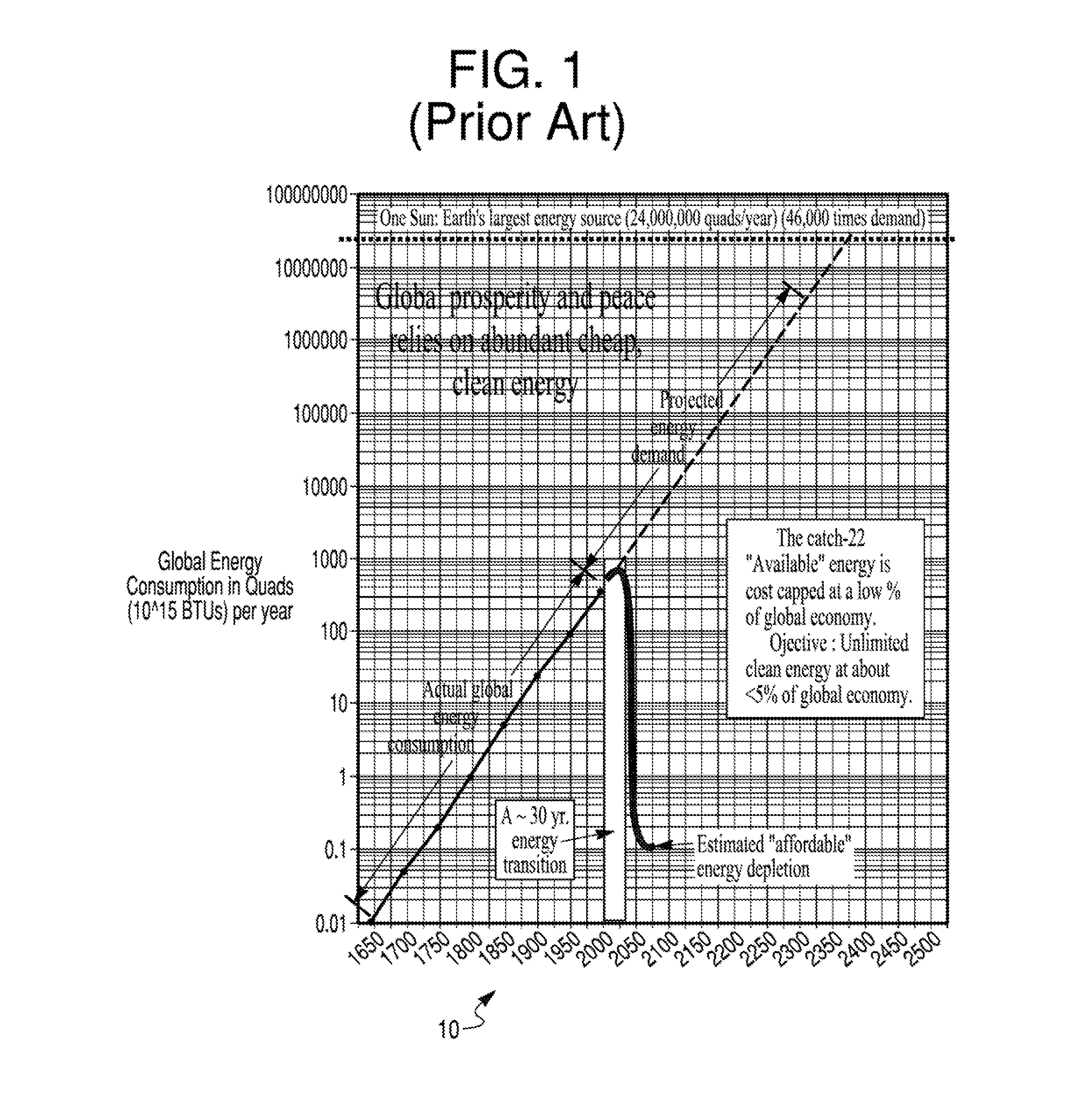

Patents

Literature

273results about "Collector working fluids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

