitrification by soda-citric acid cobalt (II)

InactiveCN102698581ARealize resourcesBig craft investmentAlkali metal nitratesDispersed particle separationCobaltCitric acid cycle

The invention discloses a technology for producing sodium sulfate and sodium nitrate by simultaneous wet flue gas desulfurization and denitrification by soda-citric acid cobalt (II). By the technology, SO2 and NO can be converted into Na2SO4 and NaNO3 respectively, so as to realize reclamation of SO2 and NO. The method is different from the general way of converting NO into N2 by denitration, adopts the conventional absorption process, has a mild operation condition, is performed at a normal temperature and pressure, has high desulfurization and denitrification ratio, is small in investment, and low in operation cost, and the absorption liquid is easy to regenerate.

Owner:CHENGDU UNIV OF INFORMATION TECH

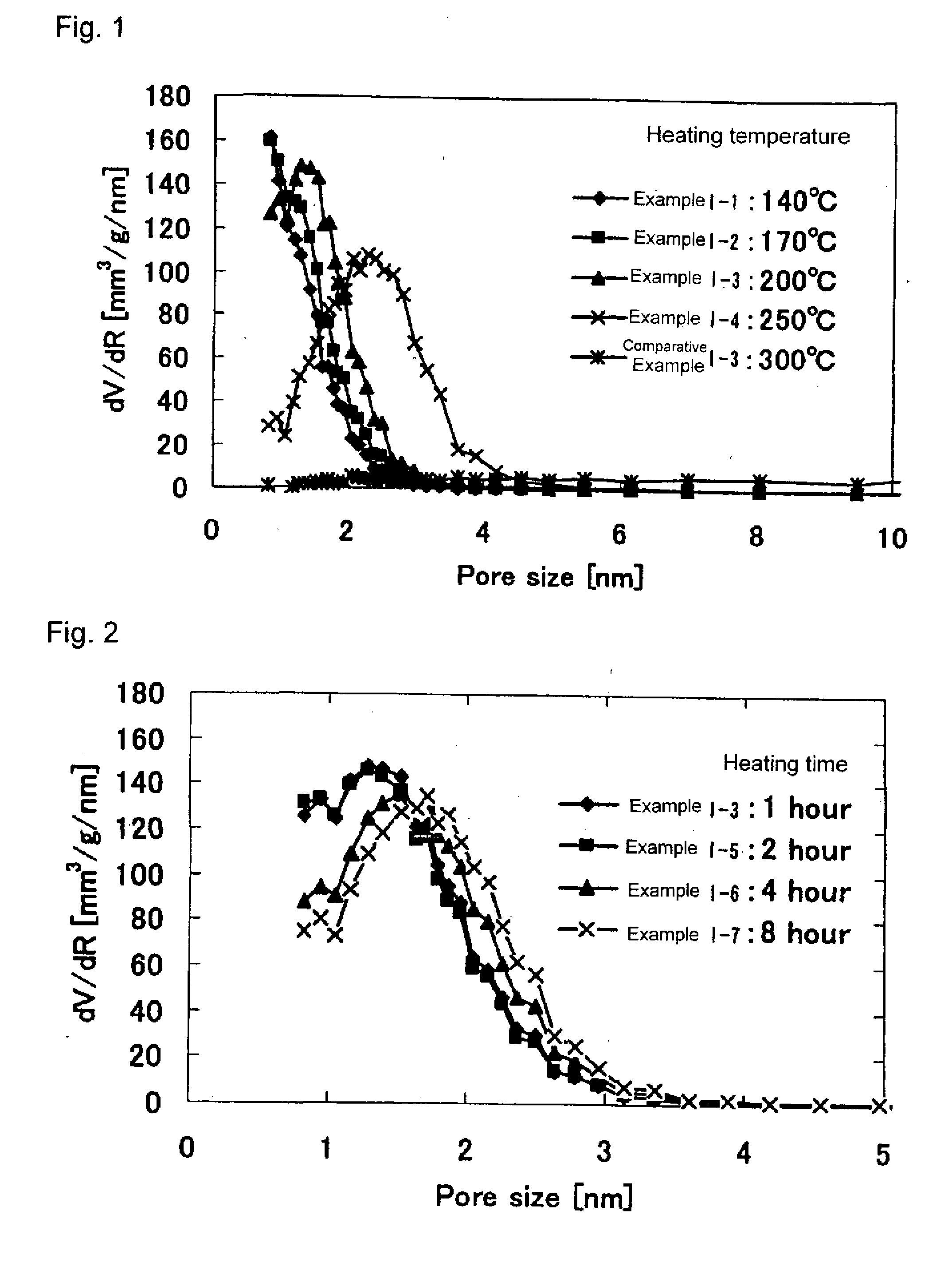

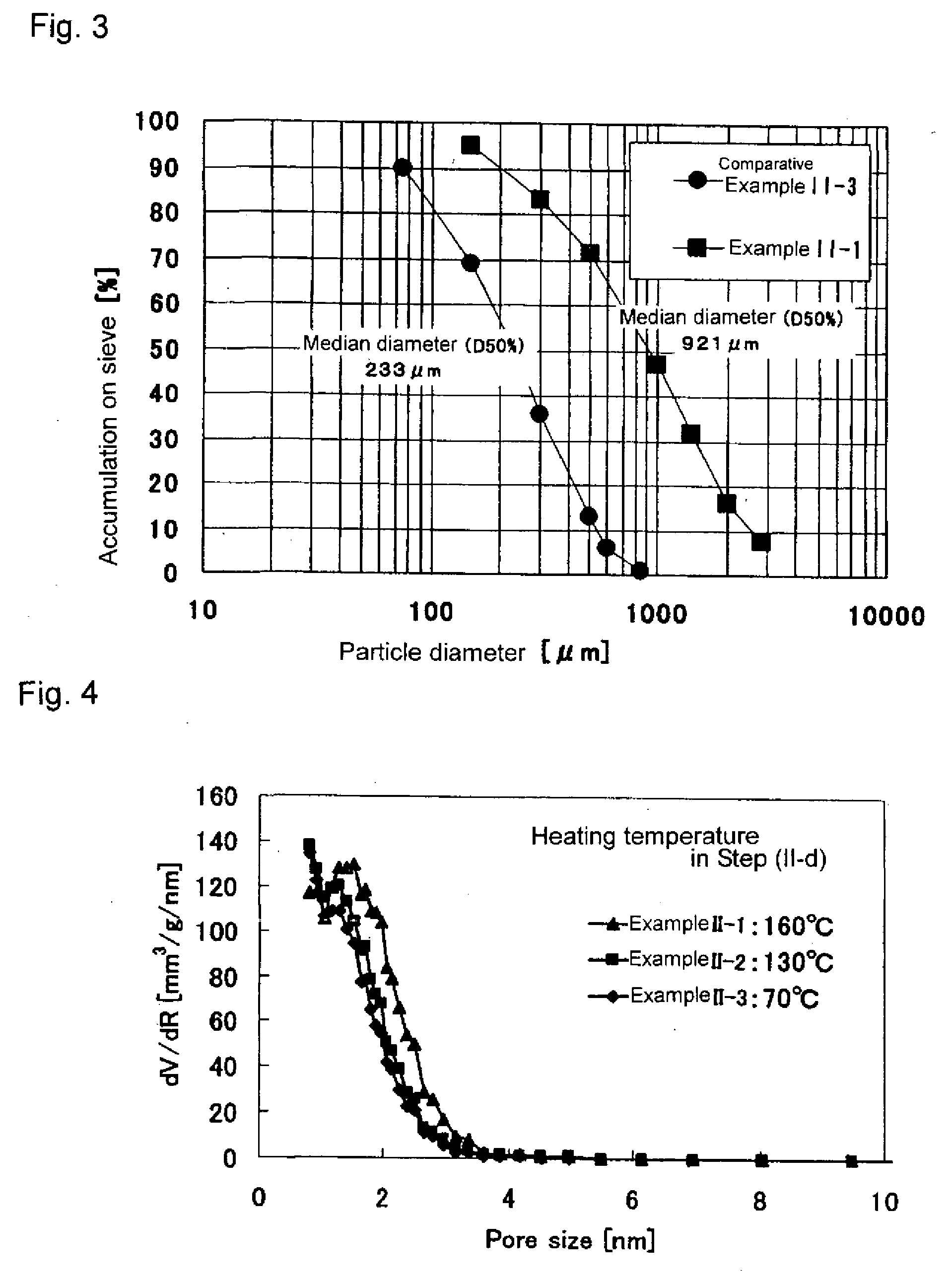

Method for producing iron oxyhydroxide and adsorbing material comprising iron oxyhydroxide

InactiveUS20090028770A1Improve adsorption capacityEfficient productionPhosphorus oxidesNitrogen compoundsIndustrial effluentHazardous substance

The present invention provides a method for advantageously producing an iron oxyhydroxide exhibiting excellent capability of adsorbing harmful substances, such as a phosphrous components and endocrine disrupting chemicals, which are contained in industrial wastewater, exhaust gases, etc., and an adsorbent material comprising the iron oxyhydroxide produced by the method as a main component. Specifically, the present invention provides an adsorbent material produced by a method comprising the steps of:(a) adding a base to an aqueous iron ion-containing solution, adjusting the pH of the resultant mixture to 9 or less, to form a precipitate that contains an iron oxyhydroxide;(b) drying the precipitate at a temperature of 100° C. or lower to obtain an iron oxyhydroxide;(c) contacting the resultant iron oxyhydroxide with water; and(d) subjecting the resultant iron oxyhydroxide to a heat treatment under a gas atmosphere having an inert gas concentration of 80% or greater at a temperature of 100 to 280° C.

Owner:JAPAN SCI & TECH CORP +2

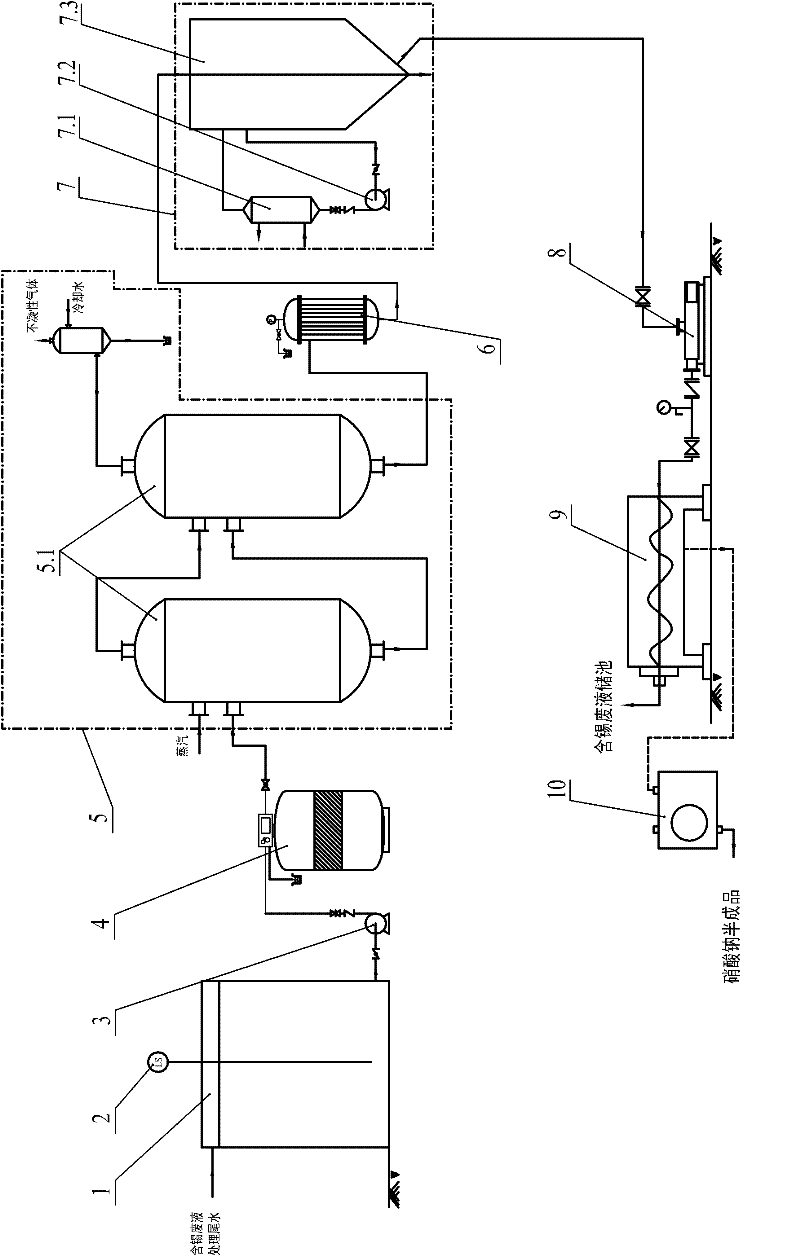

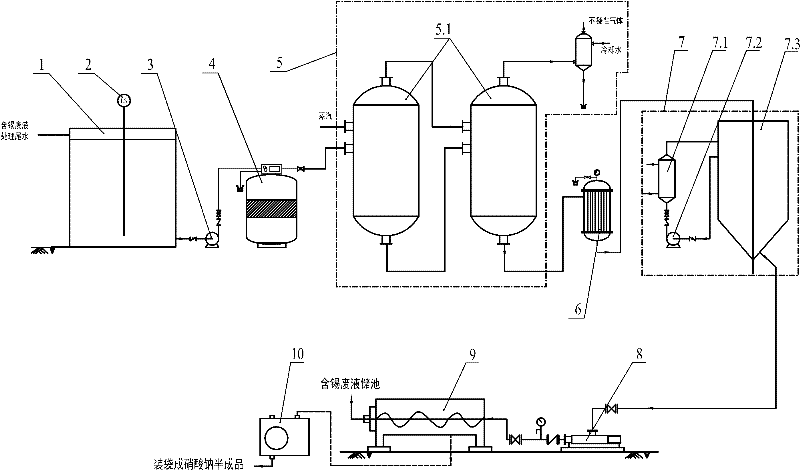

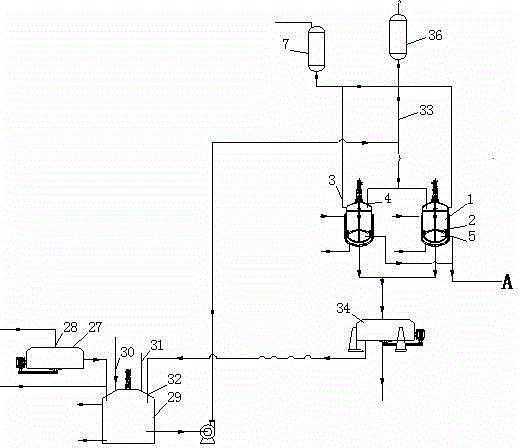

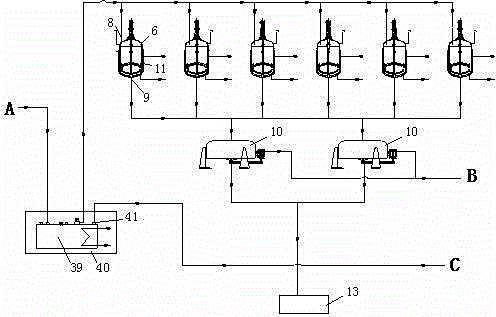

System and technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water

ActiveCN102351220AEasy to operate and manageGuaranteed operating efficiencyAlkali metal nitratesMultistage water/sewage treatmentFiltrationSlag

