Equipment special for producing bulk wet salt by using sodium sulfate type brine

A special equipment, sodium sulfate technology, applied in the field of preparation of salt nitrate, can solve the problem of high energy consumption, and achieve the effect of improving the efficiency of salt and nitrate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

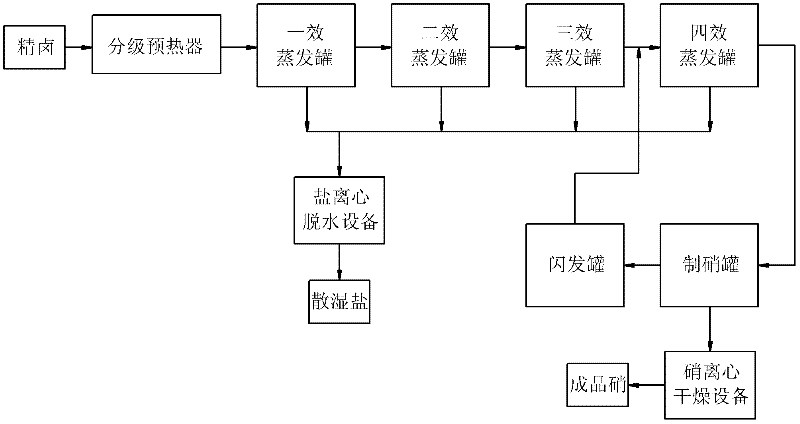

[0038] figure 1 It is a schematic flow chart of the multi-effect vacuum evaporation process in the prior art.

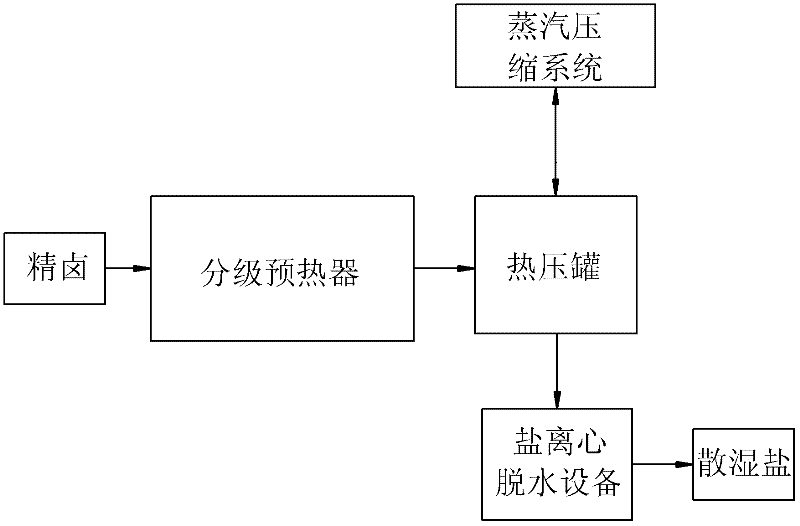

[0039] figure 2 It is a schematic flow chart of the MVR process in the prior art, mainly including a graded preheater, an autoclave and a vapor compression system for compressing the secondary steam generated by the autoclave, and the outlet of the autoclave is connected to the salt centrifugal dehydration equipment. The invention improves the process on the existing MVR process.

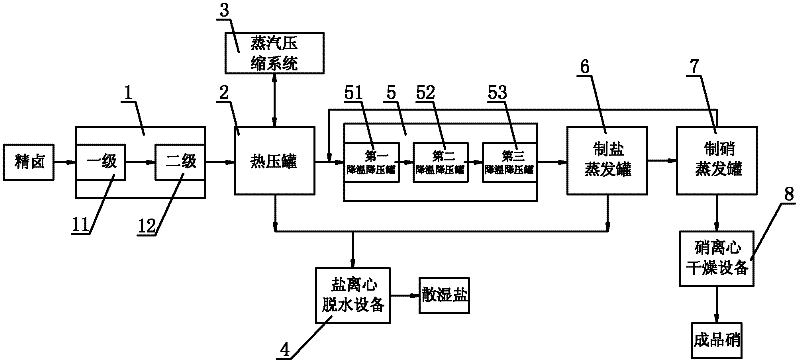

[0040] image 3 It is the best embodiment of the special equipment for producing wet salt from sodium sulfate type brine of the present invention, including a staged p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com