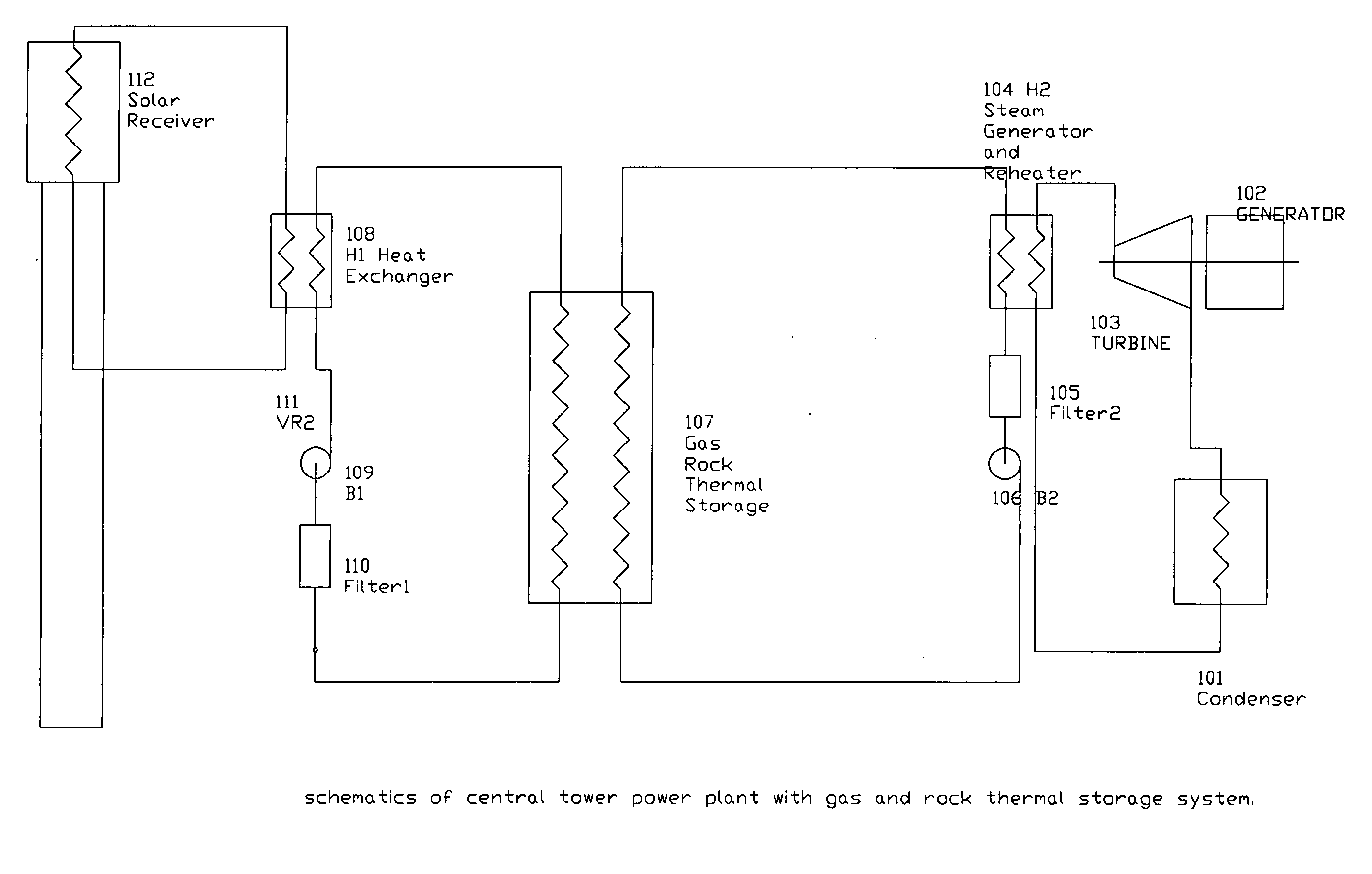

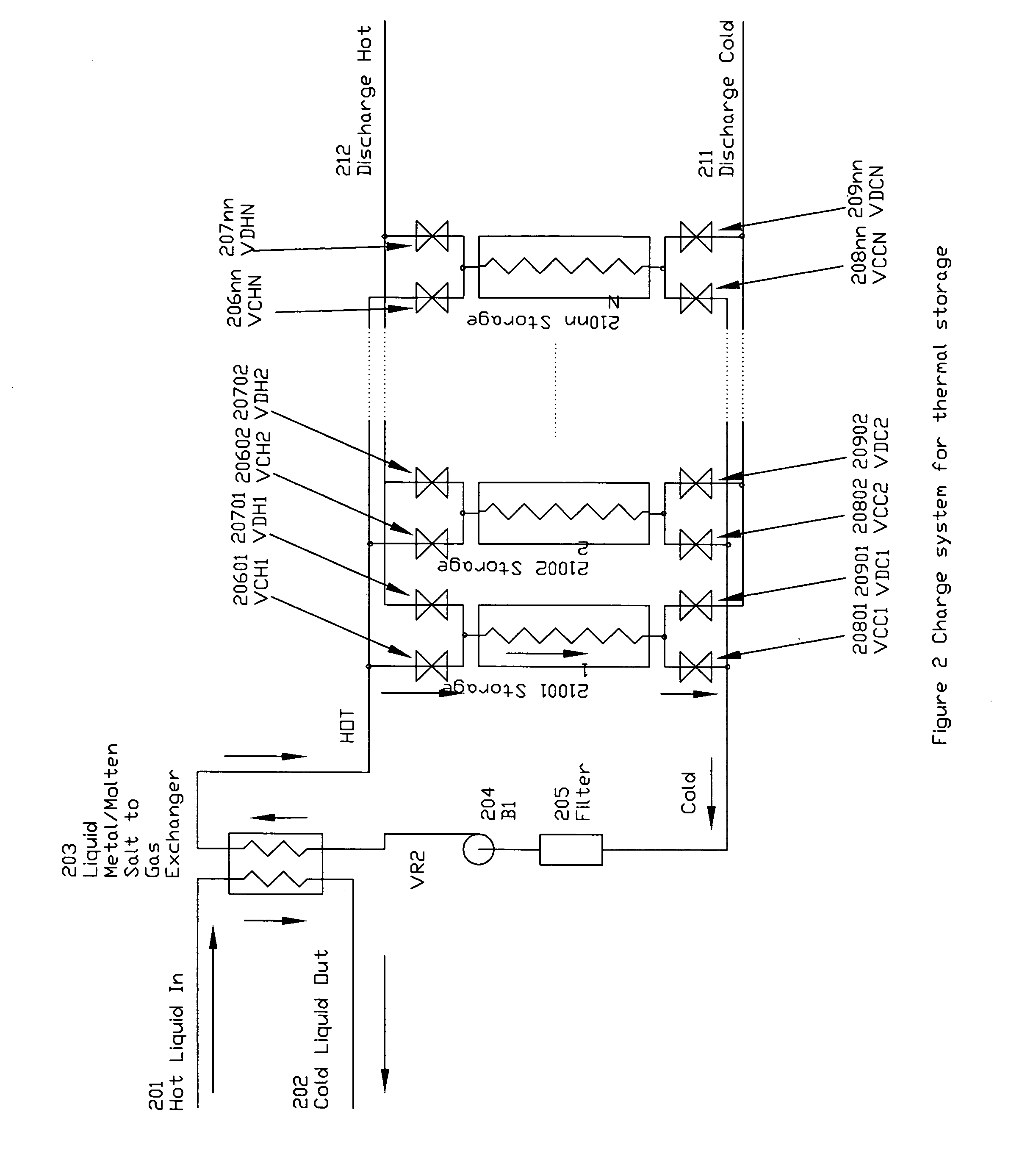

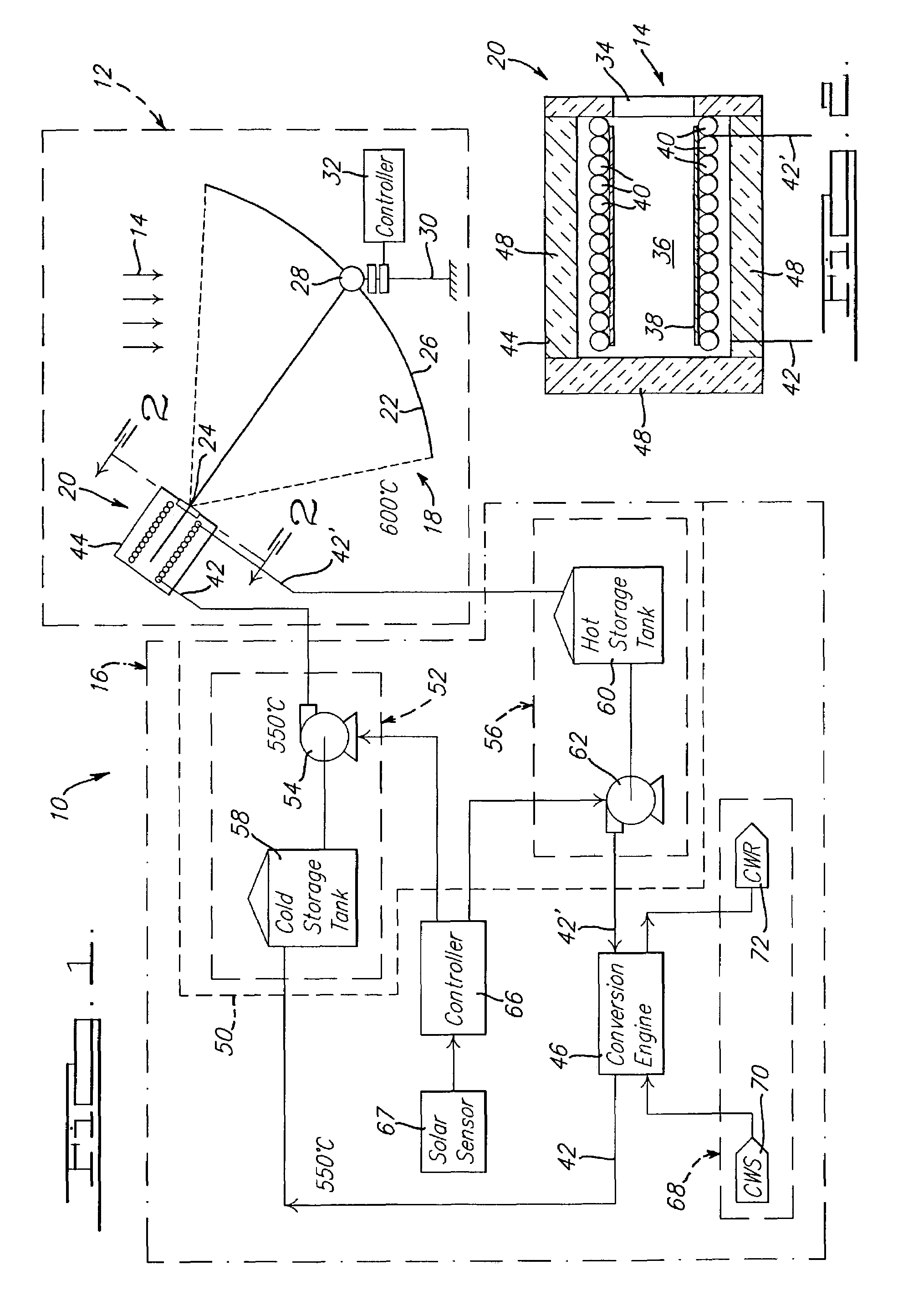

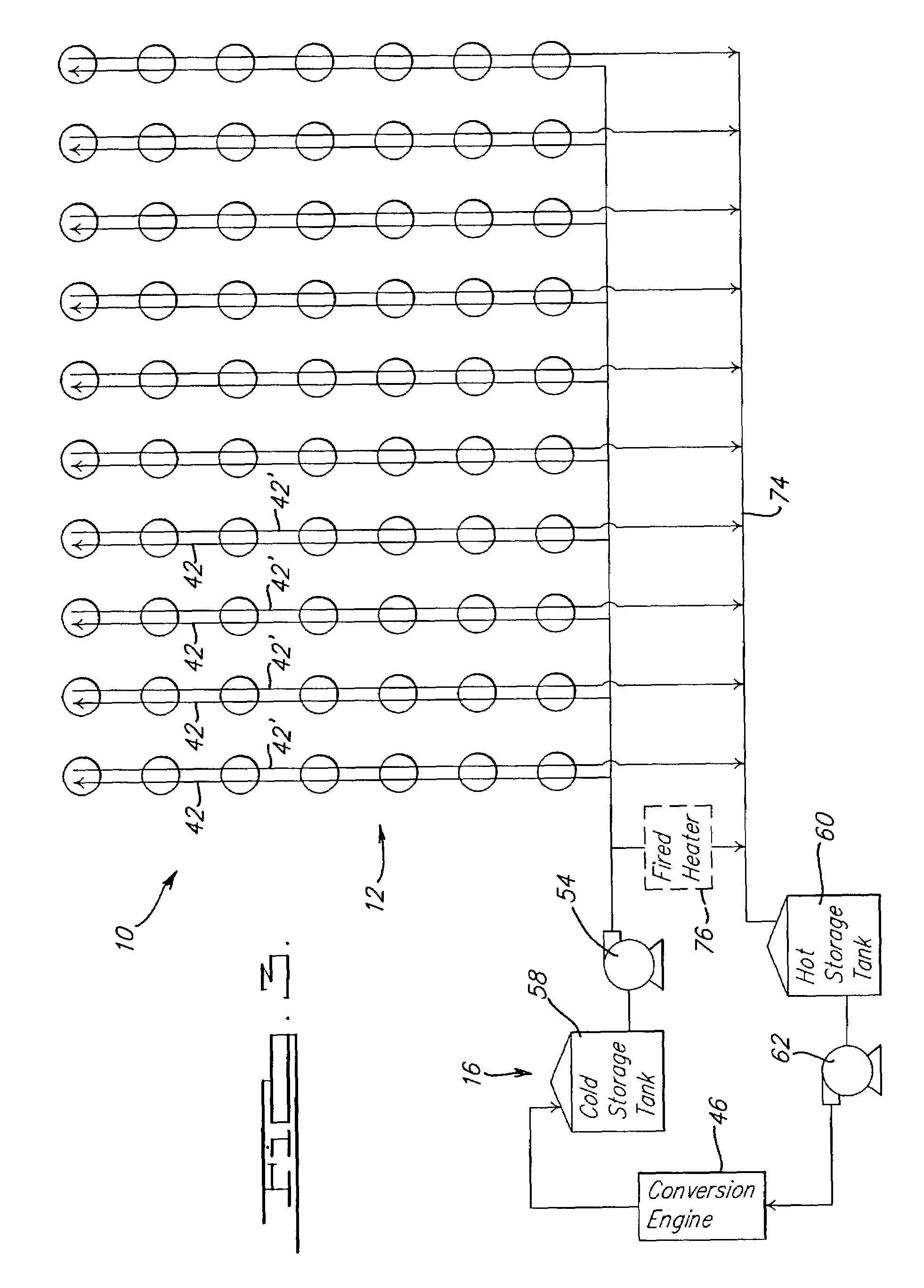

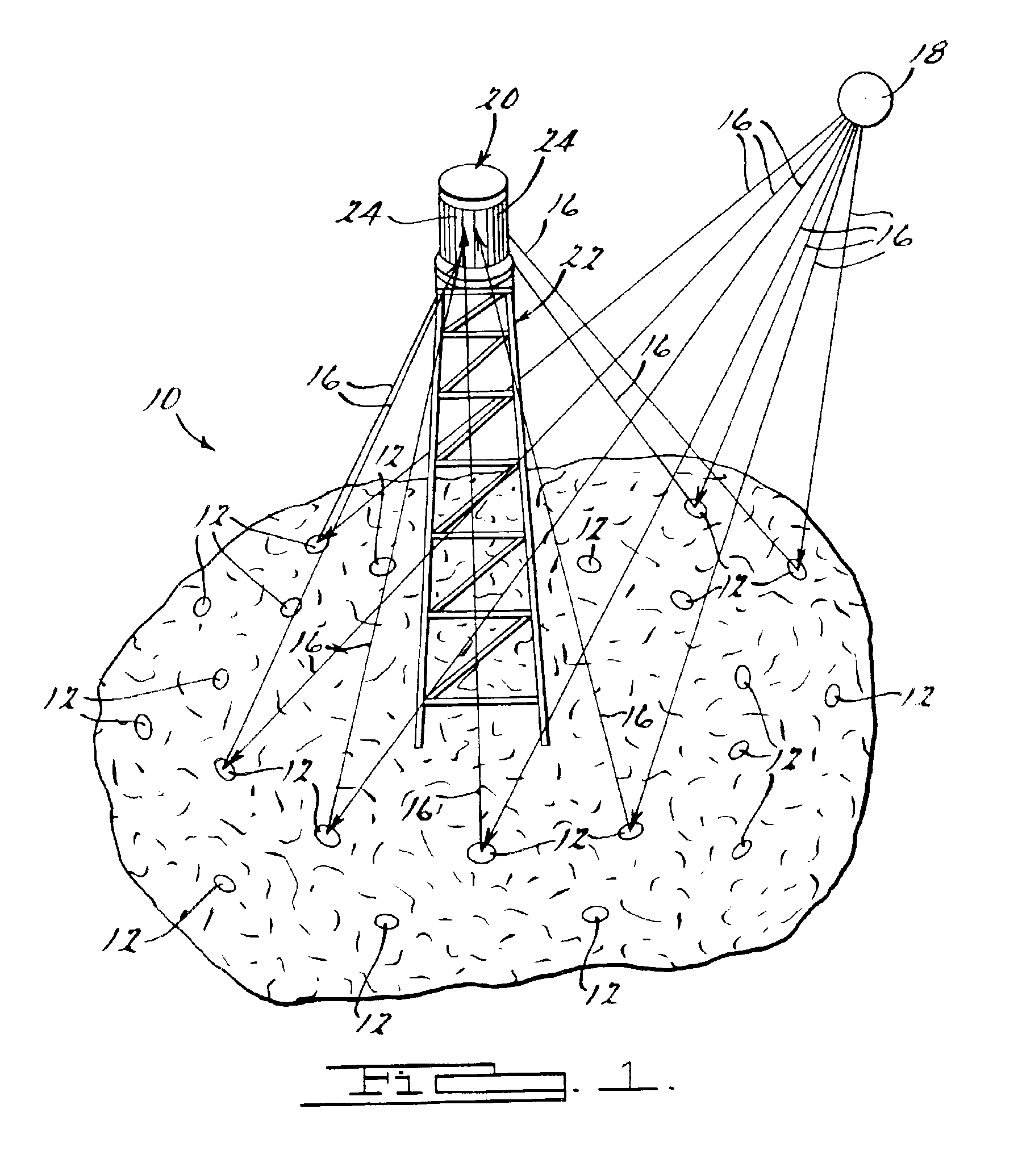

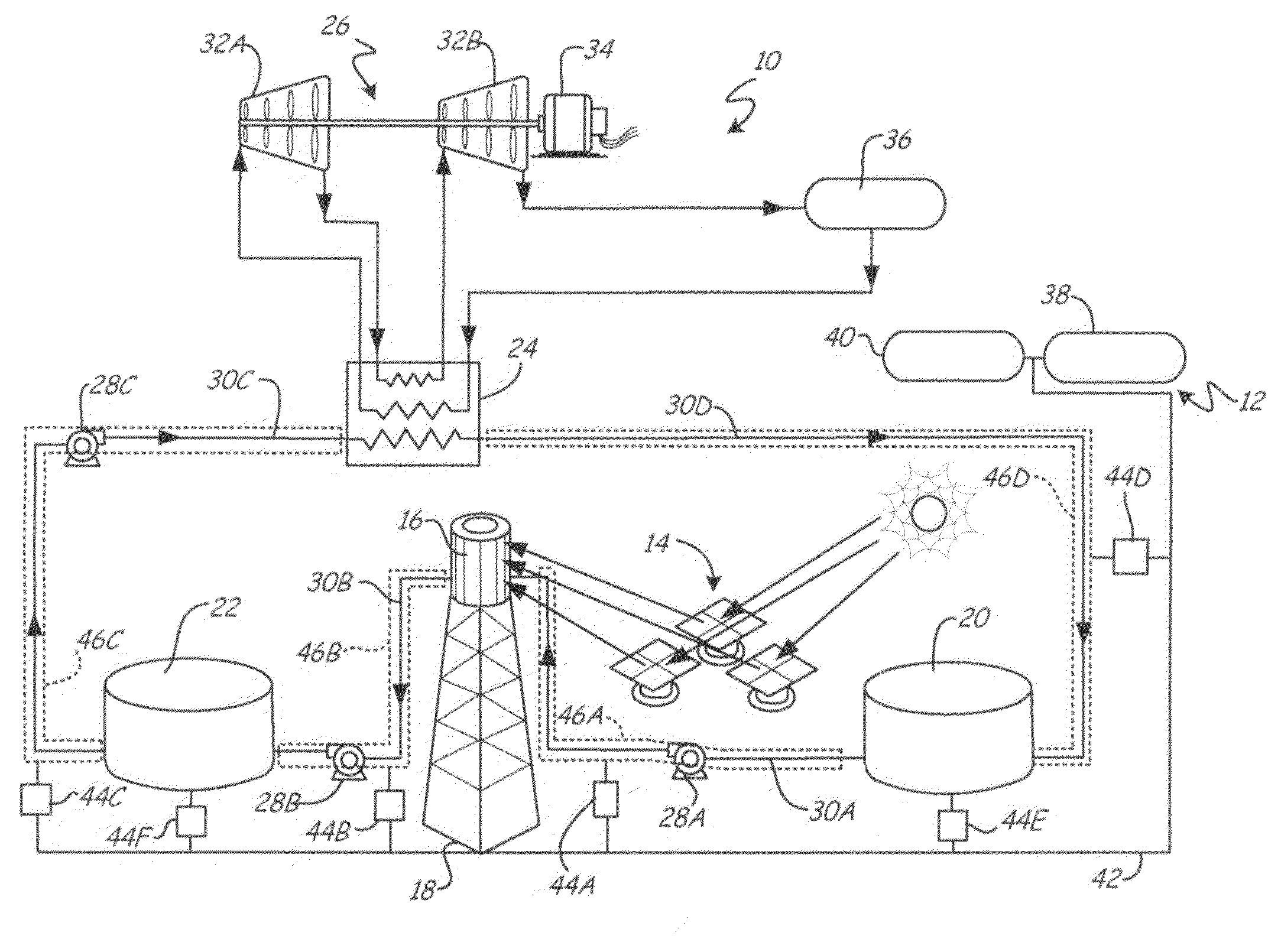

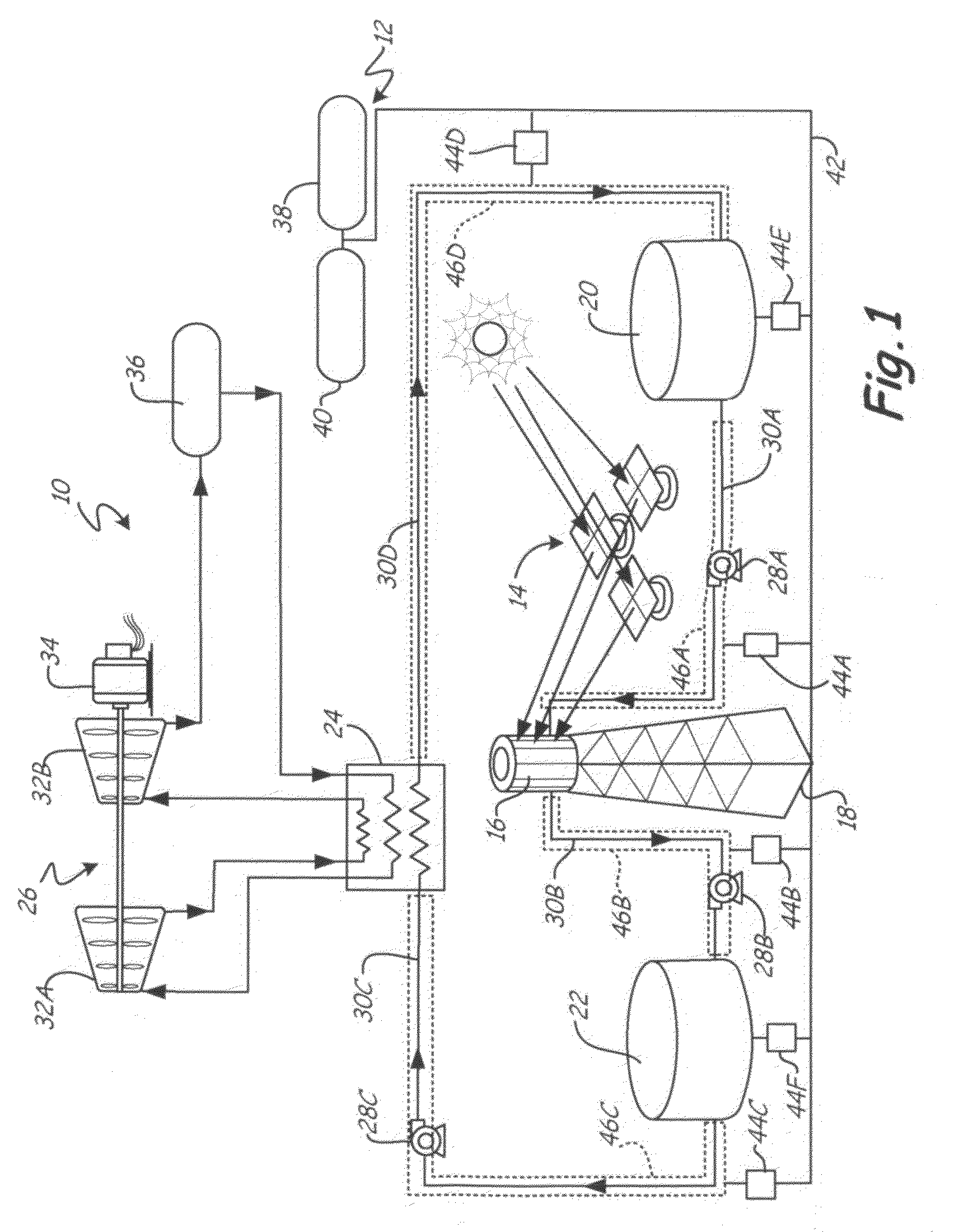

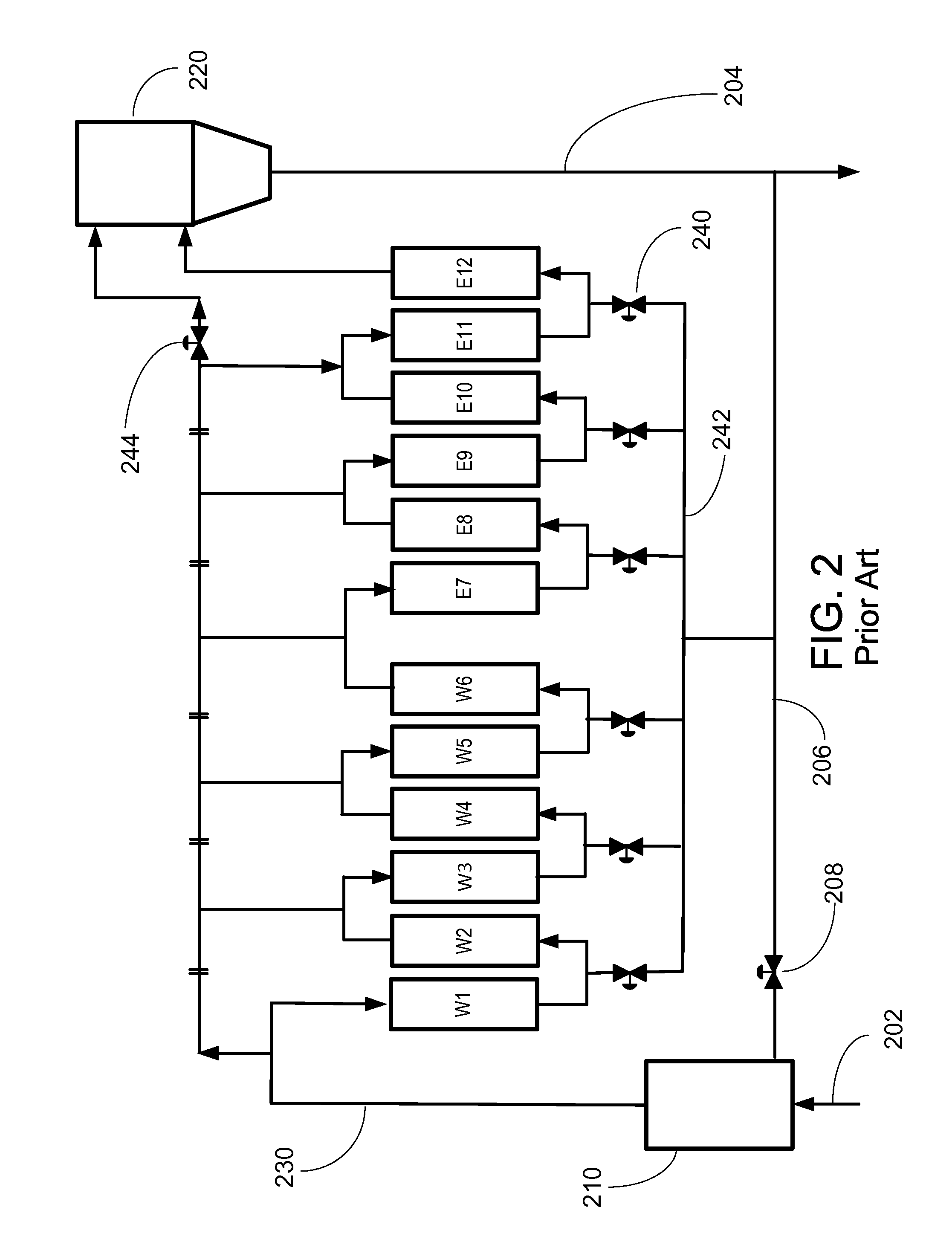

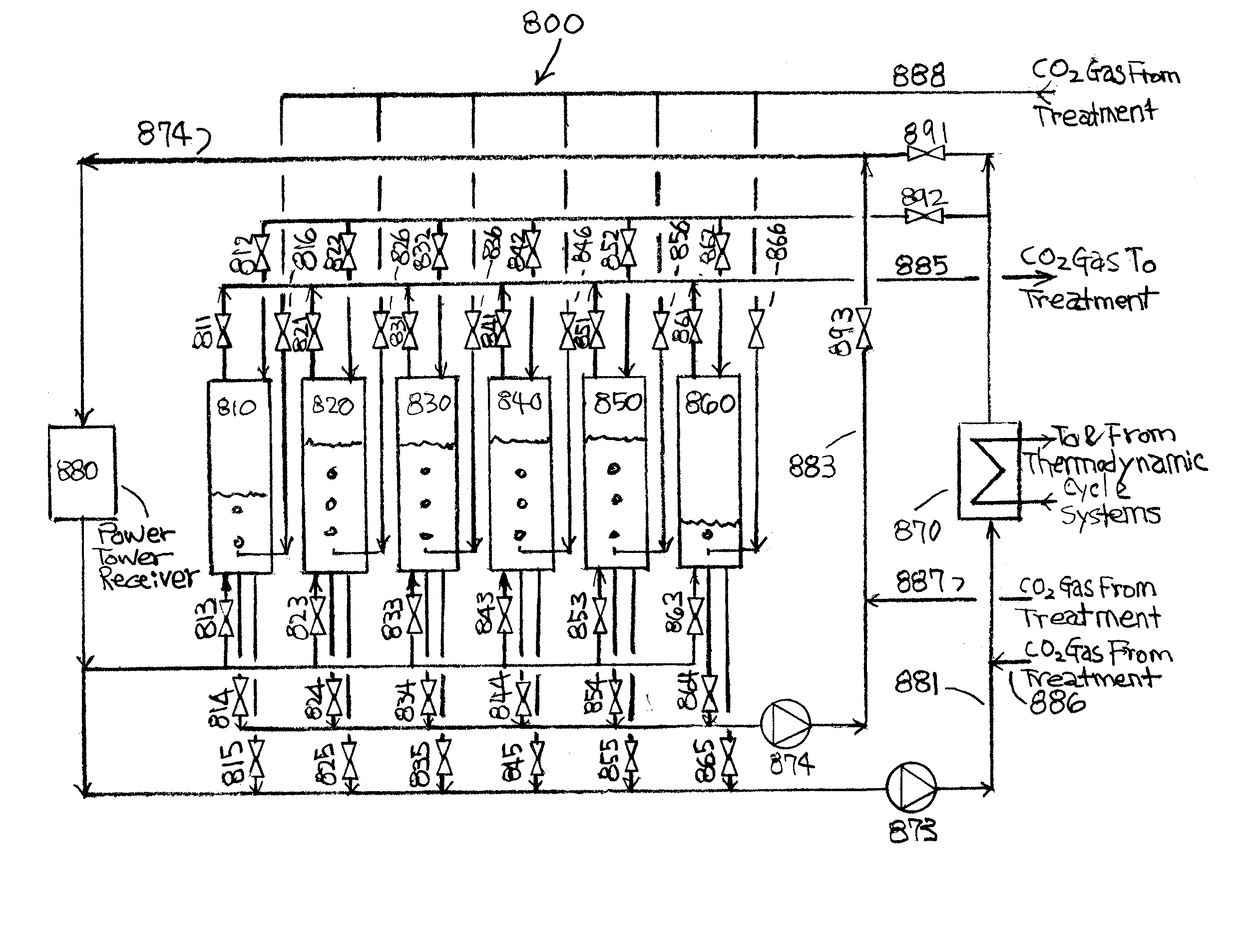

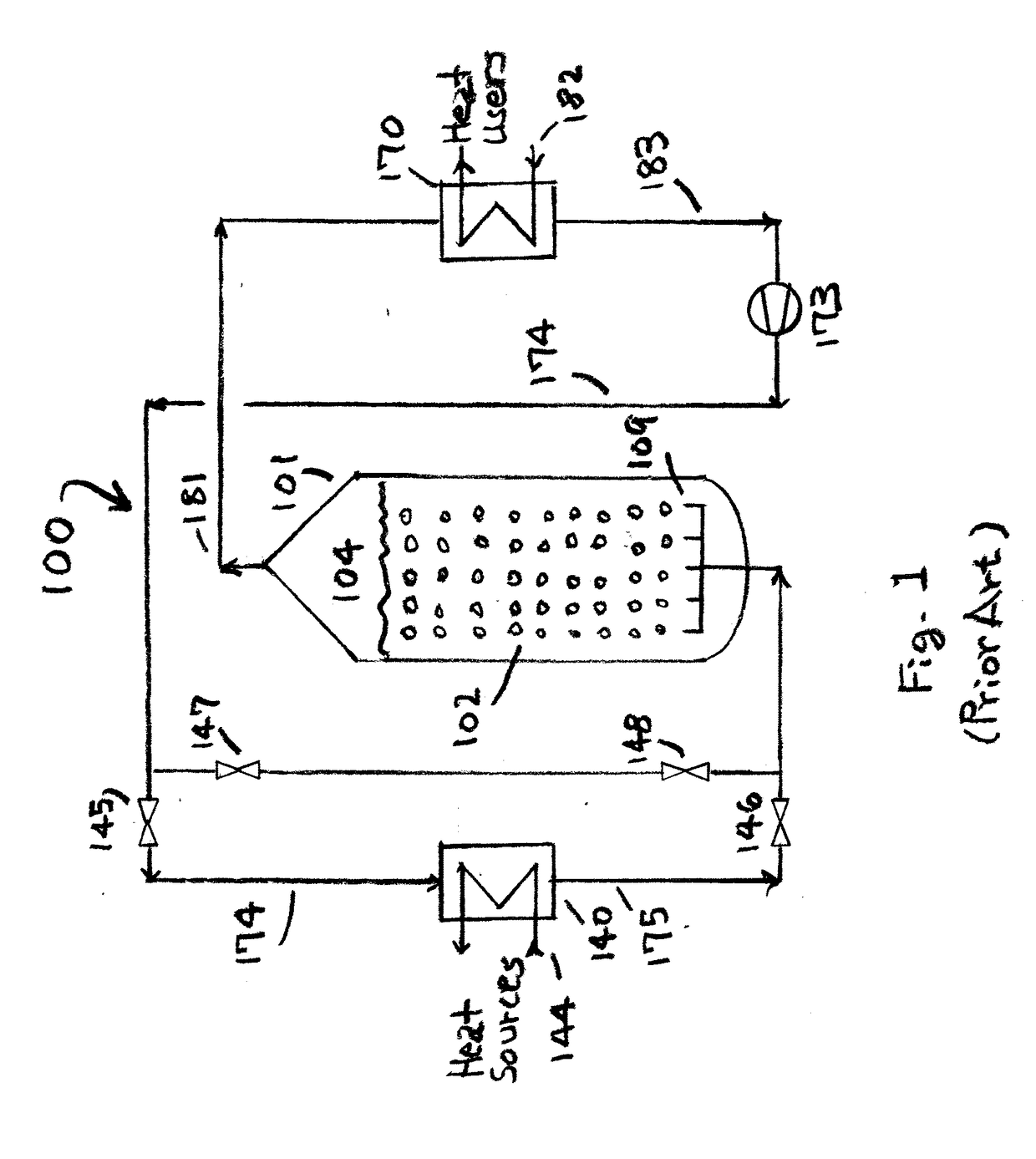

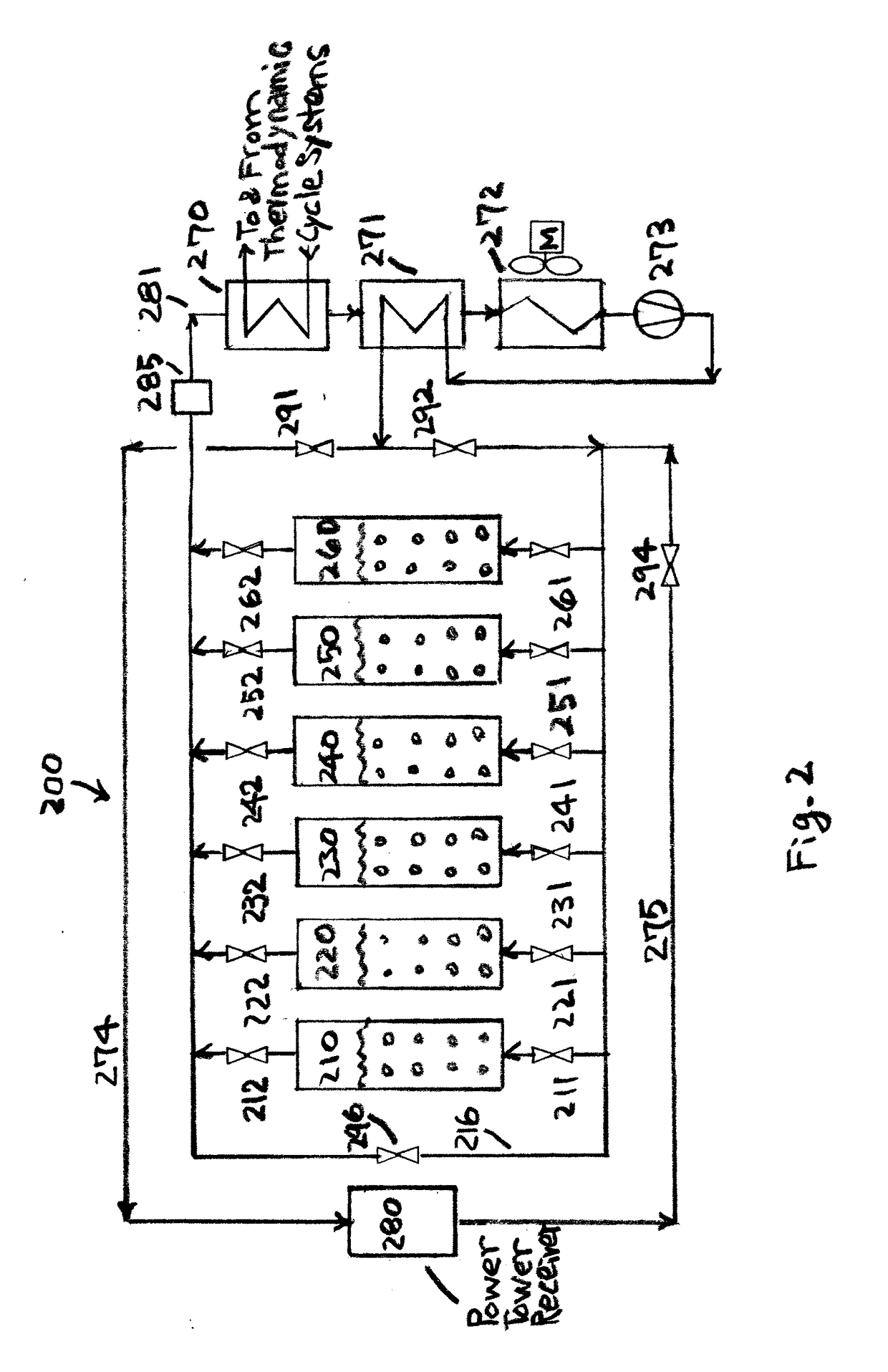

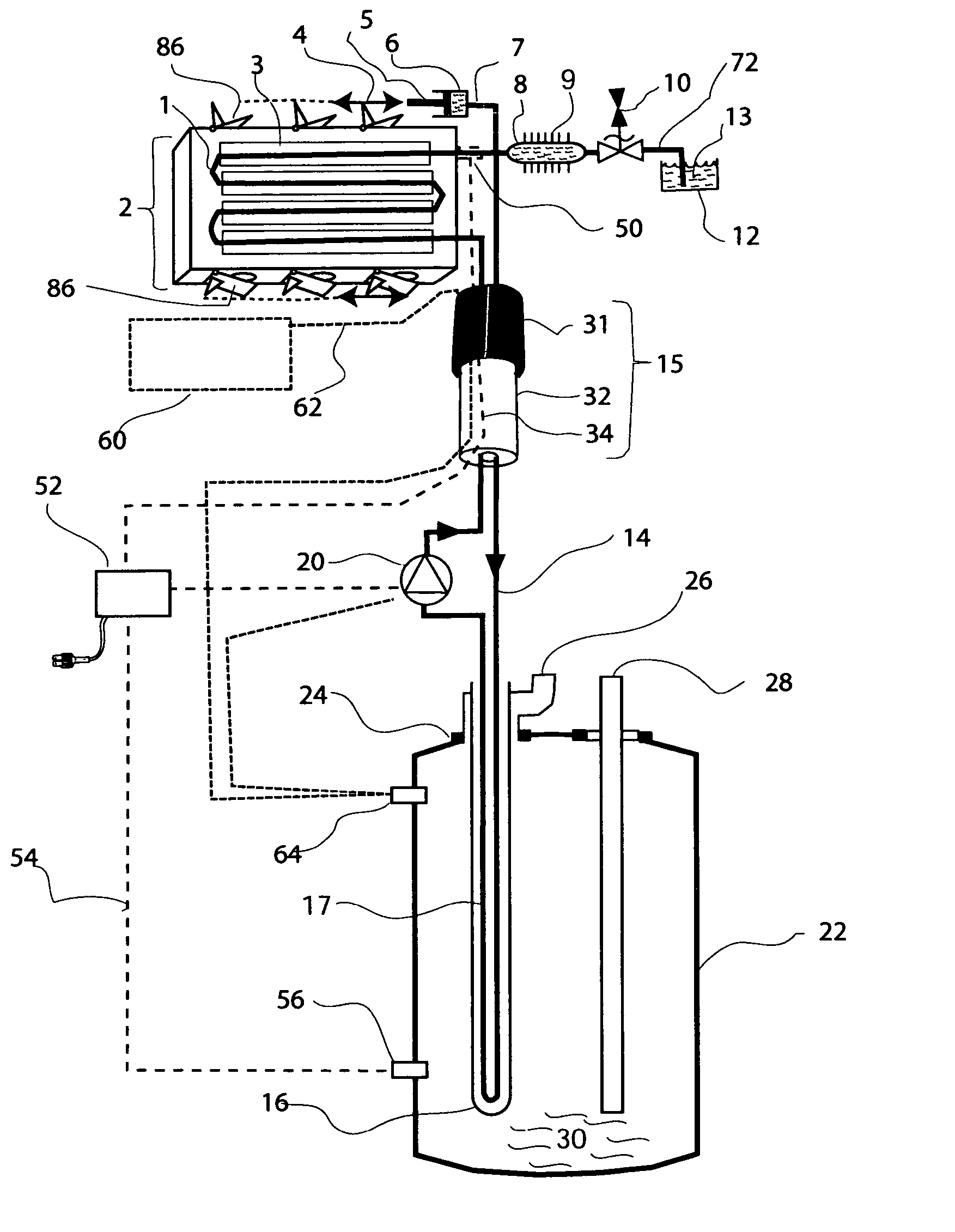

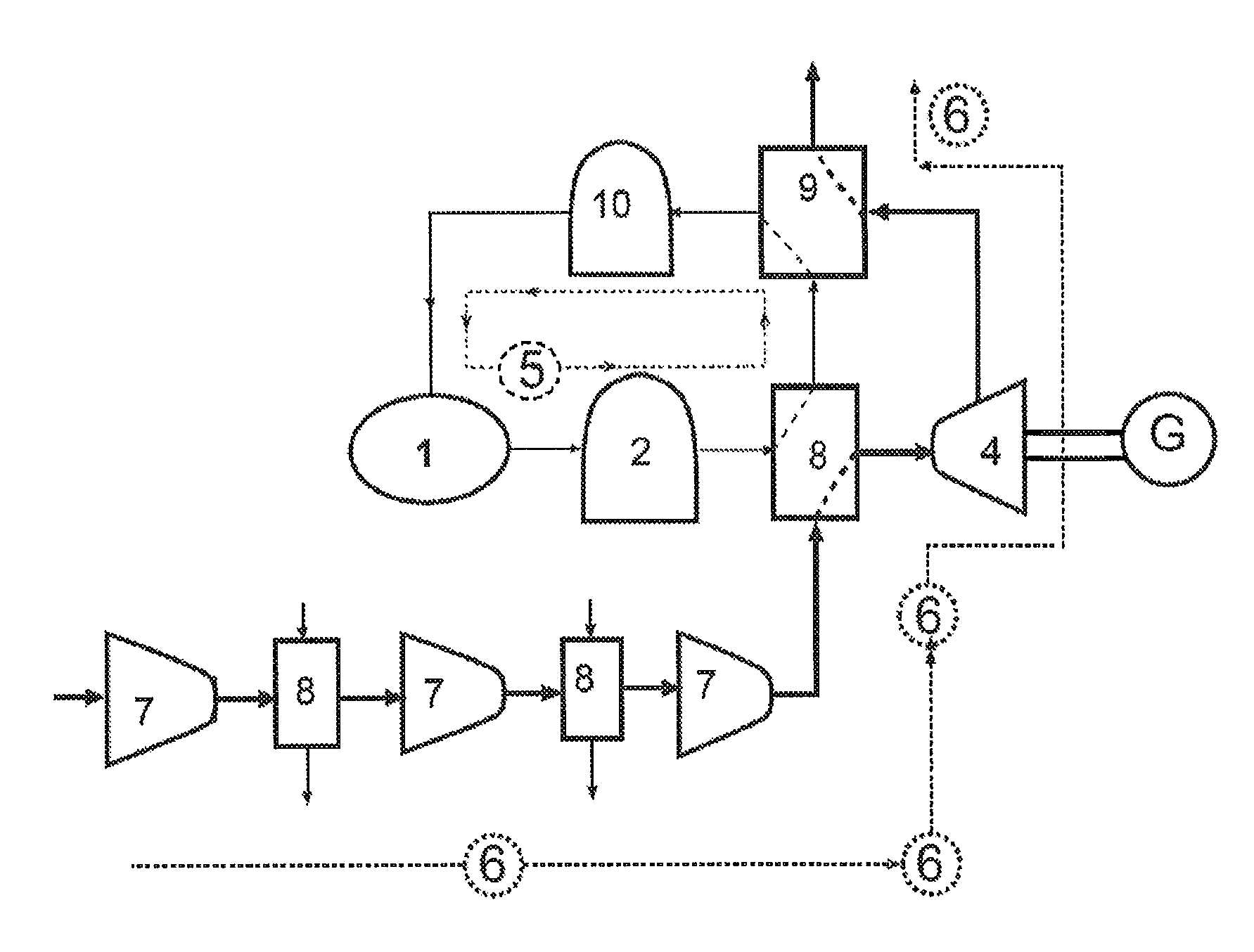

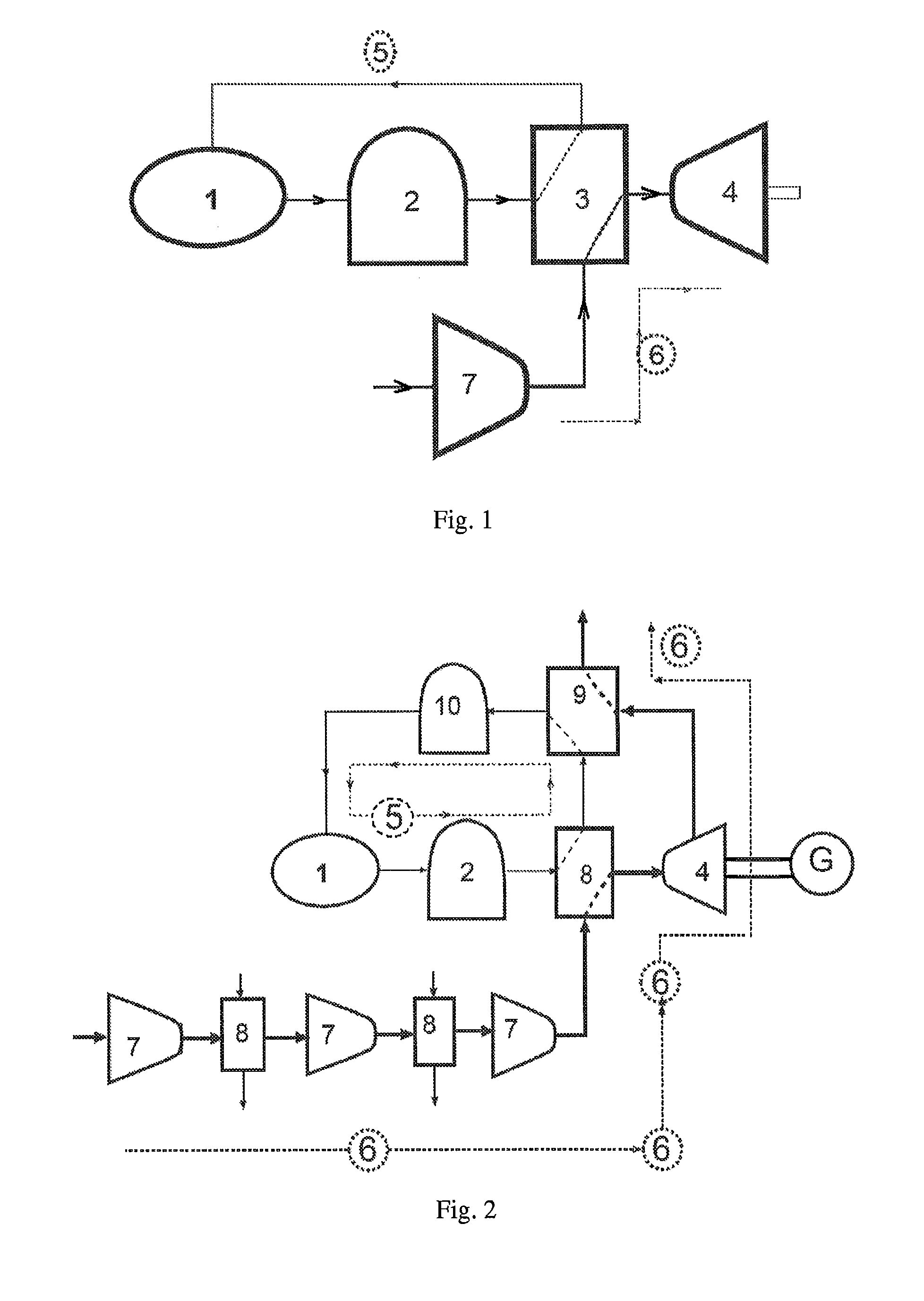

Method and apparatus for solar energy storage system using gas and rock

InactiveUS20080066736A1Quality improvementLow costSolar heating energyFrom solar energyThermal energyEngineering

A method and Apparatus for solar energy storage system uses gas for thermal transport for central tower solar thermal electric power plant to provide high quality, low cost, and continuously electric power generation. The storage contains a number of storage modules that each module can store energy for a given period of time. The thermal energy from central tower charges the modules one by one during the sunny time, while the thermal electric power plant discharge the modules one by one as long as it works. A control and a connection valve system control and connect the charge and discharge modules with the central tower and the power plant according to pre-arranged sequences. Fans at the cool side of the storage system push the circulation gas into the central tower or the thermal storage modules. In the discharge system, the hot gas from storage system is send to the heat exchange system, and to generate steam and to super heat steam for the power plant. In the charge system, the cold gas is pushed into the central receiver thermal exchange unit and to be heated, and the hot gas is then circulated back to storage system to charge up the storage system.

Owner:ZHU YANONG

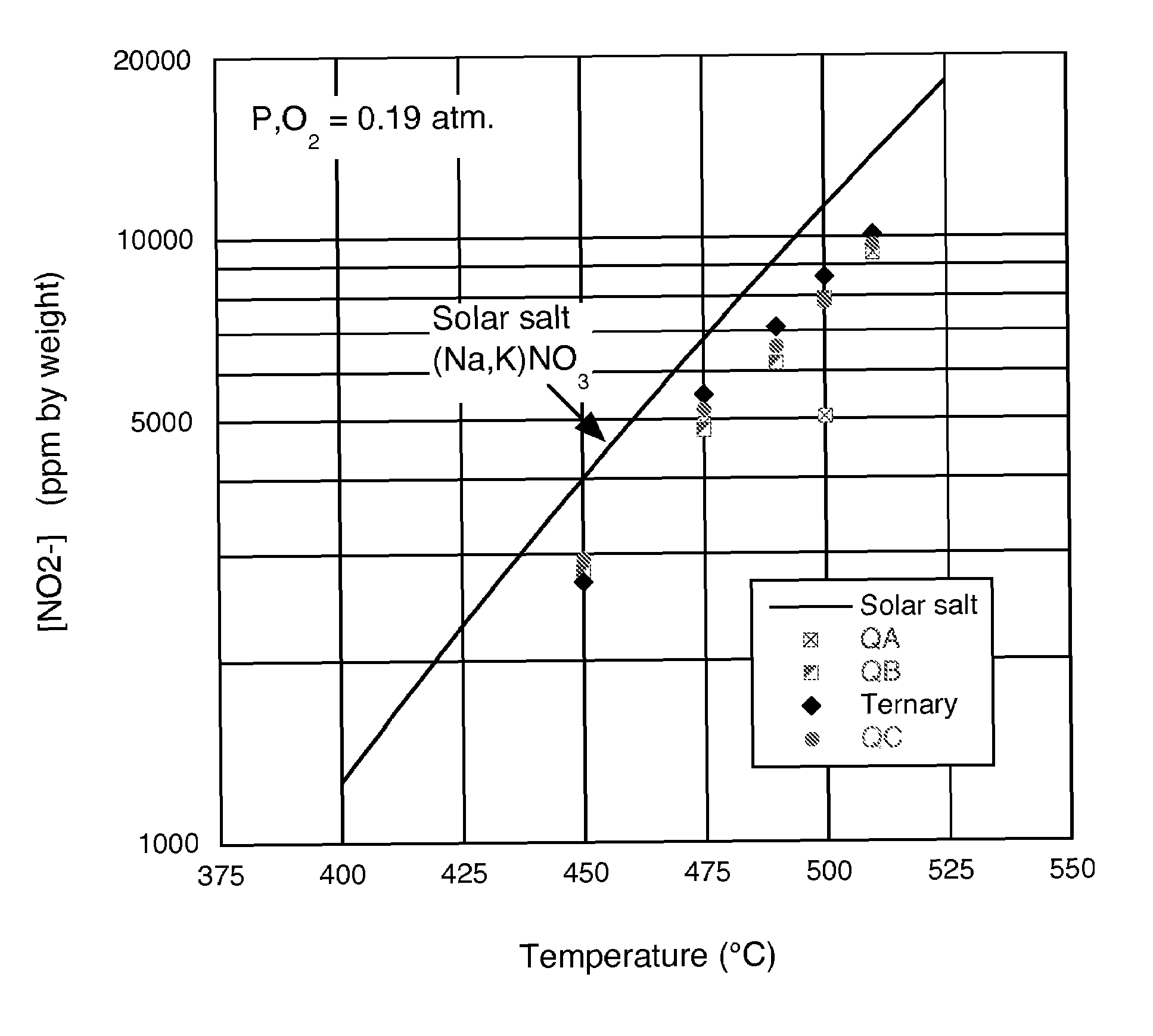

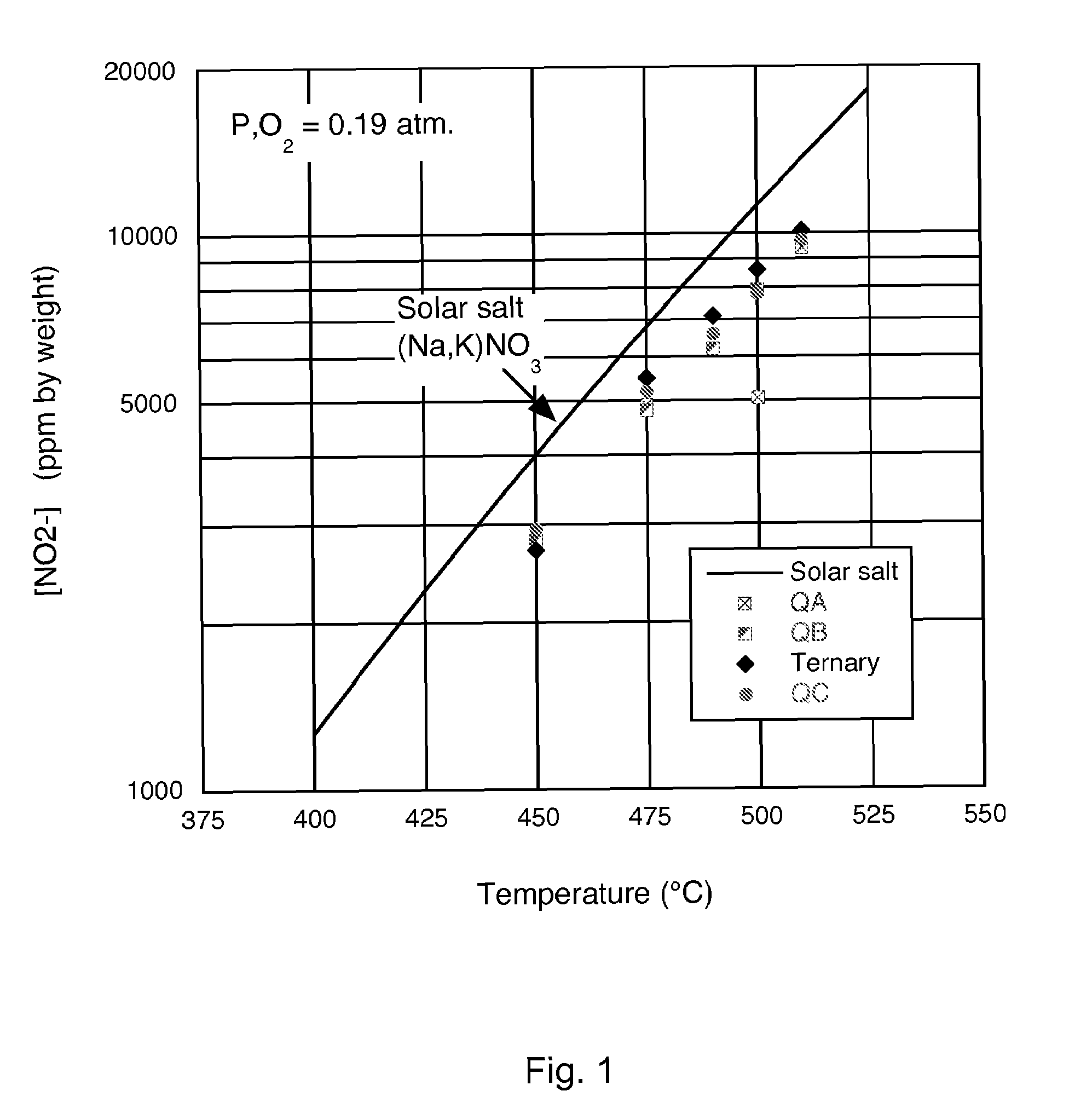

Low-melting point inorganic nitrate salt heat transfer fluid

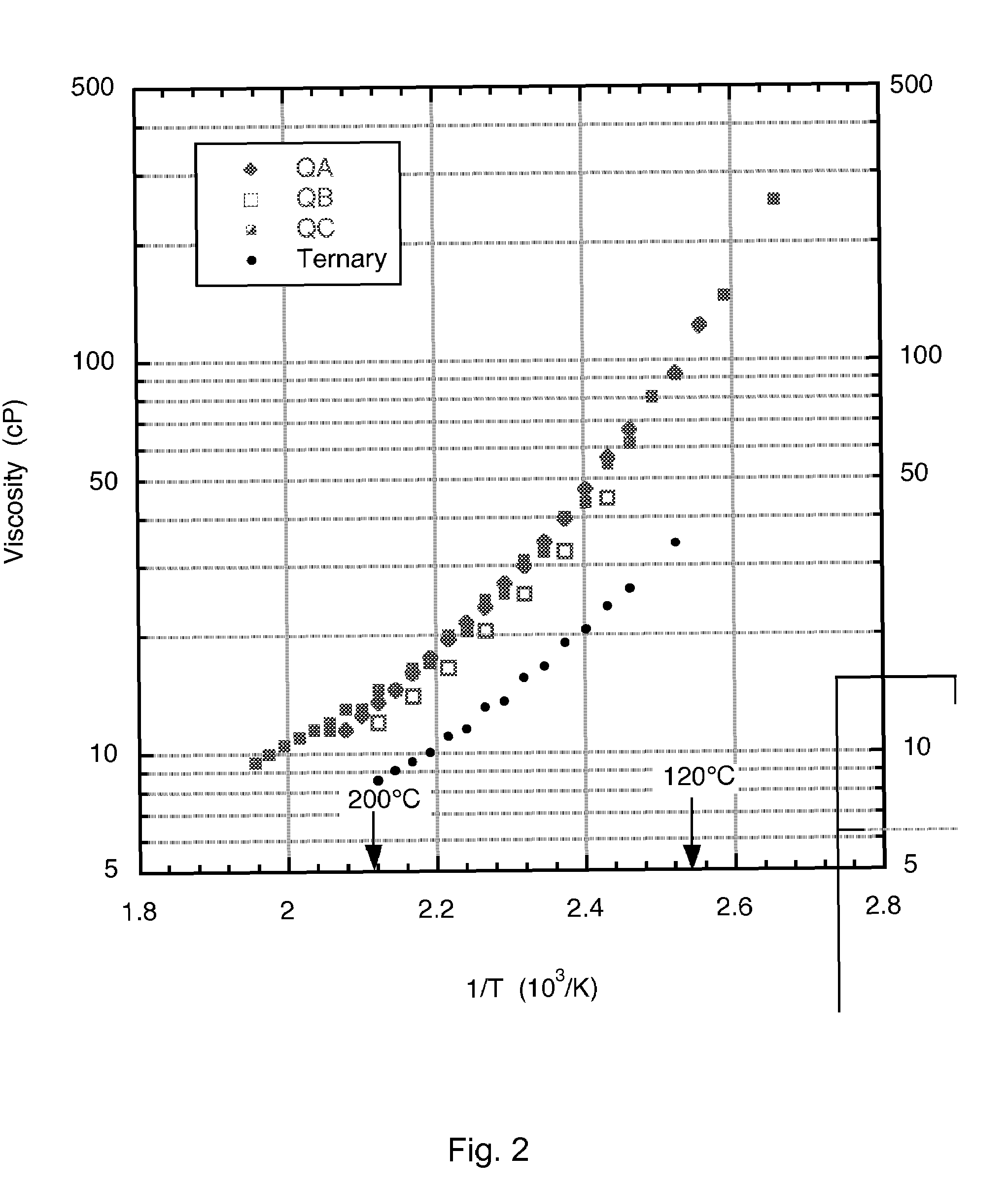

A low-melting point, heat transfer fluid made of a mixture of four inorganic nitrate salts: 9-18 wt % NaNO3, 40-52 wt % KNO3, 13-21 wt % LiNO3, and 20-27 wt % Ca(NO3)2. These compositions can have liquidus temperatures less than 100 C; thermal stability limits greater than 500 C; and viscosity in the range of 5-6 cP at 300 C; and 2-3 cP at 400 C.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