The invention relates to a system and a technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water. The system for recovering sodium nitrate from tin-containing waste liquid treatment tail water comprises a waste water storage pool, a purification refining device, a multi-effect evaporator, a filter, a crystallization device, a centrifugal machine and a drying machine. The technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water comprises the following steps of collecting tin-containing waste liquid treatment tail water, storing the collected tin-containing waste liquid treatment tail water in the waste water storage pool, feeding the tin-containing waste liquid treatment tail water in the waste water storage pool into the purification refining device to carry out purification refining, feeding the tin-containing waste liquid treatment tail water subjected to purification refining into the multi-effect evaporator, feeding steam into the multi-effect evaporator to carry out circulation evaporation, feeding the steam obtained by the previous step into the filter to carry out heat filtration, feeding the filtrate into the crystallization device to carry out crystallization to obtain crystals, carrying out centrifugation of the obtained crystals by the centrifugal machine to obtain solid slag and a mother solution, transferring the solid slag to the drying machine to carry out drying to obtain a sodium nitrate finished product, and feeding the mother solution back to the waste water storage pool for recycle. The system for recovering sodium nitrate from tin-containing waste liquid treatment tail water has the advantages of relatively low recovery cost, simple and convenient operation management, long-term and stable operation and no discharge of pollutants.

Owner:无锡金品环境技术有限公司

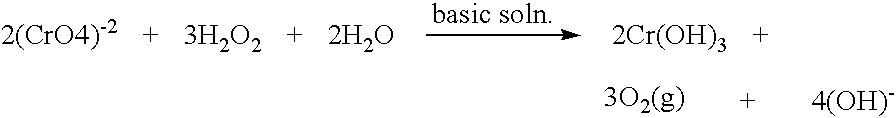

Aqueous solution of chromium salt and method for producing same

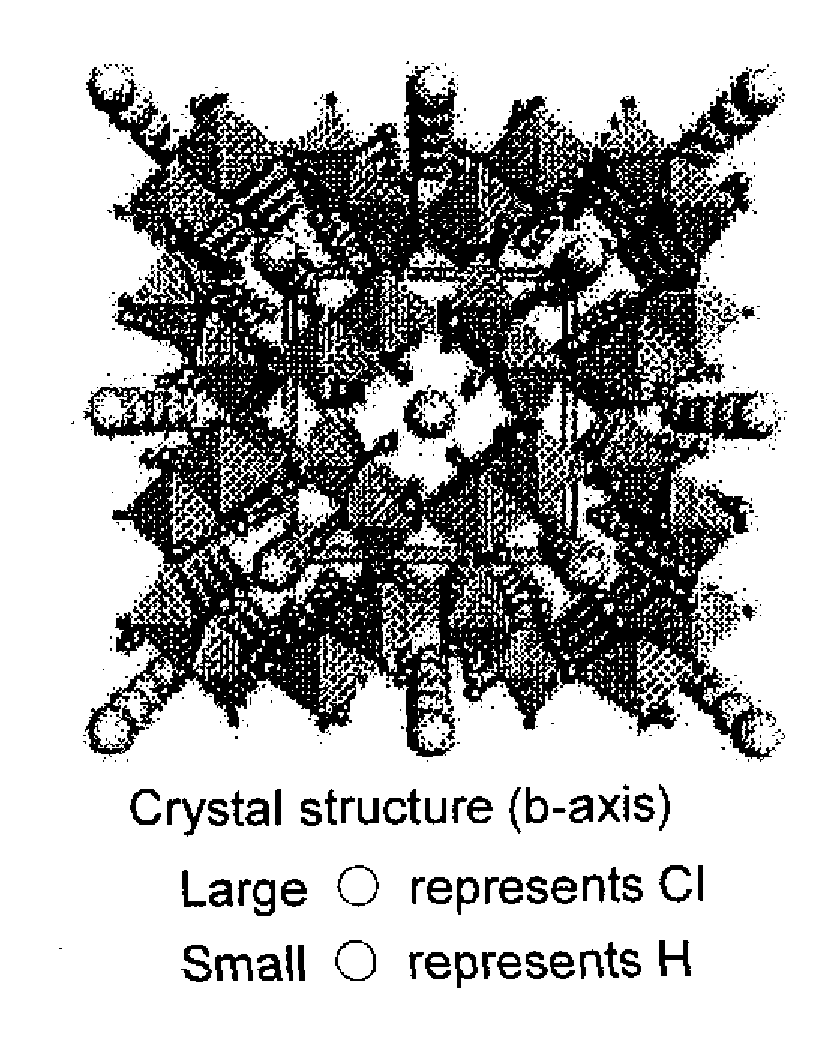

InactiveUS20070086938A1Overcome disadvantagesPigmenting treatmentNitrogen compoundsOXALIC ACID DIHYDRATEChloride

Disclosed is an aqueous solution of a chromium salt, in which the oxalic acid content is 8% by weight or less relative to chromium. In the aqueous solution of the chromium salt, the total organic carbon content is 4% by weight or less relative to chromium. The chromium salt is preferably a chromium chloride, a chromium phosphate, or a chromium nitrate. The chromium chloride preferably contains a basic chromium chloride represented by the composition formula Cr(OH)xCly (wherein 0<x≦2, 1≦y<3, and x+y=3). The chromium phosphate is preferably one represented by the composition formula Cr(H3−3 / nPO4)n (wherein n is a number satisfying 2≦n≦3). The chromium nitrate is preferably a basic chromium nitrate represented by the composition formula Cr(OH)x(NO3)y (wherein 0<x≦2, 1≦y<3, and x+y=3).

