Method for preparing water soluble sylvite

A water-soluble, potassium-salt technology, applied in chemical instruments and methods, alkali metal carbonates, alkali metal nitrates, etc., can solve the problems of low heat energy utilization efficiency, low microwave reaction temperature, complex operation, etc., to solve heat conduction Poor performance, reduced process energy consumption, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

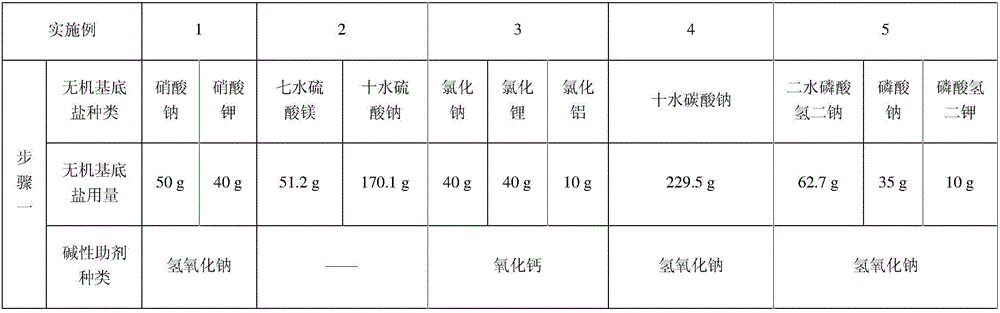

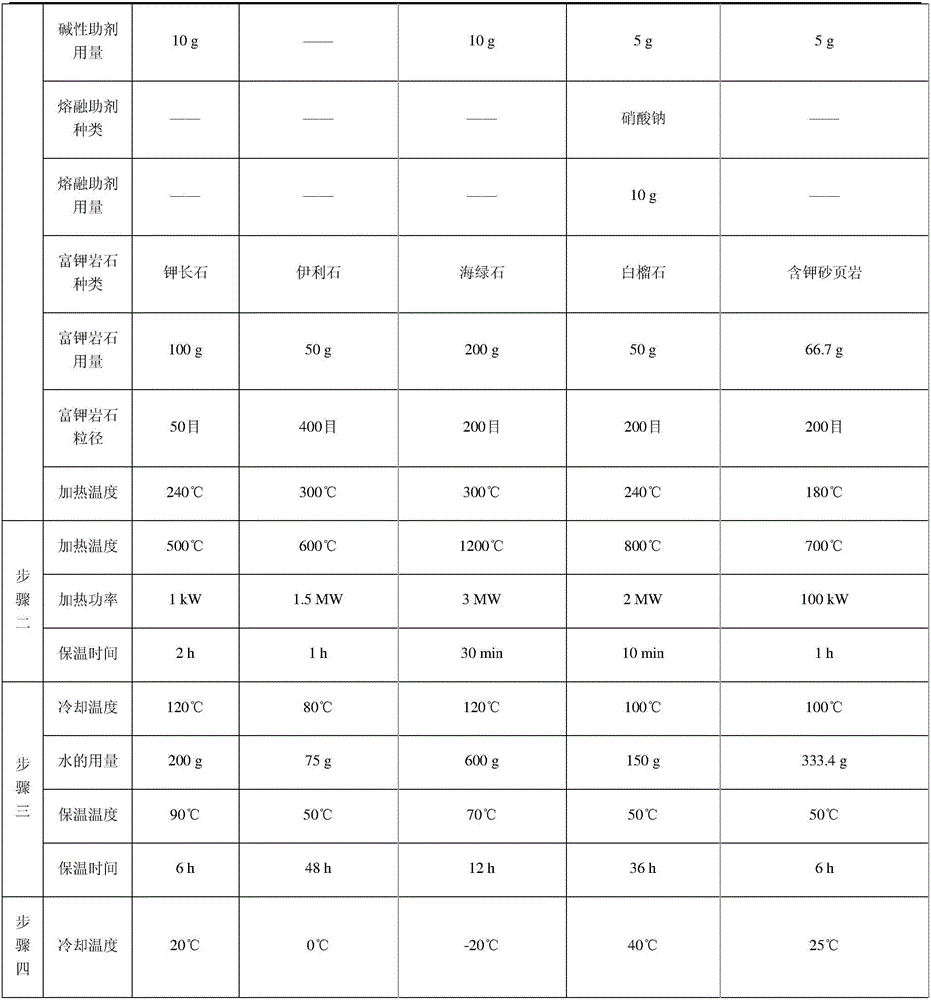

[0022] The preparation method of described a kind of water-soluble potassium salt comprises the steps:

[0023] In step 1, the inorganic base salt is uniformly mixed with the pulverized potassium-rich rock powder to obtain the first mixture; the first mixture is heated to no more than 300°C, and the inorganic base salt is melted to obtain the second mixture .

[0024] Preferably, the basic auxiliary agent and / or melting auxiliary agent can be mixed with the inorganic base salt, and then heated to no more than 300°C; wherein, the mass ratio of the inorganic base salt to the basic auxiliary agent is not less than 9 :1, the mass ratio of the inorganic base salt to the melting aid is 8:1 to 9:1; thereby ensuring that the mass ratio of the potassium-rich rock to the first mixture is 1:3 to 2:3.

[0025] Specifically, the inorganic base salt includes metal cations and acid radical anions, and the metal cations are selected from sodium, potassium, calcium, magnesium, lithium, iron, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com