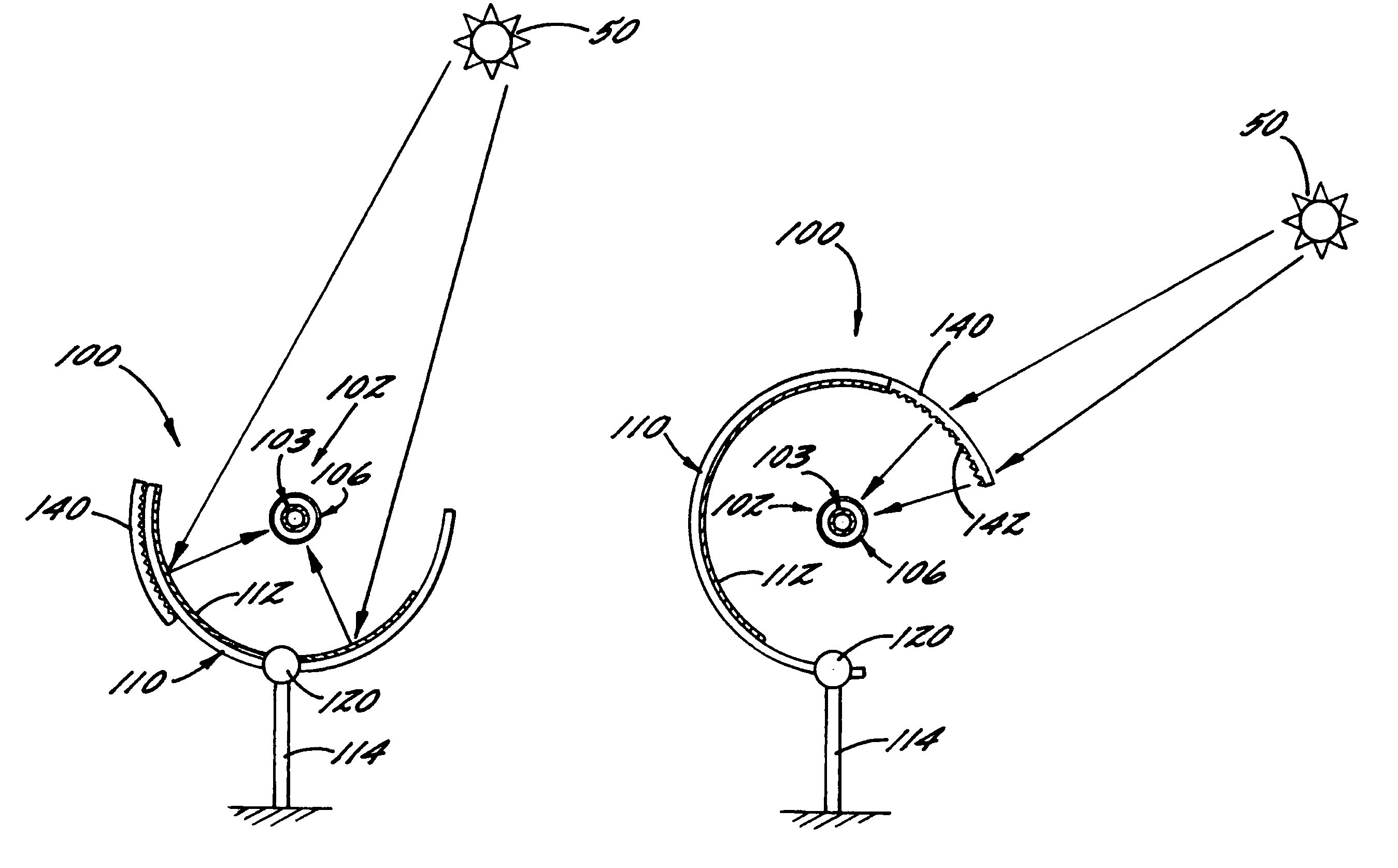

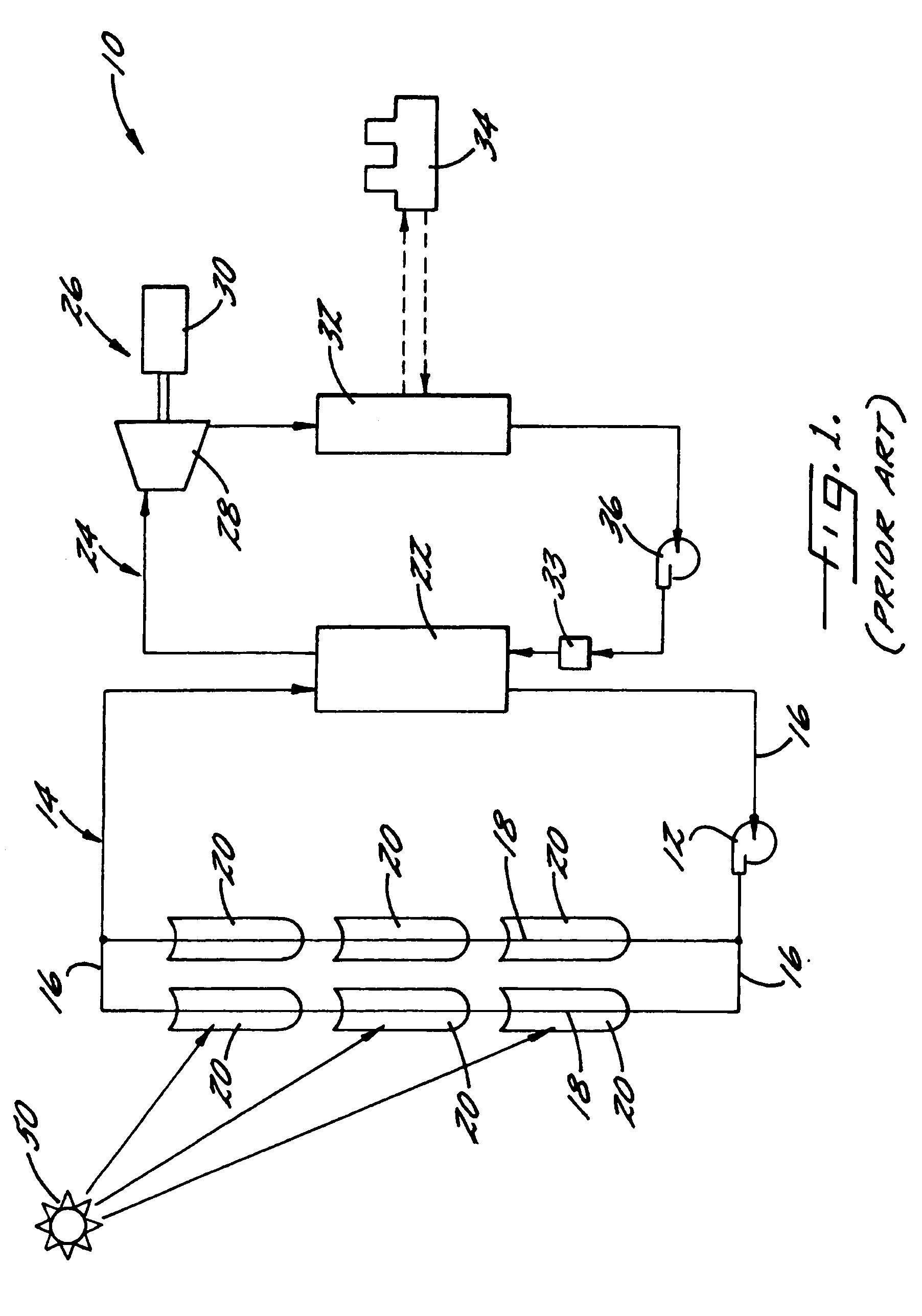

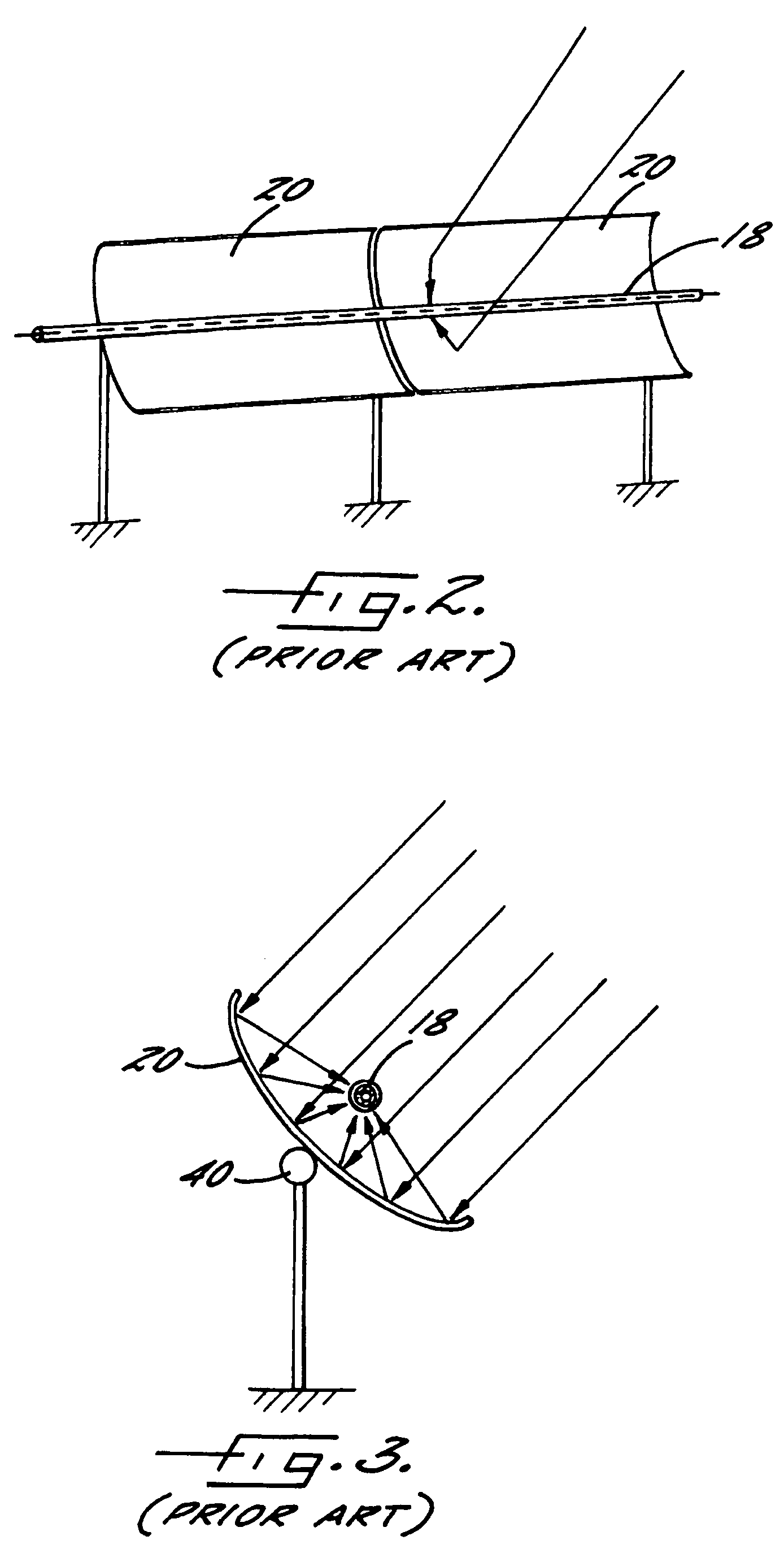

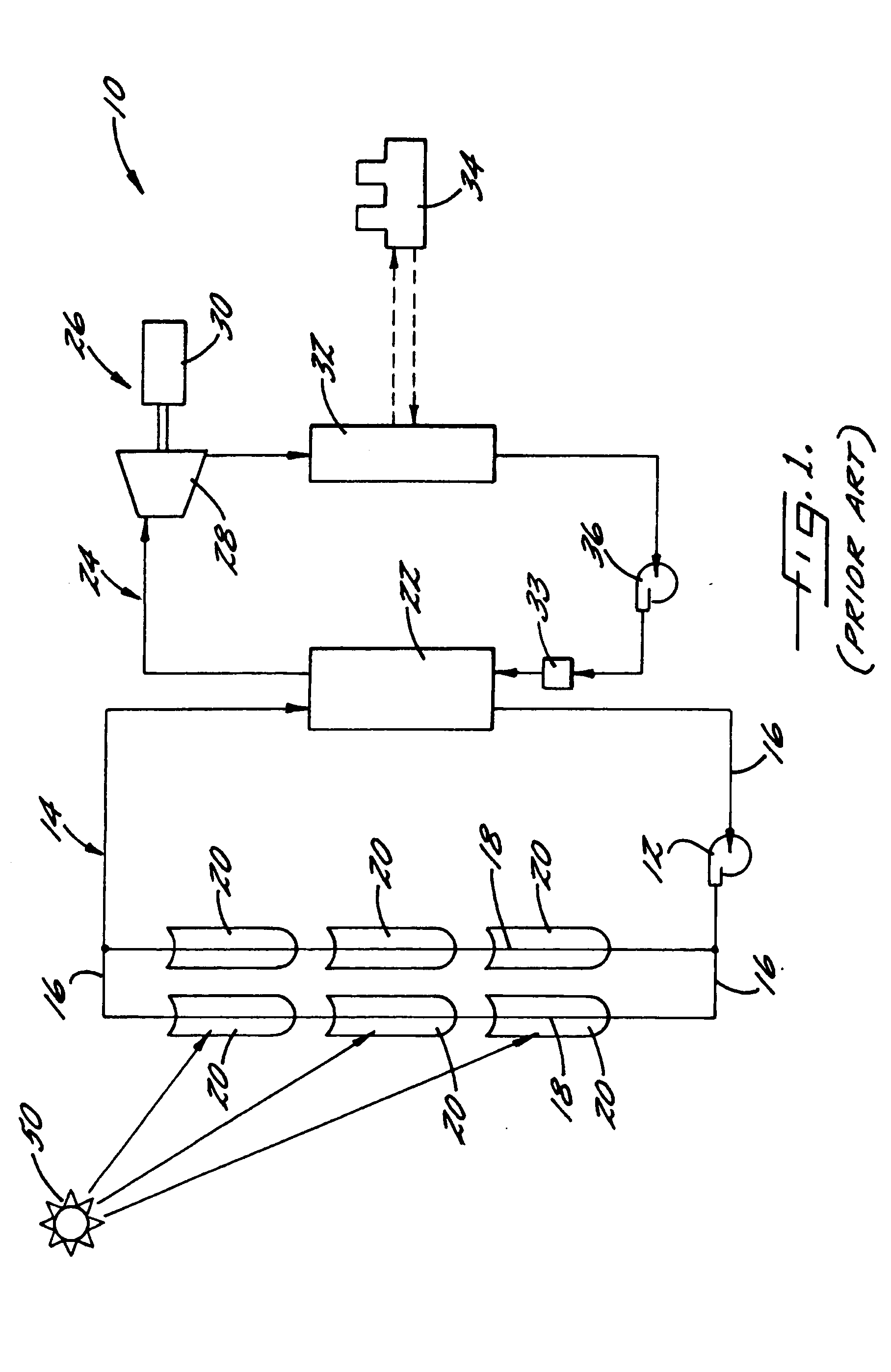

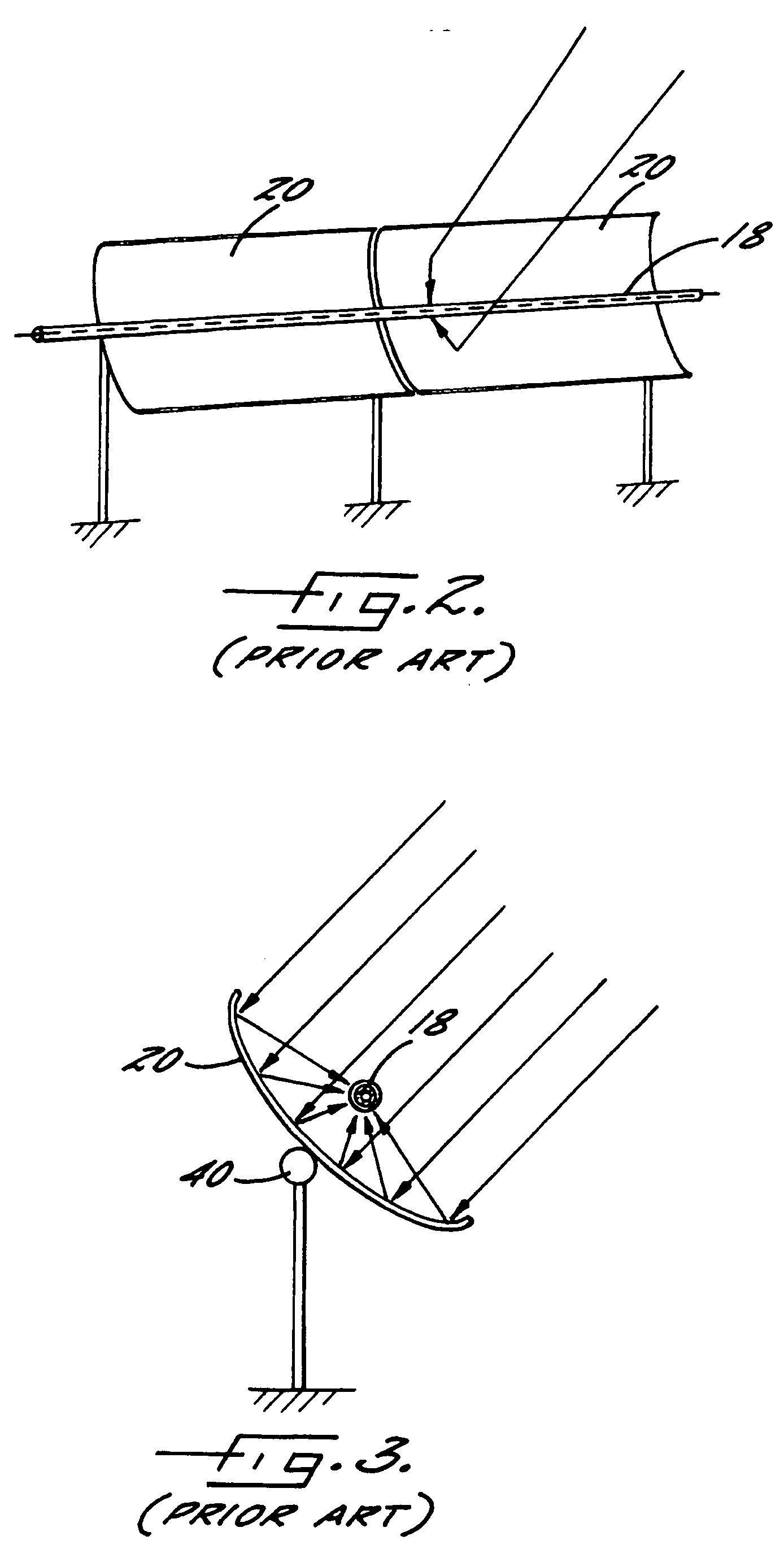

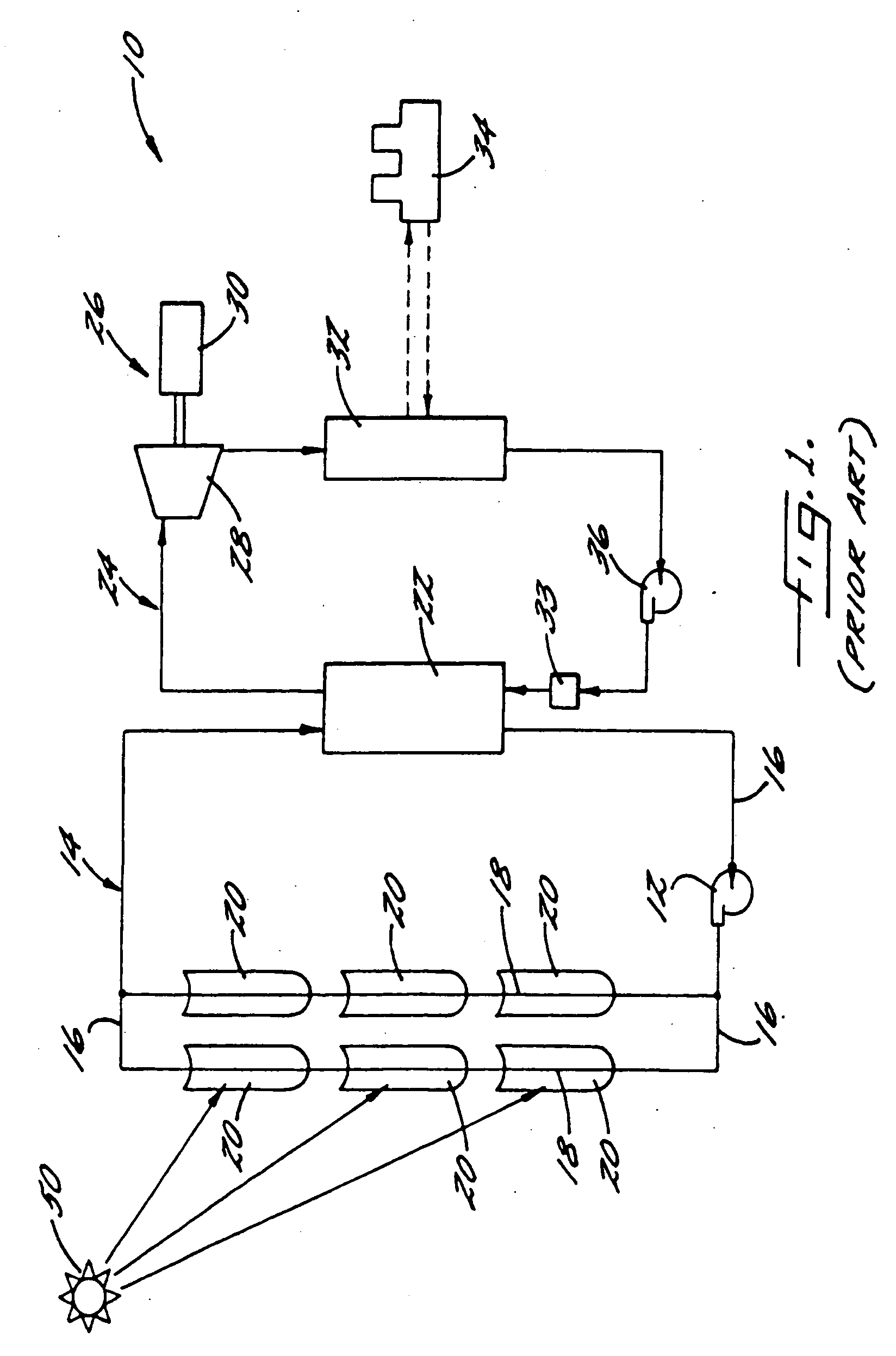

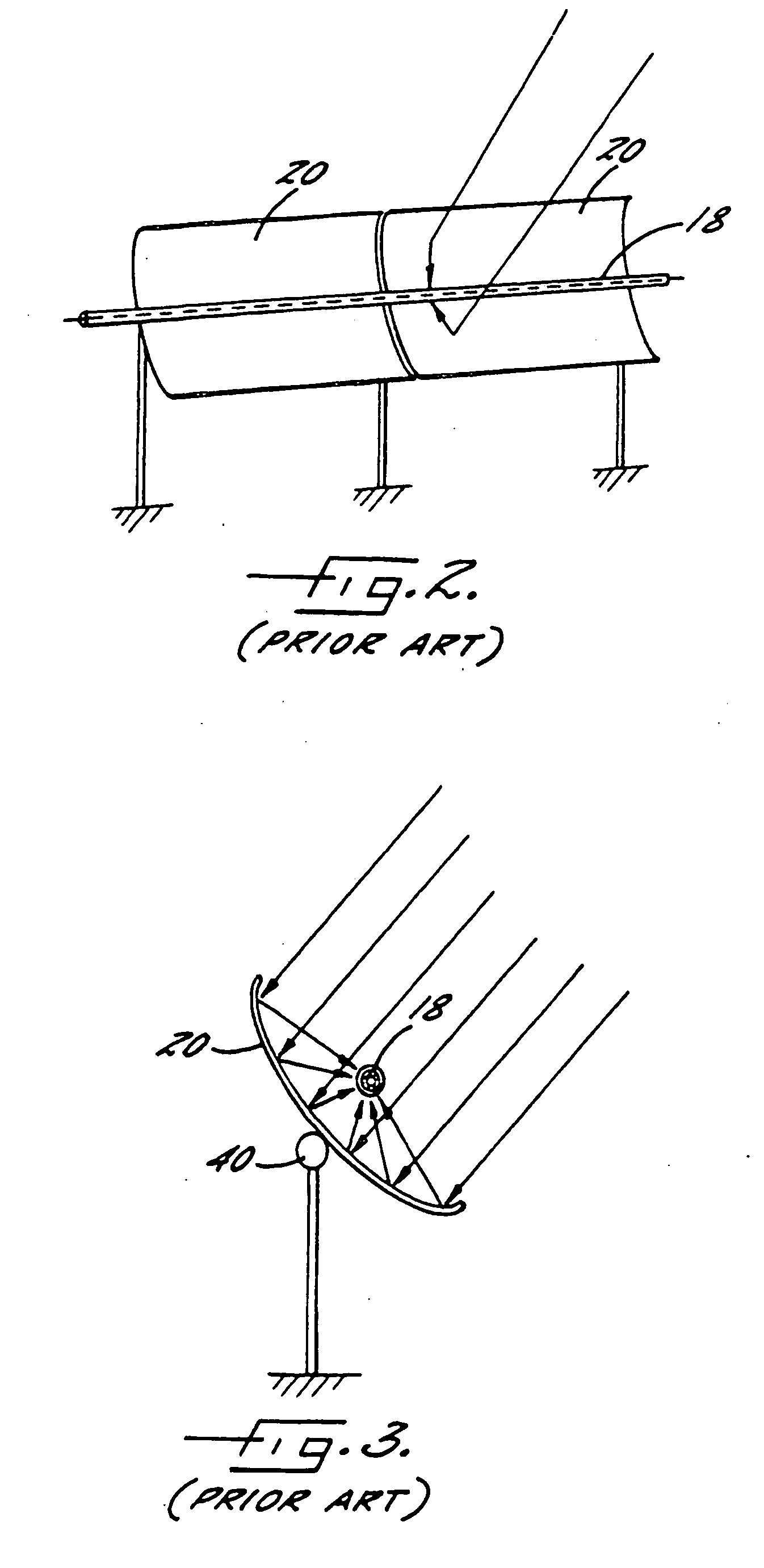

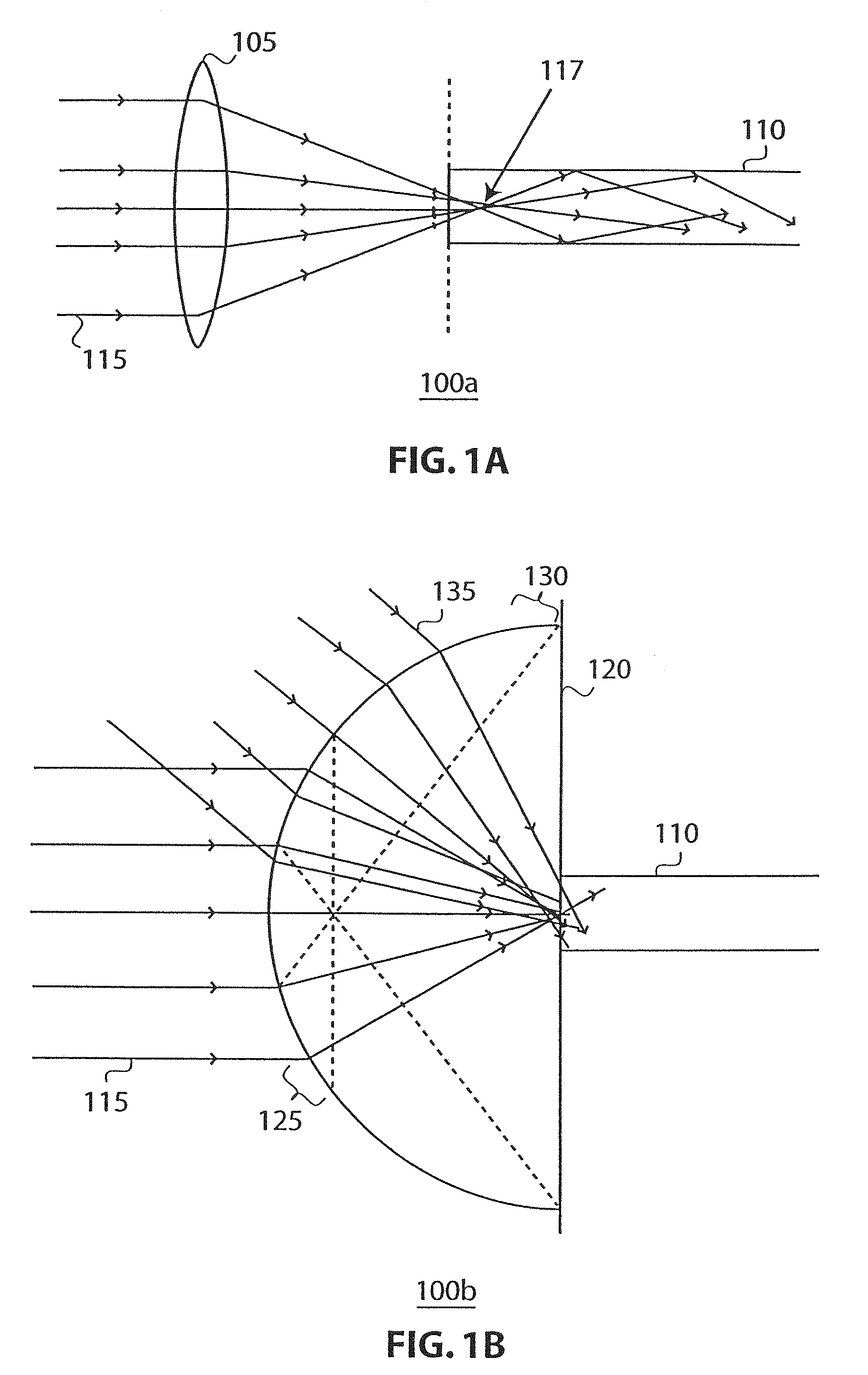

Solar collector and method

InactiveUS7055519B2Control the amount of heating of the receiverAvoid spreadingSolar heating energySolar heat collector controllersElectricityEngineering

An apparatus and method for collecting solar energy are provided. The apparatus is a trough-type solar collector having one or more mirrors and lenses for directing solar radiation toward a receiver configured to receive a heat transfer fluid therein. The amount of solar radiation directed toward the receiver can be controlled by adjusting one or more of the mirrors and / or lenses or by adjusting a shade. Thus, the collector can direct different amounts or solar radiation toward the receiver, thereby selectively heating the receiver at different rates, e.g., to preheat the receiver, to heat fluid in the receiver for power generation, or to thaw solidified fluid in the receiver. Subsequently, the heated fluid can be used to generate steam and / or electricity.

Owner:UNITED TECH CORP +2

Solar collector and method

InactiveUS20050126560A1Avoid spreadingControl the amount of heating of the receiverSolar heating energySolar heat collector controllersElectricityEngineering

An apparatus and method for collecting solar energy are provided. The apparatus is a trough-type solar collector having one or more mirrors and lenses for directing solar radiation toward a receiver configured to receive a heat transfer fluid therein. The amount of solar radiation directed toward the receiver can be controlled by adjusting one or more of the mirrors and / or lenses or by adjusting a shade. Thus, the collector can direct different amounts or solar radiation toward the receiver, thereby selectively heating the receiver at different rates, e.g., to preheat the receiver, to heat fluid in the receiver for power generation, or to thaw solidified fluid in the receiver. Subsequently, the heated fluid can be used to generate steam and / or electricity.