Owner:NIPPON CHECMICAL IND CO LTD

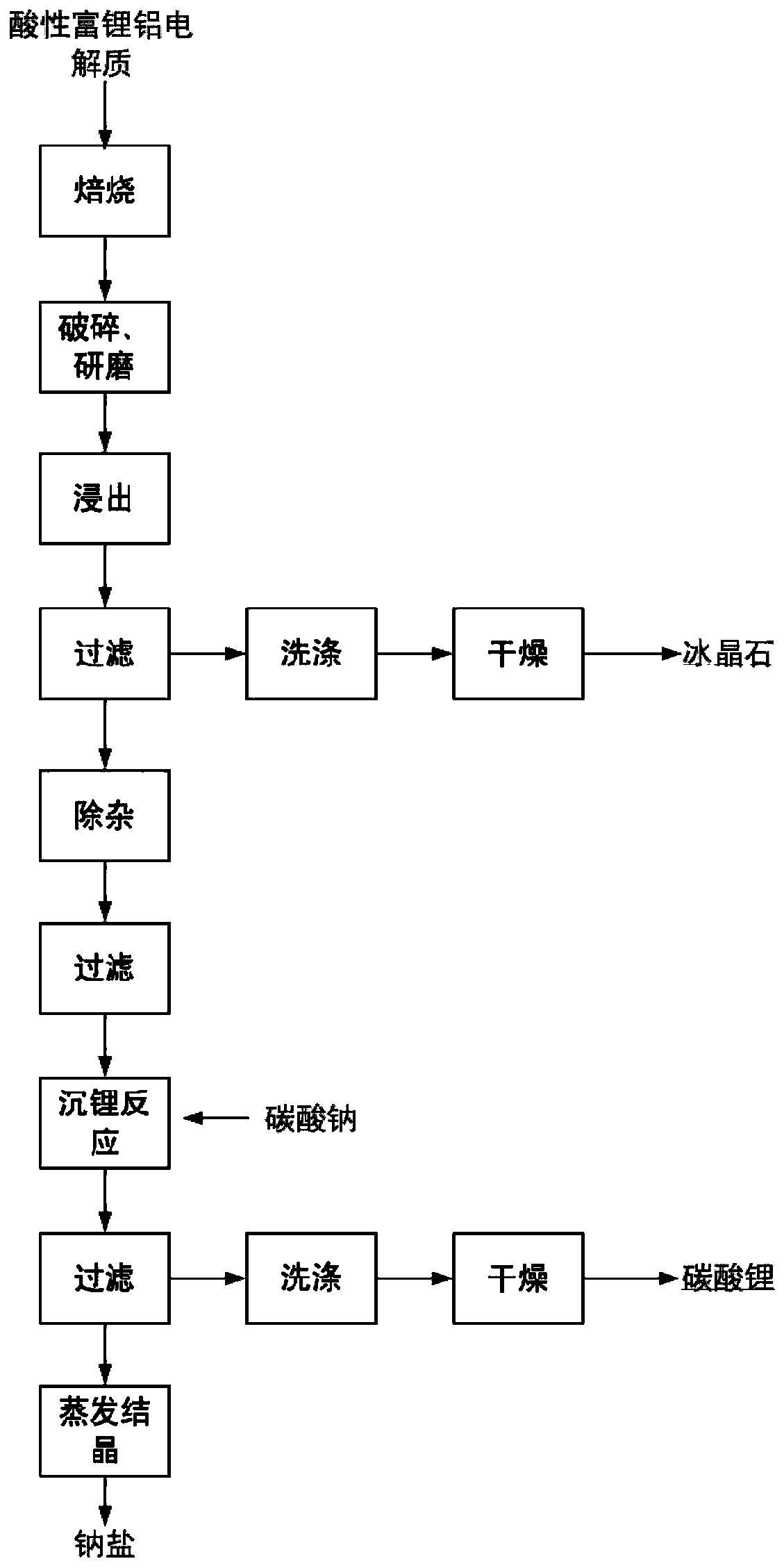

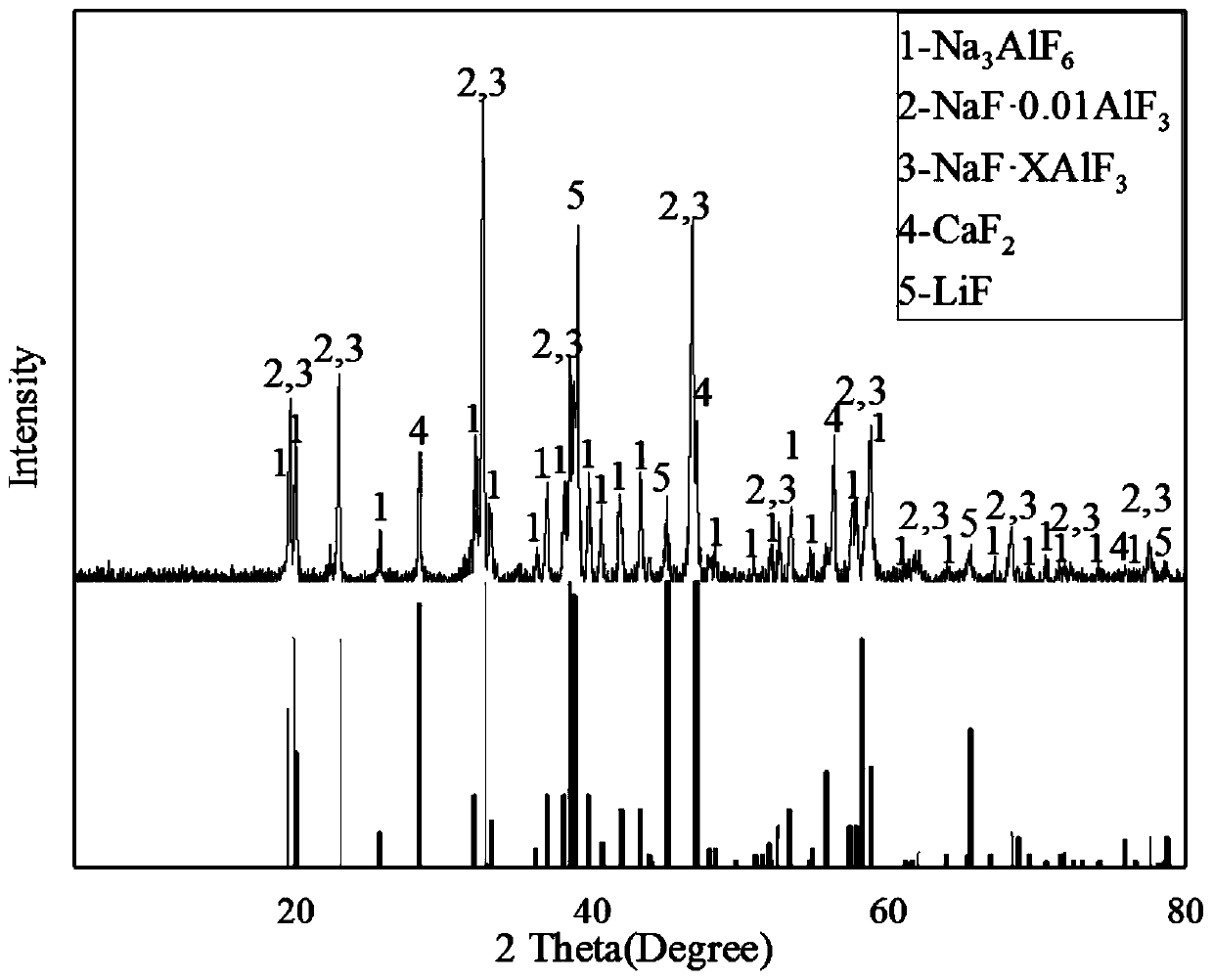

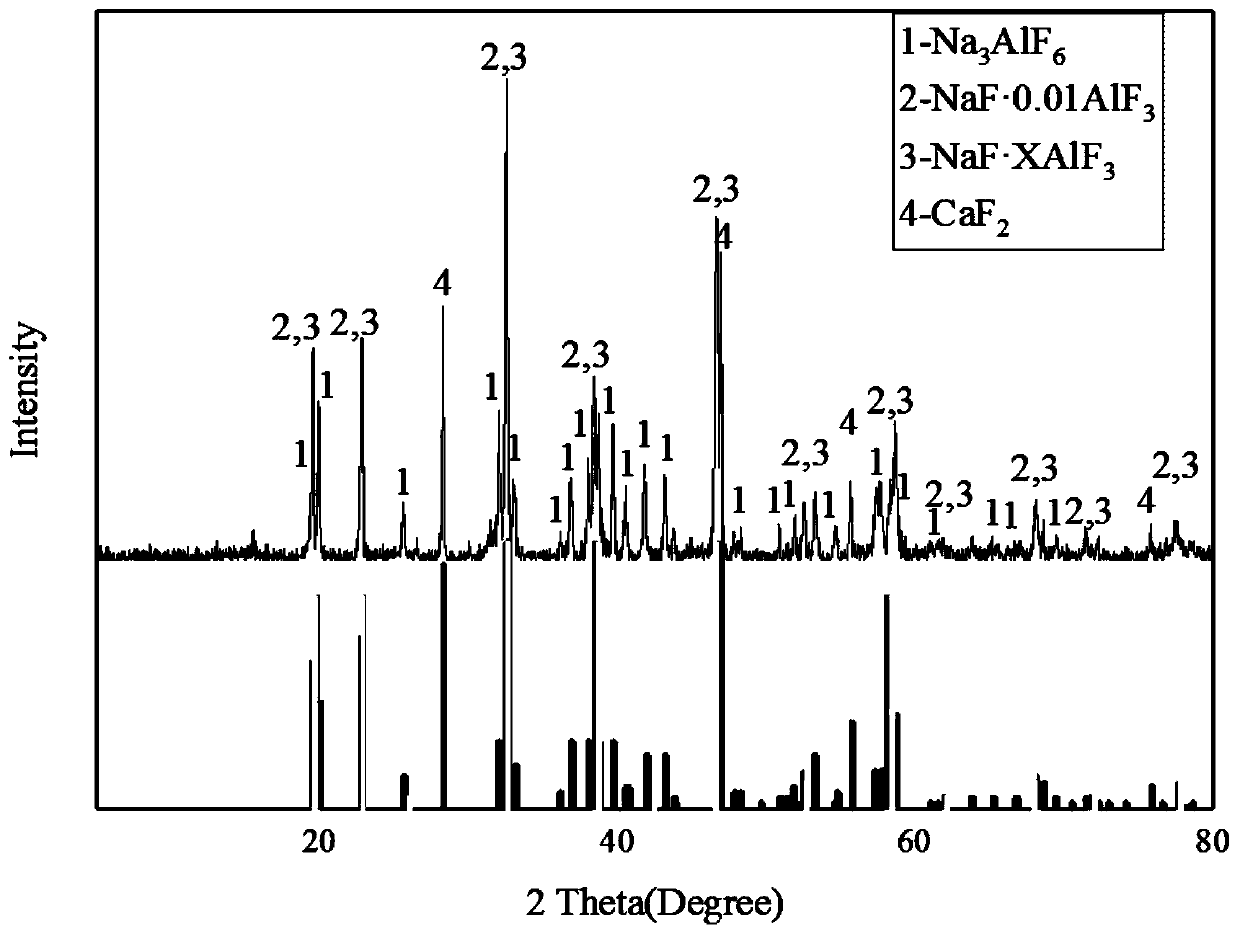

Resource treatment method for lithium-rich aluminum electrolyte

ActiveCN110240182AChange molecular ratioEasy to operateCalcium/strontium/barium fluoridesAlkali metal nitratesAluminum IonInorganic salts

The invention relates to a resource treatment method for a lithium-rich aluminum electrolyte. The method comprises the following steps: firstly performing heat treatment on the lithium-rich aluminum electrolyte to obtain a product A; performing leaching treatment on the roasting product A with a water-soluble inorganic salt as a leaching agent in water, and performing filtering to obtain a filter residue B and a filtrate B; adding an alkali or an aqueous solution of the alkali to the filtrate B to remove aluminum ions in the filtrate B to obtain a filtrate C; and adding a water-soluble carbonate or an aqueous solution of the carbonate to the filtrate C to make lithium ions in the filtrate C be converted into lithium carbonate precipitation, and then performing filtering to obtain lithium carbonate and a filtrate D. The technical problem perplexing aluminum electrolysis industry of rich and high content lithium in an excess aluminum electrolyte and inefficient utilization of valuable metals is solved, the economic benefit is improved, and stable production of an electrolytic aluminum enterprise is promoted.

Owner:CENT SOUTH UNIV

Pastillation of Ammonium Sulfate Nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

Zero-emission sewage reutilization device and method

PendingCN106186550AGuaranteed uptimeReduce evaporationCalcium/strontium/barium carbonatesAlkali metal nitratesReverse osmosisSedimentation

The invention relates to the technical field of zero-emission sewage reutilization and provides a zero-emission sewage reutilization device. A zero-emission sewage reutilization method sequentially comprises steps as follows: miscellaneous salt is subjected to coagulative sedimentation, sodium carbonate is added and calcium carbonate precipitates are obtained; caustic soda is added, and magnesium hydroxide is obtained; membrane filtration is performed, the pH value is regulated, ion exchange softening, advanced oxidation, biochemical treatment with a biological membrane are performed, filtration with a membrane filter and nanofiltration are performed, lime milk is added to interception water obtained through nanofiltration, calcium sulfate is obtained, a supernatant flows back to a miscellaneous salt sedimentation basin, nanofiltration permeate water is concentrated through a reverse osmosis separator A and then is concentrated by a brine concentrator, fresh water produced by the brine concentrator is concentrated by a reverse osmosis concentrator B and flows back to the brine concentrator, concentrated water produced by the brine concentrator enters an crystallizing evaporator and is subjected to hot separation and cold separation, sodium chloride and sodium nitrate are obtained respectively, most crystallization mother liquor is subjected to refluxing treatment, and a small part of crystallization mother liquor is dried; reverse osmosis produced water and distilled water are reused. According to the invention, commercial calcium carbonate, magnesium hydroxide, calcium sulfate, sodium chloride, sodium nitrate salts and high-quality reused water are recycled, emission of solid waste is small, and the operating cost is low.

Owner:GELANTE ENVIRONMENTAL PROTECTION ENG BEIJING CO LTD

Performance enhancing composition and use thereof

The performance of a mammal, manifested as a reduced oxygen uptake (VO2) during physical exercise, can be enhanced by administering to said mammal a non-toxic amount of nitrate and / or nitrite. Liquid, semi-solid and solid snack and food products and nutritional supplements, such as sport drinks are made available.

Owner:HEARTBEET LTD

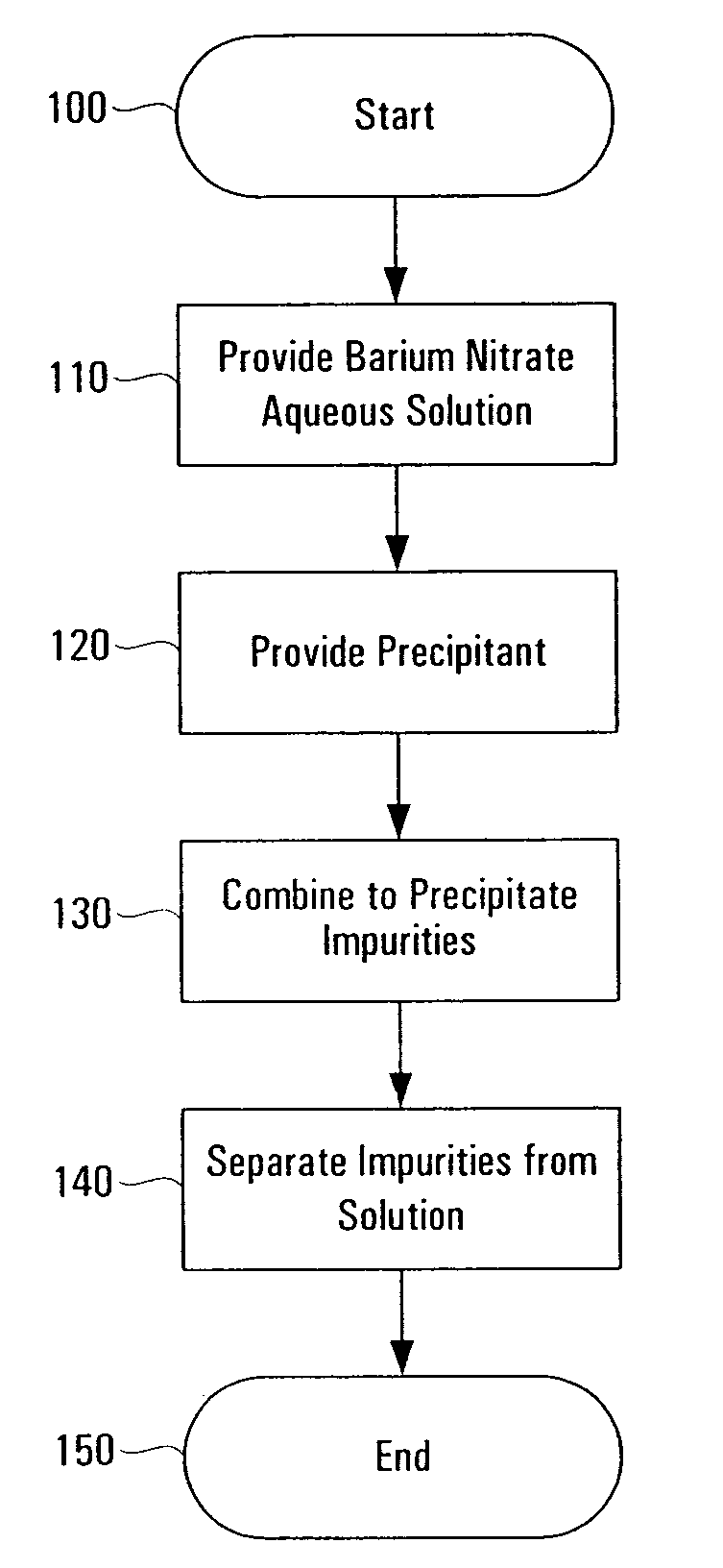

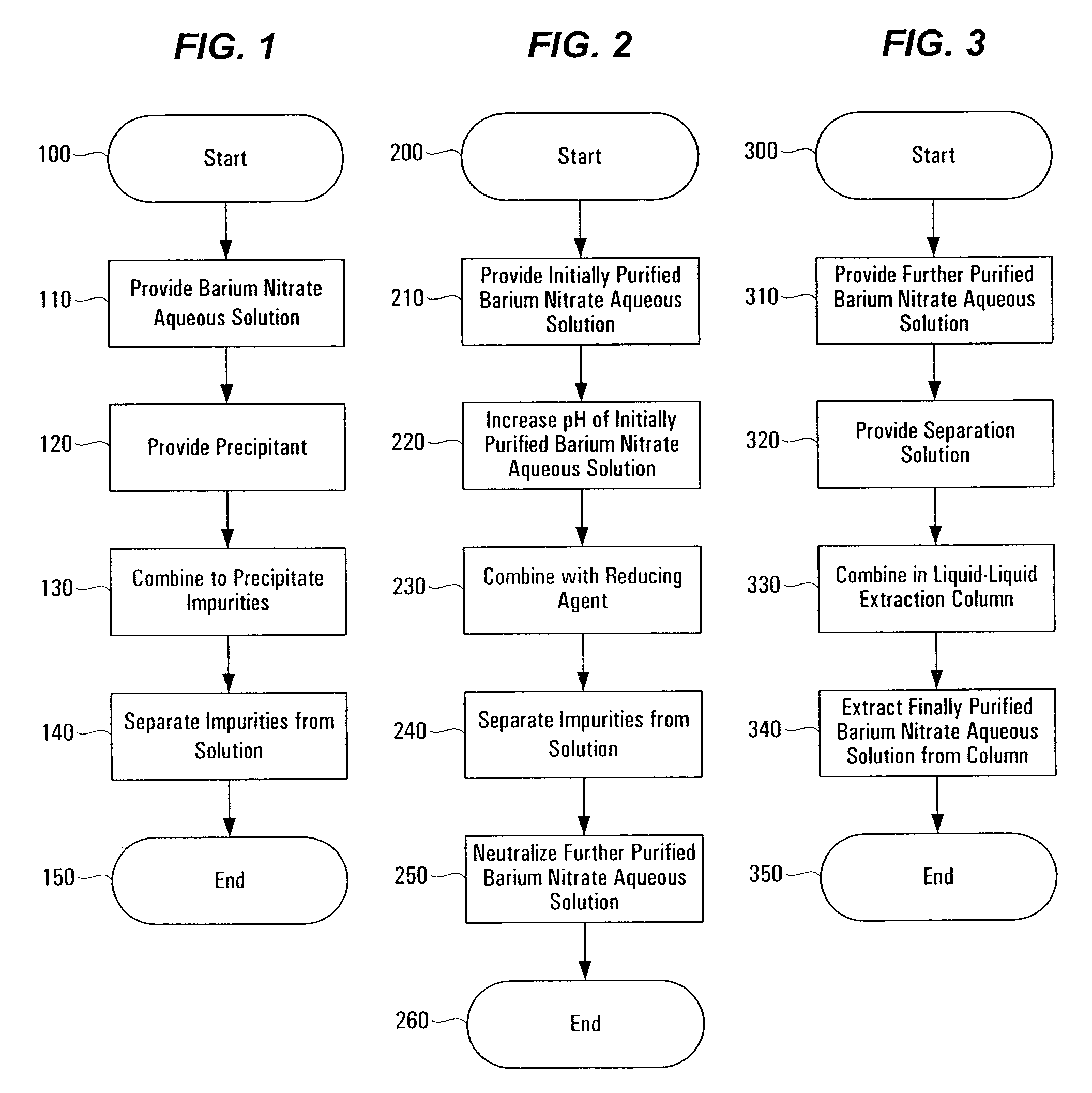

Method of purifying barium nitrate aqueous solution

InactiveUS7648687B1Solid sorbent liquid separationLiquid solutions solvent extractionBarium nitrateOxidation state

Purification techniques have been developed for ceramic powder precursors, e.g., barium nitrate. These techniques can be performed using one or more of the following operations: (1) removal of impurities by precipitation or coprecipitation and separation using a nonmetallic-ion-containing strong base, e.g., tetraalkylammonium hydroxides; (2) reduction of higher oxidation-state-number oxymetal ions and subsequent precipitation as hydroxides that are separated from the solution; and (3) use of liquid-liquid exchange extraction procedures to separate certain impurities.