Owner:UNITED TECH CORP +2

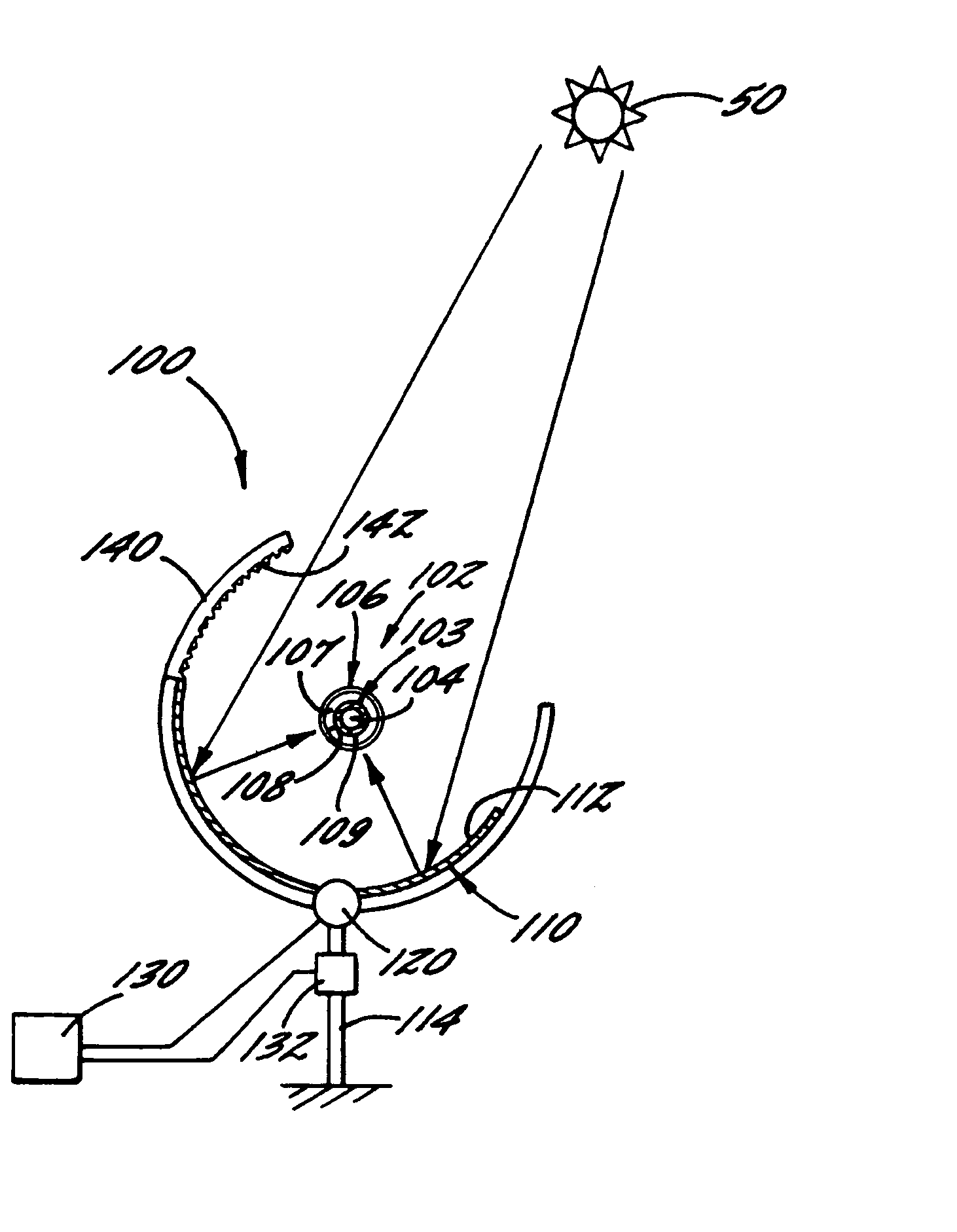

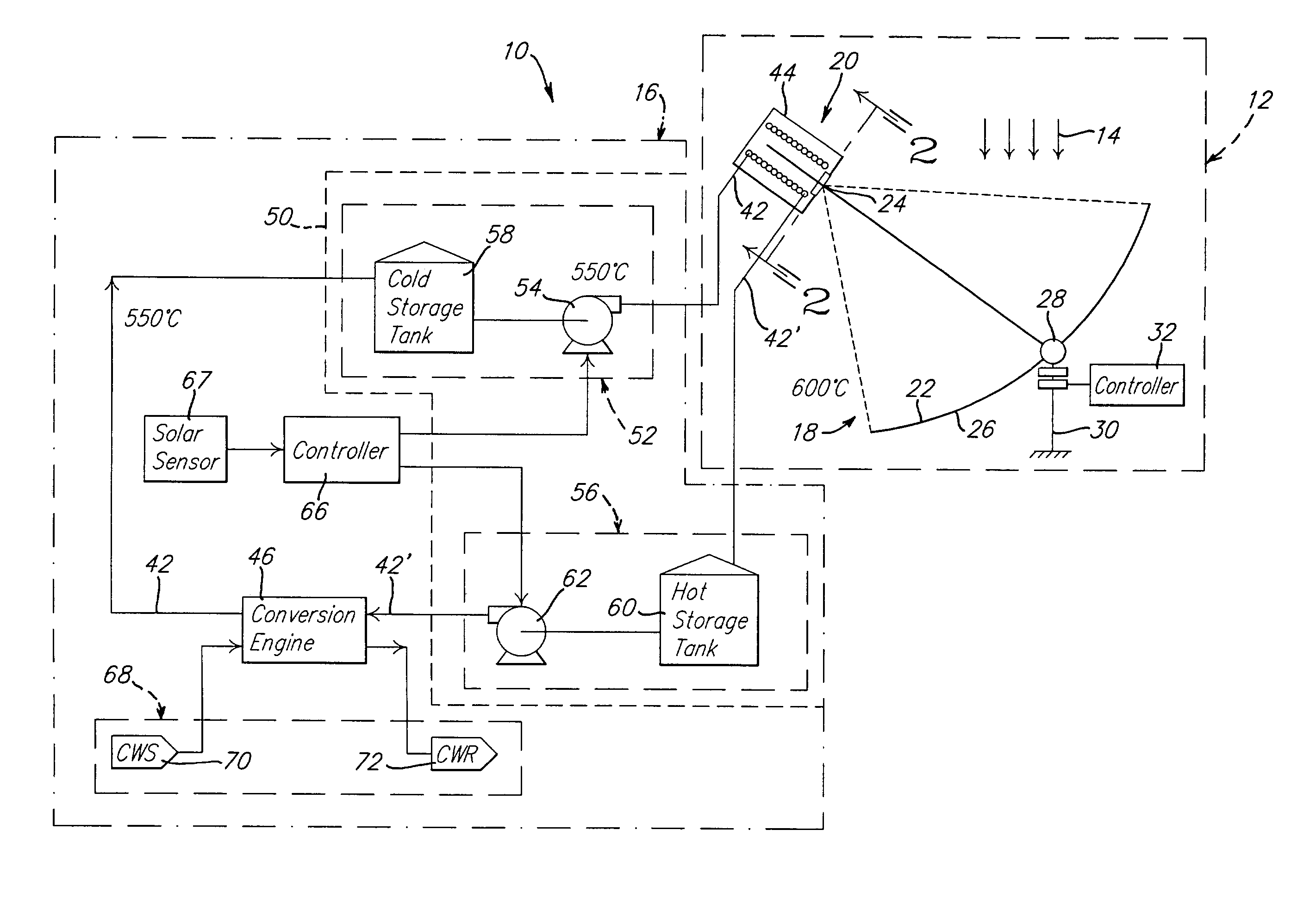

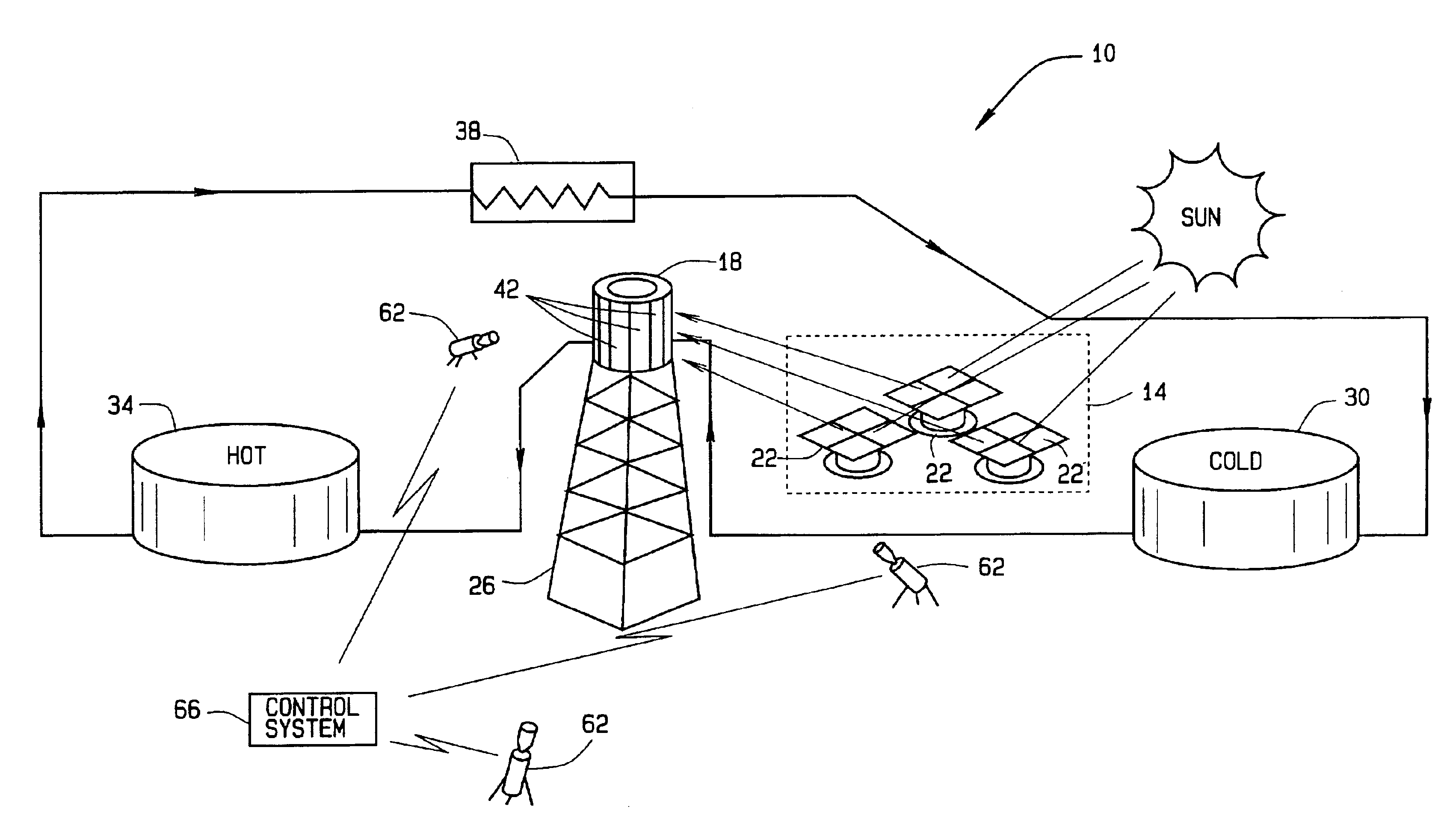

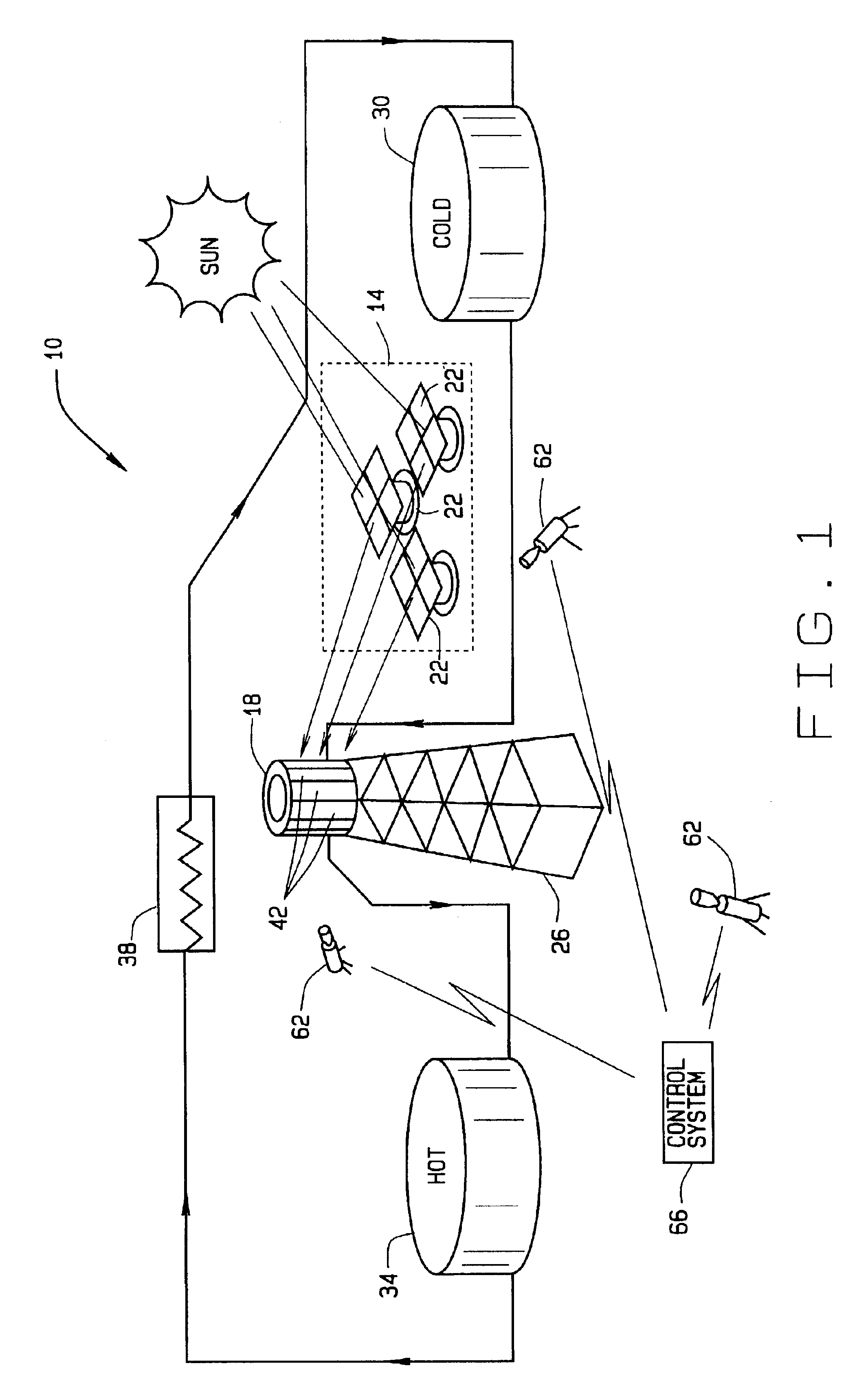

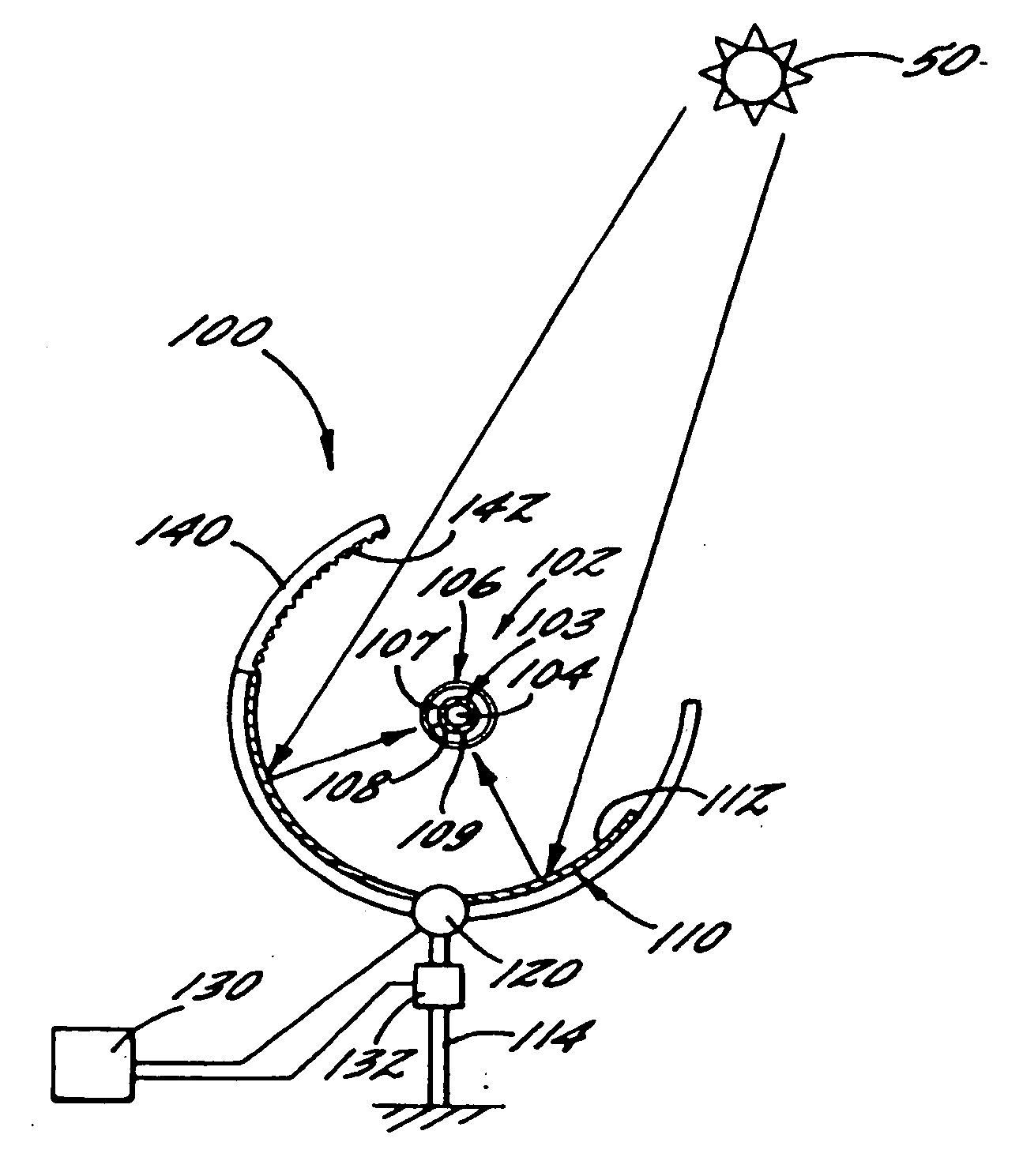

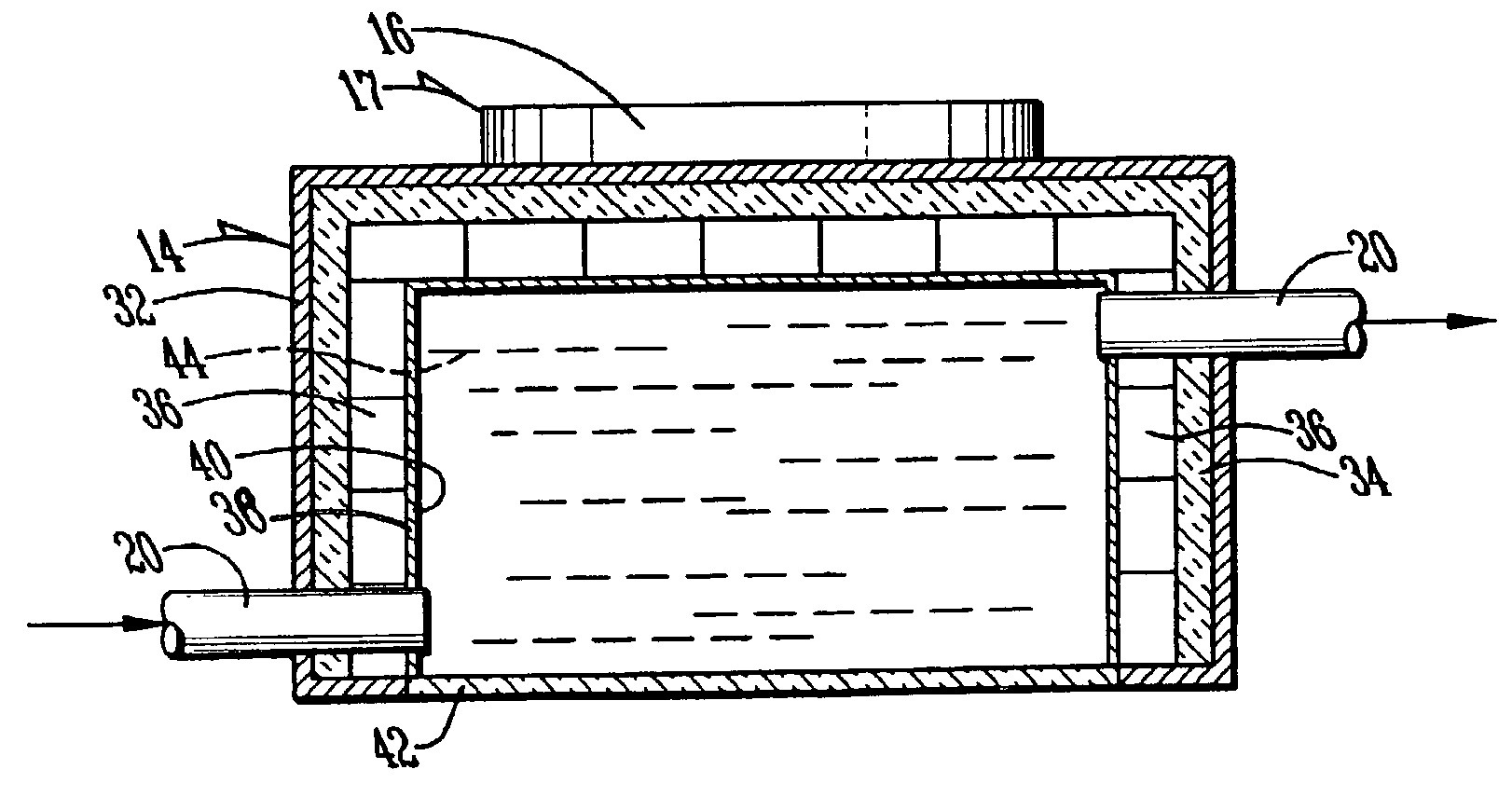

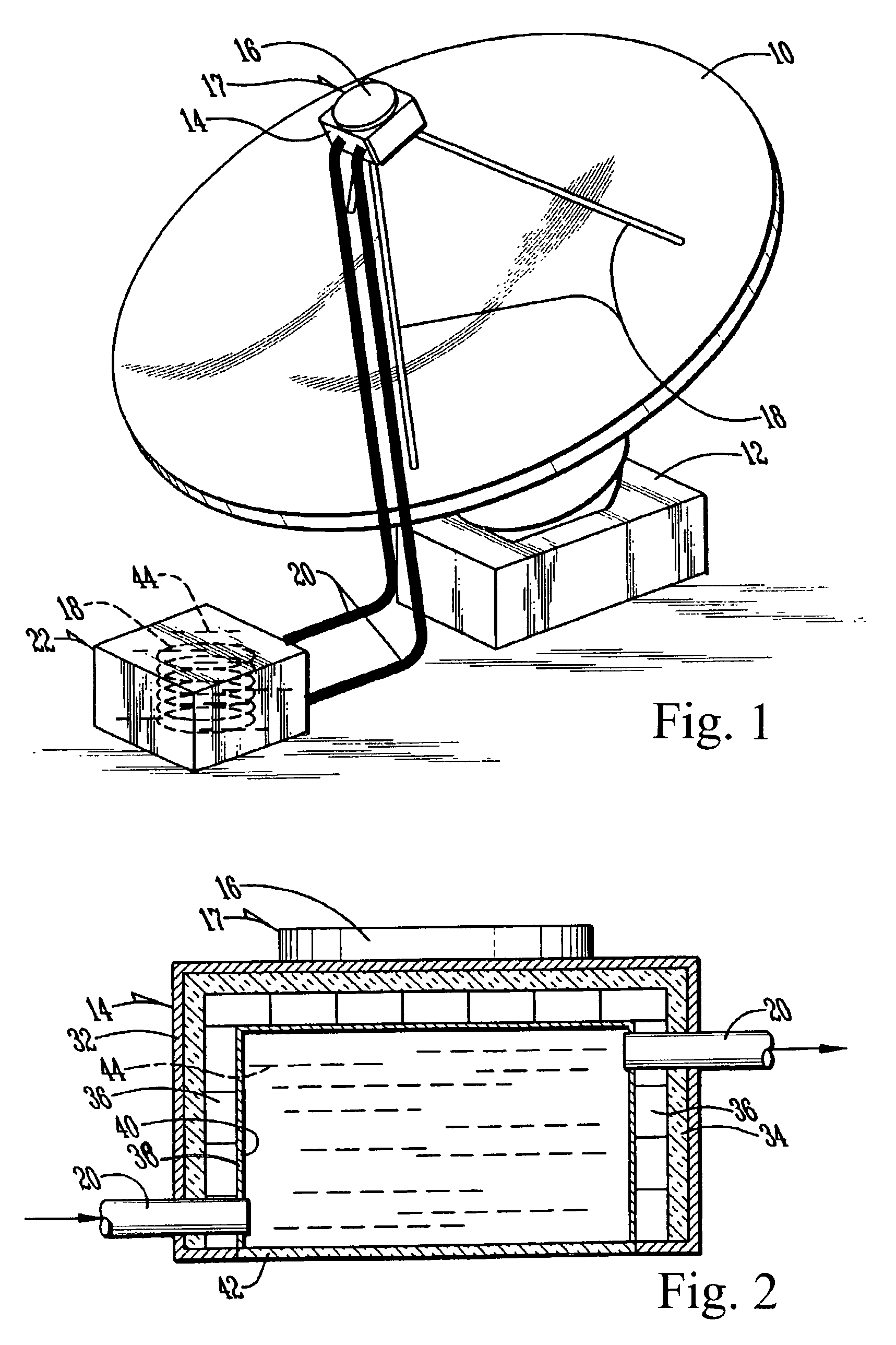

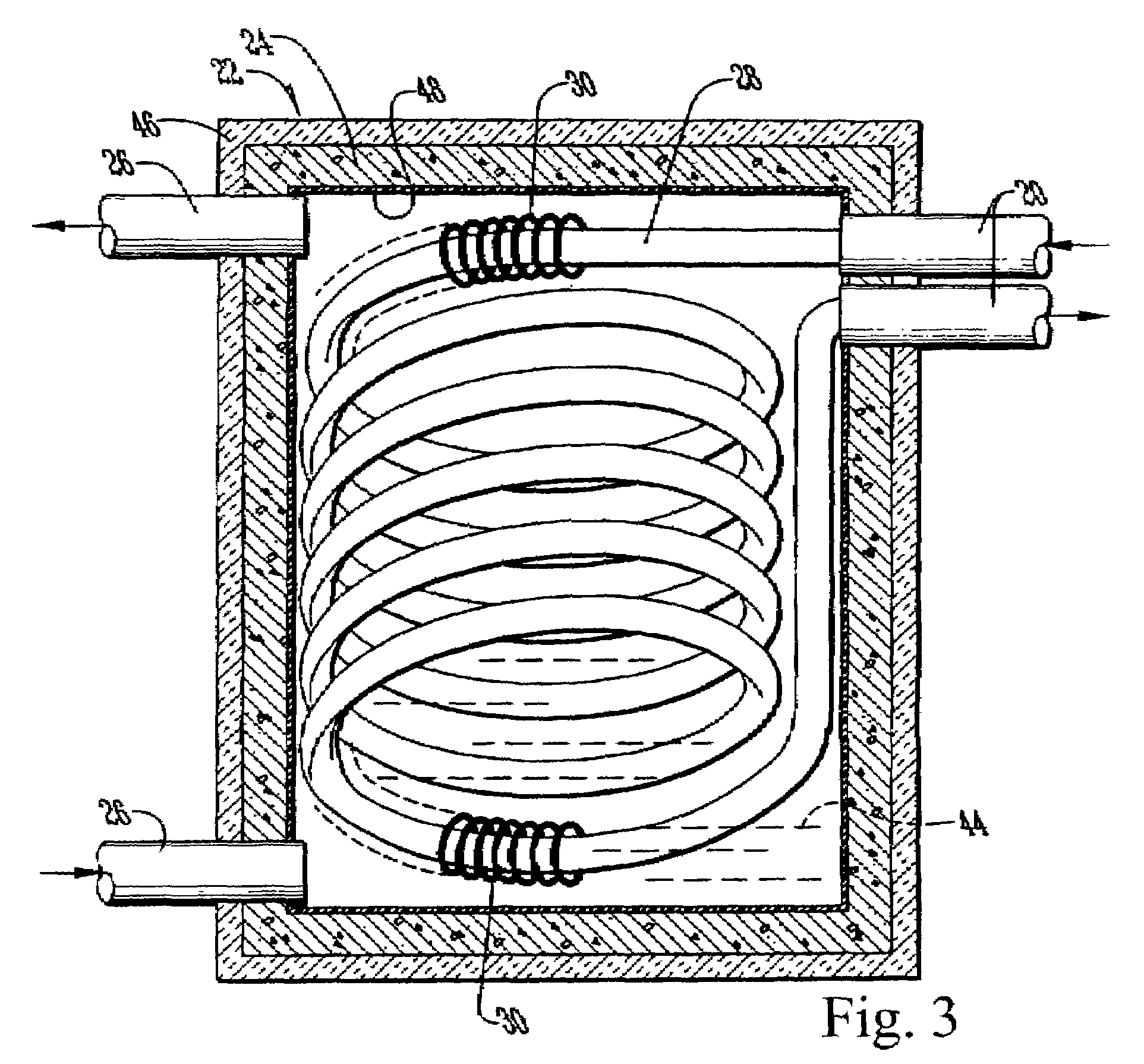

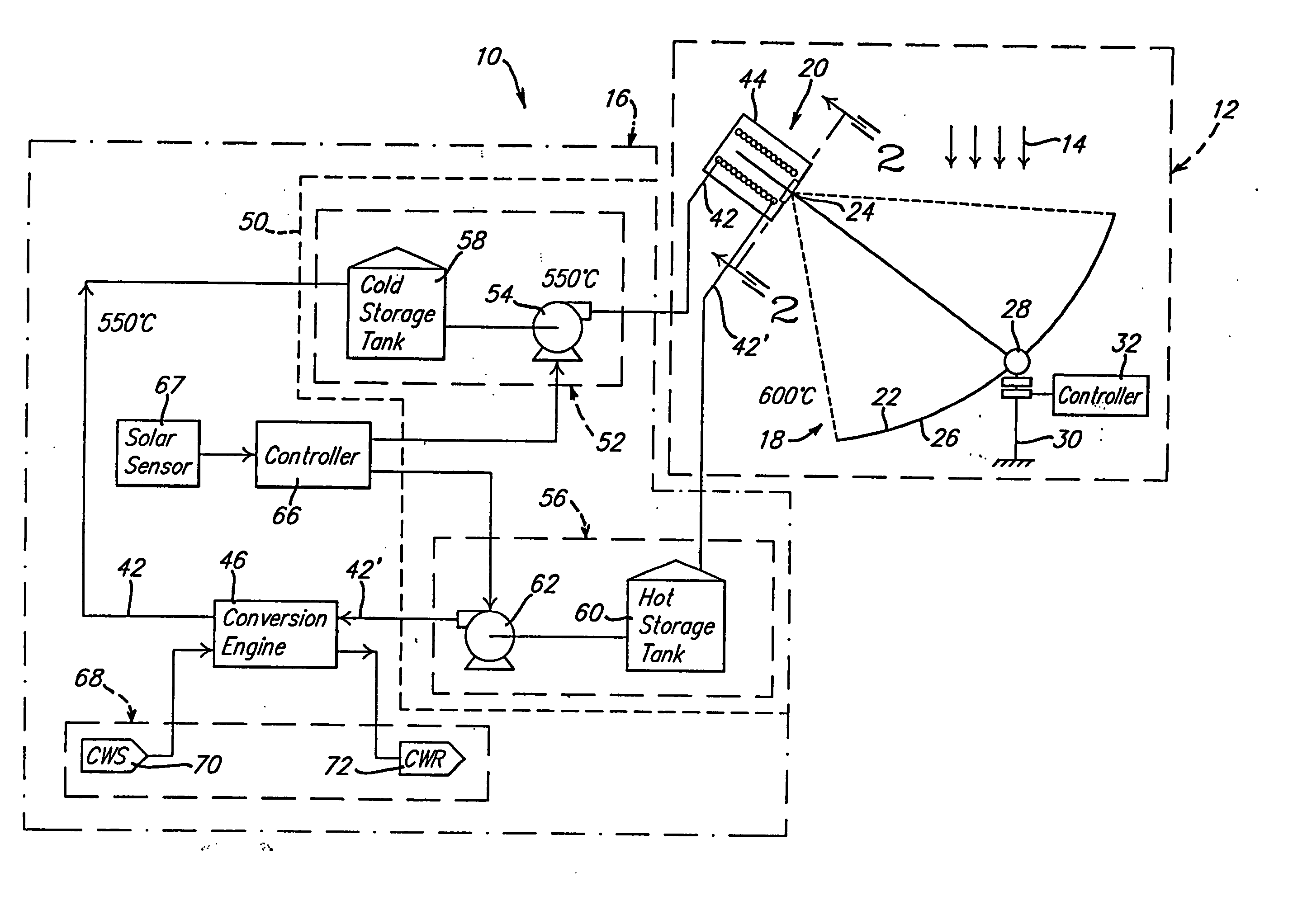

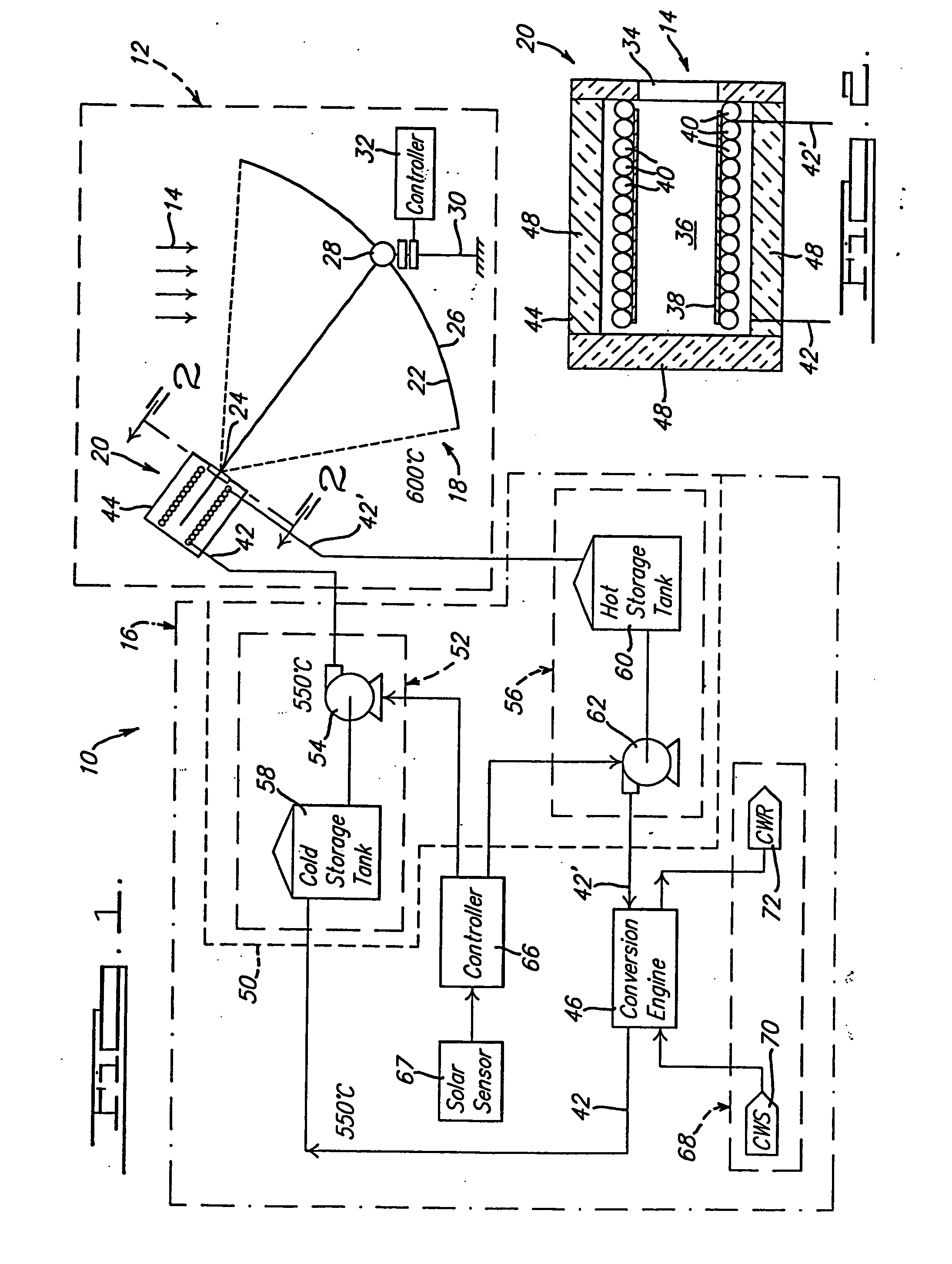

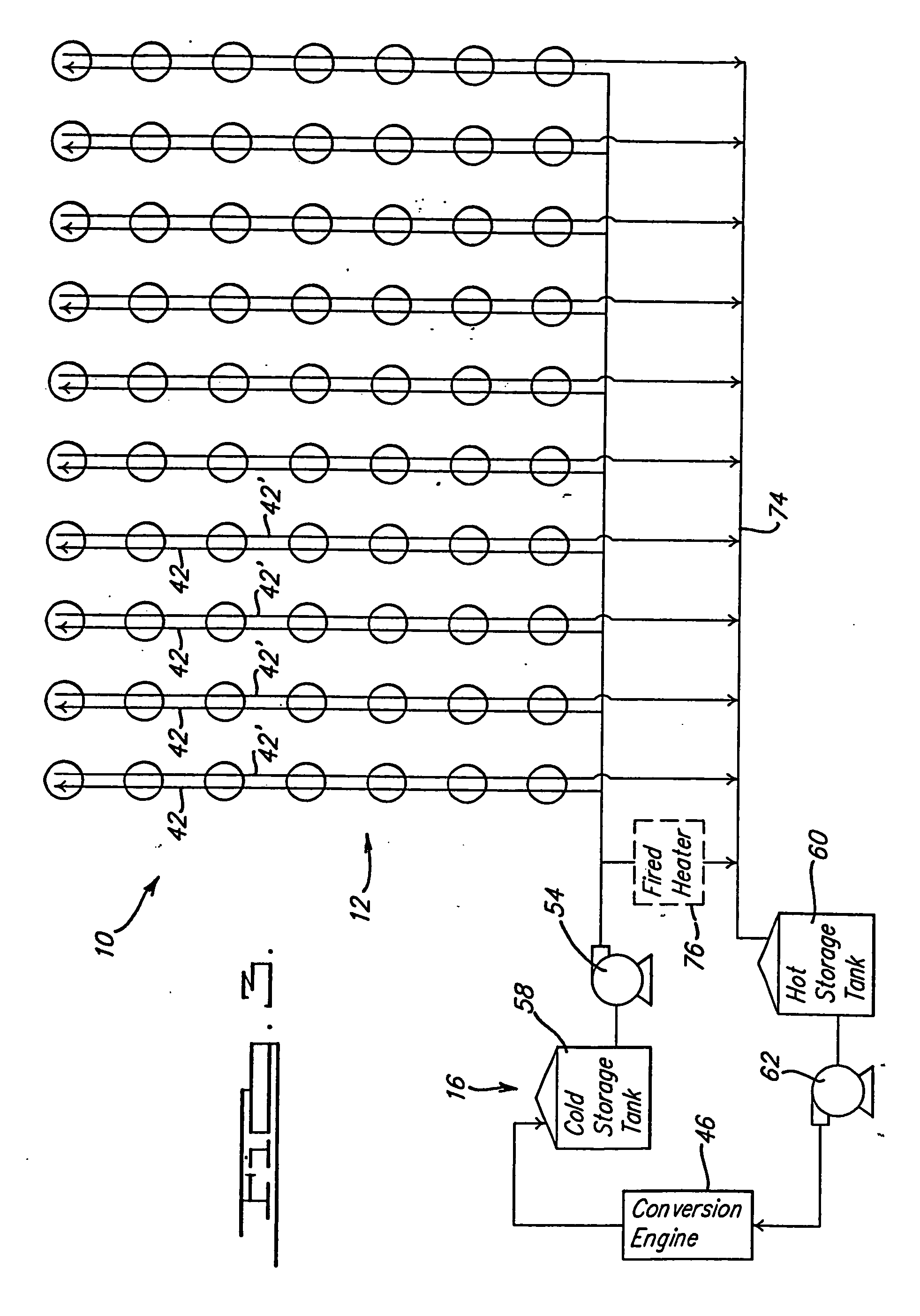

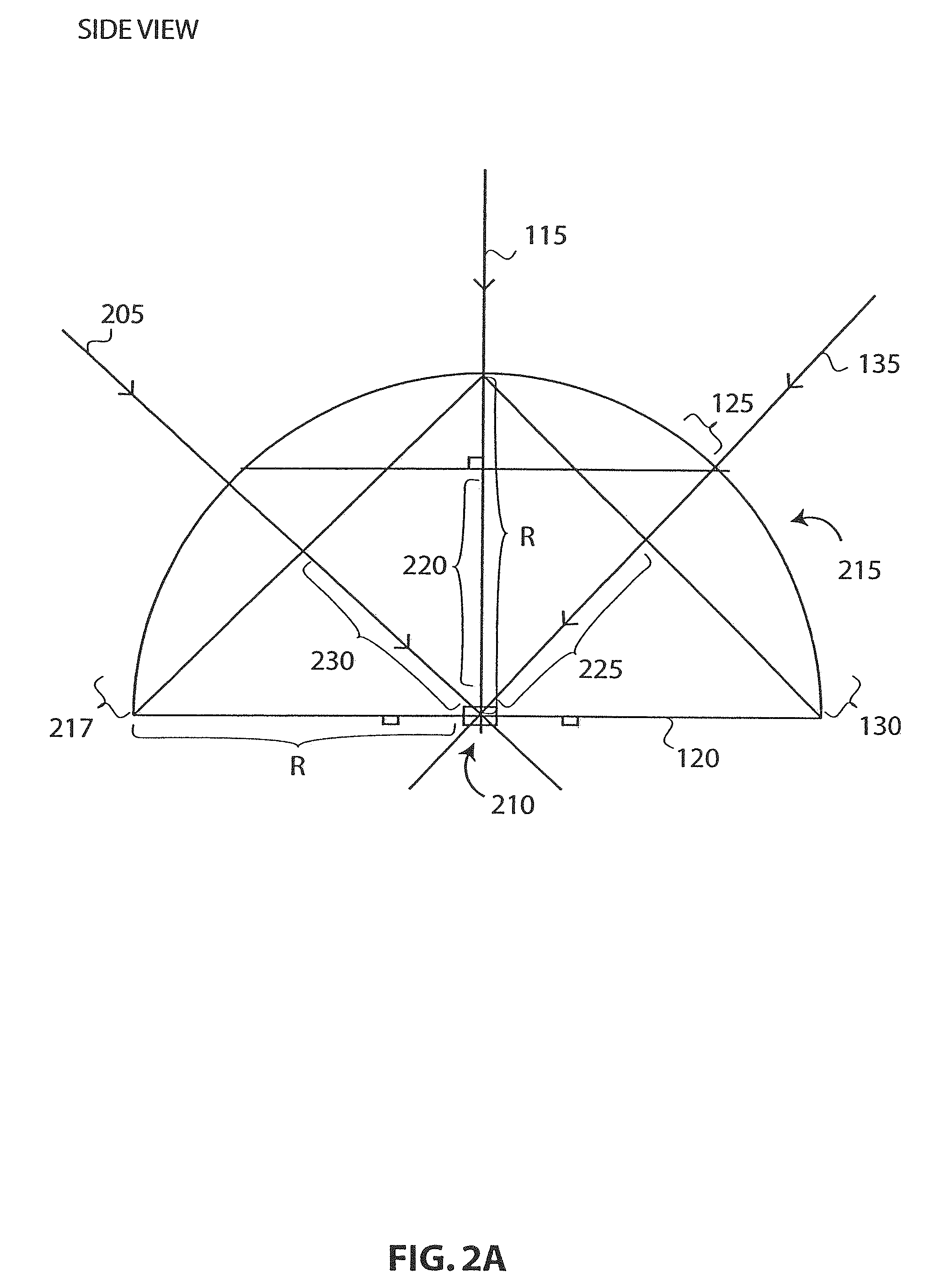

Solar dish concentrator with a molten salt receiver incorporating thermal energy storage

A solar power system capable of storing heat energy and converting sun light to electrical power. The solar power system includes a solar collection system which gathers and transmits concentrated solar energy to an absorber / cavity. The thermal energy is extracted from the absorber / cavity via a fluid and transported to a heat conversion system. The heat conversion system uses the thermal energy to create electricity.

Owner:SOLARRESERVE TECH +1

Infrared temperature sensors for solar panel

A solar receiver system for utilizing solar energy to produce electrical power and to generate a temperature profile of a plurality of receiver tubes utilized in the system. The solar receiver system includes a solar receiver having a plurality of receiver panels including the plurality of receiver tubes through which a coolant flows. Additionally, the solar receiver system includes a plurality of IR cameras adapted to view at least a portion of a surface area of the solar receiver. Each IR camera is adapted to have a field of view including a different specified region of the surface area of the solar receiver. Furthermore, the solar receiver system includes a master control system adapted to receive an IR image from each IR camera, wherein each IR image depicts surface area temperatures and variances over the region of the solar receiver viewed by each IR camera. The master control system generates a temperature profile of the surface area of the solar receiver utilizing the IR images.

Owner:UNITED TECH CORP +2

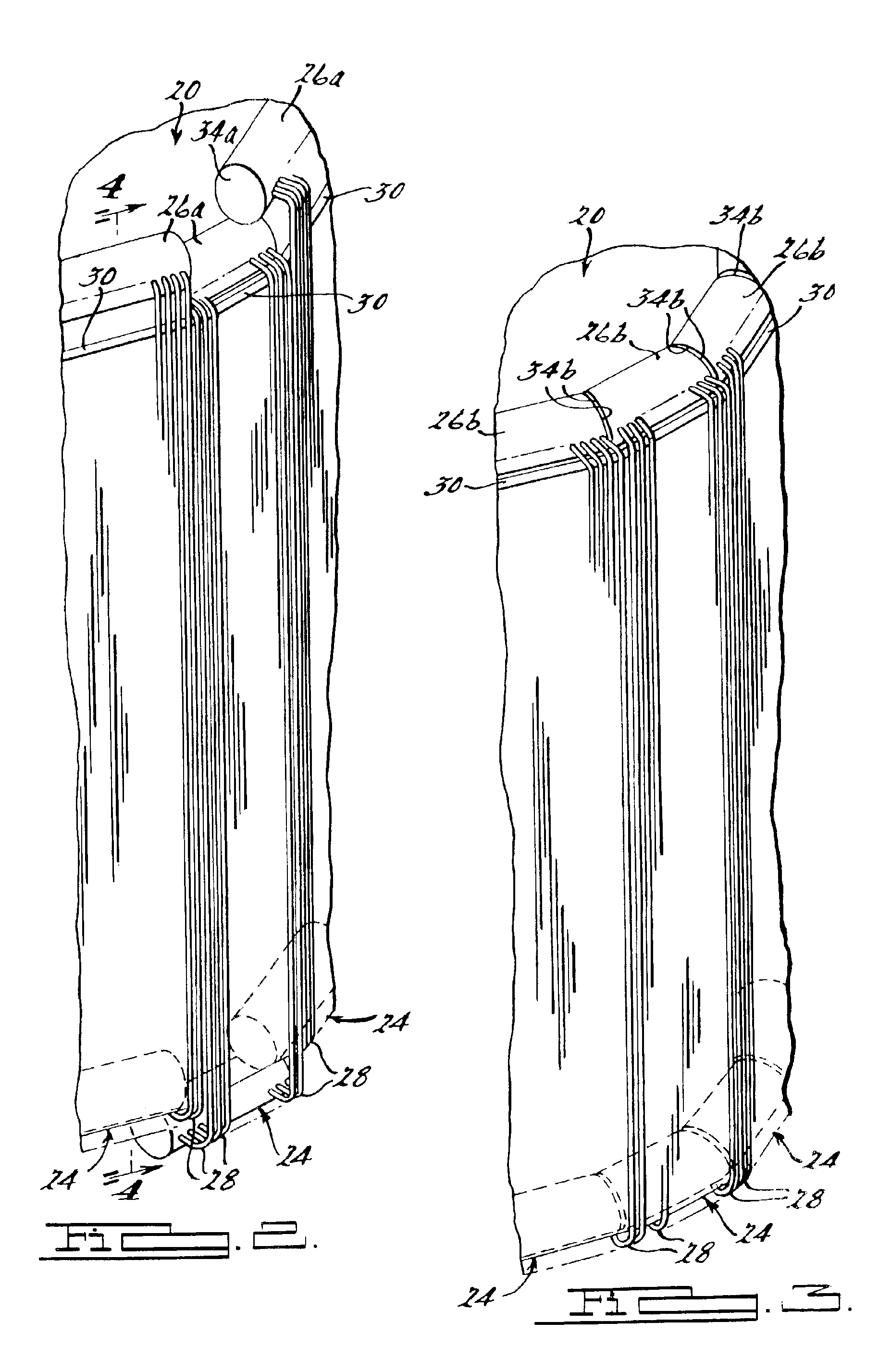

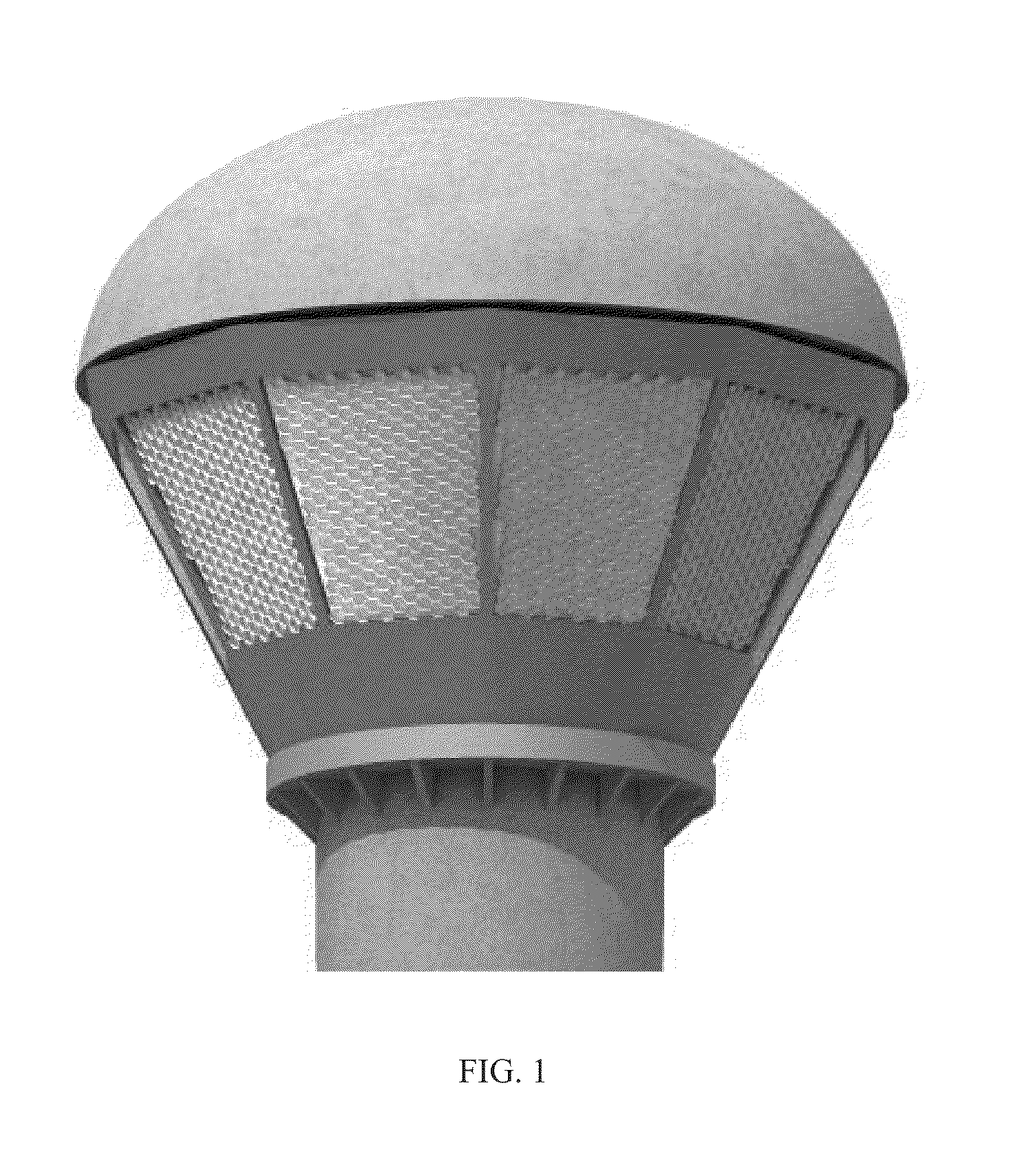

Solar central receiver with inboard headers

ActiveUS6931851B2Overcome deficienciesEliminate gapsSolar heating energyFrom solar energyTelecommunicationsCentral receiver

A solar power plant having a plurality of receiver panels mounted in a circular fashion about a solar receiver. Each receiver panel includes a plurality of tubes that terminate at each end at a header. To eliminate the presence of gaps between the tubes of adjacent receiver panels the headers are staggered or beveled. In the staggered configuration the headers of adjacent receiver panels are located in different elevations so that the headers of adjacent receiver panels may overlap each other, thus allowing the headers and tubes of adjacent receiver panels to be positioned closer together to eliminate gaps between the tubes of adjacent panels. In the beveled configuration the headers are angled such that the terminal ends of adjacent headers are parallel and positioned in a closely abutting relationship, resulting in the absence of gaps between adjacent headers and tubes.

Owner:SOLARRESERVE TECH

Solar collector and method

InactiveUS20060225729A1Control the amount of heating of the receiverAvoid spreadingSolar heating energySolar heat collector controllersElectricityEngineering

An apparatus and method for collecting solar energy are provided. The apparatus is a trough-type solar collector having one or more mirrors and lenses for directing solar radiation toward a receiver configured to receive a heat transfer fluid therein. The amount of solar radiation directed toward the receiver can be controlled by adjusting one or more of the mirrors and / or lenses or by adjusting a shade. Thus, the collector can direct different amounts or solar radiation toward the receiver, thereby selectively heating the receiver at different rates, e.g., to preheat the receiver, to heat fluid in the receiver for power generation, or to thaw solidified fluid in the receiver. Subsequently, the heated fluid can be used to generate steam and / or electricity.

Owner:SOLARRESERVE TECH

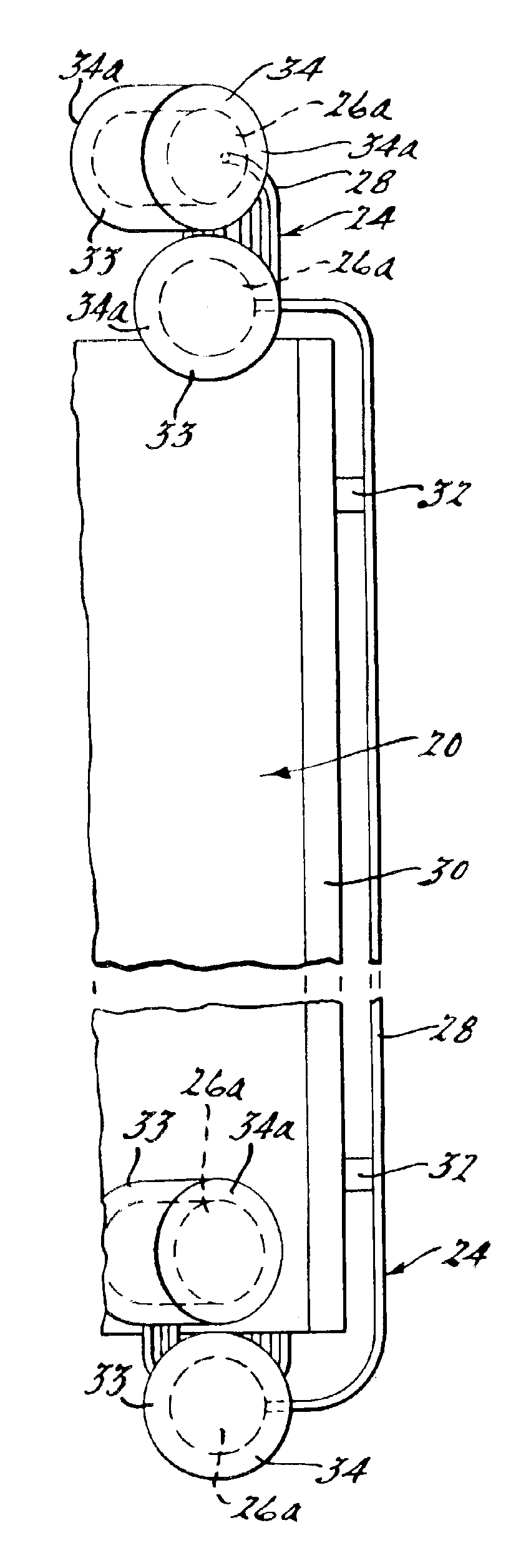

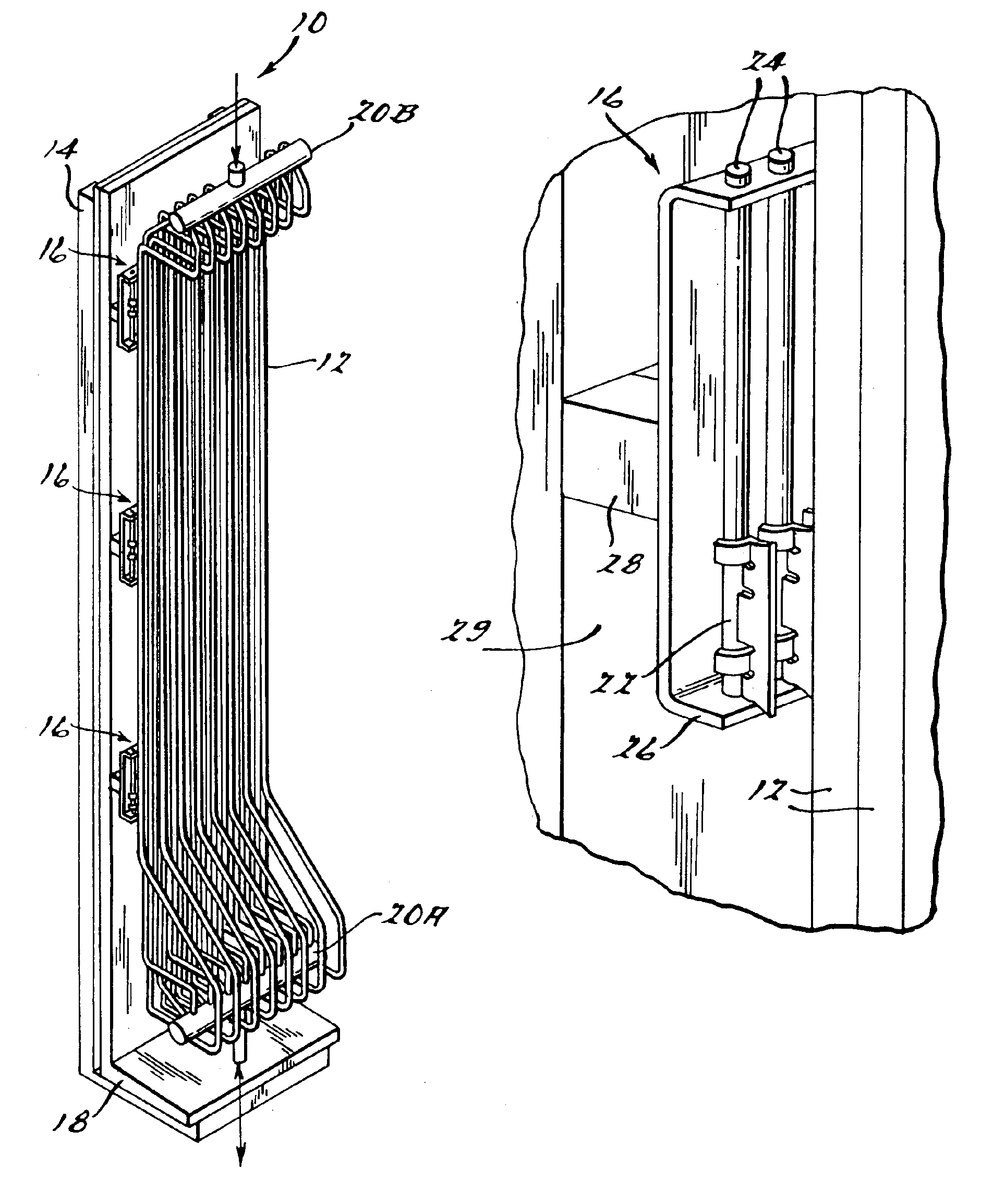

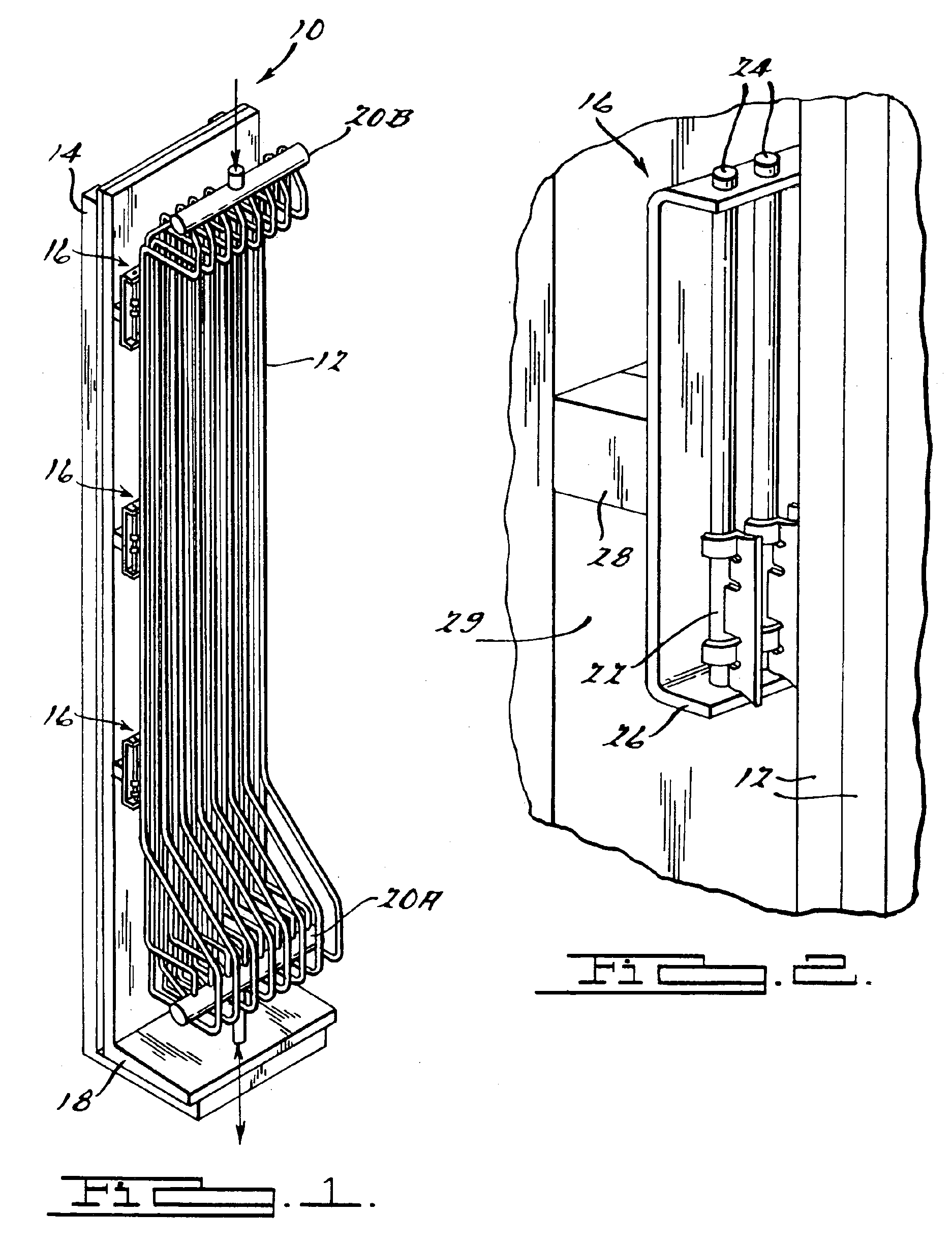

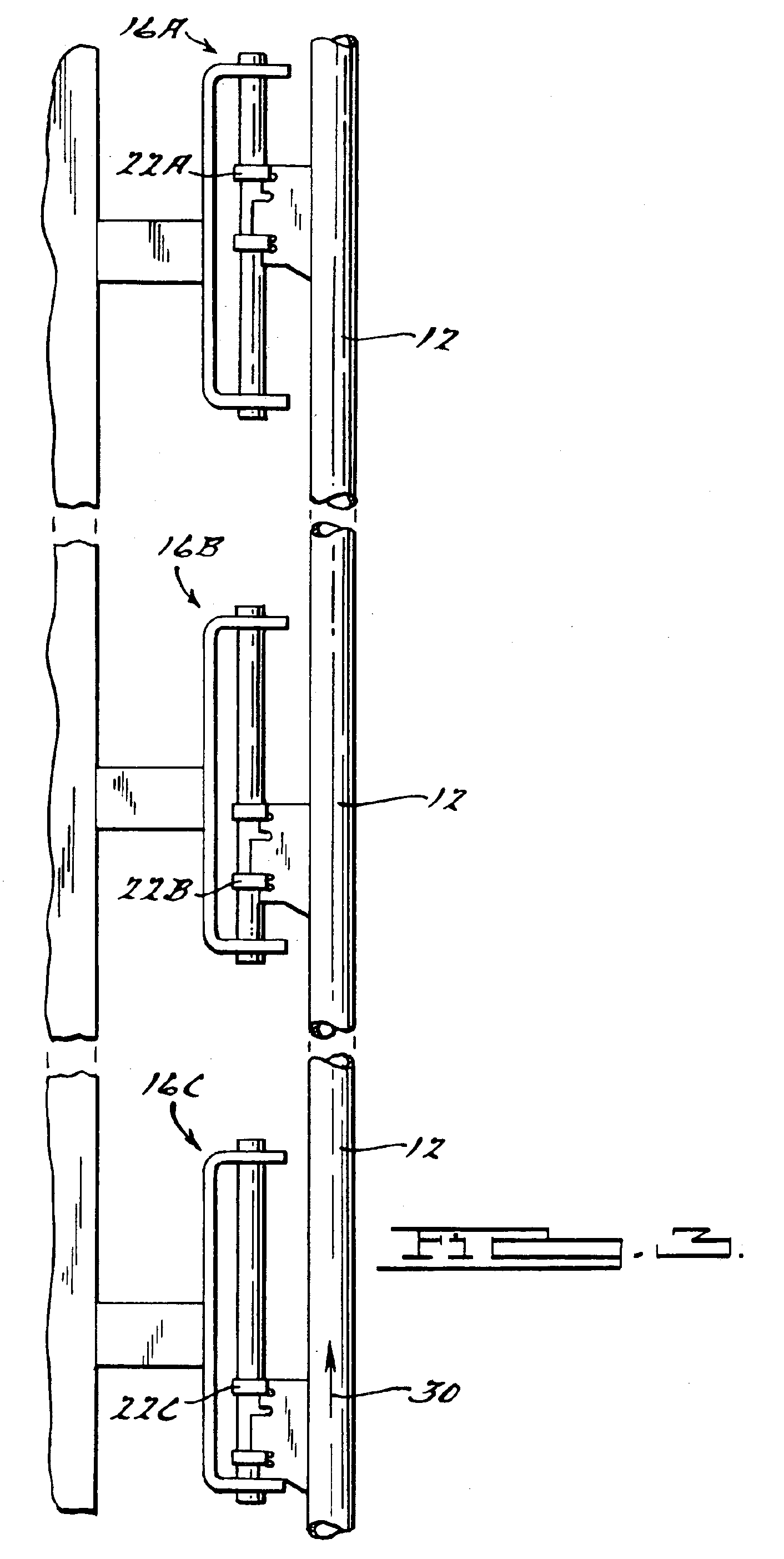

Bottom supported solar receiver panel apparatus and method

ActiveUS7011086B2Shorten piping lengthEasy maintenanceSolar heating energySolar heat devicesEngineeringPiping

A bottom supported solar receiver tube / header assembly having a bottom clip for supporting the entire load of a plurality of tubes carrying a heat absorbing fluid. The tubes are allowed to expand vertically upwardly under thermal flux conditions created when the fluid absorbs heat from the solar receiver panel. A receiver panel assembly incorporating a plurality of the bottom supported receiver tubes requires less piping than a comparably sized, conventional receiver panel assembly with top supported tubes and even better facilitates access and maintenance of valves associated with the receiver panel assembly. The invention further allows a solar receiver panel assembly to be constructed with significantly fewer drain and vent valves than previously developed, top supported receiver panel assemblies.

Owner:SOLARRESERVE TECH +1

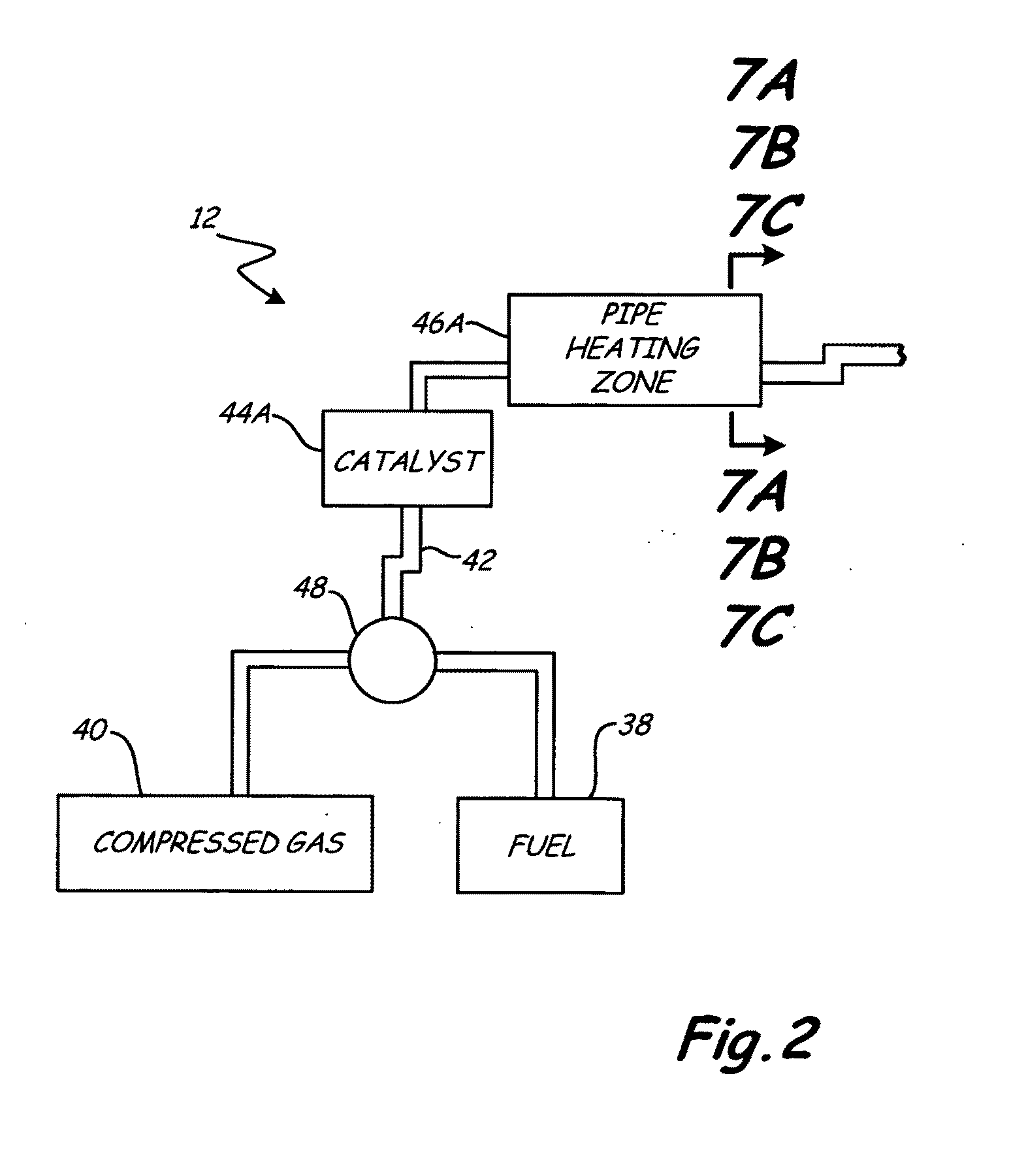

Catalyzed hot gas heating system for concentrated solar power generation systems

A solar power generation system includes a fluid housing, a solar collector, and a heating system. The fluid housing contains a heat transfer medium. The solar collector concentrates solar energy onto the heat transfer medium. The heating system includes at least one gas tank containing a gas and fluidically connected to a first catalyst. The first catalyst is configured to catalyze gas from the gas tank to create hot gas. The heating system also includes a first hot gas pipe fluidically connected to the first catalyst and positioned with respect to the fluid housing such that hot gas flowing through the first hot gas pipe comes into thermal contact with the heat transfer medium within the fluid housing.

Owner:SOLARRESERVE TECH

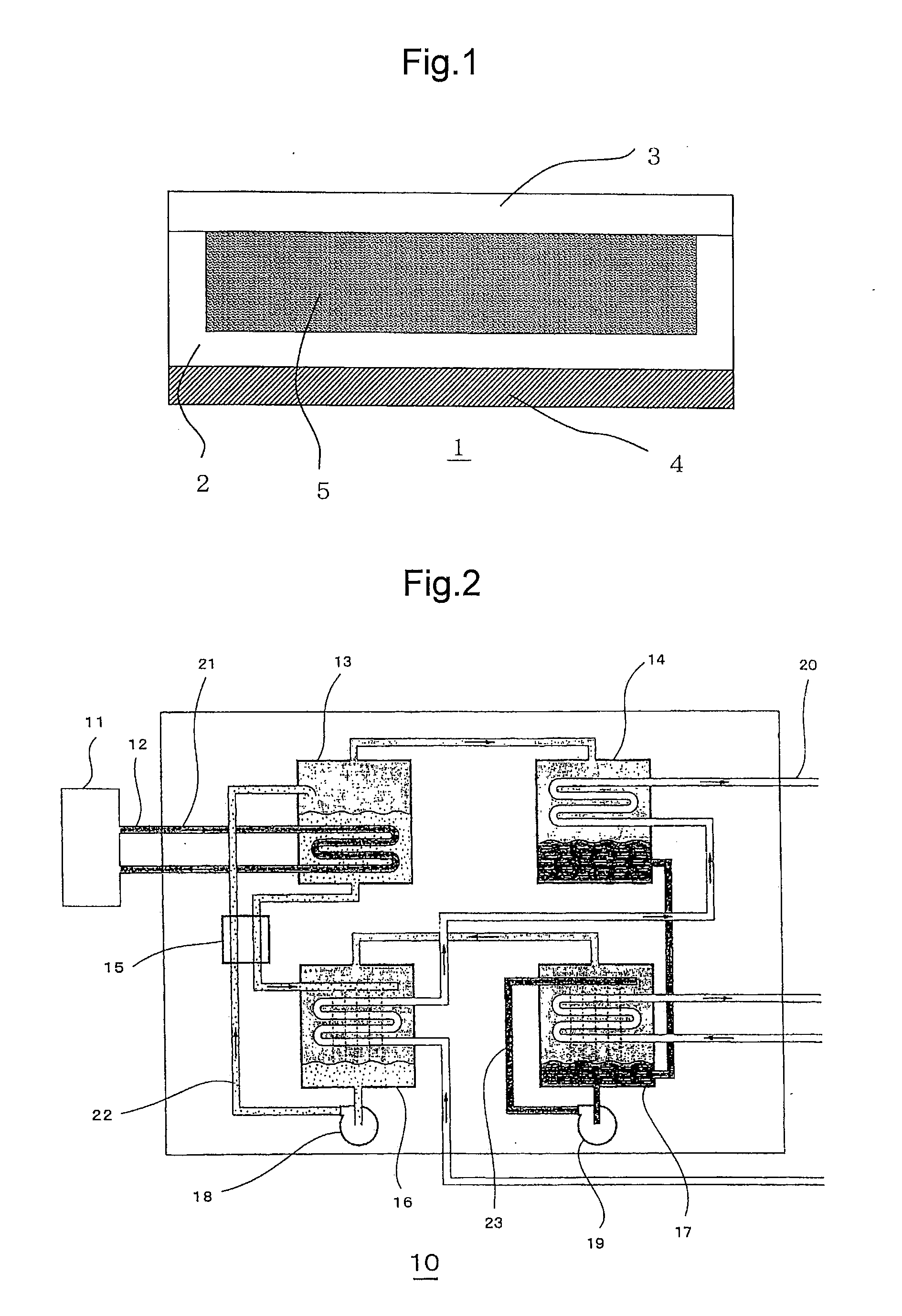

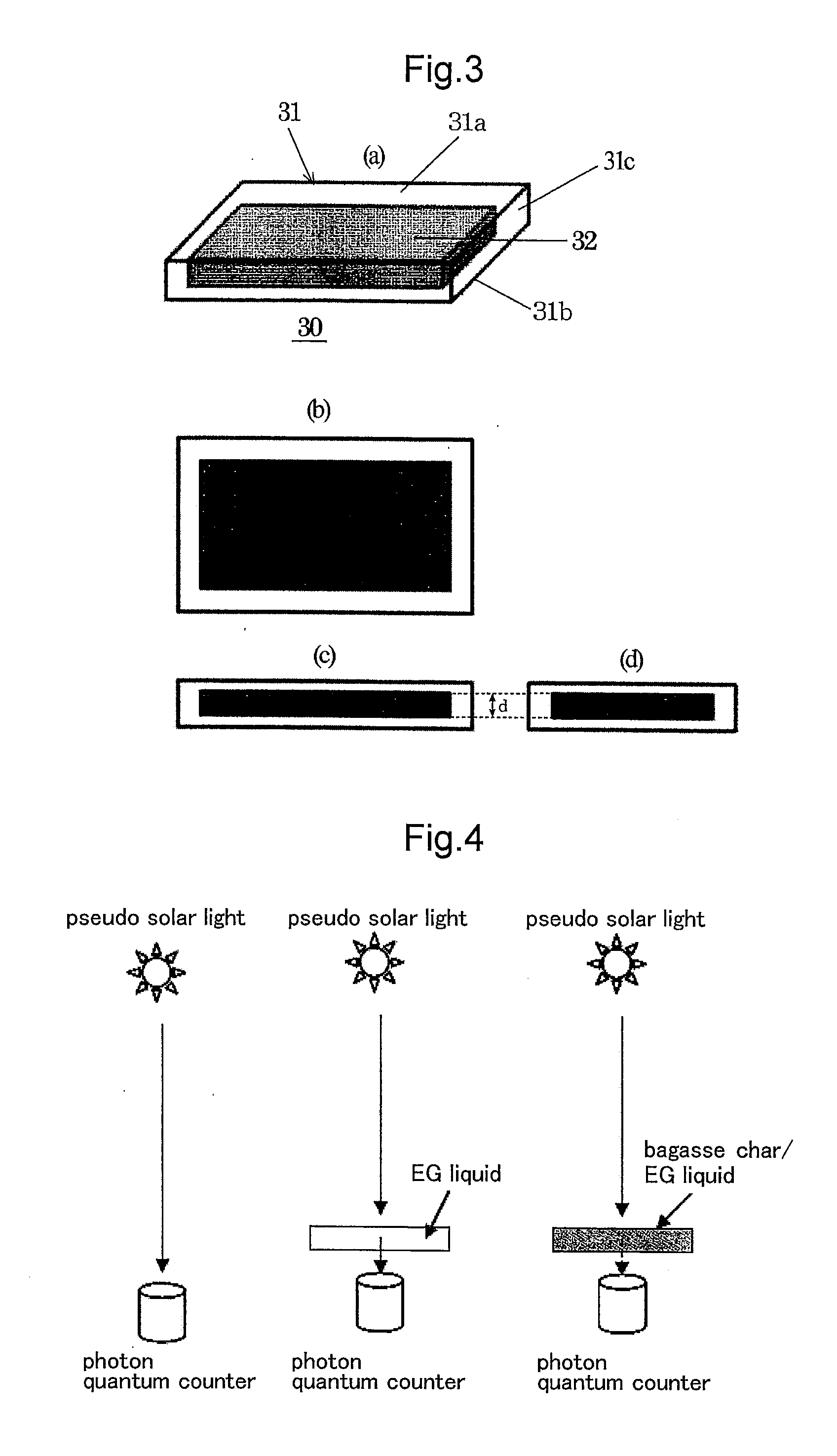

Solar Light (Heat) Absorption Material and Heat Absorption/Accumulation Material and Solar Light (Heat) Absorption/Control Building Component Using the Same

InactiveUS20120017622A1Light absorbing abilityEfficient use ofSolar heating energySolar heat devicesSolar lightLiquid medium

A solar light (heat) absorption material is provided which has an excellent solar light (heat) absorbing ability and a simple structure, and may be usable as a low-cost and high-performance heat absorption / accumulation material, the inventive material being usable also as a solar light (heat) absorption / control building component that allows easy change of its solar light (heat) absorption / control ability. The material comprises particles dispersed into a liquid medium having a specific heat ranging from 0.4 to 1.4 cal / g / ° C. and a melting point of 5° C. or lower. The dispersed particles have L*value of 30 or less as determined by the CIE-Lab color system (light source D65).

Owner:UNIVERSITY OF THE RYUKYUS +1

Solar co-generator

InactiveUS7173179B2Improve energy conversion efficiencyImprove photovoltaic efficiencySolar heating energySolar heat devicesThermal energyAnti-reflective coating

A solar co-generator for producing both heat energy and electricity is disclosed. A solar concentrator directs sunlight into a container lined with solar cells and filled with a thermal transfer fluid. The fluid is transparent with respect to certain wavelengths of light that may be converted to electricity by the solar cell, but is opaque with respect to longer wavelengths, particular the infrared band. The infrared portion of the sunlight heats the thermal transfer fluid, which then transfer that heat through a storage facility using a heat exchange mechanism. The thermal transfer fluid increases the efficiency of photovoltaic generation by preventing heating of the solar cells due to infrared radiation. The thermal transfer fluid may be a mixture containing barium sulfate and a suspension of zinc sulfide phosphors. A fluorescing anti-reflective coating may be applied to the solar cells to further increase efficiency.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

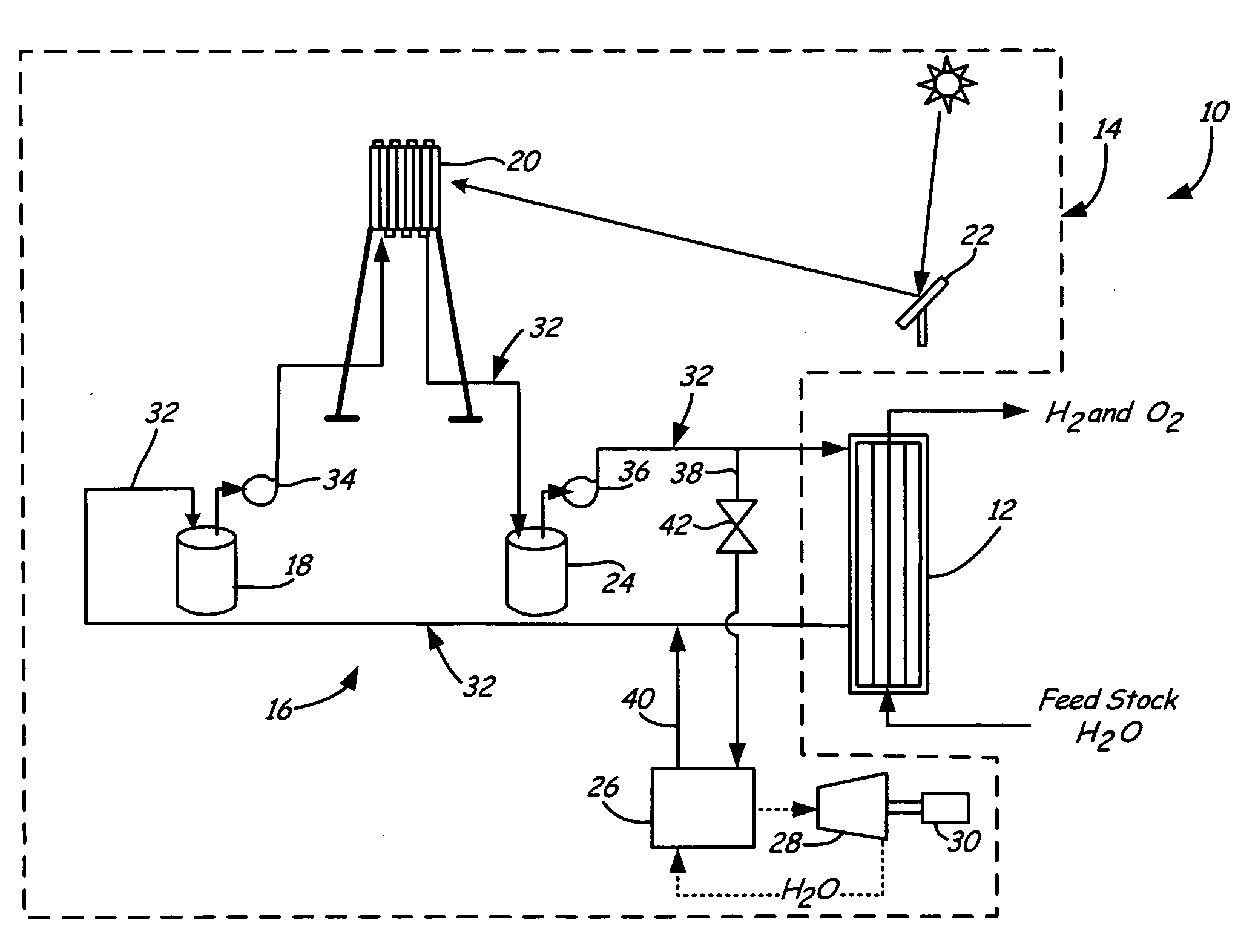

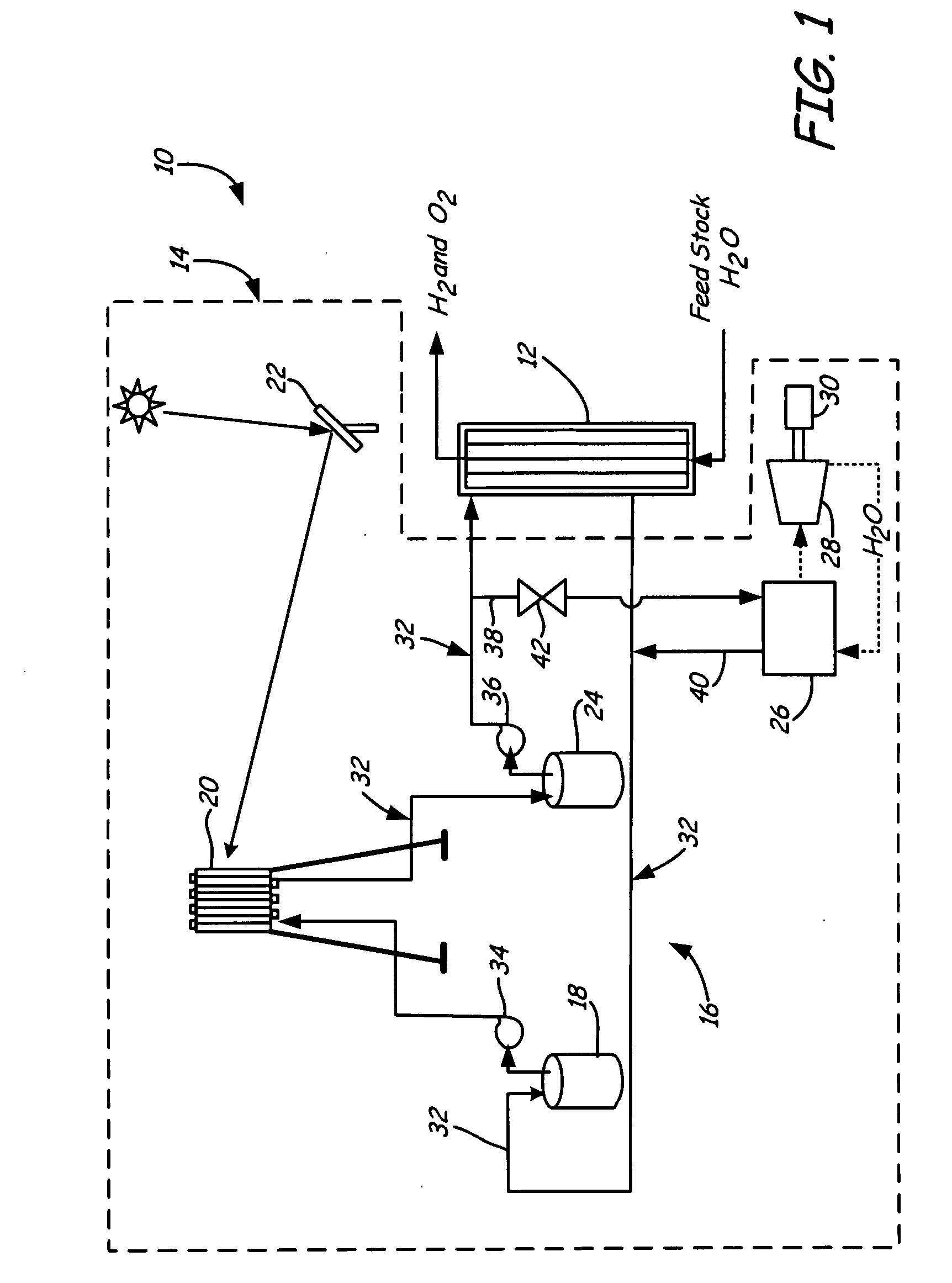

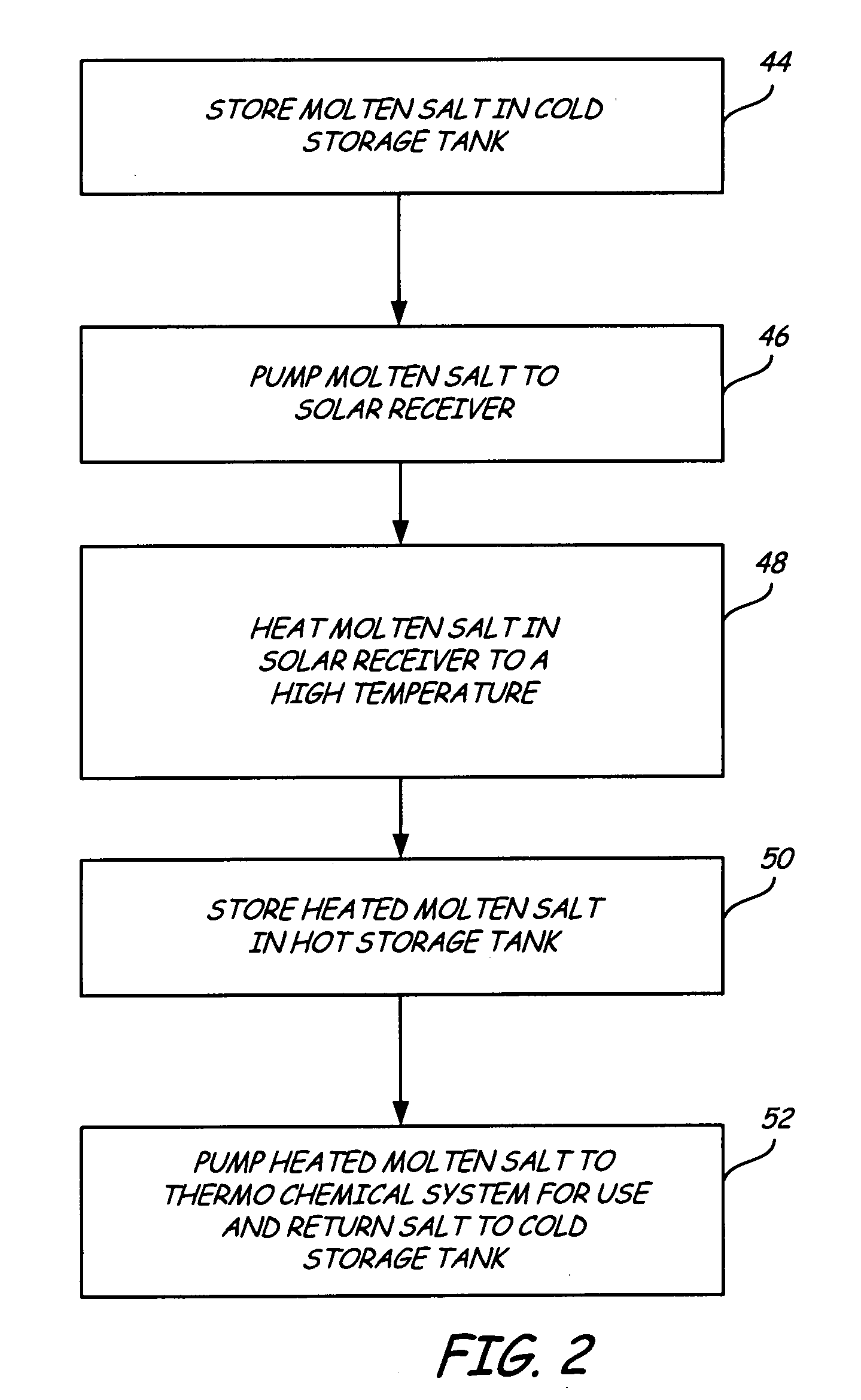

Solar power for thermochemical production of hydrogen

A solar-powered hydrogen production system includes a thermochemical system and solar heating system. The thermochemical system produces hydrogen. The solar heating system has a molten salt heat transfer medium for providing thermal energy to the thermochemical system.

Owner:SOLARRESERVE TECH

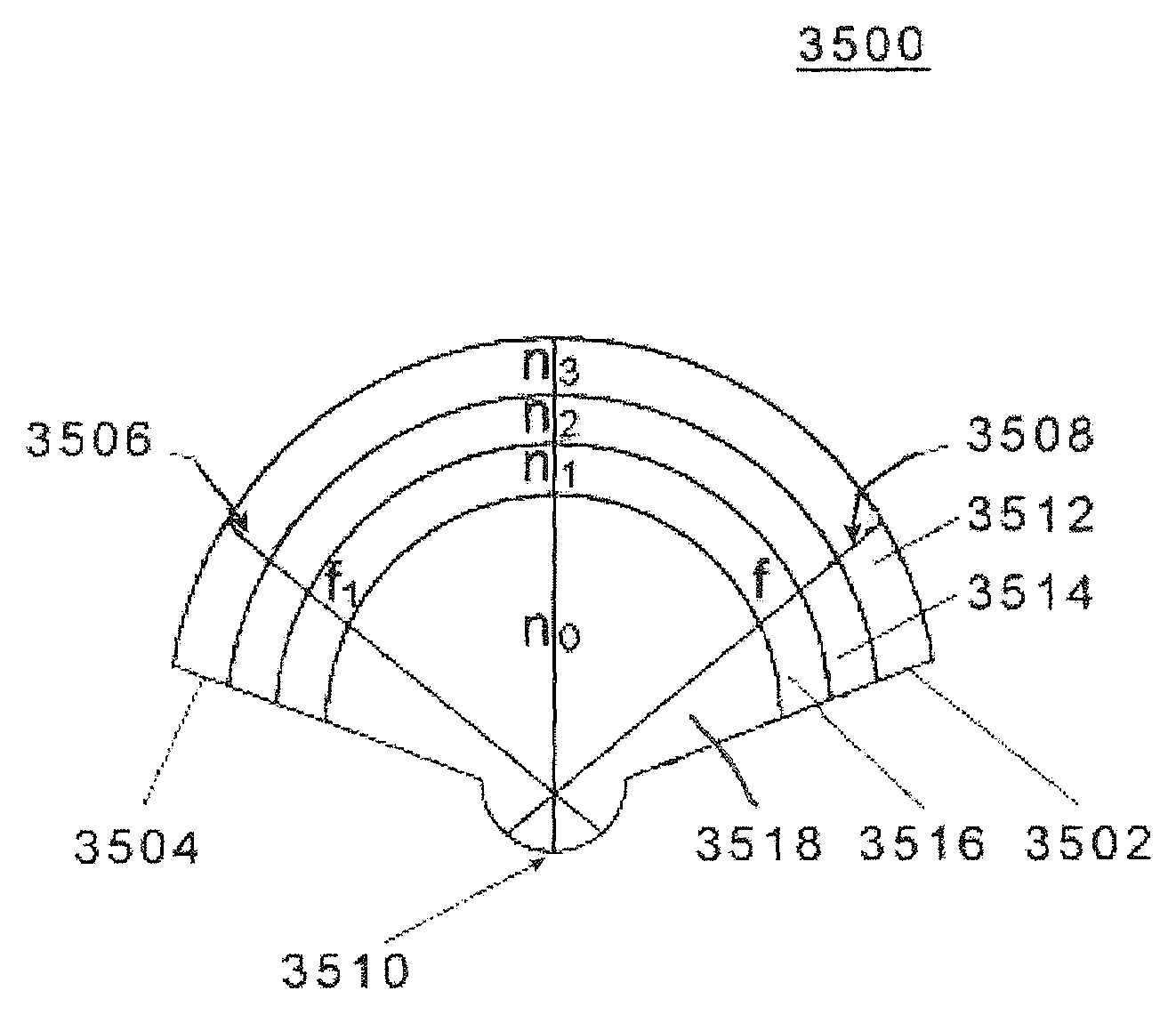

Solar Receivers for Use in Solar-Driven Thermochemical Processes

InactiveUS20130234069A1Improve efficiencyImprove system efficiencySolar heating energyHydrogenThermochemical cycleElectricity

Solar receivers which produce heat at very high temperatures (in excess of 1000° C.) are described herein. The receiver produces the high temperature heat and radiates the heat to a containment element (e.g., pipe) that contains a heat transfer fluid which absorbs the heat. The fluid is preferably a material which is thermally and chemically stable at the temperatures involved. The heat transfer fluid absorbs the heat and can deliver it to a reactor system to drive an endothermic reaction, such as thermochemical water splitting, CO2 capture, and / or syngas production. Alternatively, the heat can be used to directly generate electricity through a high temperature heat engine such as a Brayton or combined Brayton+Rankine cycle.