Owner:EESTOR

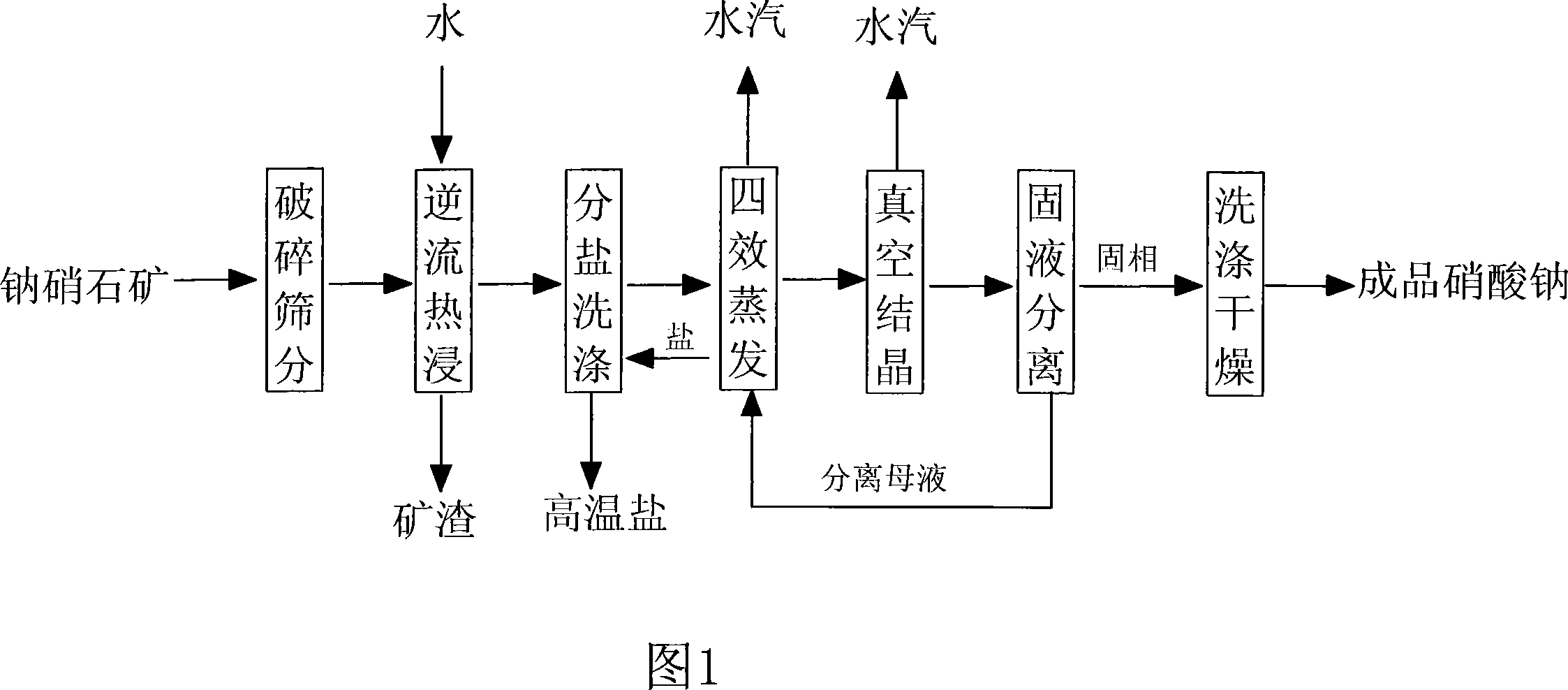

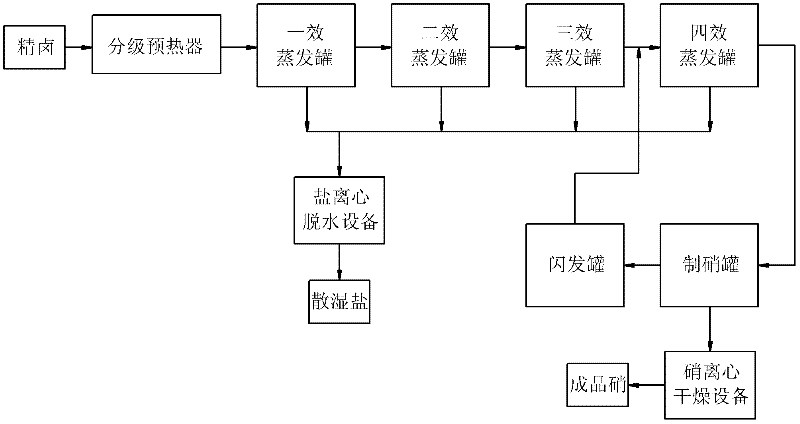

Method for producing sodium nitrate by chilisaltpeter ore

InactiveCN101182013ASmall particle sizeLow grade requirementsAlkali metal nitratesWater savingCentrifugation

The invention relates to a production method for producing sodium nitrate with nitratine and the process steps thereof are that ore is crushed with the particle diameter below 2cm and is first treated with a multi-stage countercurrent hot soak so as to ensure that the content of NaNO3 in leaching solution is more than or equal to 450g / l, and then with a four-effect evaporation to remove NaCl and NaSO4 to ensure that the content of NaNO3 is more than or equal to 950g / l, and finally with centrifugation and drying after a three-stage vacuum cold separation crystallization to obtain the finished sodium nitrate. By adopting the method which has low dependency on natural conditions, water saving and low energy consumption and is suitable for low-grade nitratine mining, the overall yield of the sodium nitrate can reach more than 75 percent.

Owner:TURPAN BRANCH OF SINKIANG NITRATE MINERALS

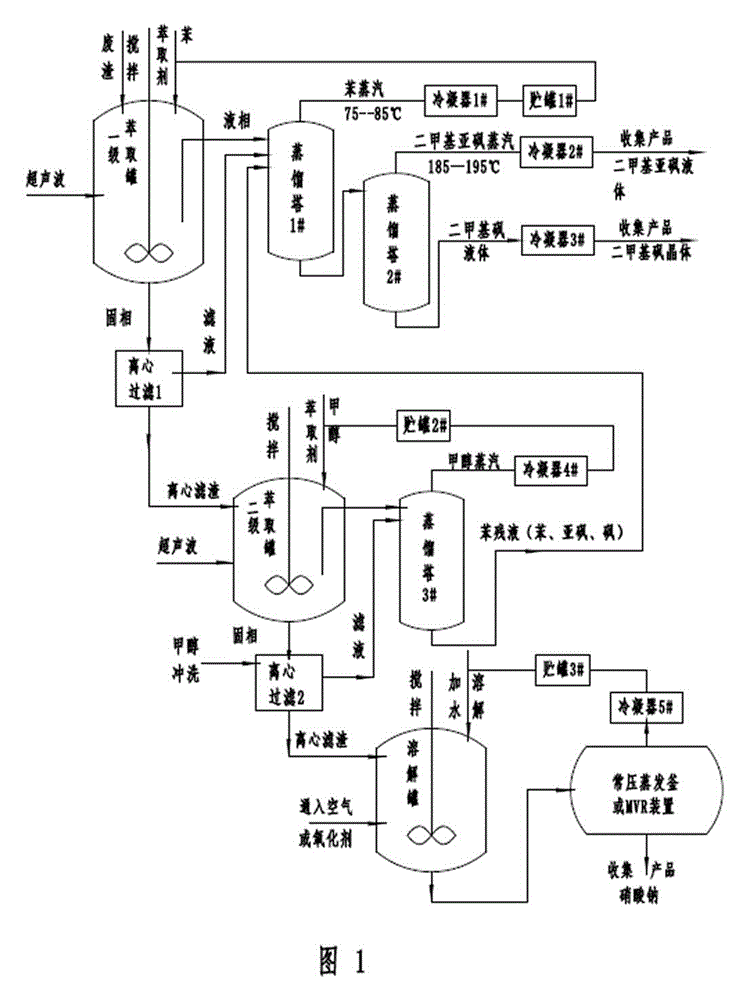

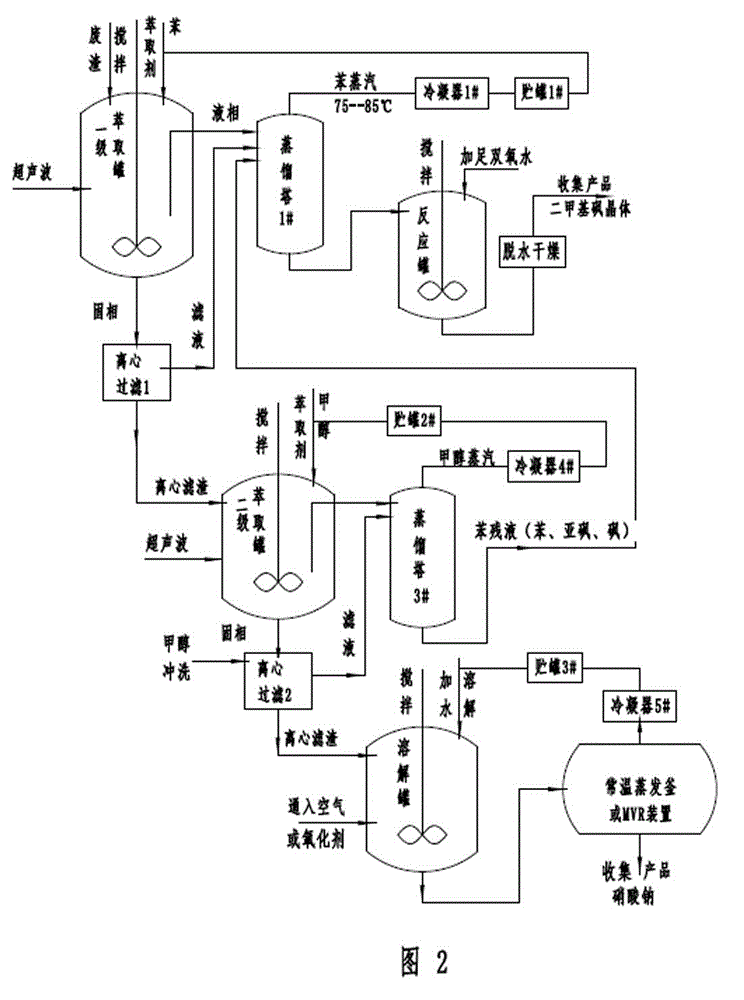

Waste dimethyl sulfoxide recovery and treatment method

ActiveCN104311460ASimple processReduce energy consumptionOrganic chemistryOrganic compound preparationActive componentWastewater

The invention discloses a waste dimethyl sulfoxide recovery and treatment method. The waste dimethyl sulfoxide recovery and treatment method is characterized in that a waste dimethyl sulfoxide solution is added with nitric acid, the mixture undergoes a neutralization reaction and an oxidation reaction, and dimethyl sulfone, sodium nitrate and sodium methanesulfonate crystals are separated from the reaction products. The method provided by the invention can realize recovery and recycle of a plurality of active components of the waste dimethyl sulfoxide, realizes change waste into valuables, is environmentally friendly and has the advantages of simple processes, environmental friendliness, no waste water discharge, low energy consumption and high extraction efficiency.