Owner:HENRY ASEGUN

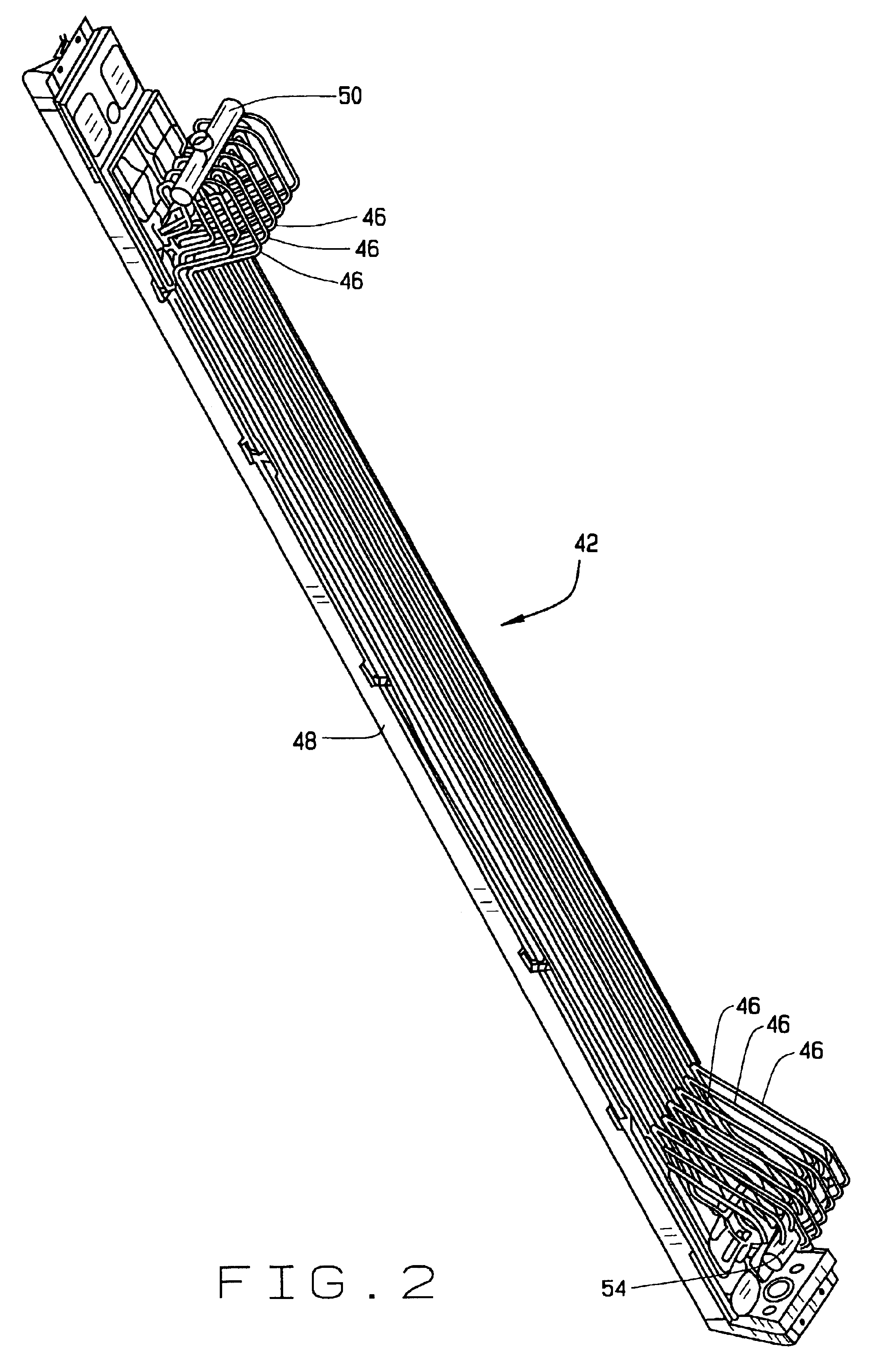

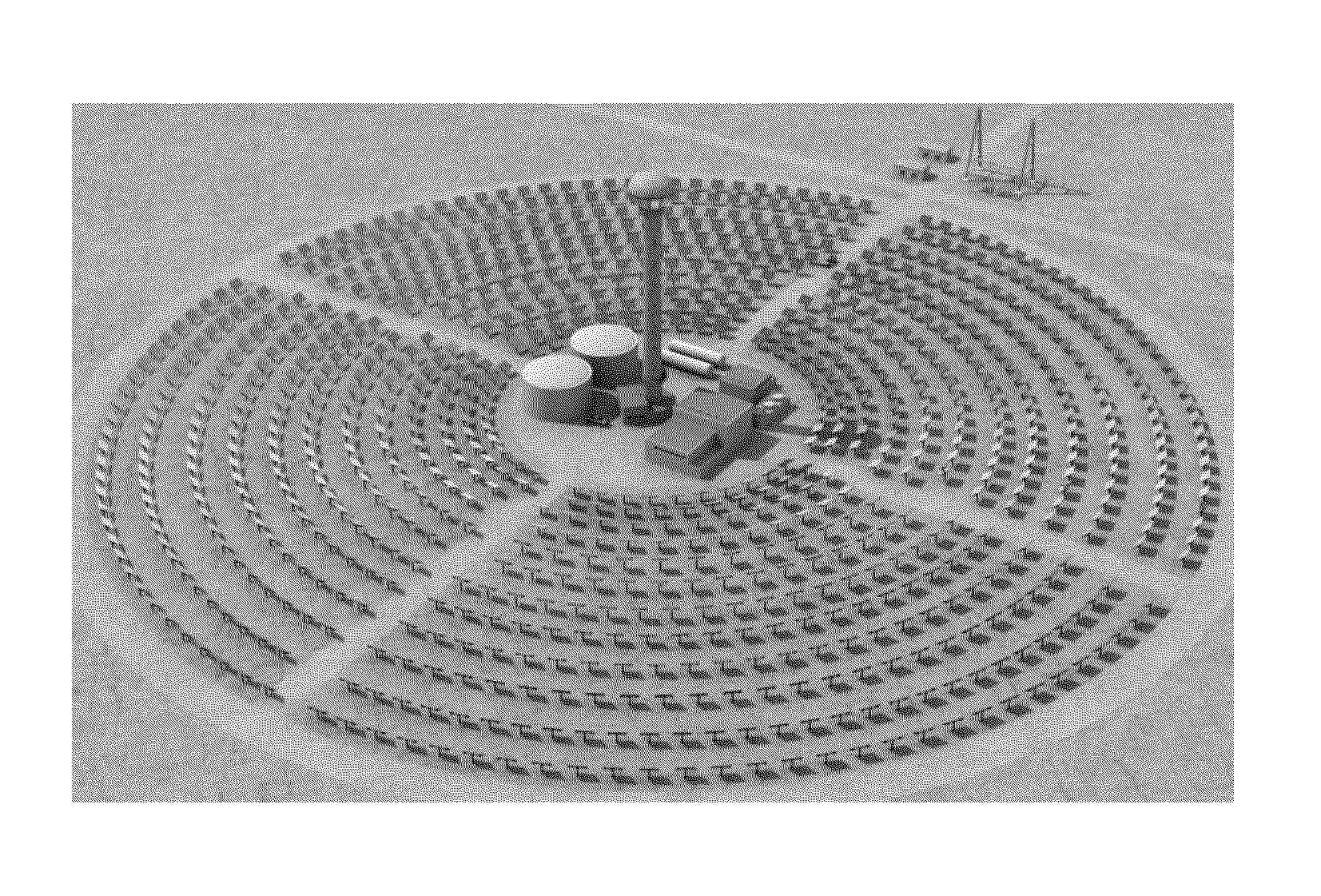

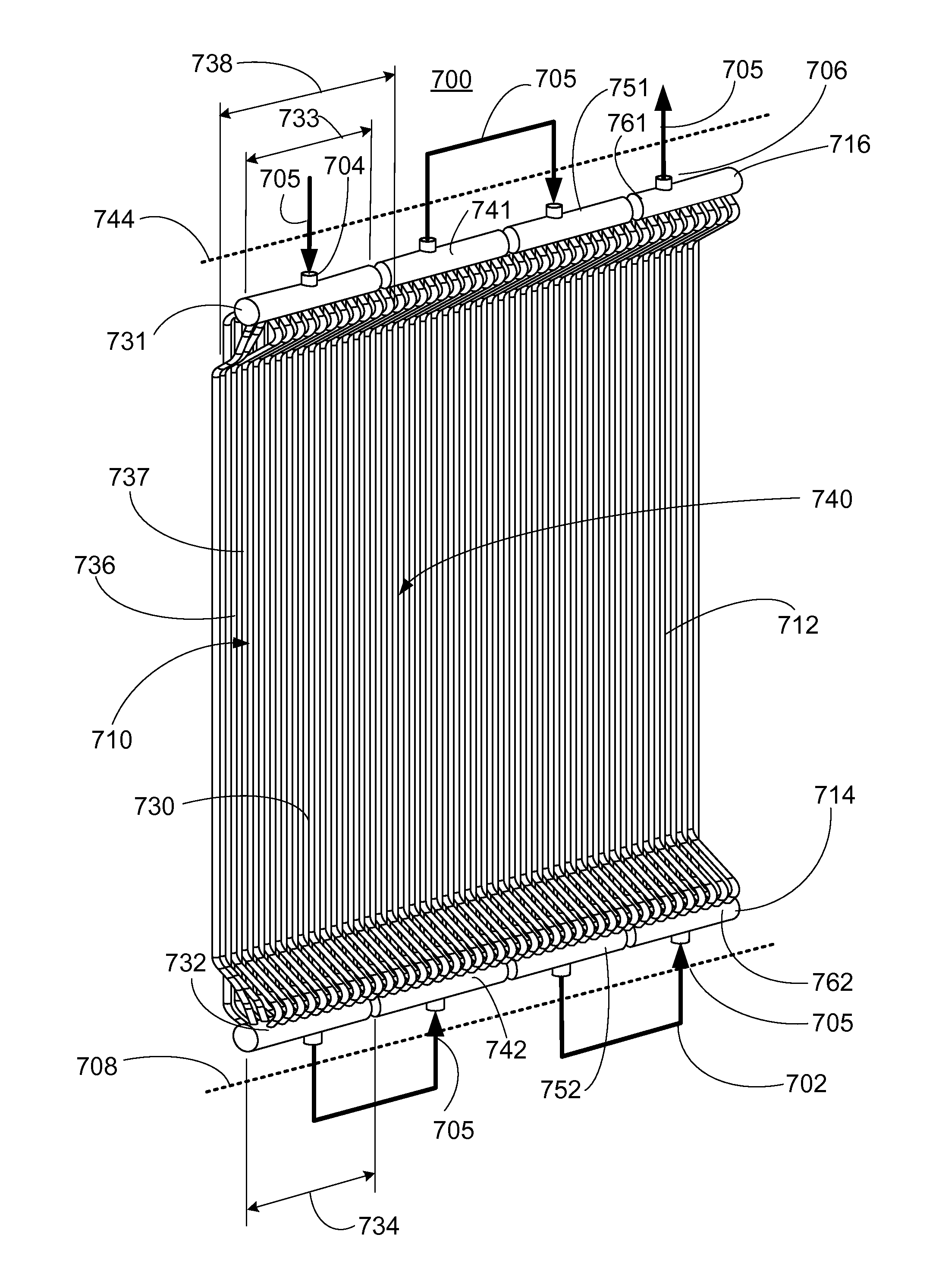

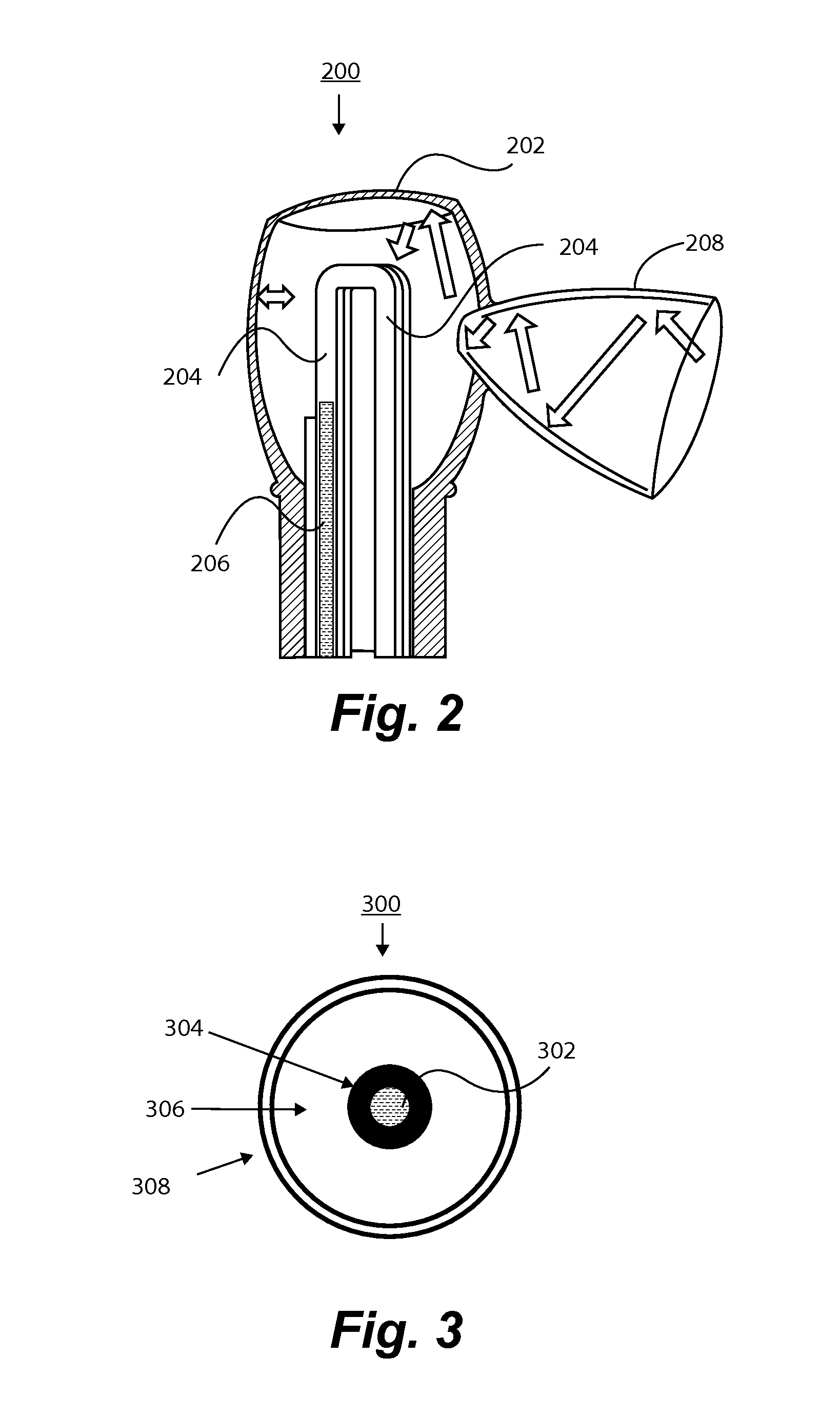

Shop assembled vertical serpentine flow molten salt solar receiver

ActiveUS20130192586A1Simple designSimple in modularSolar heating energySolar heat devicesMolten saltEngineering

A solar receiver is disclosed. The solar receiver is modular, has multiple tube panels in a rectangular / square / polygonal / circular configuration, and is designed for use with molten salt or another heat transfer fluid. The heat transfer fluid flows in a vertical serpentine path through the sides (facets) of the solar receiver. The solar receiver can be shop assembled and can be used with a support tower to form a solar power system.

Owner:THE BABCOCK & WILCOX CO

Solar dish concentrator with a molten salt receiver incorporating thermal energy storage

Owner:THE BOEING CO +1

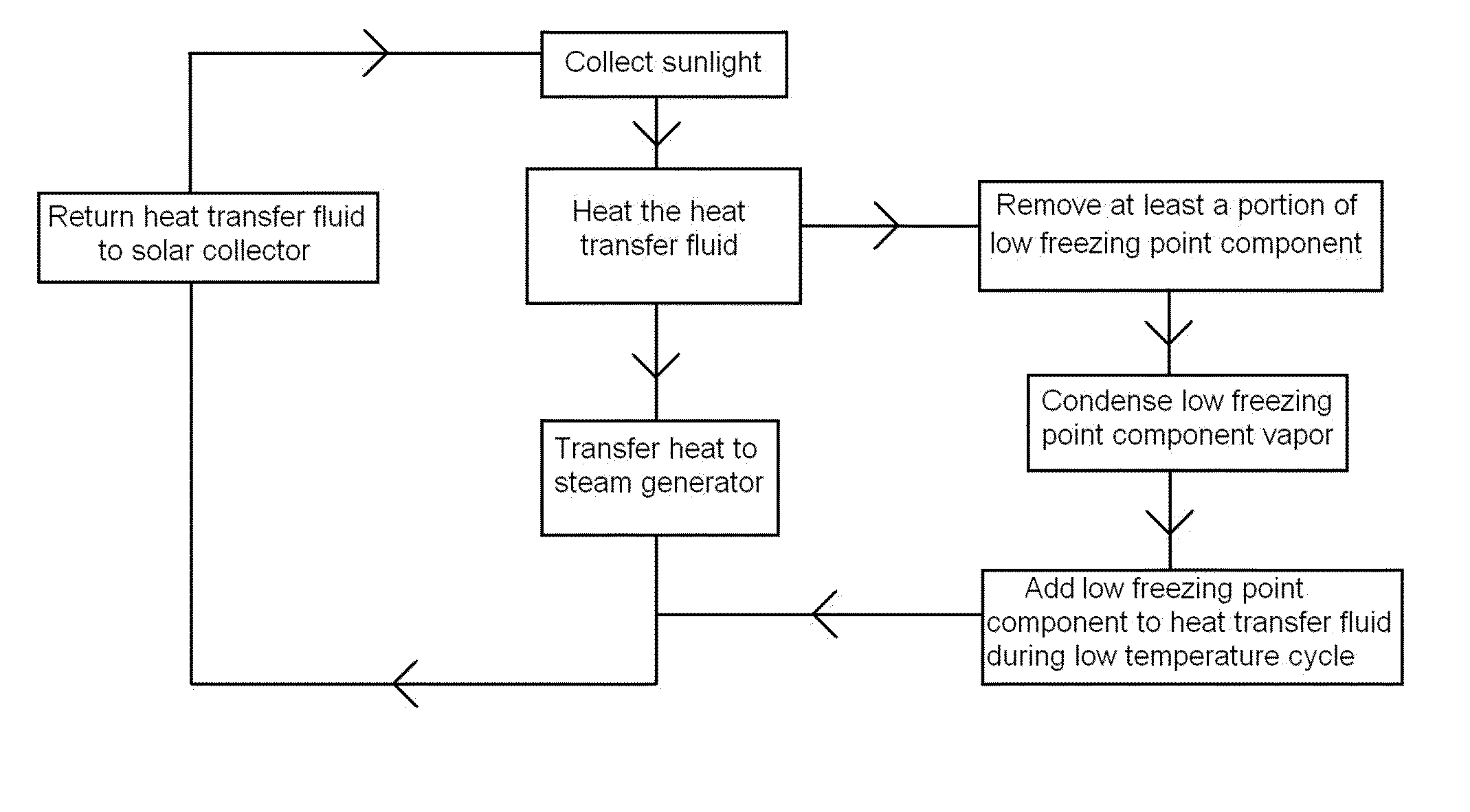

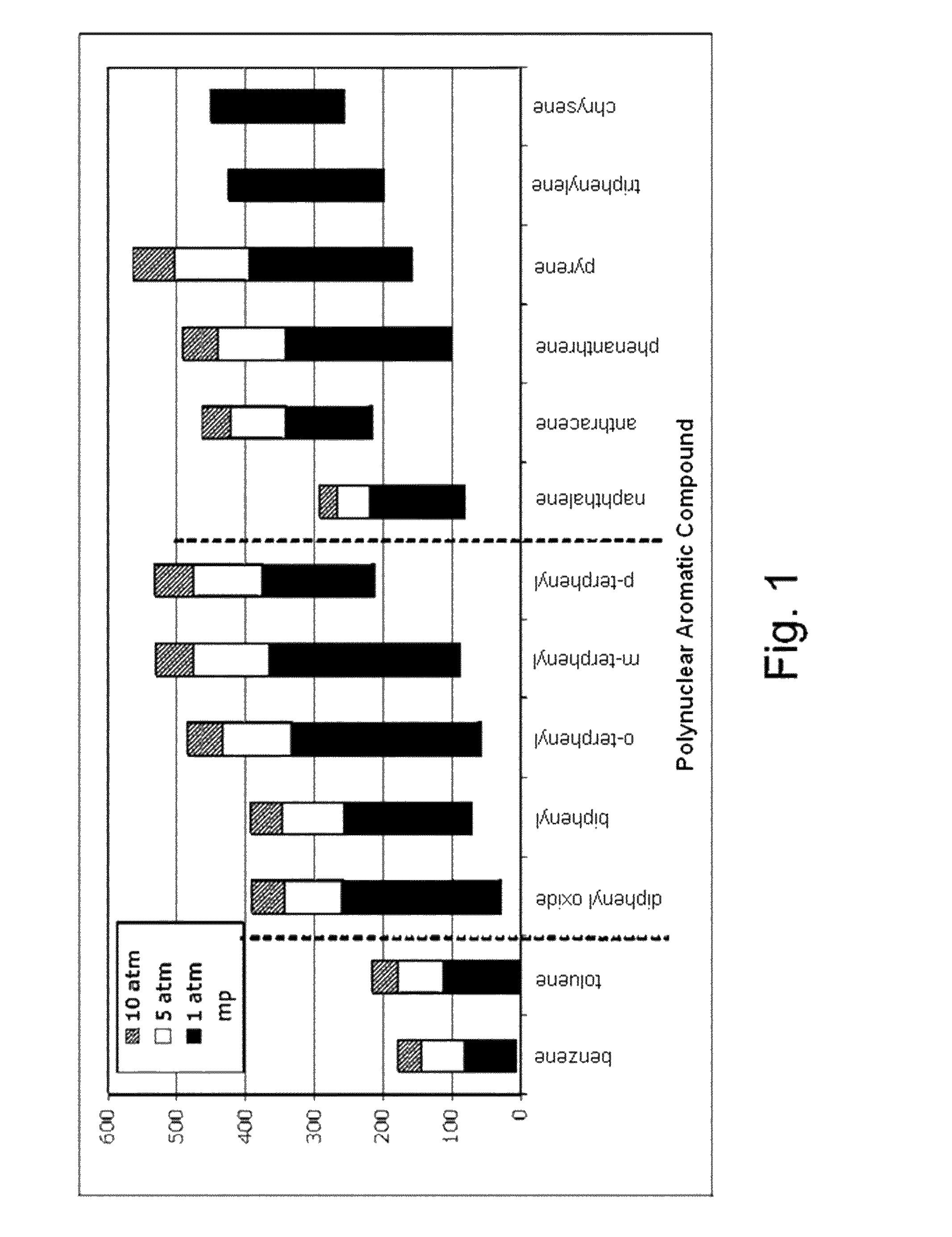

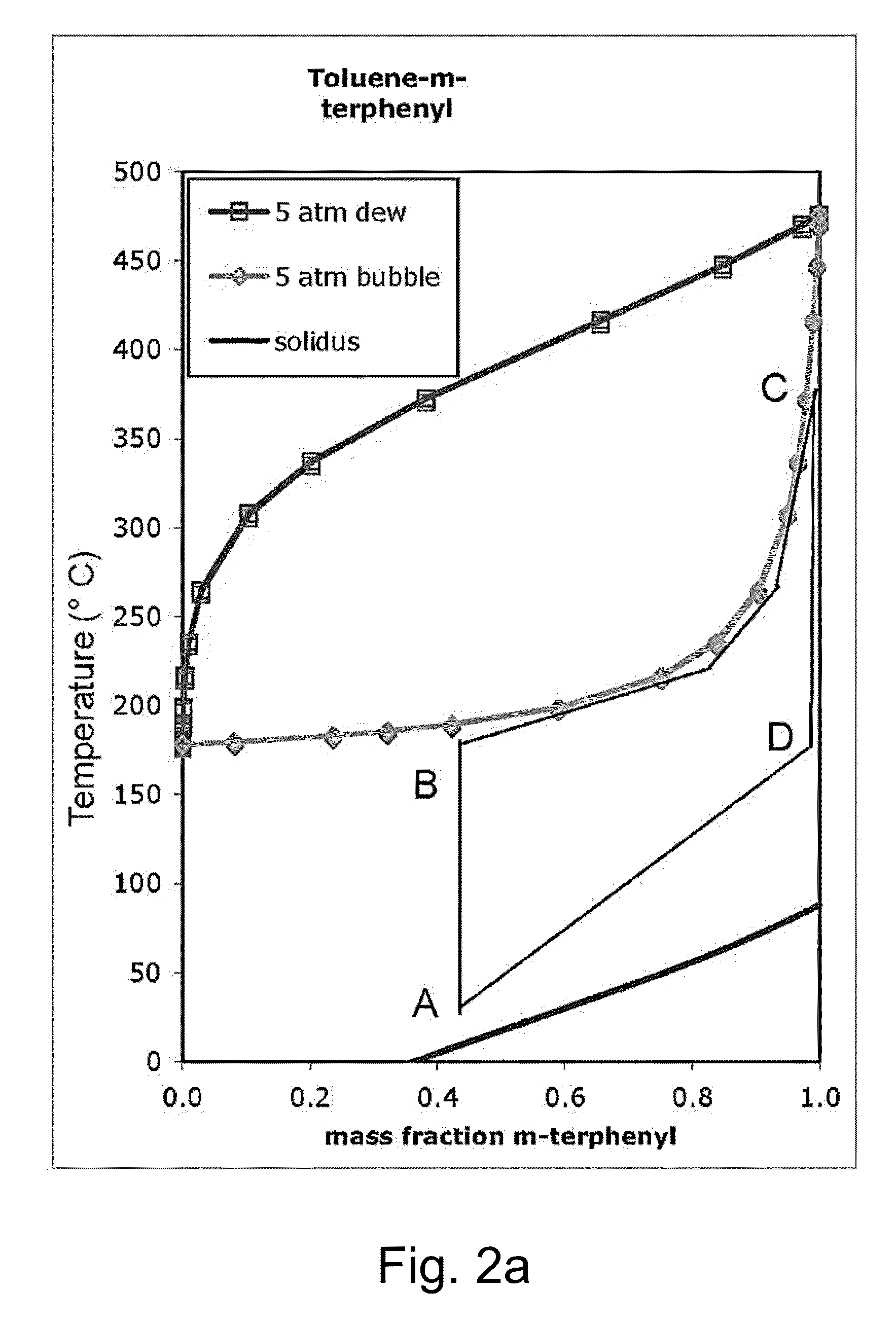

Extended-range heat transfer fluid using variable composition

ActiveUS20110146959A1Increasing boiling point temperatureLow vapor pressureSolar heating energySolar heat devicesGas phaseBoiling point

The present invention provides systems and methods for transferring heat using a variable composition organic heat transfer fluid that remains liquid over a wide operating temperature range useful for solar heating applications. Variable composition heat transfer fluids of the present invention comprise a miscible mixture, optionally a completely miscible mixture, of a high boiling point component selected for its beneficial high temperature physical properties, and a low freezing point component selected for its beneficial low temperature physical properties. In some embodiments, the low freezing point component is removed from the heat transfer fluid as the heat transfer fluid is heated, for example by being removed in the vapor phase, thereby selectively varying the composition and physical properties (e.g., vapor pressure, boiling point, etc.) of the heat transfer fluid as a function of temperature.

Owner:WISCONSIN ALUMNI RES FOUND

Sensible Thermal Energy Storage (STES) Systems

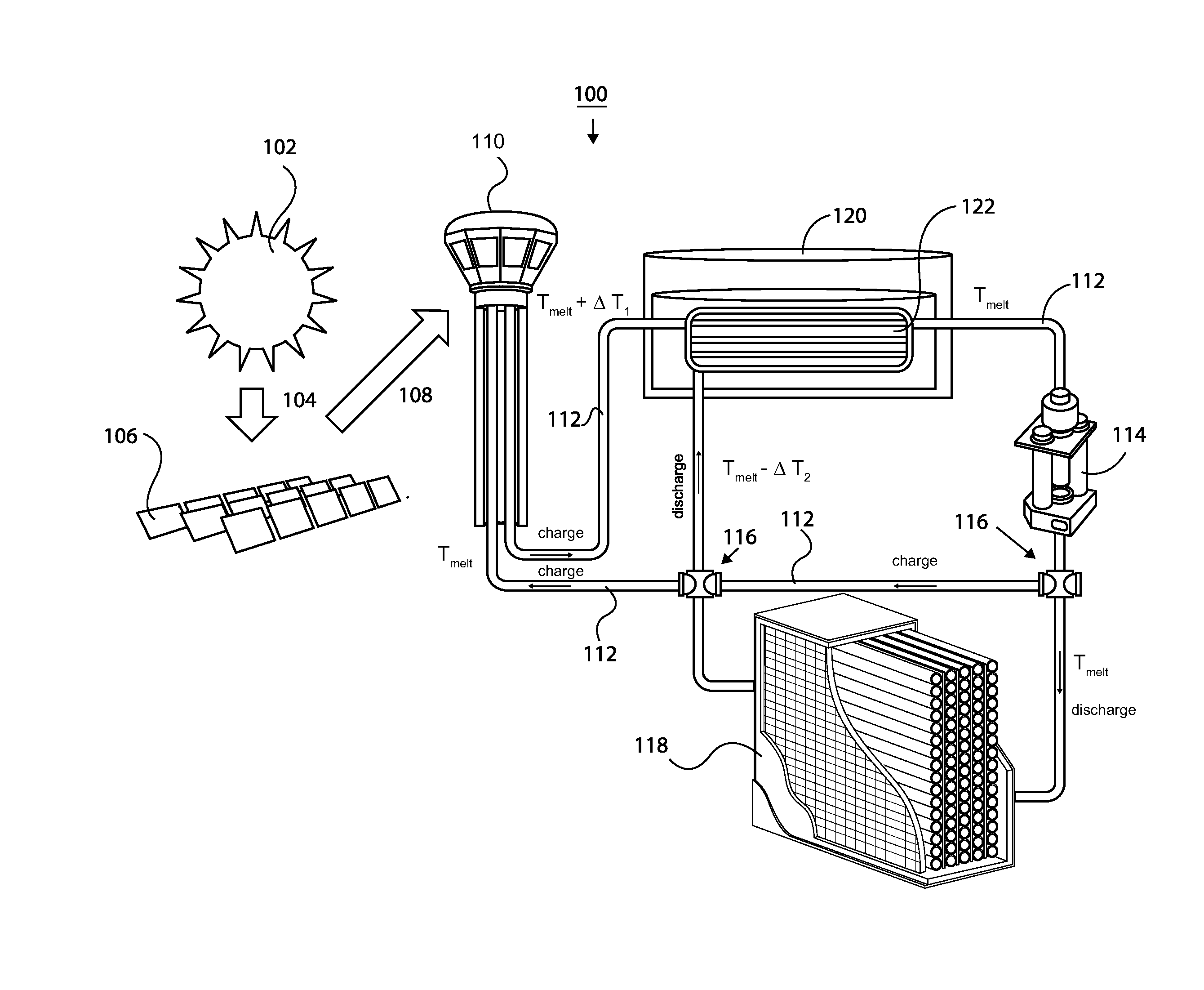

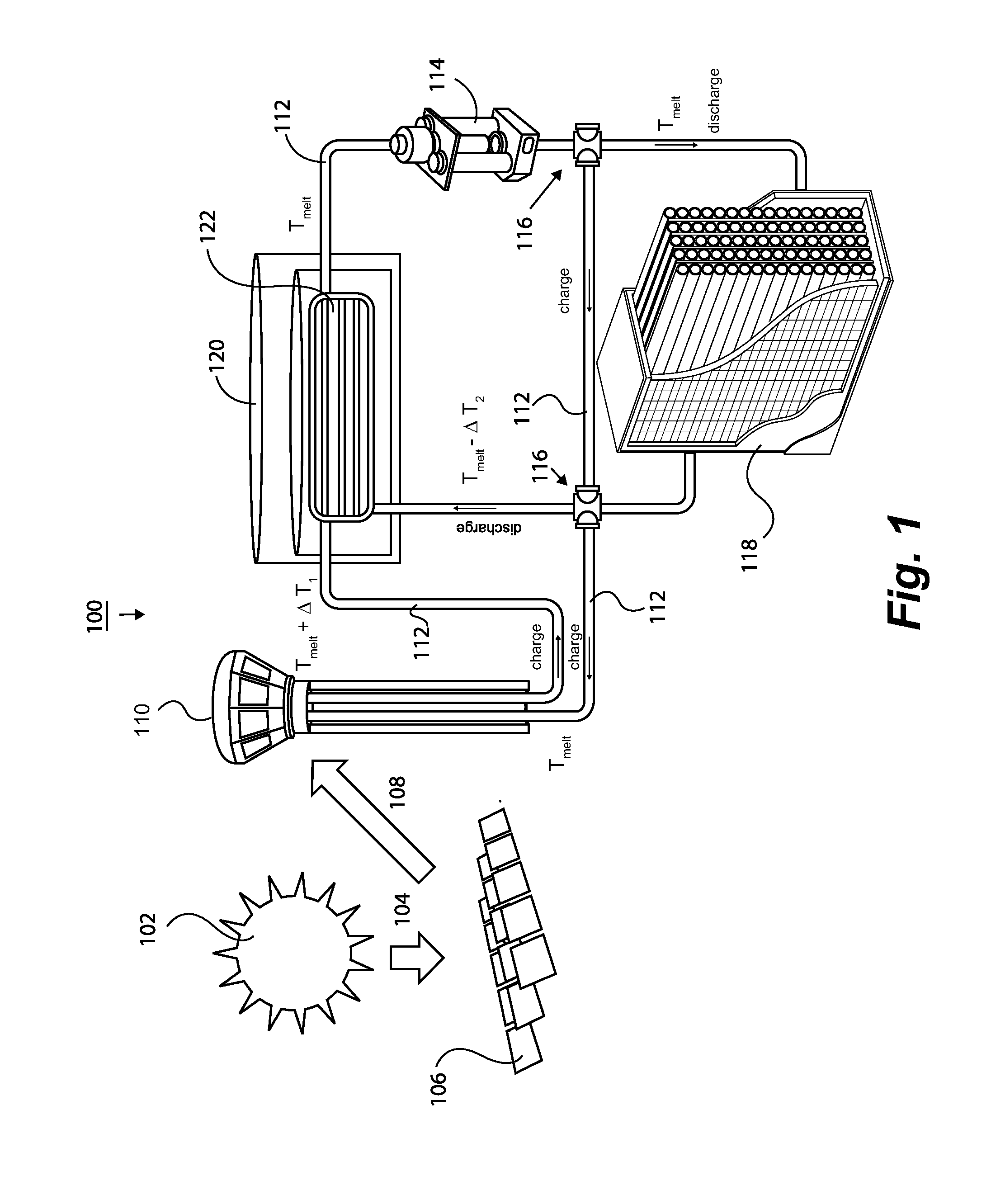

ActiveUS20170067667A1Increase heat storageImprove recovery efficiencySolar heating energyFrom solar energyThermal energyLiquid layer

Two sensible thermal energy storage (STES) systems in multiple chambers containing molten eutectic salts have been devised for use at temperatures above 565° C. For the first type, the thermal energy of low specific heat of an immiscible gaseous heat transfer fluid (HTF) at temperatures above 900° C. is readily converted to dispatchable heat of high specific heat in the molten eutectic salt liquid layers operating at high temperatures, which can again produce a gaseous HTF at a constant temperature of 700° C. or higher for the lower electricity generation capacities. For the second type, the molten eutectic salt liquids are used as a thermal energy storage (TES) medium and also a HTF at temperatures above 700° C. for the higher electricity generation capacities. These STES systems provide an effective cushion against the disturbances of heat supply from the sun.

Owner:CHOI PETER B

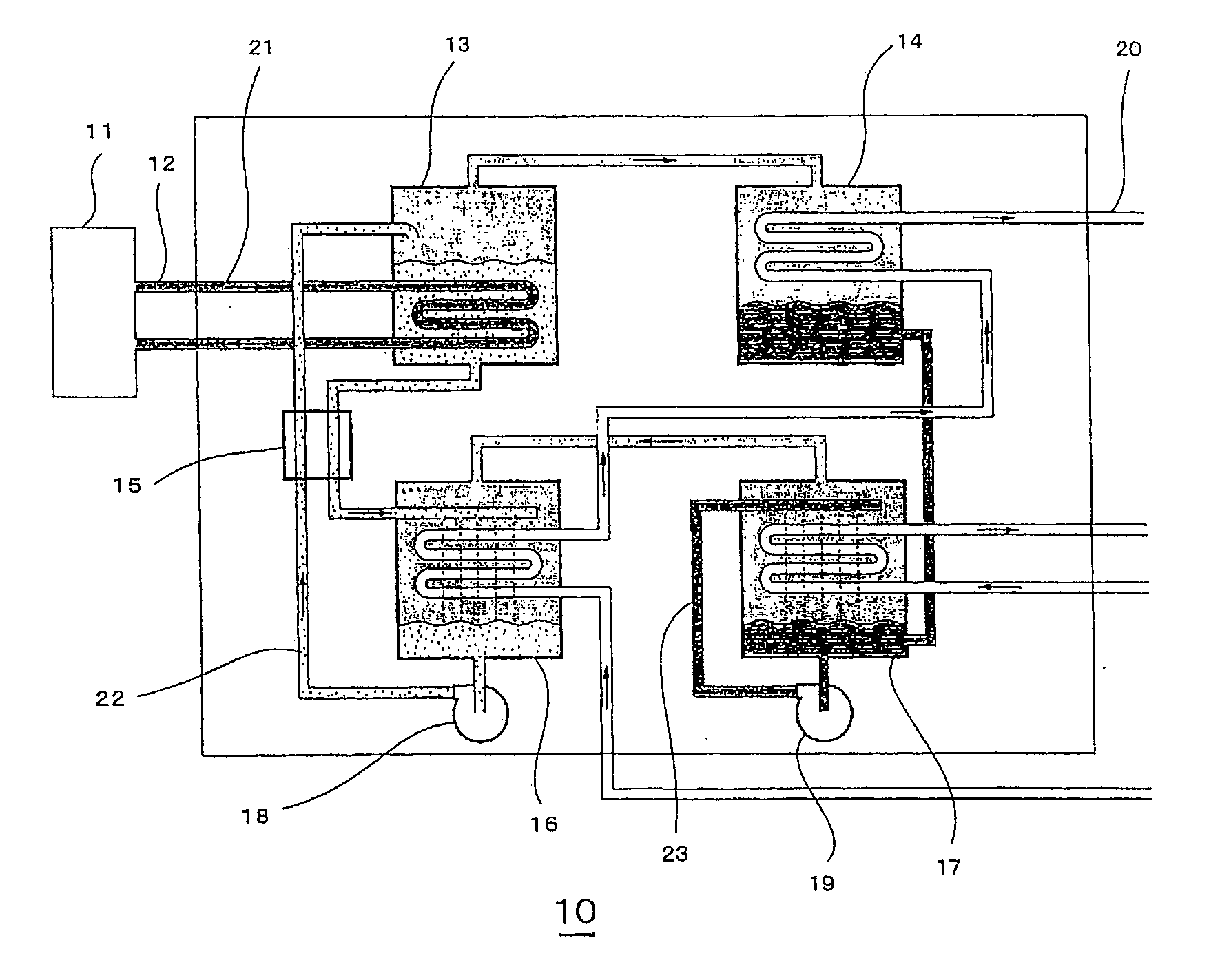

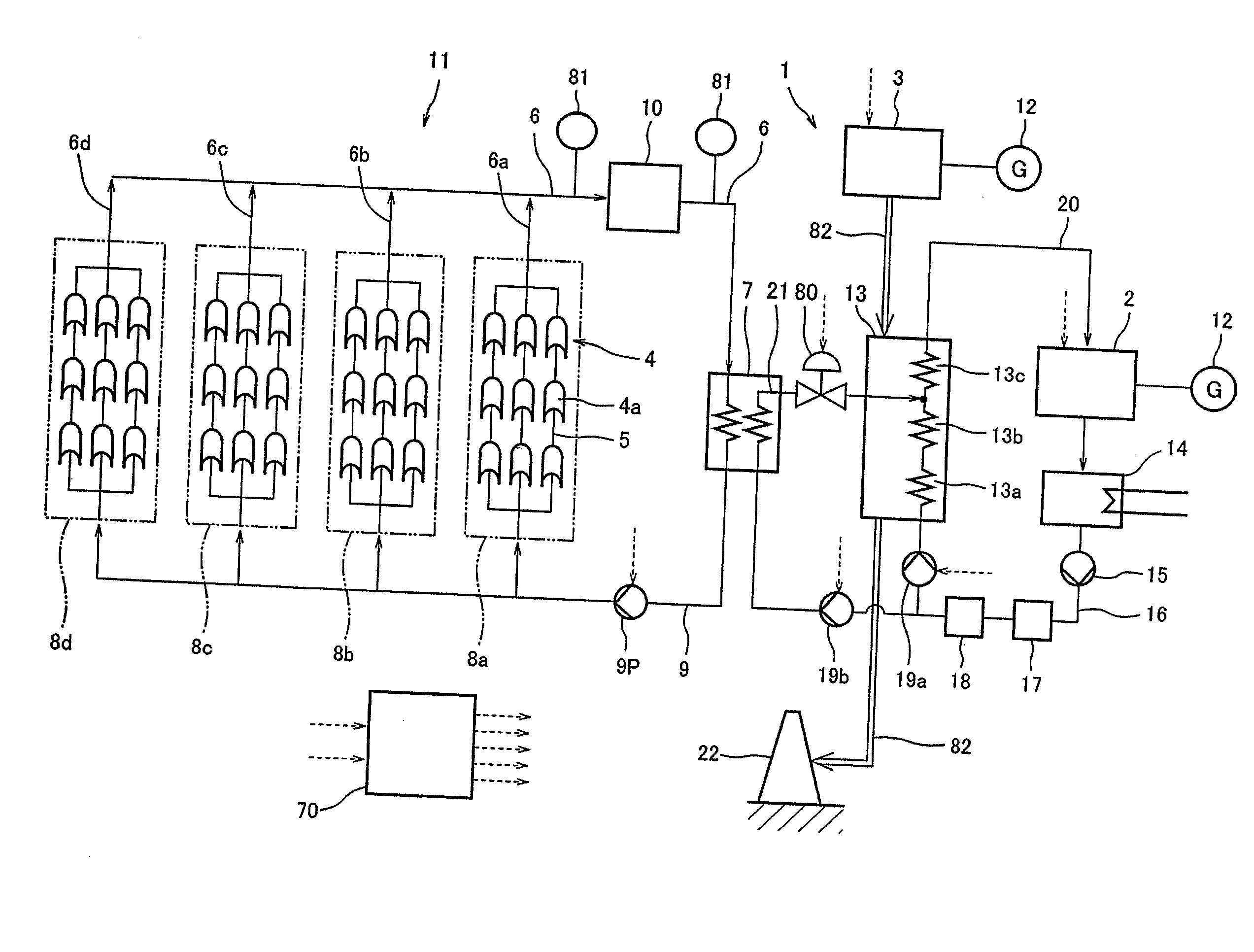

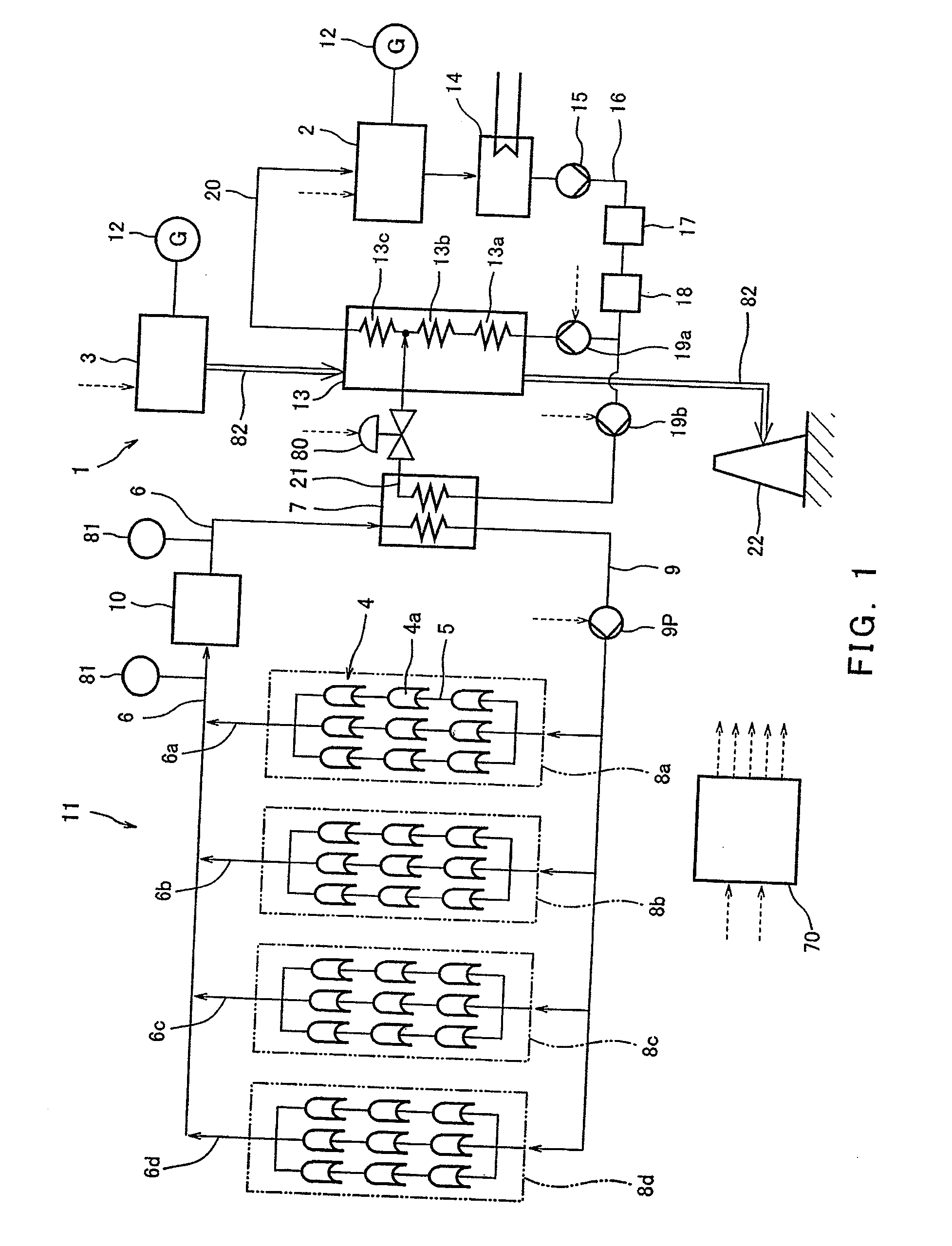

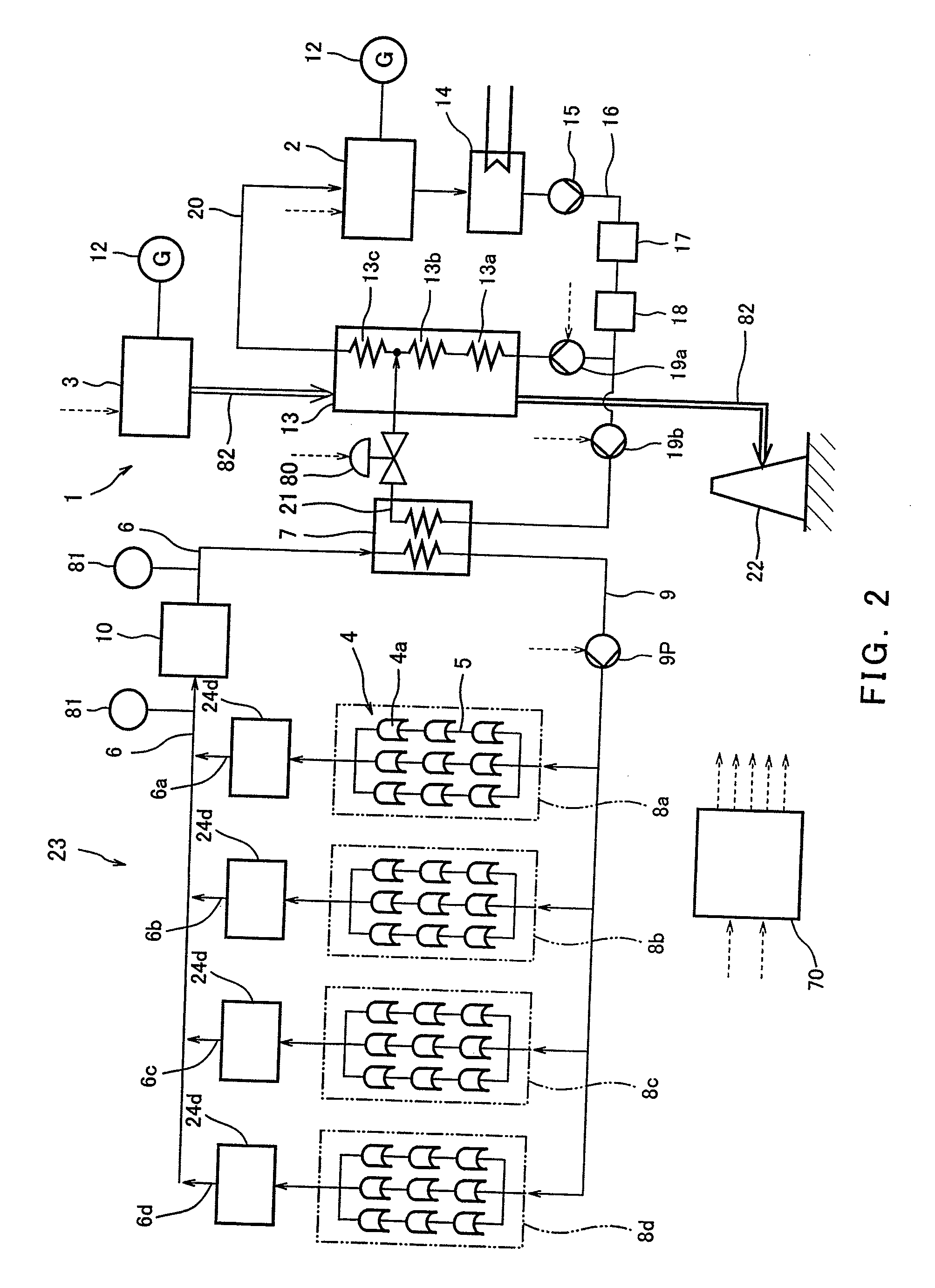

Thermal Electric Power Generation System, Heating Medium Supply System, and Temperature Fluctuation Suppressing Device

InactiveUS20090165780A1Narrow downEliminate short-cycleAuxillary drivesSolar heating energyTime lagEngineering

A temperature fluctuation suppressing device for a heating medium is provided which is capable of sufficiently suppressing temperature fluctuations of the heating medium at the time of supplying collected solar heat for steam generation. The temperature fluctuation suppressing device includes a heating medium mixer provided on a heating medium supply passage configured to supply a liquid heating medium to a heat exchanging device, the heating medium mixer including: a heating medium passage forming member having plural heating medium passages; an inlet member and an outlet member provided separately from the inlet member, whereby the heating medium continuously flowing into the heating medium passage forming member through the inlet member passes through the plural heating medium passages with time-lags to form respective streams, which are then joined together before flowing out through the outlet member.