Owner:夏瑜 +1

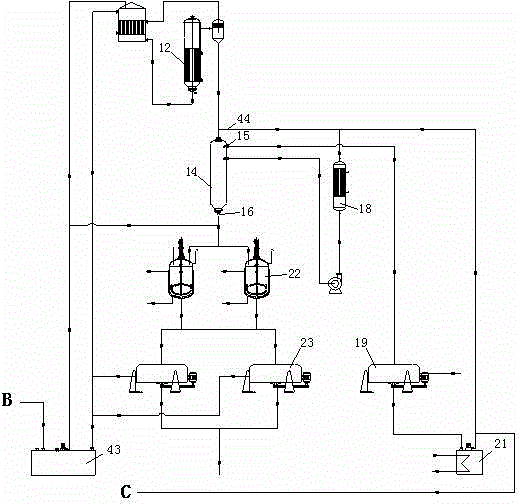

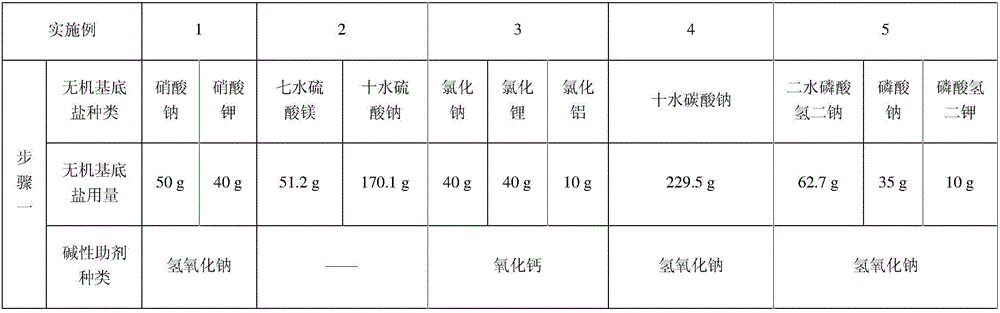

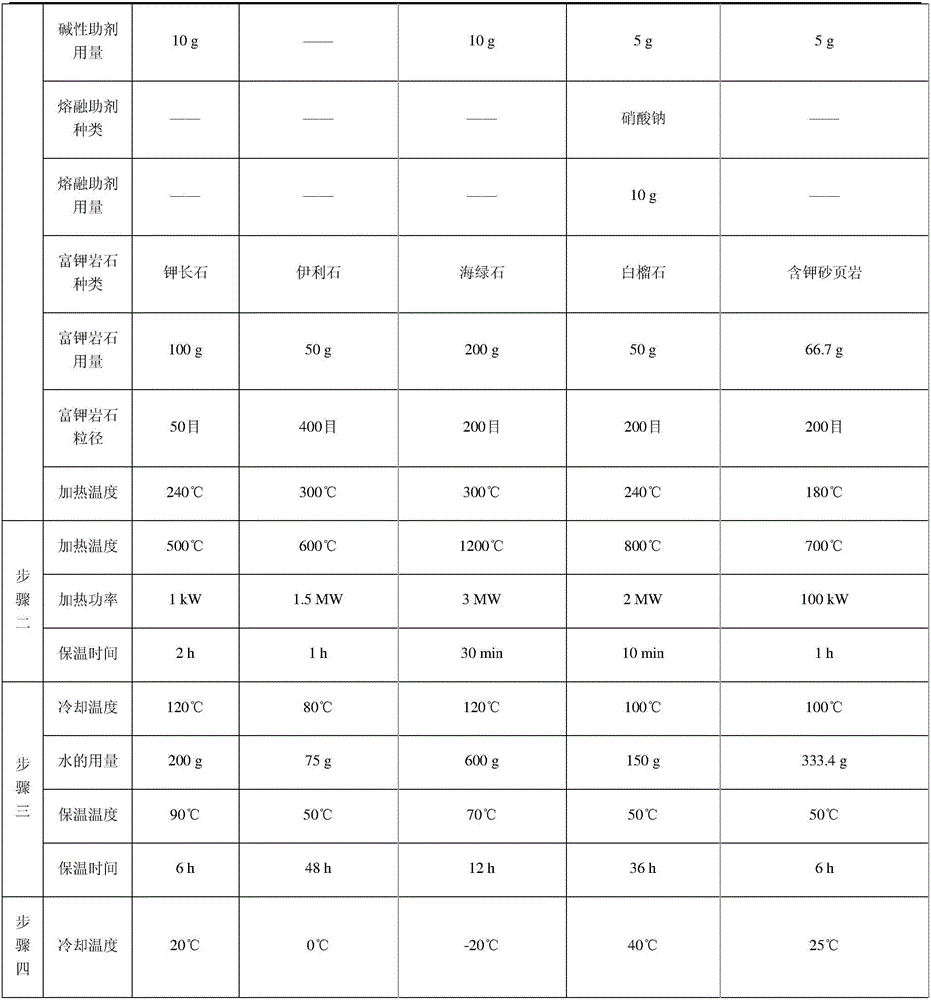

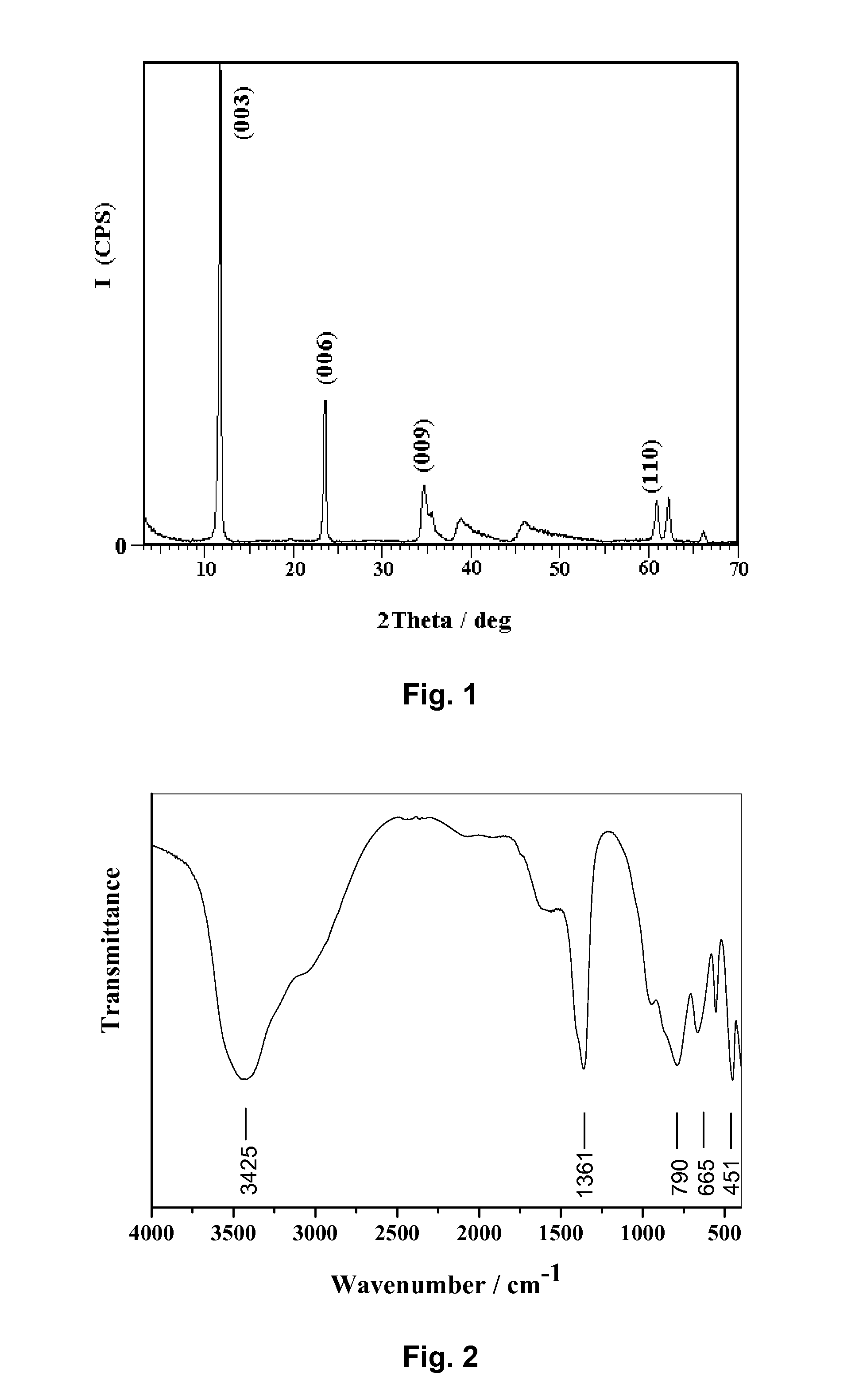

Method for preparing water soluble sylvite

ActiveCN106276983ADecomposition does not occurNo operabilityAlkali metal nitratesAlkali metal chloridesMicrowavePotassium

The invention discloses a method for preparing water soluble sylvite. The method includes the steps that A, inorganic base salt and smashed potassium-rich rock are mixed to obtain a first mixture, acid radical negative ions of the inorganic base salt correspond to negative ions of the water soluble sylvite, and the potassium-rich rock is the silicate mineral with the mass percent larger than or equal to 8% in terms of K2O; B, the first mixture is heated to be at the temperature smaller than or equal to 300 DEG C and melted, and a second mixture is obtained; C, the second mixture is heated to be at the temperature of 500 DEG C to 1,200 DEG C in a microwave mode, the temperature is kept for 10 min to 2 h, and a third mixture is obtained; D, the third mixture is cooled to be at the temperature of 80 DEG C to 120 DEG C, then water is led into the cooled third mixture, a fourth mixture is obtained, the temperature of the fourth mixture is kept for 6 h to 48 h at the temperature of 50 DEG C to 90 DEG C, solid-liquid separation is carried out, and then first filtered liquid is obtained; E, the first filtered liquid is concentrated and cooled, and the soluble sylvite is separated out. According to the preparing method, the potassium-rich rock serves as a raw material, a water solution of the soluble sylvite is obtained through two-time extracting, the technology is simple, the preparing cost is low, and the technology is safe.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Clean method for preparing layered double hydroxides

ActiveUS8088349B2Prevent materialAvoid prolonged useLithium compoundsManganese oxides/hydroxidesCleaning methodsLayered double hydroxides

Disclosed is a clean method for preparing layered double hydroxides (LDHs), in which hydroxides of different metals are used as starting materials for production of LDHs by atom-economical reactions. The atom efficiency of the reaction is 100% in each case because all the atoms of the reactants are converted into the target product since only M2+(OH)2, M3+(OH)3, and CO2 or HnAn− are used, without any NaOH or other materials. Since there is no by-product, filtration or washing process is unnecessary. The consequent reduction in water consumption is also beneficial to the environment.

Owner:BEIJING UNIV OF CHEM TECH

Method for recycling dimethyl sulfoxide waste residue through multi-stage extraction

InactiveCN104592067ANo secondary pollutionSolve pollutionOrganic chemistryOrganic compound preparationDistillationSodium nitrite

The invention provides a method for recycling dimethyl sulfoxide waste residue through multi-stage extraction. The first-stage extraction comprises the steps of separating dimethyl sulfone and dimethyl sulfoxide by using an extracting agent (benzene) and respectively recycling the extracting agent (benzene), dimethyl sulfoxide and dimethyl sulfone products by using a distilling and condensing way; the second-stage extraction comprises the steps of separating benzene residual liquor containing dimethyl sulfone and dimethyl sulfoxide out of the solid phase (obtained after the first-stage extraction) in the presence of an extracting agent (methanol), respectively recycling the extracting agent (methanol) and the benzene residual liquor by using a distilling and condensing method and returning the benzene residual liquor to a former distillation tower; the solid phase in the second-sage extraction is dissolved by using water, air or oxidant is introduced to oxidize sodium nitrite into sodium nitrate, and then sodium nitrate is evaporated and crystallized to extract inorganic components. The treatment method disclosed by the invention is simple and safe in process, low in evaporation temperature, operated at ordinary pressure, easy to implement and low in operation cost, the whole course is of close circulation, components of the waste residue are completely recycled, the recycling efficiency is high, the secondary pollution of waste is avoided, pollution problem caused by the dimethyl sulfoxide production waste residue can be solved, and a certain economic value is created.

Owner:HUBEI UNIV

Strontium nitrate and method for manufacturing same

Low-cost, high-purity strontium nitrate that is low in Ba, Na, Ca, Cr, and other impurities and that is suitable for use in airbags or the like is provided. High-purity strontium nitrate having a Ba content of 0.01 wt % or lower, an Na content of 0.005 wt % or lower, a Ca content of 0.01 wt % or lower, a Cr content of less than 0.001 wt %, and a purity of 99.5 wt % or higher is produced by a manufacturing method comprising a first step for performing crystallization by adding nitric acid to an aqueous solution obtained by dissolving a strontium compound as a starting material, a second step for separating the resulting crystals, a third step for crystallizing the resulting separated solution, and a fourth step for separating the resulting crystals.

Owner:DOWA METALS & MINING CO LTD +1

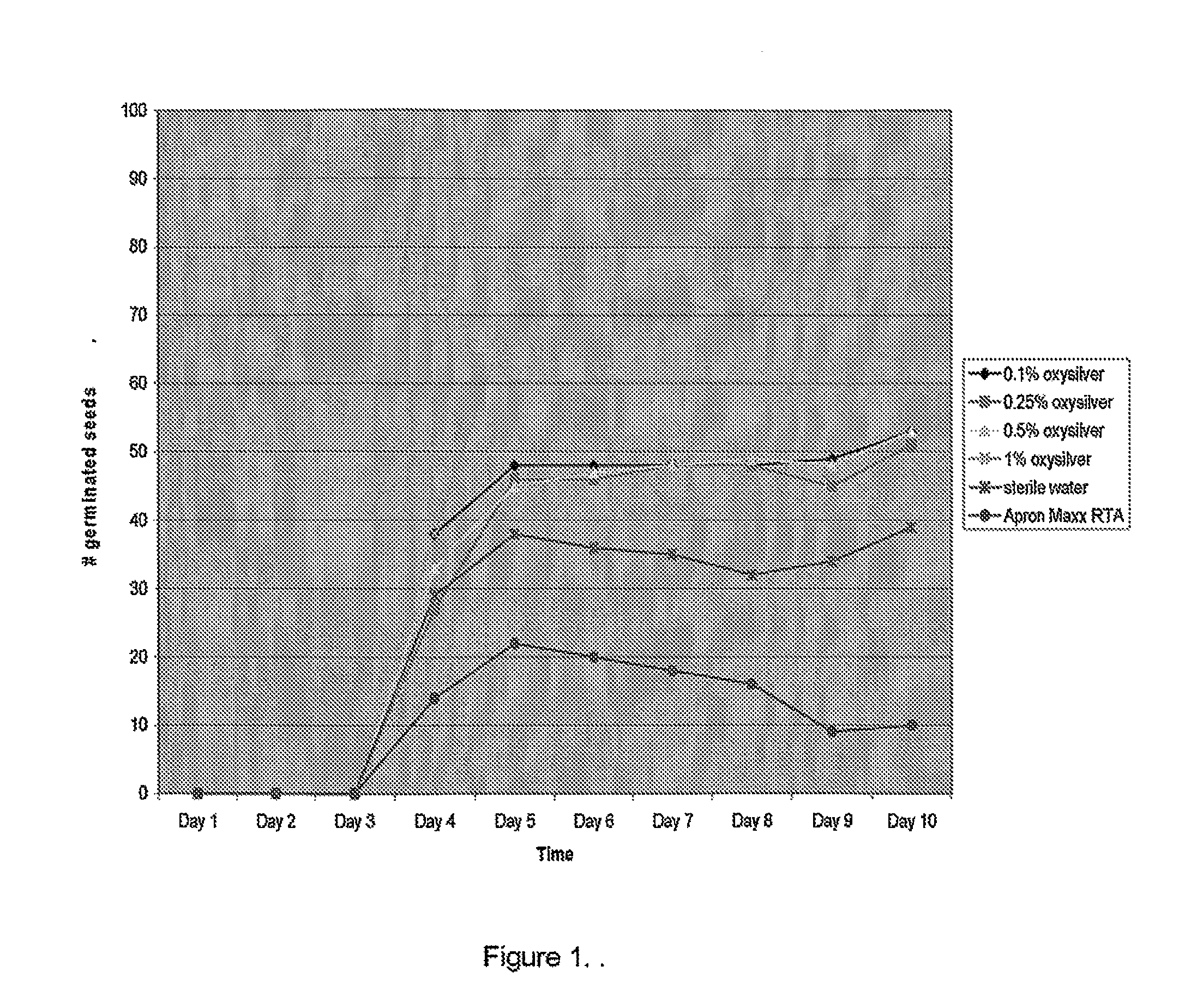

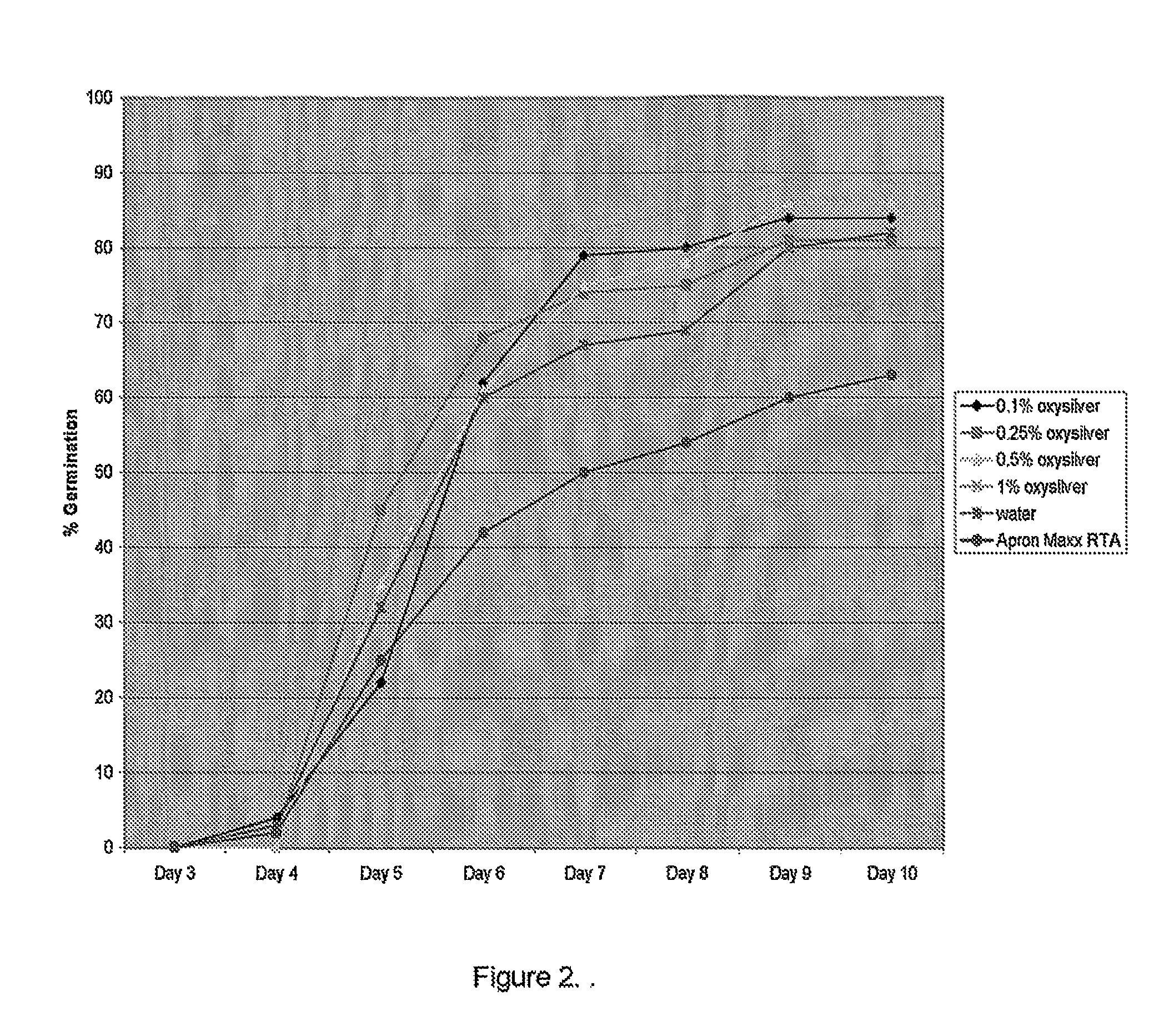

Compositions and Methods Comprising High Valency Silver for Increasing Seed Germination

InactiveUS20110275518A1Promote seed germinationImproved and efficient active agent delivery systemBiocideNitrogen compoundsBiofilmGermination

The present invention is compositions and methods for improving seed germination rates or speed using a composition comprising at least one high valency silver ion. The compositions and methods of the present invention are effective in treating biofilms.

Owner:MARQUES LYRIAM L +2

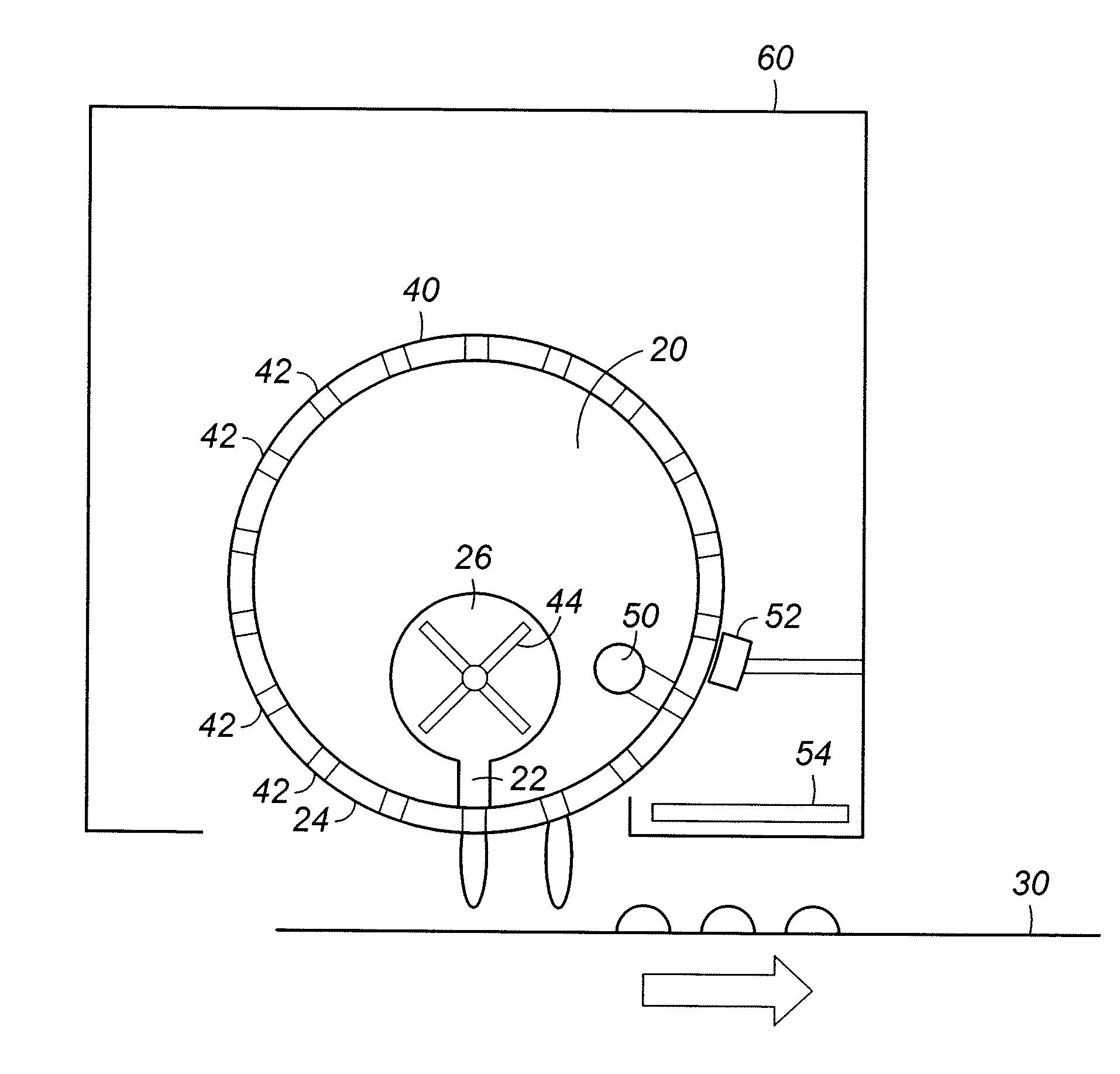

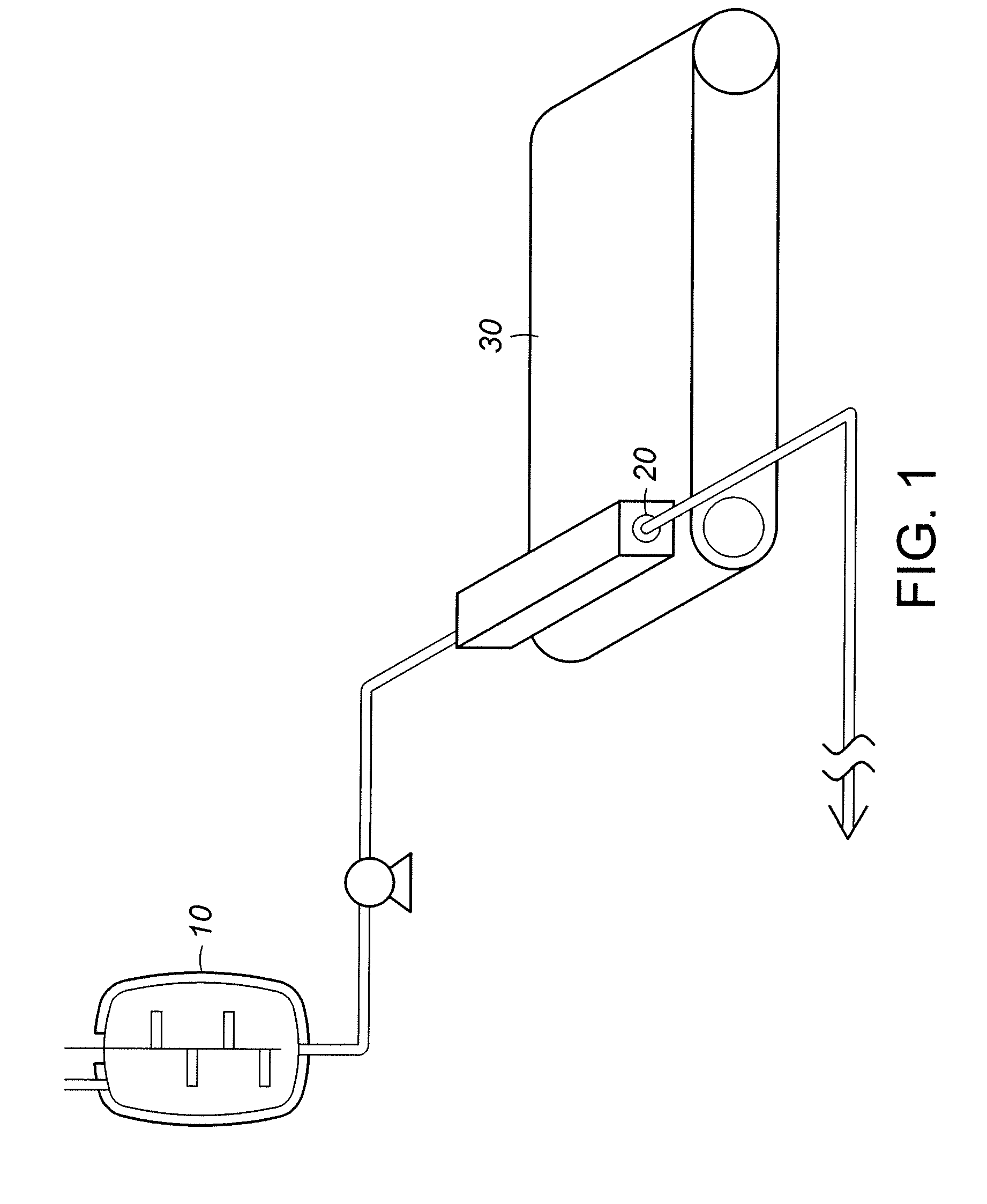

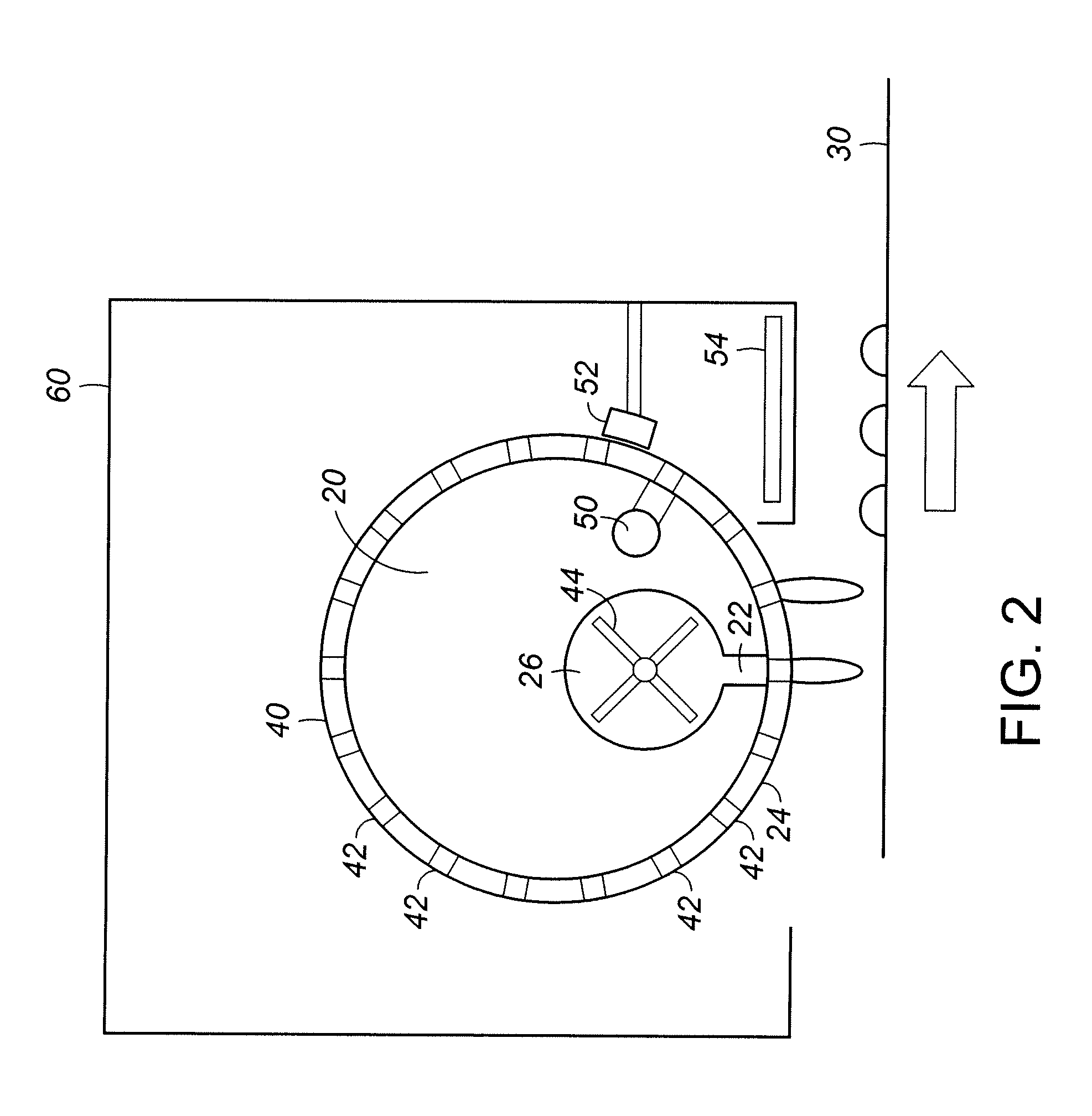

Pastillation of ammonium sulfate nitrate

A process is presented for the production of ammonium sulfate nitrate. The process provides for producing a highly uniform product and having a substantially uniform size. The process includes reacting ammonium sulfate and ammonium nitrate to form an FASN slurry melt. The slurry melt is continuously stirred and heated to keep the slurry melt under a shear thinned condition and at a uniform temperature until the slurry melt is extruded, cooled and solidified.