Owner:KAWASAKI HEAVY IND LTD

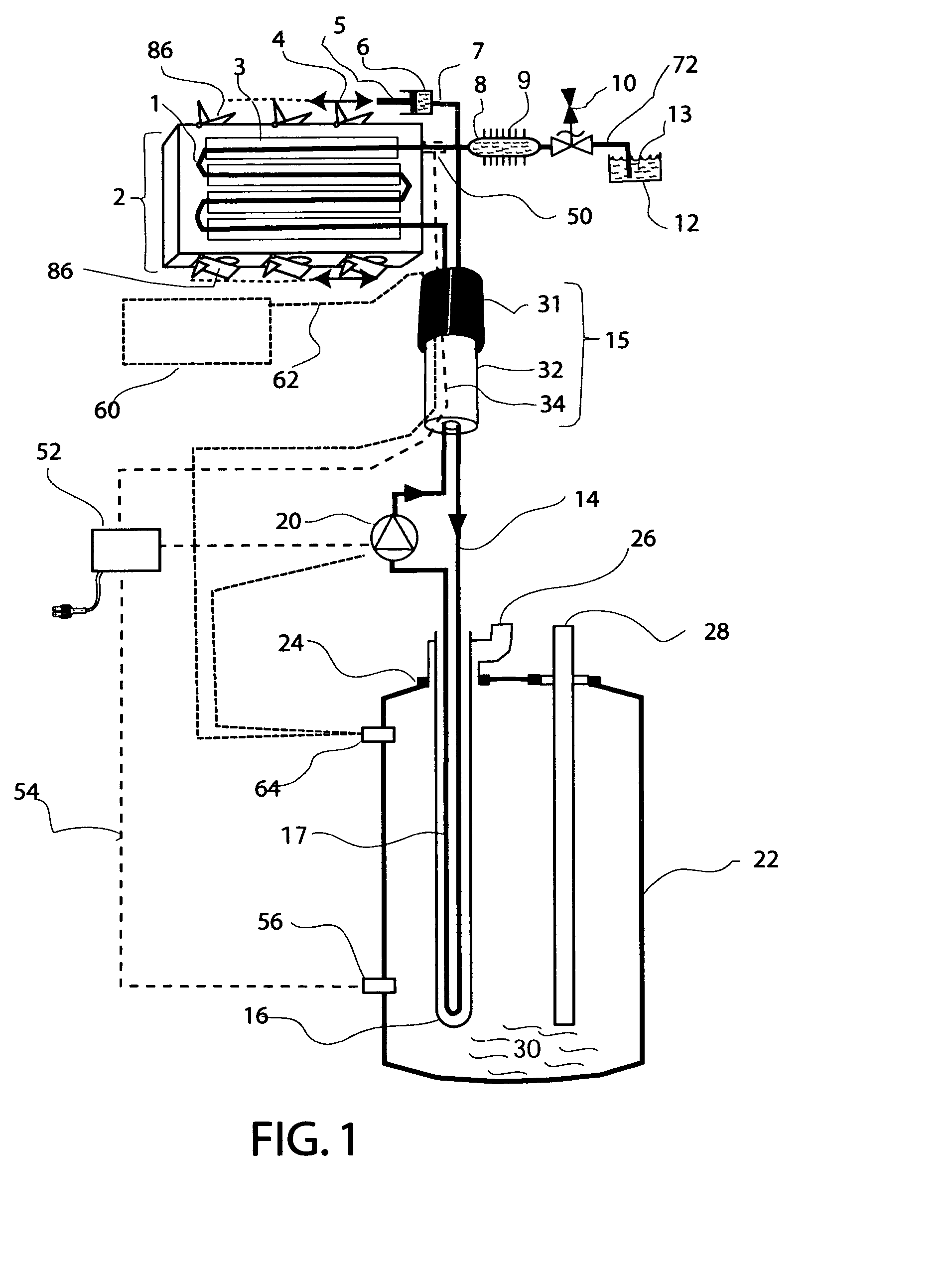

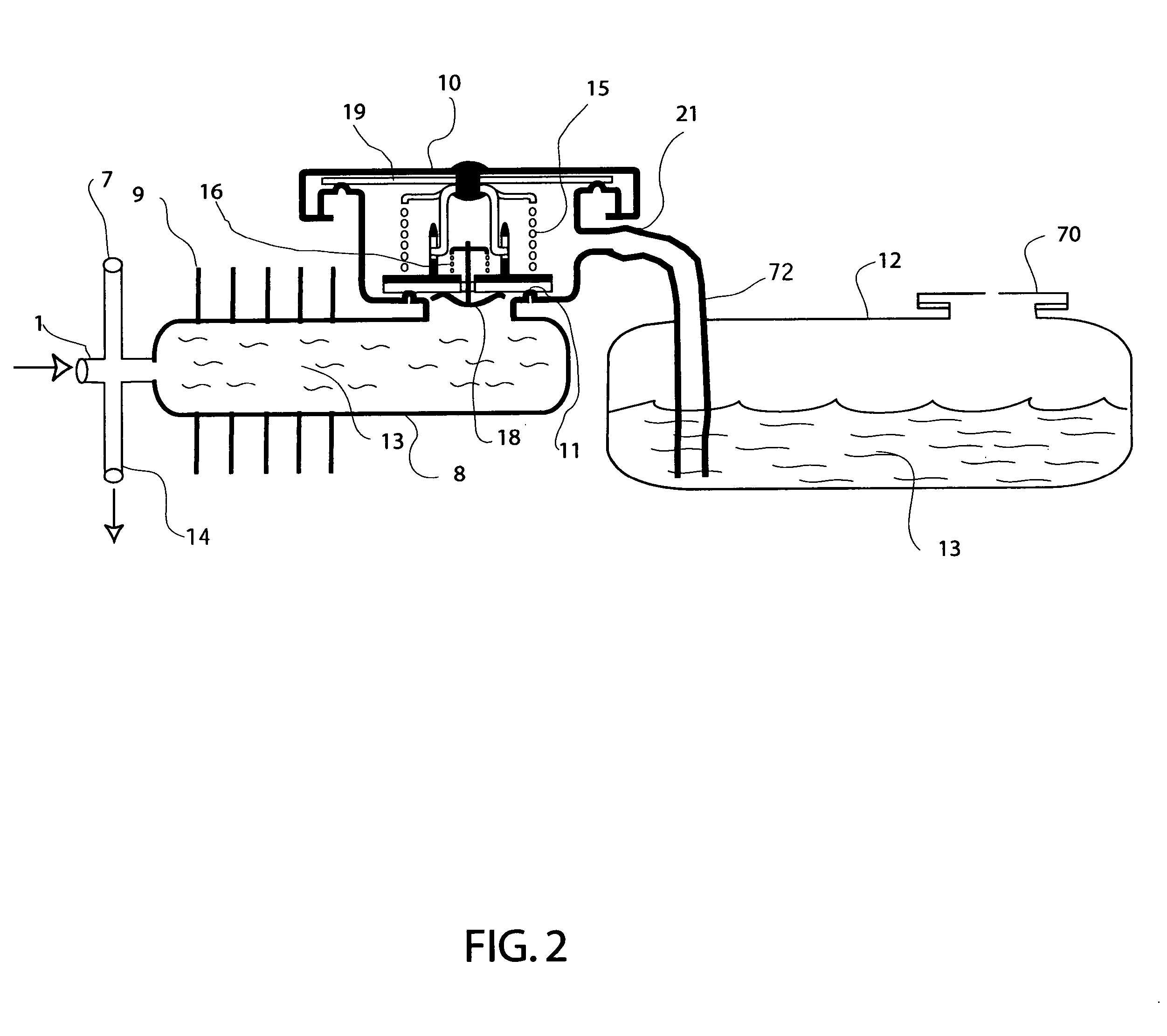

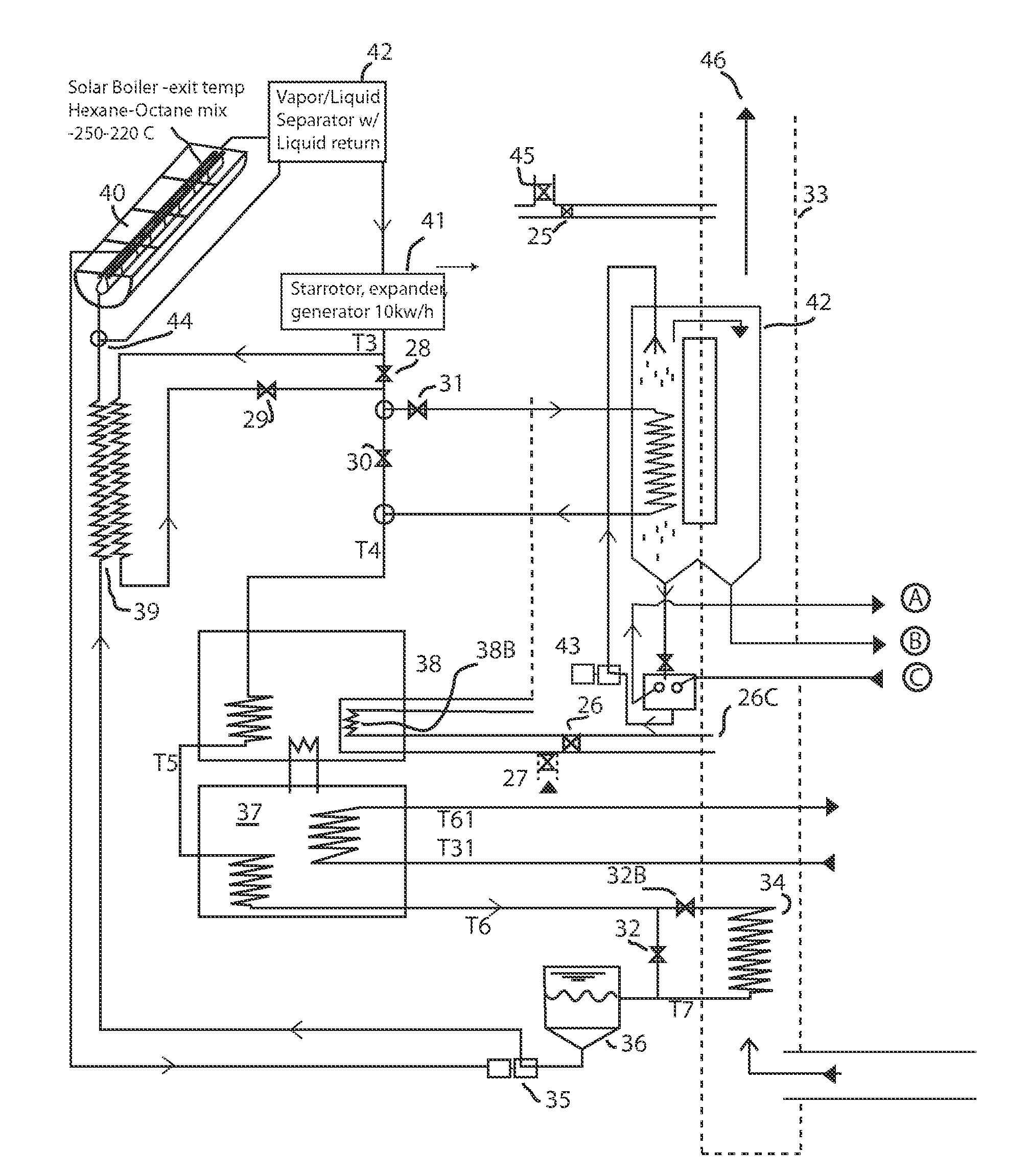

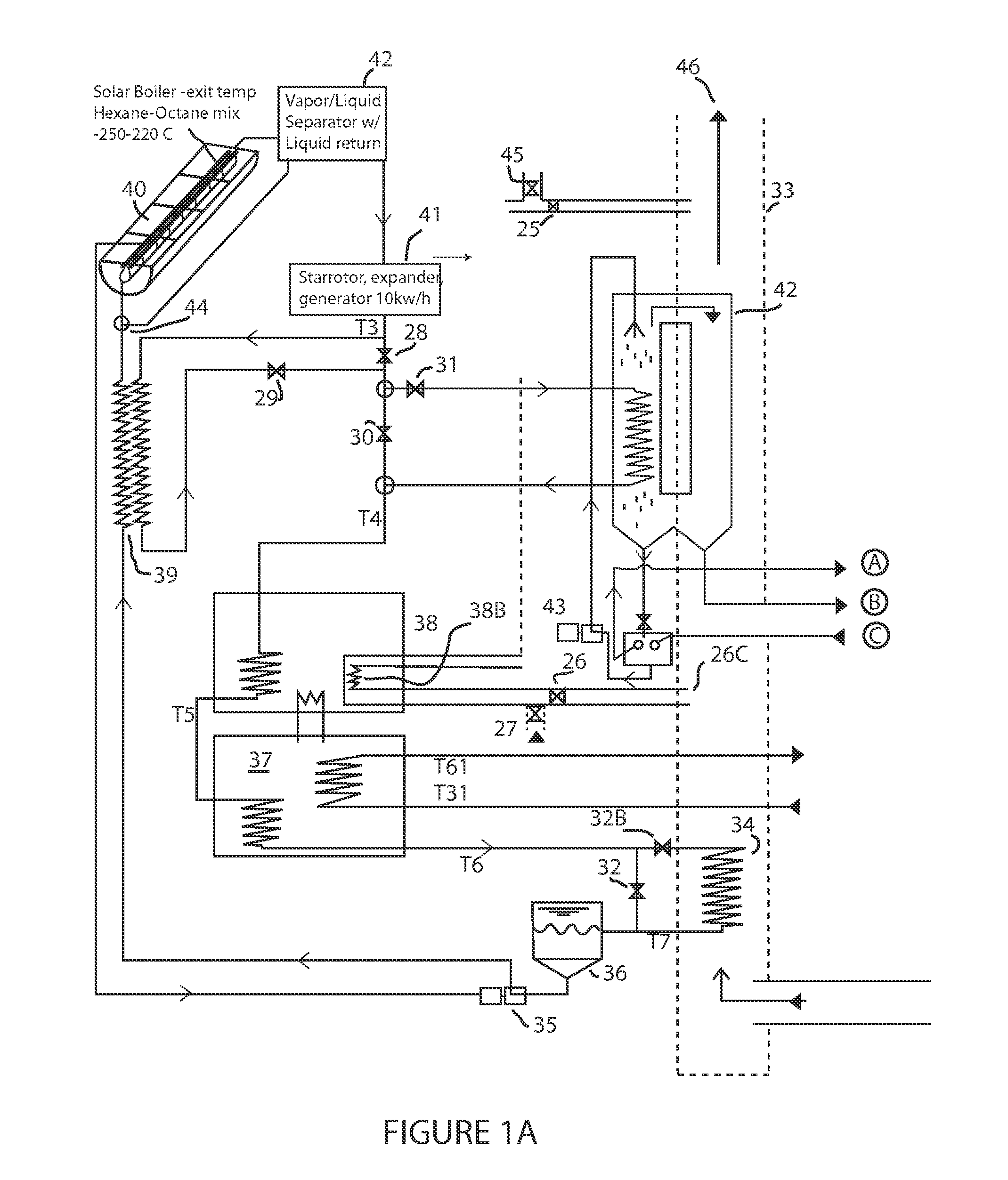

Solar heat transfer system (HTPL), high temperature pressurized loop

InactiveUS7913684B2More materialReduce material usageSolar heating energySolar heat devicesModem deviceEngineering

Delivering heat from modem high temperature solar collectors to hot water storage tanks is more effectively done using unpressurized when cold, self-pressurized on heat up, automatic air eliminating, higher temperature fluid loops. A pressurizing valve, an overflow reservoir and a vacuum relief valve are used. Non-toxic water / antifreeze mixtures are pressurized up to about two atmospheres resulting in a 265° Fahrenheit boiling point. Loss of circulation under full sun results in solar collector boiling under pressure. The steam generated in the solar collector is condensed in the pressurized liquid-to-air radiator, a steam heat pipe, and water is returned to the solar collector to keep it completely full of fluid and steam. A set of pressure-actuated air dampers on the solar collector can also be used to shed the excess solar collector heat.