Owner:ADVANSIX RESINS & CHEM LLC

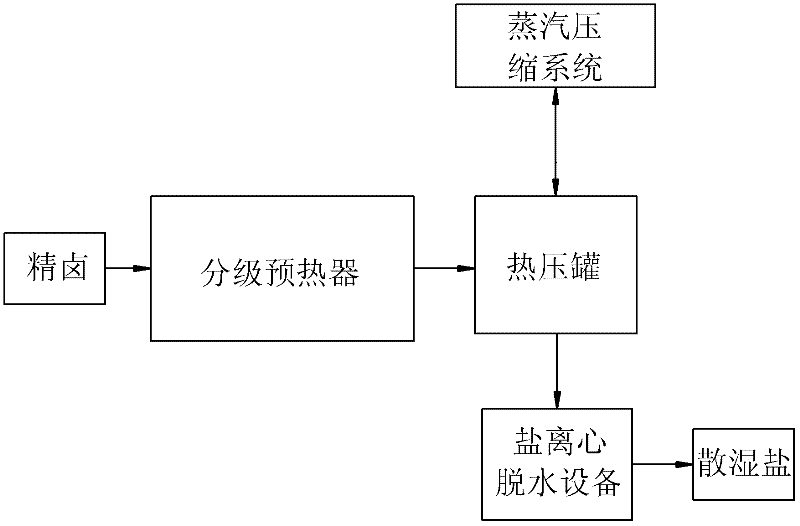

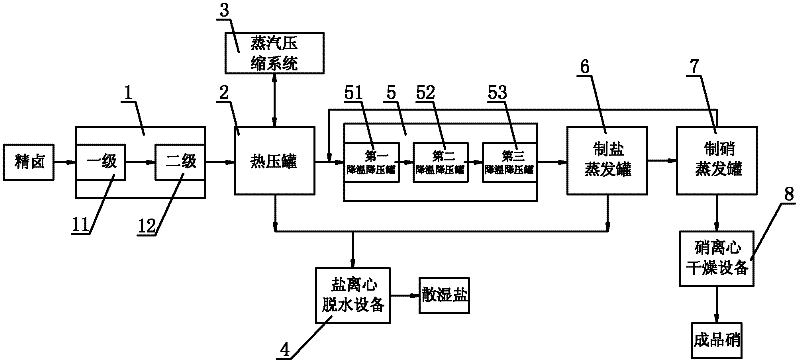

Equipment special for producing bulk wet salt by using sodium sulfate type brine

The invention relates to equipment special for producing bulk wet salt by using sodium sulfate type brine. The equipment comprises a multi-stage preheater, an autoclave and a vapor compression system; a salt slurry outlet of the autoclave is communicated with salt centrifugal dehydration equipment; the equipment also comprises an energy saving device, a salt-making vaporizing tank and a nitre-making vaporizing tank which are communicated through a pipeline; a brine outlet of the autoclave is communicated with a brine inlet of the energy saving device; a brine outlet of the energy saving device is communicated with a brine inlet of the salt-making vaporizing tank; a brine outlet of the salt-making vaporizing tank is communicated with a brine inlet of the nitre-making vaporizing tank; a salt slurry outlet of the salt-making vaporizing tank is communicated with the salt centrifugal dehydration equipment; a nitre slurry outlet of the nitre-making vaporizing tank is communicated with nitre centrifugal dehydration equipment; and a brine outlet of the nitre-making vaporizing tank is communicated with the brine inlet of the energy saving device. The equipment special for producing the bulk wet salt by using the sodium sulfate type brine is provided with the salt-making vaporizing tank and the nitre-making vaporizing tank for salt-nitre separation, the salt-making and nitre-making efficiency is improved, and the energy saving device is adopted for recycling heat.

Owner:CHINASALT JINTAN

Method for preparing inorganic sylvine crystal and feed additive by using molasses fermented waste liquid

ActiveCN101585548AImprove responseAchieve separationFood processingAlkali metal nitratesLiquid wasteFeed additive

The invention discloses a method for preparing inorganic sylvine crystal and feed additive by using molasses fermented waste liquid, comprising the pretreatment of molasses fermented waste liquid, absorbing and separating K+ ion in the pre-treated molasses fermented waste liquid through the resin column, regenerating the resin column absorbing K+, crystallizing, cooling, centrifugally separating, washing, drying the eluate containing inorganic sylvine, obtaining inorganic sylvine crystal, spray drying after heating to condense or condensing the molasses fermented waste liquid after absorbing K+ by the resin column, obtaining the feed additive. The invention has simple technique, regenerates the resin, realizes the formation reaction and the de-sorption separation of sylvine, and has low production cost; the regenerating agent is served as the reaction raw material to generate inorganic sylvine without resin regenerated waste water, and the molasses fermented waste liquid is completely used. The invention has good environmental protection effect, remarkable economical benefits and social benefits.

Owner:SOUTH CHINA UNIV OF TECH

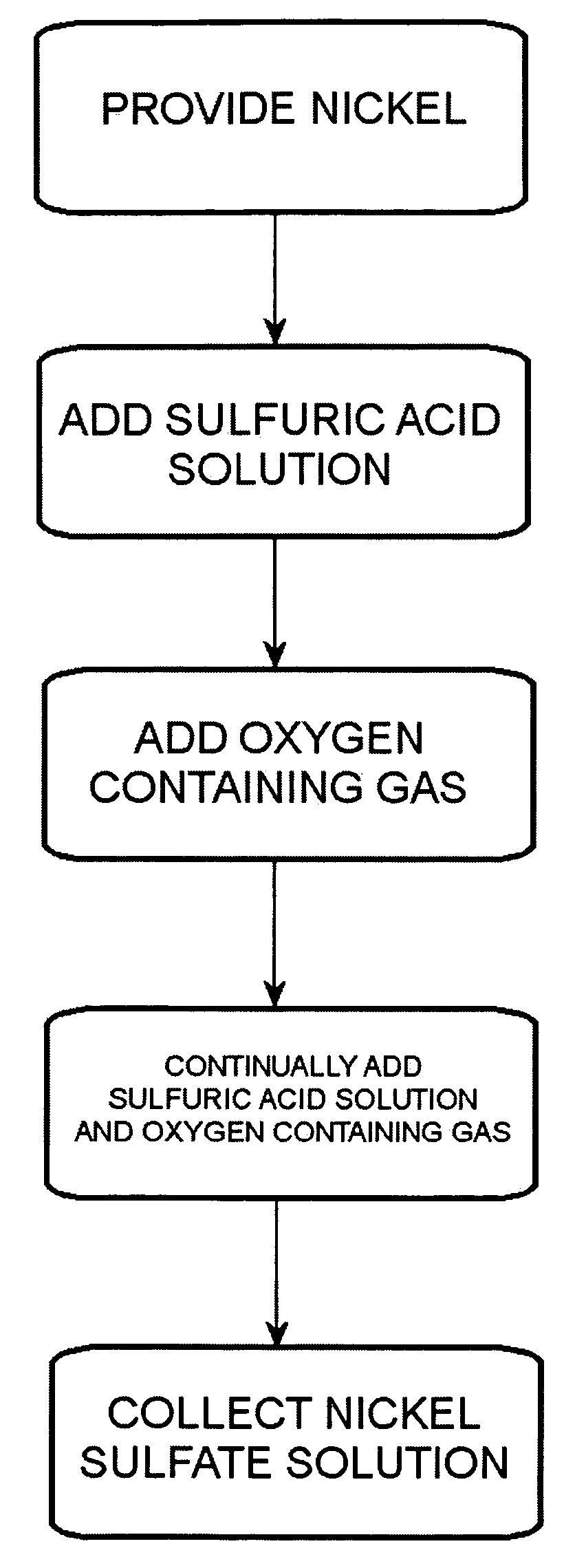

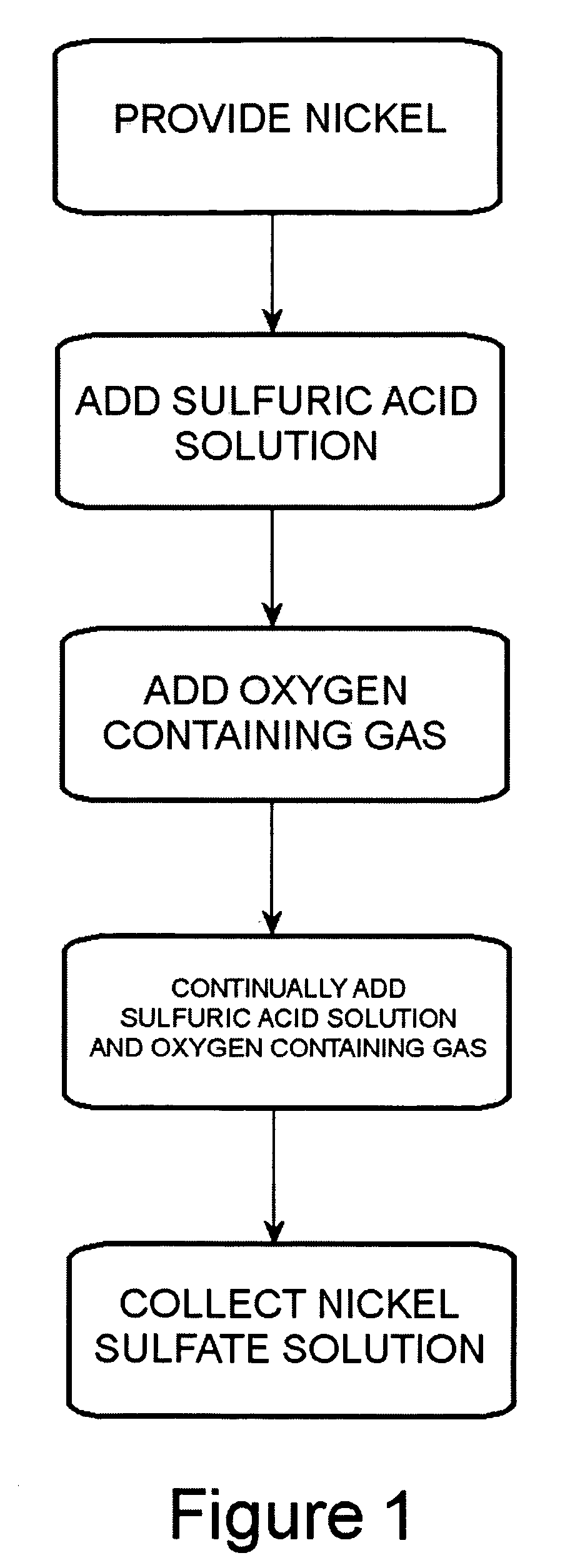

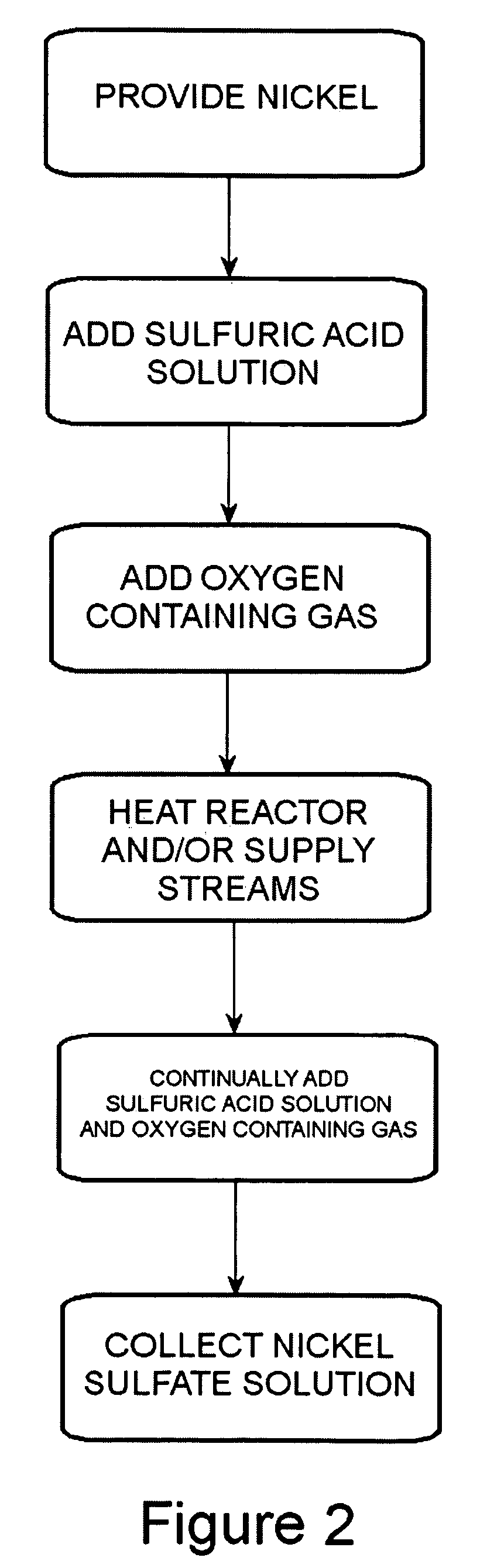

Method of producing a nickel salt solution

A method for converting nickel into a nickel salt solution. Nickel is dissolved and reacted in an oxygen-enriched acidic solution to produce a nickel salt solution as illustrated in the following chemical equation, wherein X is a conjugate base: Ni+H2X+½O2->NiX+H2O.

Owner:CHEVRON TEXACO TECH VENTURES

Method for producing EDTA ferric sodium salt by recovering Fe<II>EDTA wet-process complexed denitrated waste-liquid

ActiveCN103387506AHigh economic valueRealize resourcesOrganic compound preparationAlkali metal nitratesFlue gasSulfur

The invention discloses a method for producing EDTA ferric sodium salt by recovering a Fe<II>EDTA wet-process complexed denitrated waste-liquid. The method comprises: performing dedusting and desulphurization on a flue gas by a Fe<II>EDTA wet-process complexing denitration method, making the to-be processed flue gas enter into an absorption reactor and fully contact an absorption liquid, fully oxidizing Fe<III>EDTA and nitrogen-sulfur compounds both contained in the denitrated waste liquid by hydrogen peroxide or ozone to generate EDTA ferric sodium salt, NO<3-> and SO4<2->; and calculating the volume of a saturated solution of the generated EDTA ferric sodium salt at 100 DEG C according to the content of Fe<II>EDTA in the absorption liquid, heating and evaporating the oxidized waste liquid to the volume, cooling to 33 DEG C, and gradually separating out a reddish brown precipitate of EDTA ferric sodium salt. The method is low in investment and operation cost, the regenerated products are higher-economic-value EDTA ferric sodium salt, NaNO3 and Na2SO4, and the method helps to realize recycling of denitrated products.

Owner:ZHEJIANG SHUREN UNIV

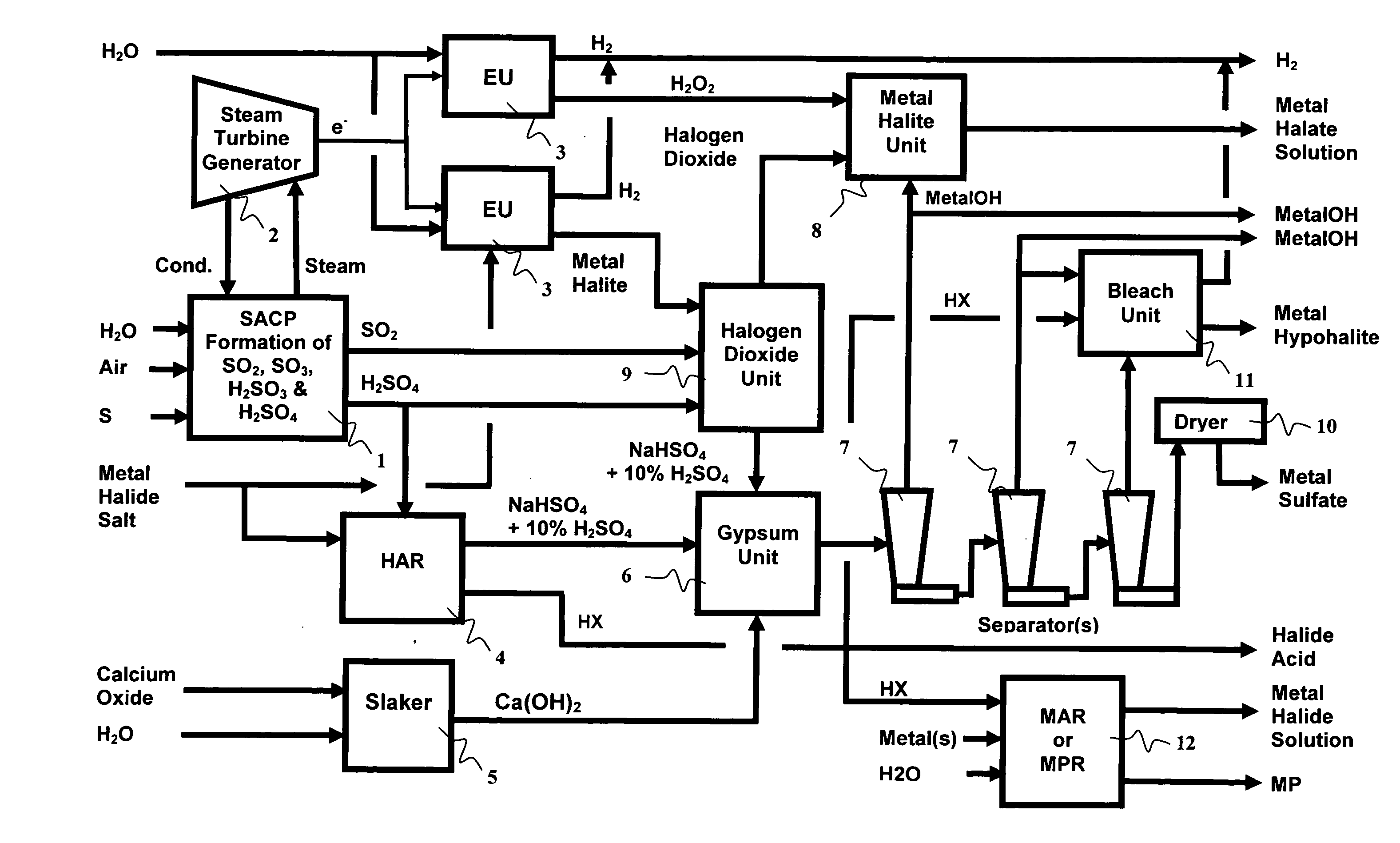

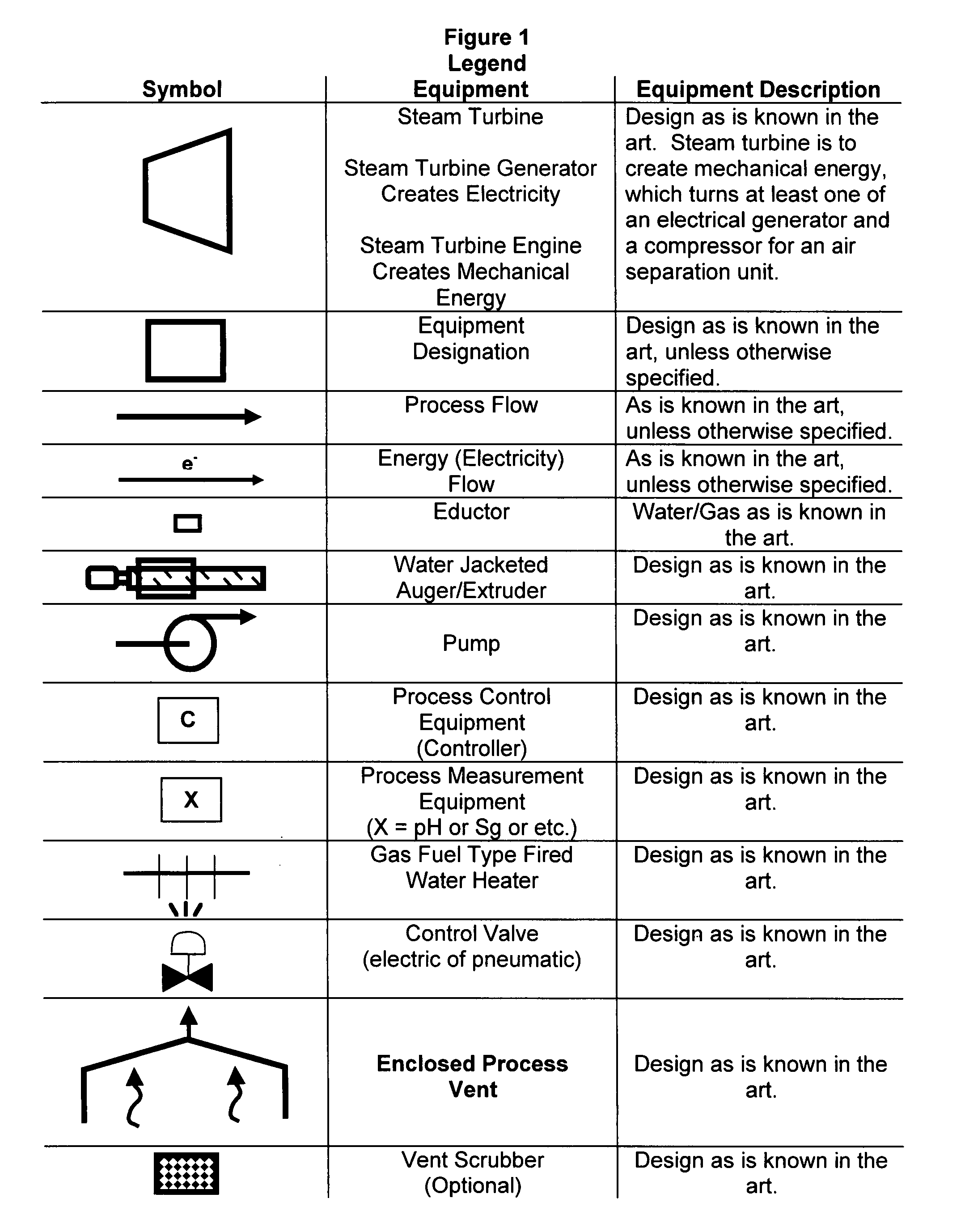

Manufacture of water chemistries

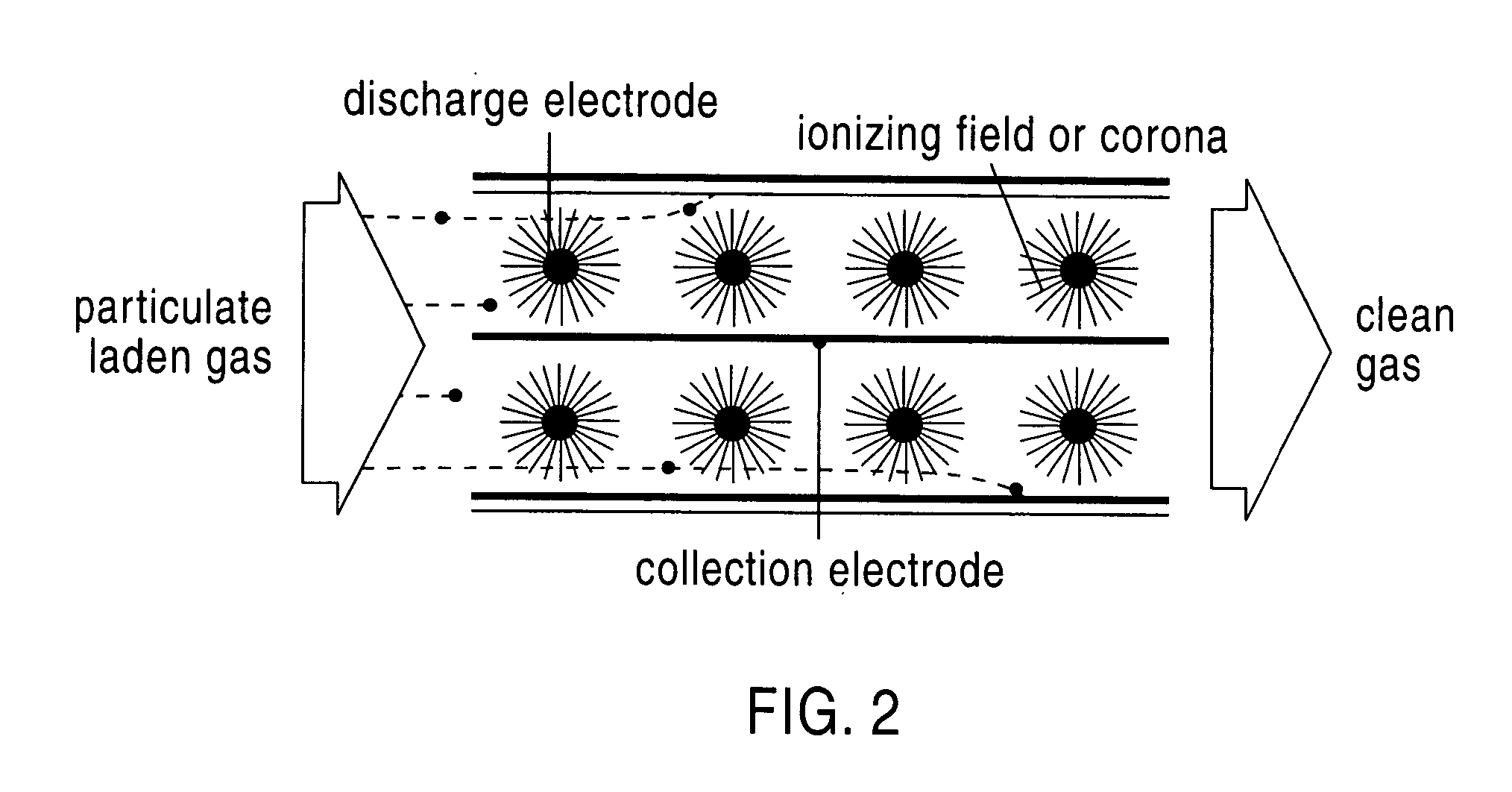

InactiveUS20080053104A1Effective and efficient and economically feasible processEfficient and effective processNitrogen compoundsElectrostatic separationPresent methodDisinfectant

As population density increases, the transportation of hazardous chemicals, including acids and disinfectants, lead to an increased incidence of spills while the consequences of spills become more serious. While solutions of halide acids, hypohalites and halites are safer disinfectants for transportation, handling, storage and use than traditional gaseous chlorine, the manufacturing cost of these disinfectants has here-to-fore limited their use. Economical processes are presented for the manufacture of O2, halogen oxides, halide acids, hypohalites, and halates; as well as polynucleate metal compounds, metal hydroxides and calcium sulfate hydrate (gypsum). The instant invention presents methods and processes that incorporate the use of sulfur. This is while environmental regulators, such as the US EPA, require an increased removal of sulfur from hydrocarbon fuels, thereby creating an abundance of sulfur, such that the refining industry is in need of a way to dispose of said abundance of sulfur.

Owner:CLEARVALUE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com