Owner:BUTLER BARRY LYNN

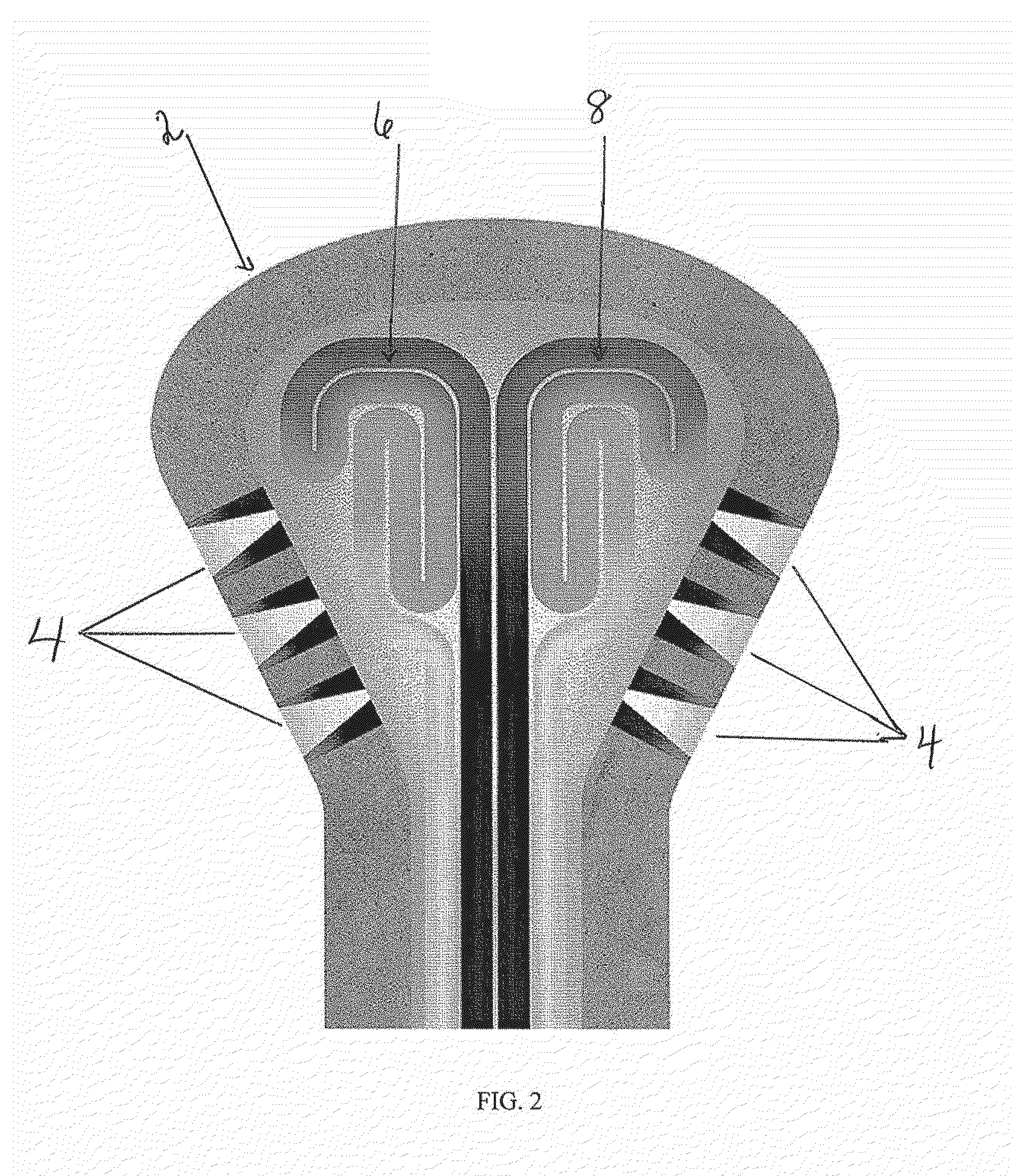

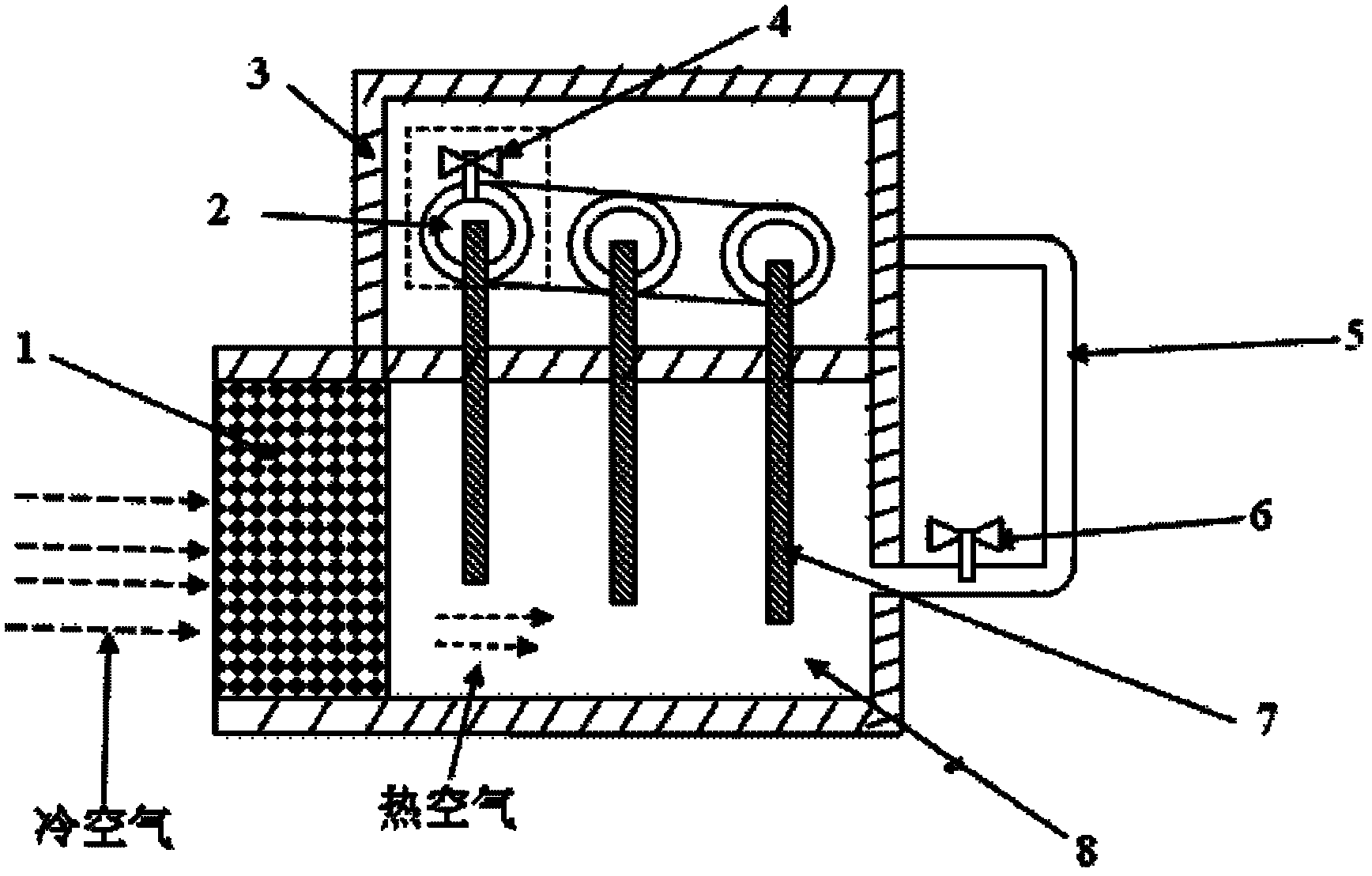

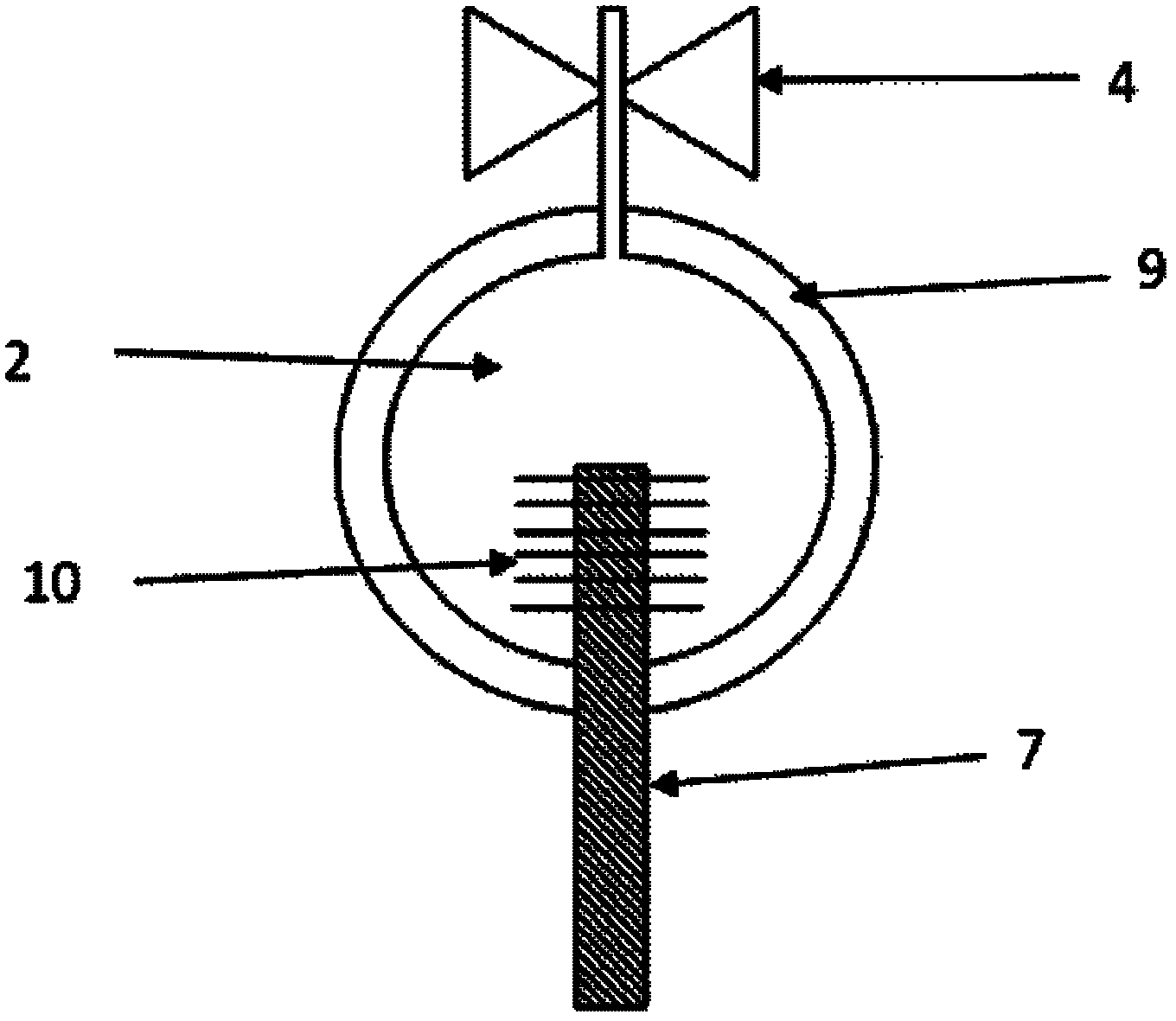

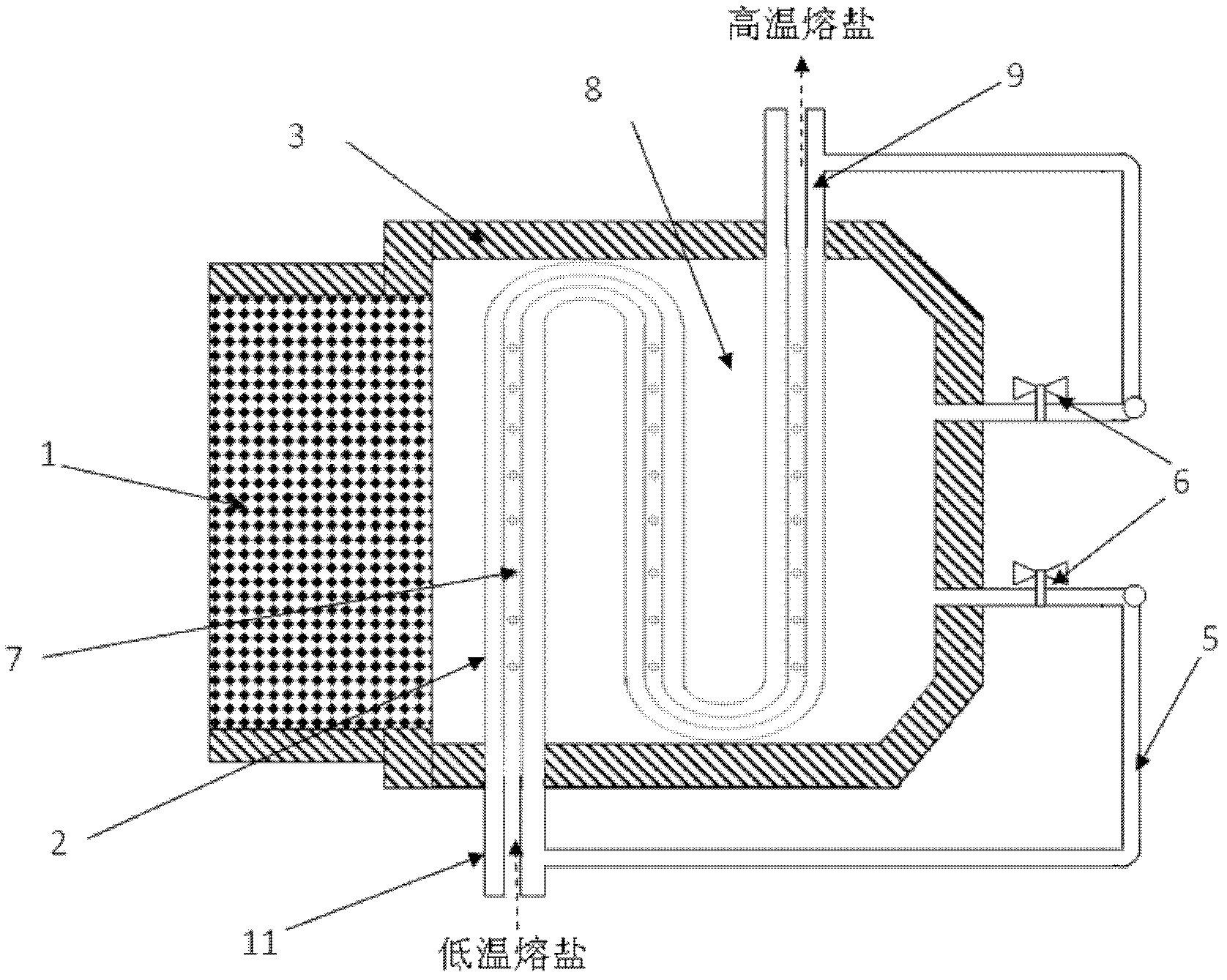

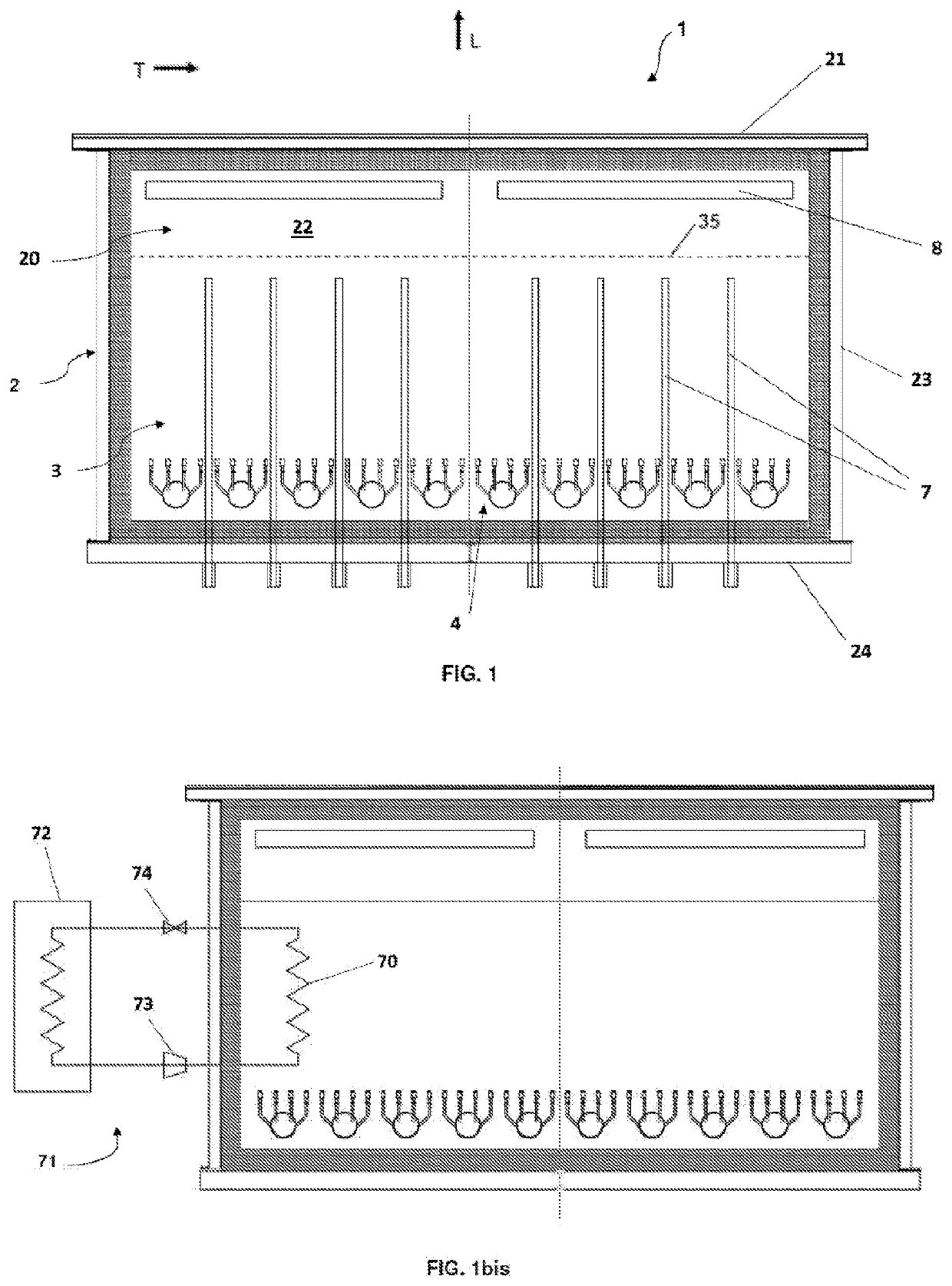

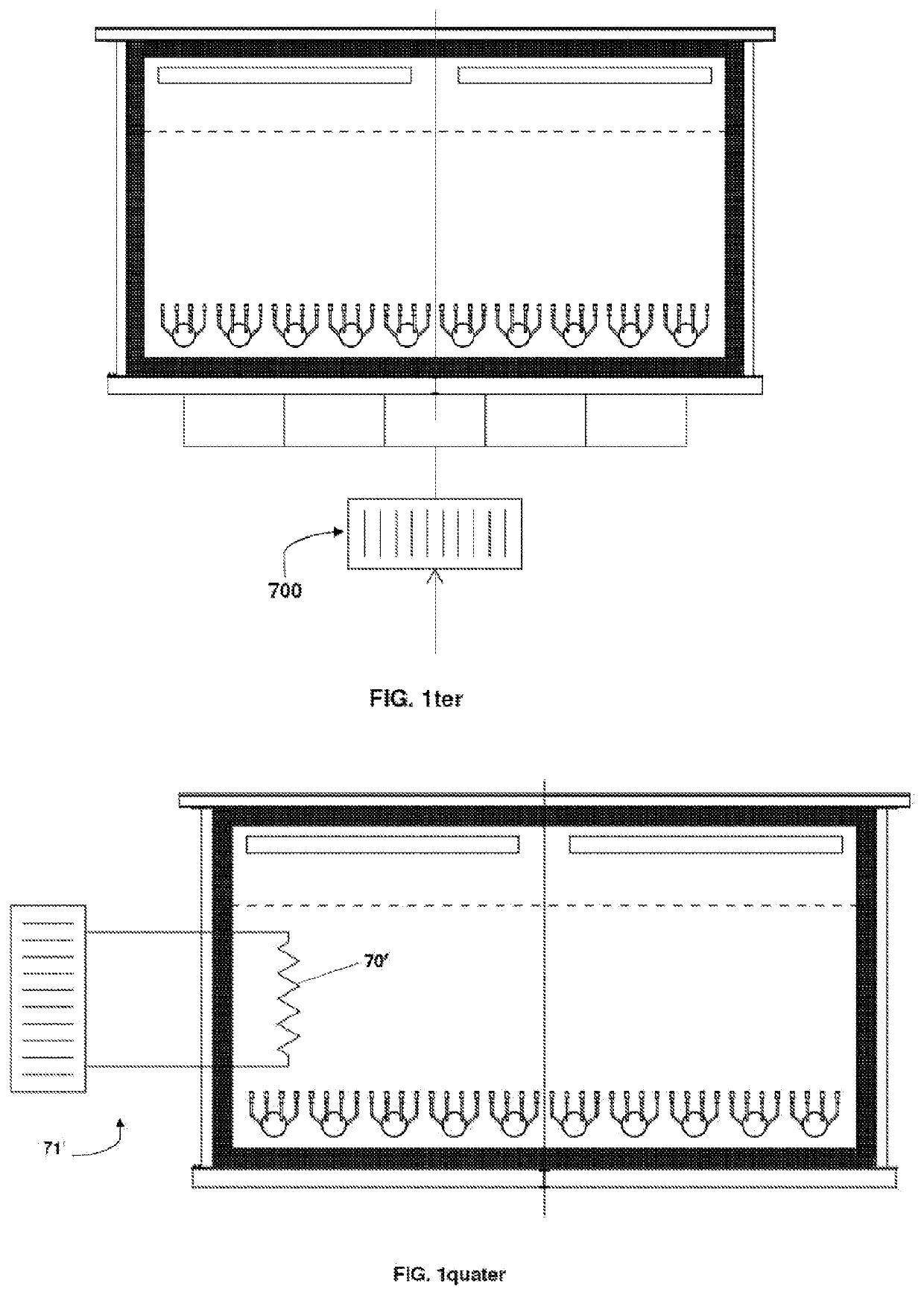

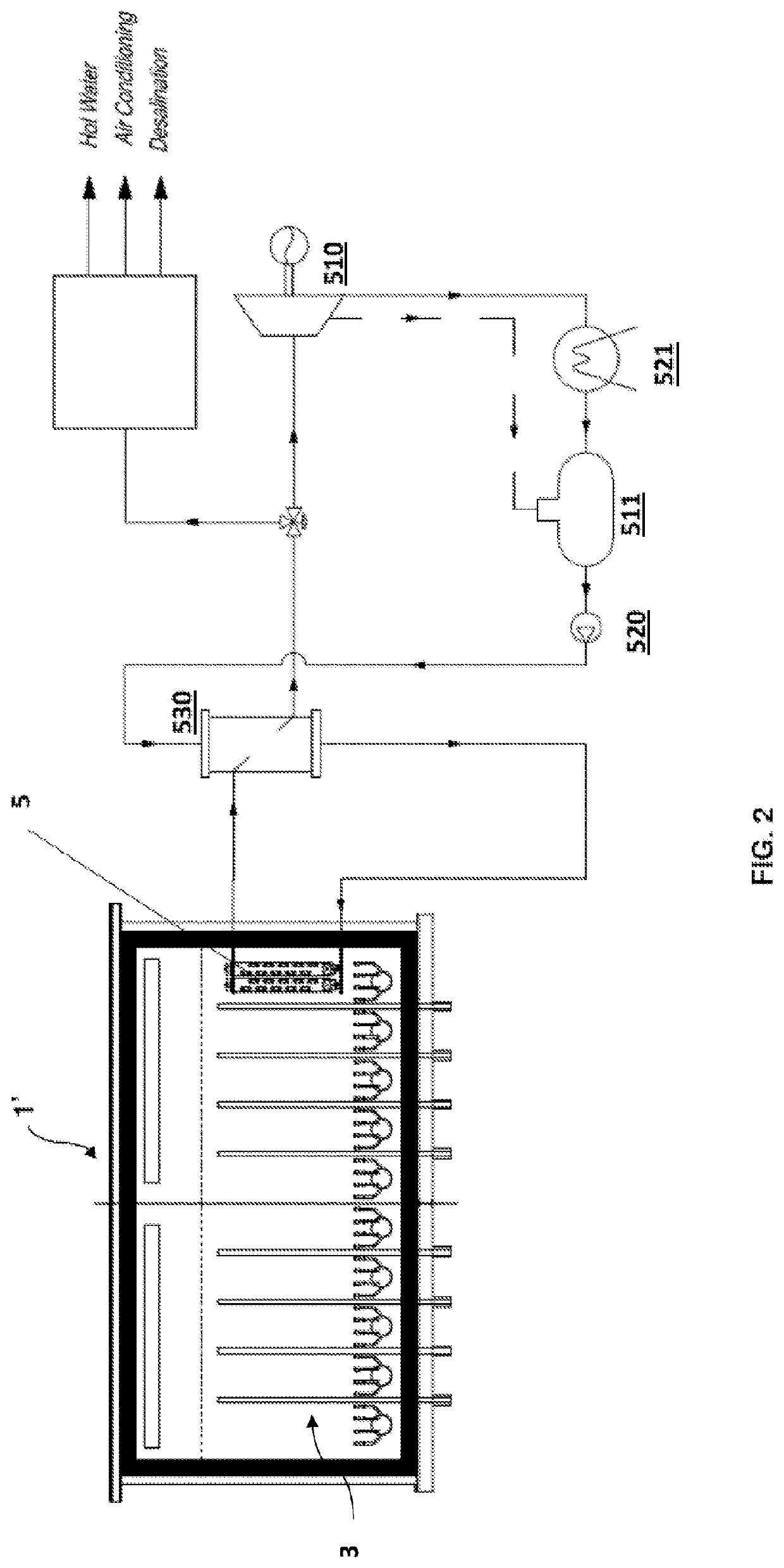

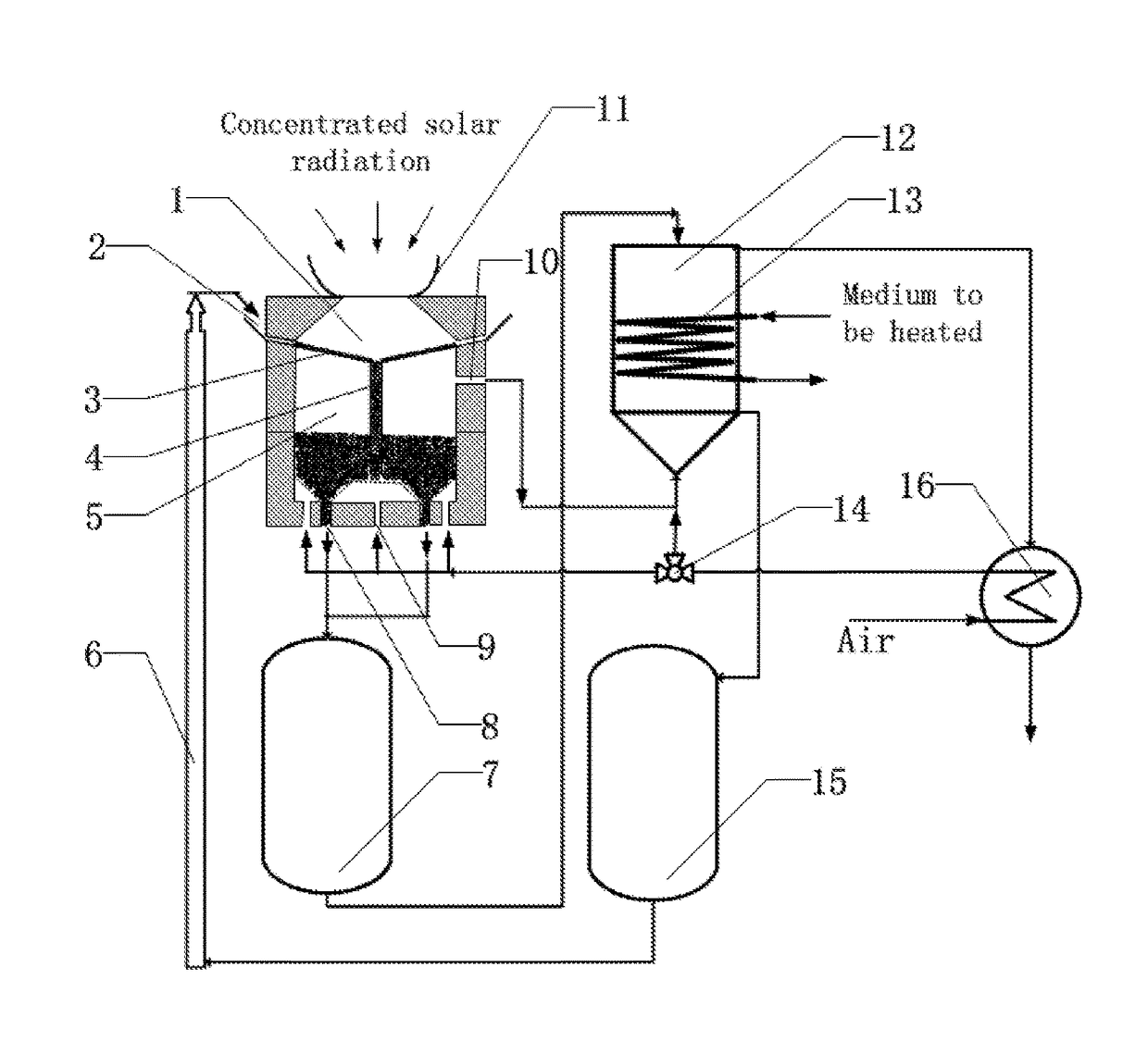

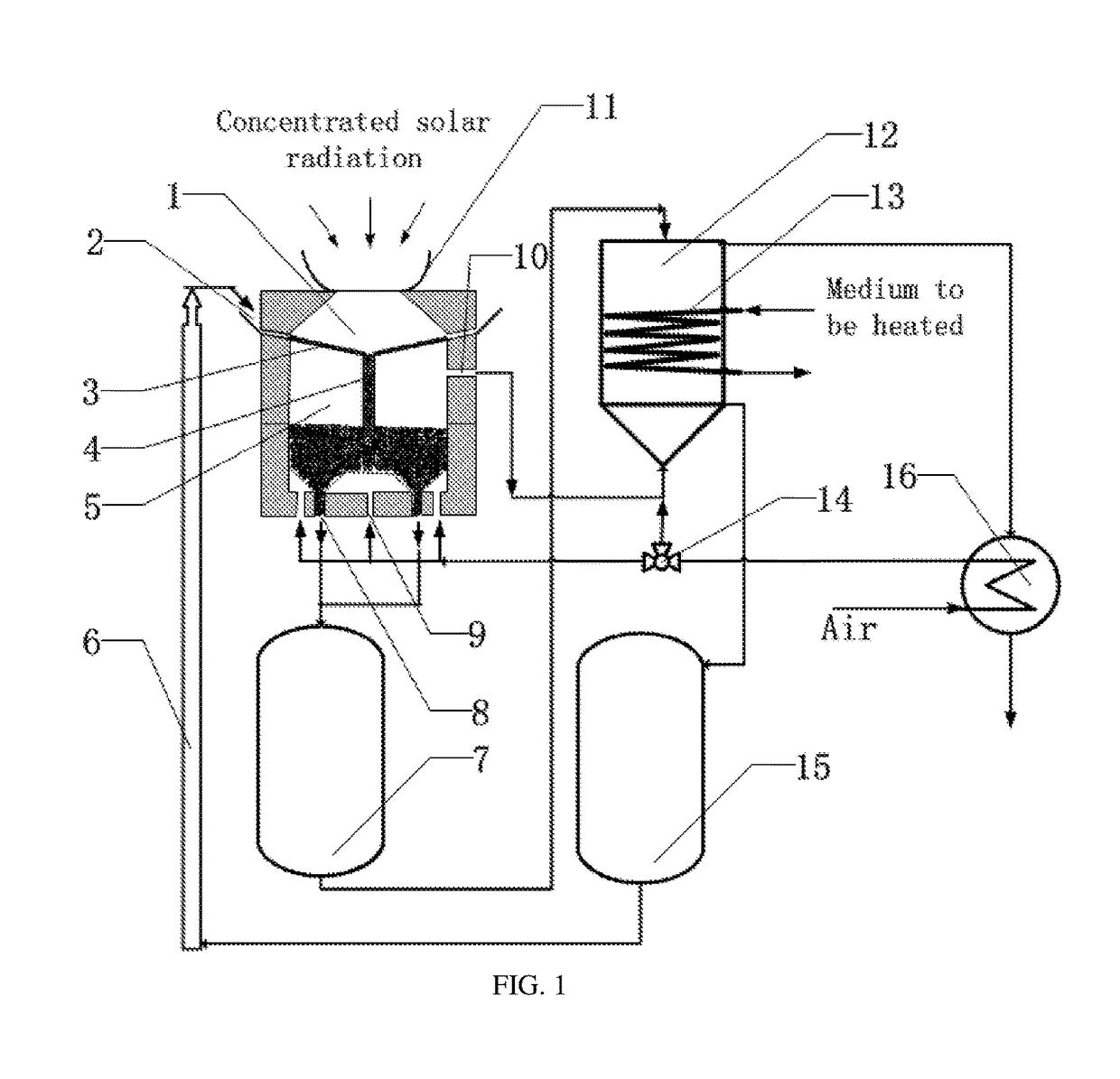

A composite heat absorber of high temperature air and molten salt

InactiveCN102278828AUniform temperature distributionImprove heat transfer efficiencySolar heating energySolar heat devicesMolten saltDaylight

The invention relates to a high-temperature air and molten salt composite heat absorber comprising a porous-structure heat absorber (1), a heat exchange cavity (8), a heat pipe (7) and a molten salt heat absorption pipe (2), wherein the porous-structure heat absorber (1) is arranged at a daylight opening of the high-temperature air and molten salt composite heat absorber (13); the molten salt heat absorption pipe (2) and the heat pipe (7) are respectively located in upper and lower cavities of the heat exchange cavity (8); one end of the heat pipe (7) is located in the lower cavity of the heat exchange cavity (8); the other end of the heat pipe (7) is inserted in an inner pipe of the molten salt heat absorption pipe (2); and the end of the heat pipe (7), located in the inner pipe of the molten salt heat absorption pipe (2), is provided with fins. In the invention, the molten salt heat absorption pipe (2) adopts a sleeve structure; molten salt circulates in the inner pipe and high-temperature air circulates in an interlayer (9) between inner and outer pipelines; the heat exchange cavity (8) and the interlayer (9) between inner and outer pipelines are communicated by utilizing a fanduct (5); and the make-break is controlled by a heat tracing valve (6).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Apparatus and method for collecting energy

Owner:HO EDWARD

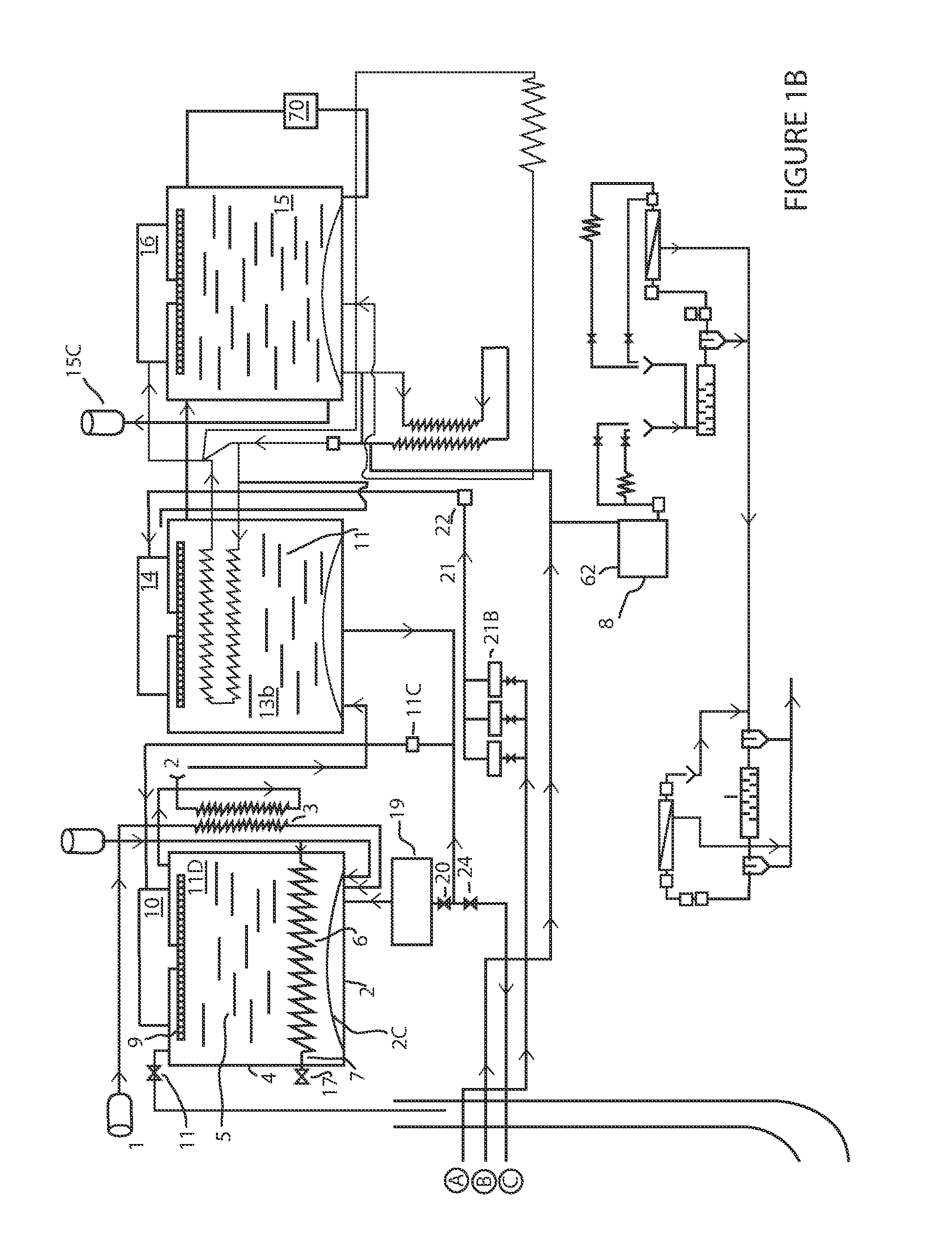

Solar Powered Heating and Air Conditioning

InactiveUS20100011794A1Efficiently use and recycleSolar heating energySolar heat devicesDesiccantPower grid

A solar powered system for providing heat, power and air condition. According to at least one aspect of the invention, there is described a system for using solar power and solar heat to heat a liquid that can be used to control heat, power, cooling, and humidity in a structure to provide an autonomous building that is independent of power grids. The solar system can utilize a desiccant cycle to cool liquid which can be used for air conditioning. An advanced recycling system can use water in stages (i.e., “gray water”) to efficiently use and recycle scarce water with a limited amount of power requirements.

Owner:DE LIMA DANIEL D

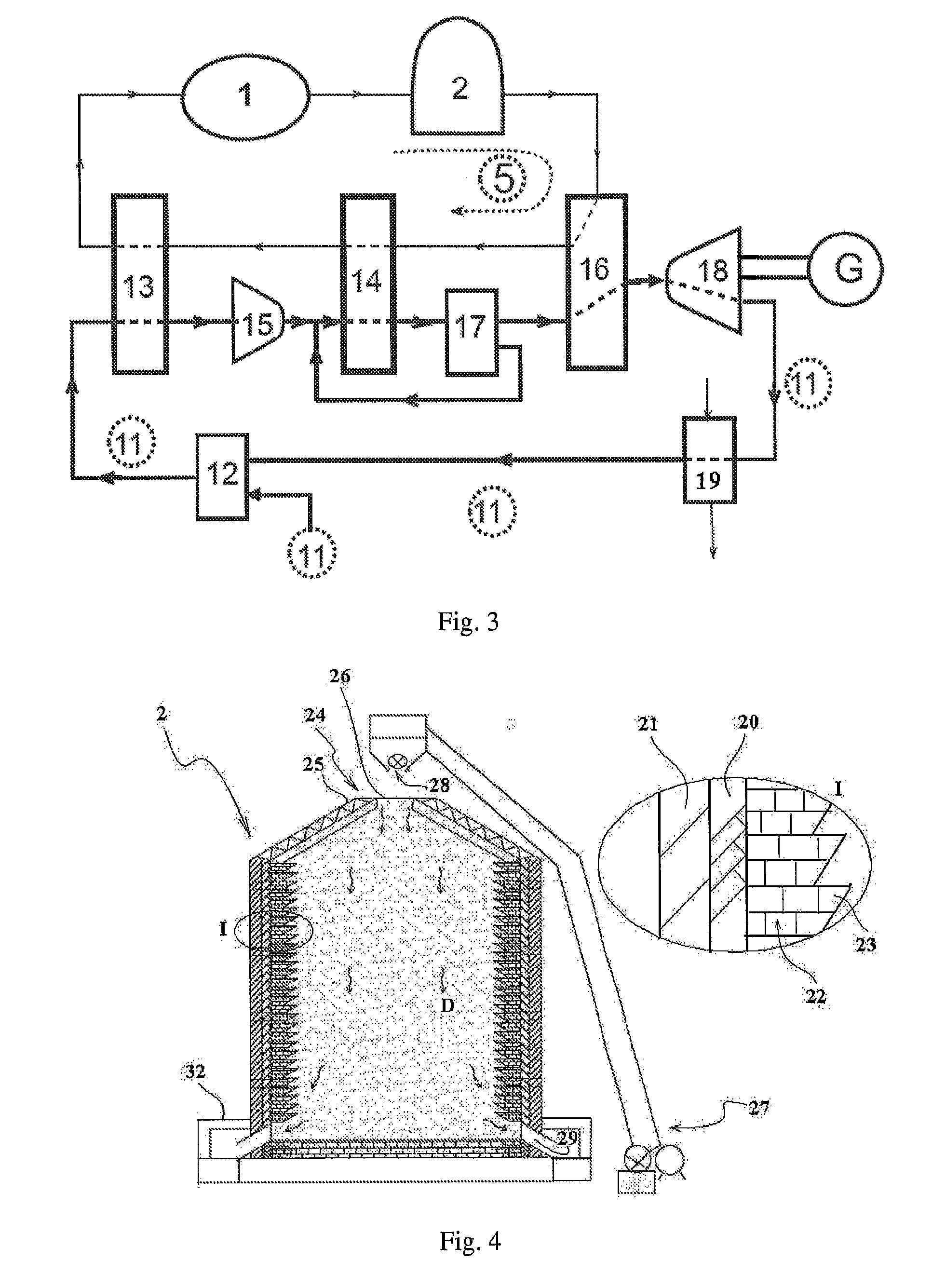

Plant and method for accumulation of energy in thermal form

PendingUS20220090827A1Zero environmental impactImprove efficiencySolar heating energyHeat storage plantsThermodynamicsEngineering

A plant for the accumulation and transfer of thermal energy, which plant has an accumulation device of the kind with a bed of fluidizable solid particles. The plant further has for each accumulation device:electric resistor means arranged within the casing and thermally connected with the bed of particles, which electric resistors are configured for transmitting thermal energy generated by Joule effect to the particles and they are fed by exceeding electric energy from wind or photovoltaic source; andheat exchange means, also thermally connected with the bed of particles and which can be selectively actuated to receive thermal energy therefrom,the overall configuration being such that the thermal energy is transferred from the resistor means to the fluidizable solid particles of the bed and from the fluidizable solid particles to the heat exchange means.

Owner:MAGALDI POWER SPA

Solar heat storage and high temperature gas generating system with working medium being flowing sand

InactiveUS20140026883A1Good effectLarge scaleSolar heating energySolar heat devicesProcess engineeringHigh pressure

A solar heat storage and high temperature gas generating system comprises a sun-tracking light concentrating device (1), a heat storage tank (2) and a heat exchange device (3), with the working medium being flowing sand (5). The flowing sand (5) is heated by the sun-tracking light concentrating device (1), and is transported into the heat storage tank (2). The flowing sand (5) is exported from the heat storage tank (2) steadily, thereby transferring heat to the high pressure gas or liquid (6) which is to be heated in the heat exchange device (3) and generating high temperature and pressure gas. The system has the advantages of good heat storage effect, large heat storage volume, high heat exchange efficiency and low operation cost.

Owner:CHEN YUQI

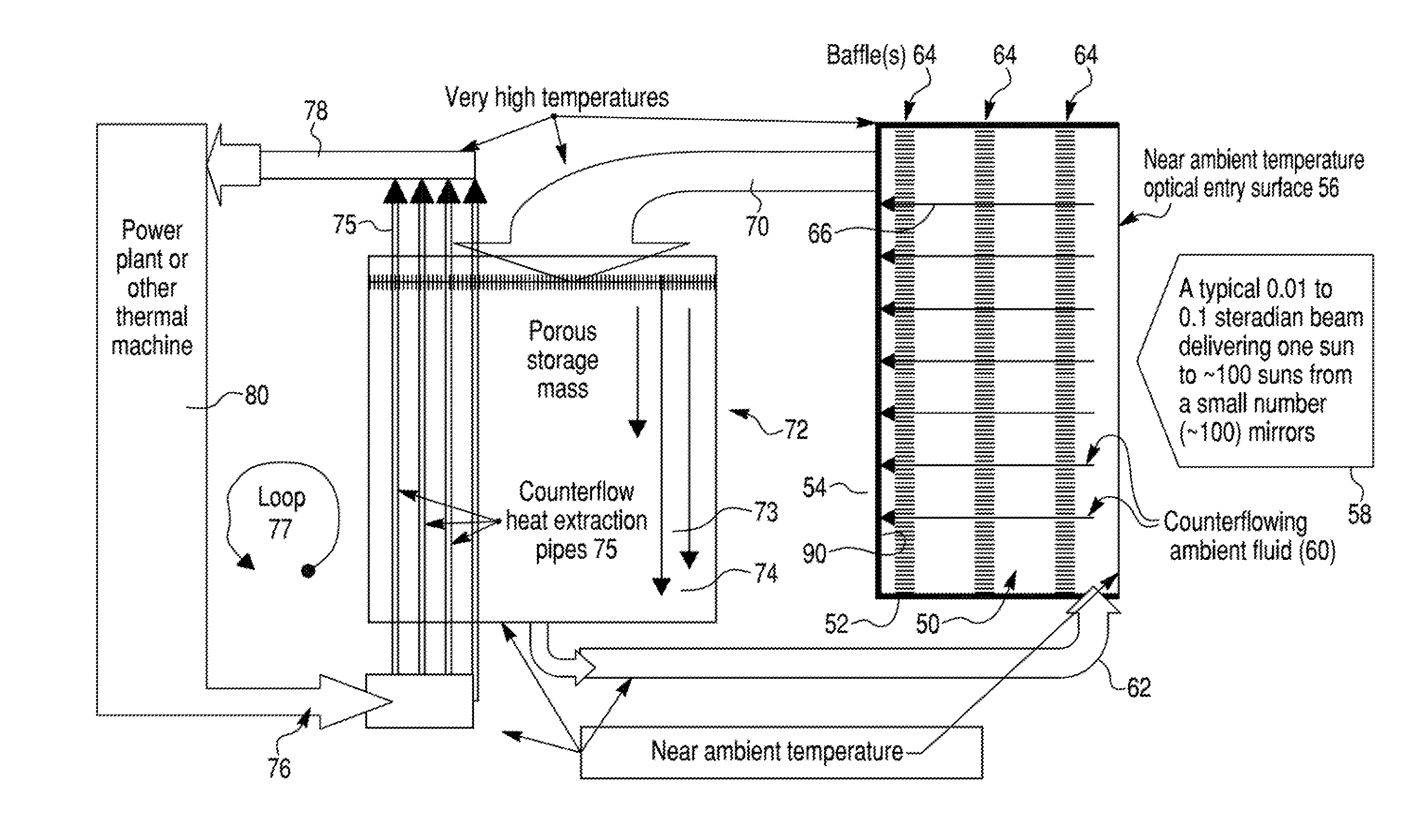

Ultra high efficiency, high temperature solar collection and storage

InactiveUS20170016649A1Little to no emissive lossKeep energy smallSolar heating energySolar heat devicesRadiative heat lossCounter flow

High-temperature solar trap collectors provide near ambient temperature solar entry surfaces and negligible thermal radiation losses by counterflowing low velocity transparent gases or liquids (fluids) to nullify internal thermal diffusion and radiative heat losses at the solar entry surface. Small steradian (sr) baffling plus wavelength-selective materials trap the entire 0.35 u to 2.7 u incoming solar spectrum and heat highly absorbing internal surfaces to high temperatures; only a small solid angle of the 2π steradians—on the order of 0.01 sr—of internal thermal radiation escapes. A nearly 100% efficient flat panel solar trapping embodiment exhibits alpha (α) absorption nearing 1.0 and radiant emission losses nearing 0.0 even at solar collection temperatures in excess of 1,000° K. Ultra high collection efficiency counterflow configurations are ideal for solar hot water, space heating, cooling, energy storage, and electric power generation applications.

Owner:ACE RONALD S

Systems and methods for thermophotovoltaics with storage

InactiveUS20160197574A1Maximizing exergetic efficiencyLow costSolar heating energyThermoelectric device manufacture/treatmentEngineeringThermophotovoltaic

Systems and methods for thermophotovoltaics with storage are disclosed. In one embodiment, includes a heat generating device configured to generate heat for a heat transfer fluid and a thermal storage device configured to receive the heat transfer fluid from the heat generating device via fluid delivery devices and cause, by the heat of the heat transfer fluid, a thermal storage material to store at least a portion of the heat of the heat transfer fluid. The system can also include a power block having a thermal emitter and a thermophotovoltaic device. The power block can be configured to receive the heat transfer fluid via the fluid delivery devices and cause, by the heat of the heat transfer fluid, the thermal emitter to emit a plurality of photons to a photovoltaic element of the thermophotovoltaic device.

Owner:GEORGIA TECH RES CORP

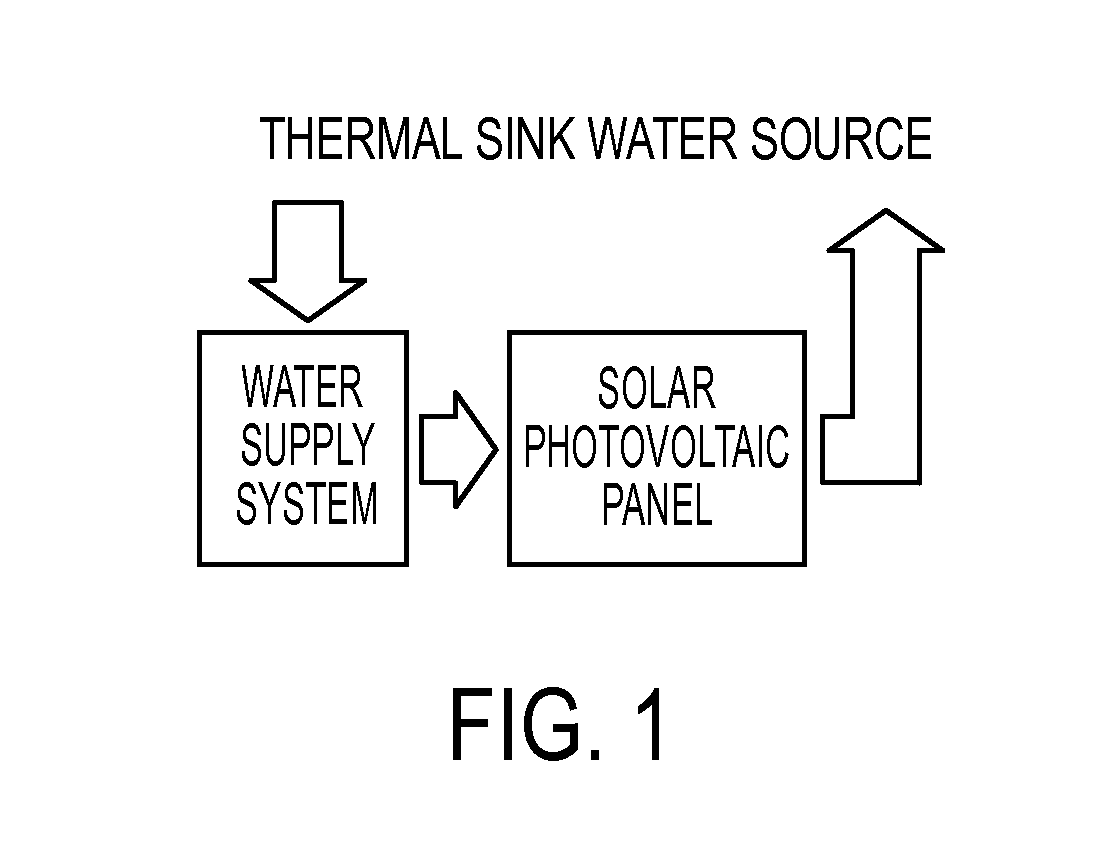

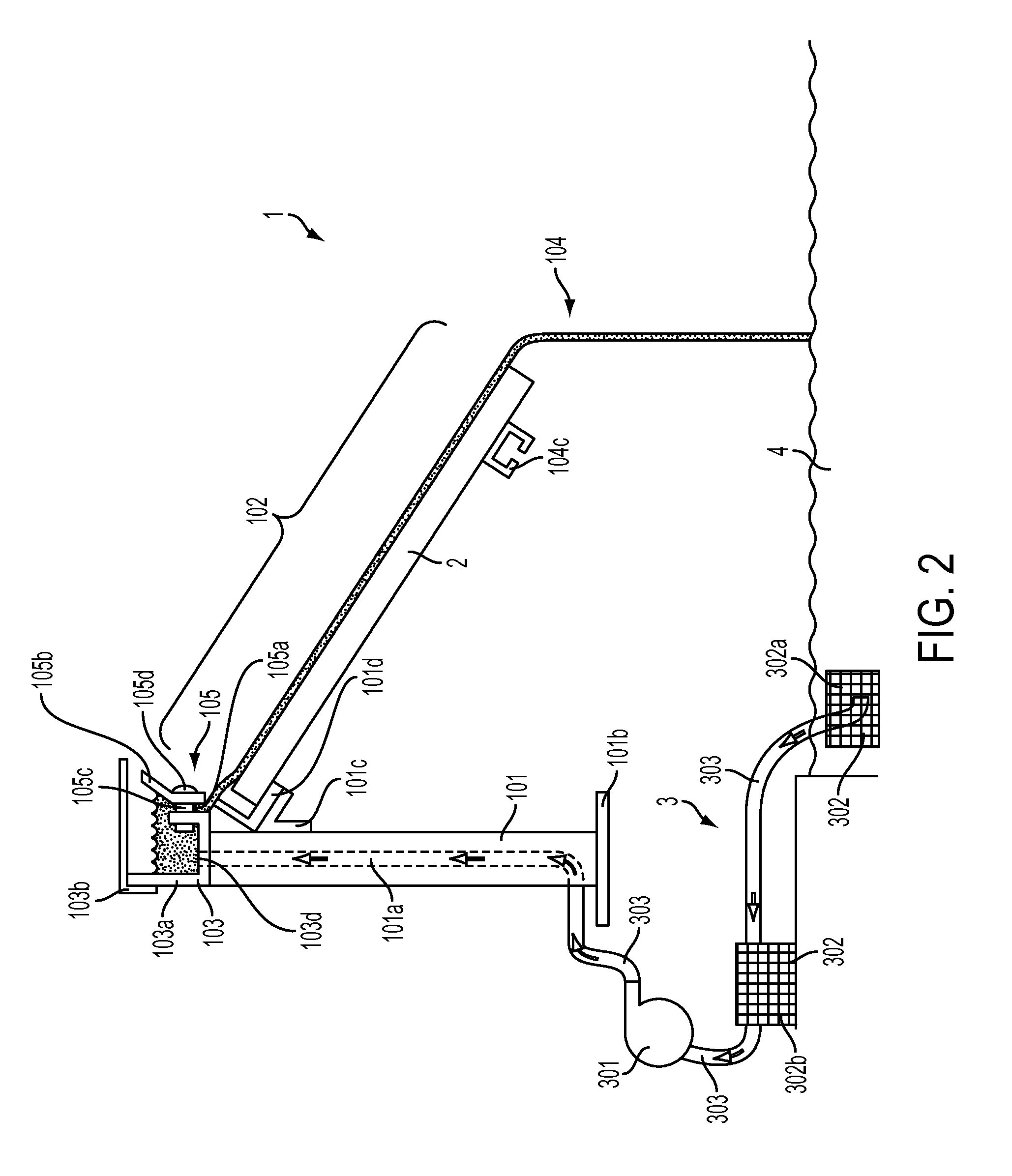

Solar photovoltaic panel cooling system and method

InactiveUS20140060620A1Extended service lifeImprove electrical performanceSolar heating energyPV power plantsWater flowEngineering

A solar photovoltaic panel system which has a thermal sink and a panel mounting structure is provided. The panel mounting structure contains a water flow section. The water flow section includes an inflow section and an outflow section. A solar photovoltaic panel is mounted between the inflow section and the outflow section. A water supply system is connected to the panel mounting structure to provide water on a top surface of the solar photovoltaic panel. The water provided from the thermal sink is returned to the thermal sink after flowing on the top surface of the solar photovoltaic panel.

Owner:TENNESSEE VALLEY AUTHORITY

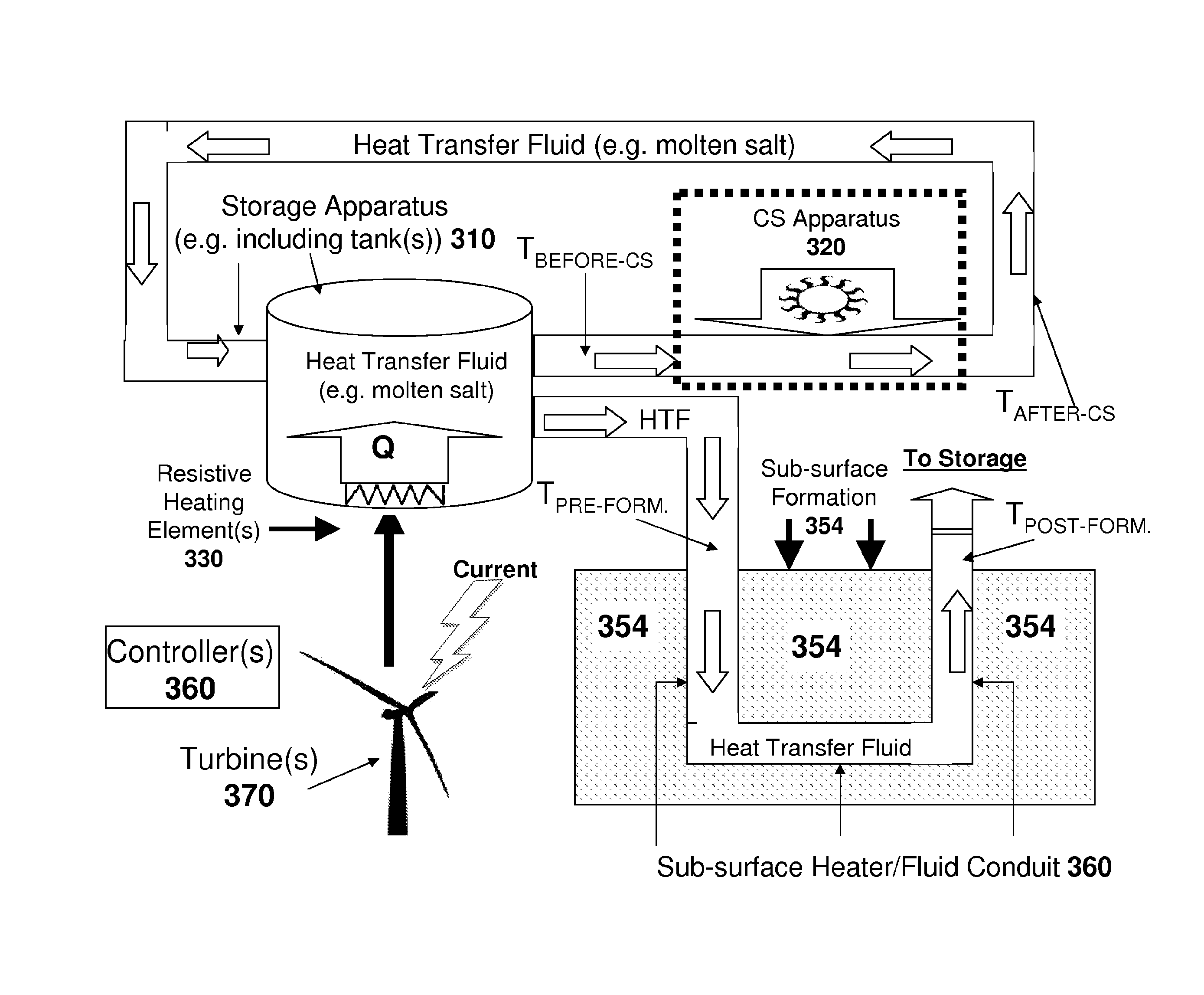

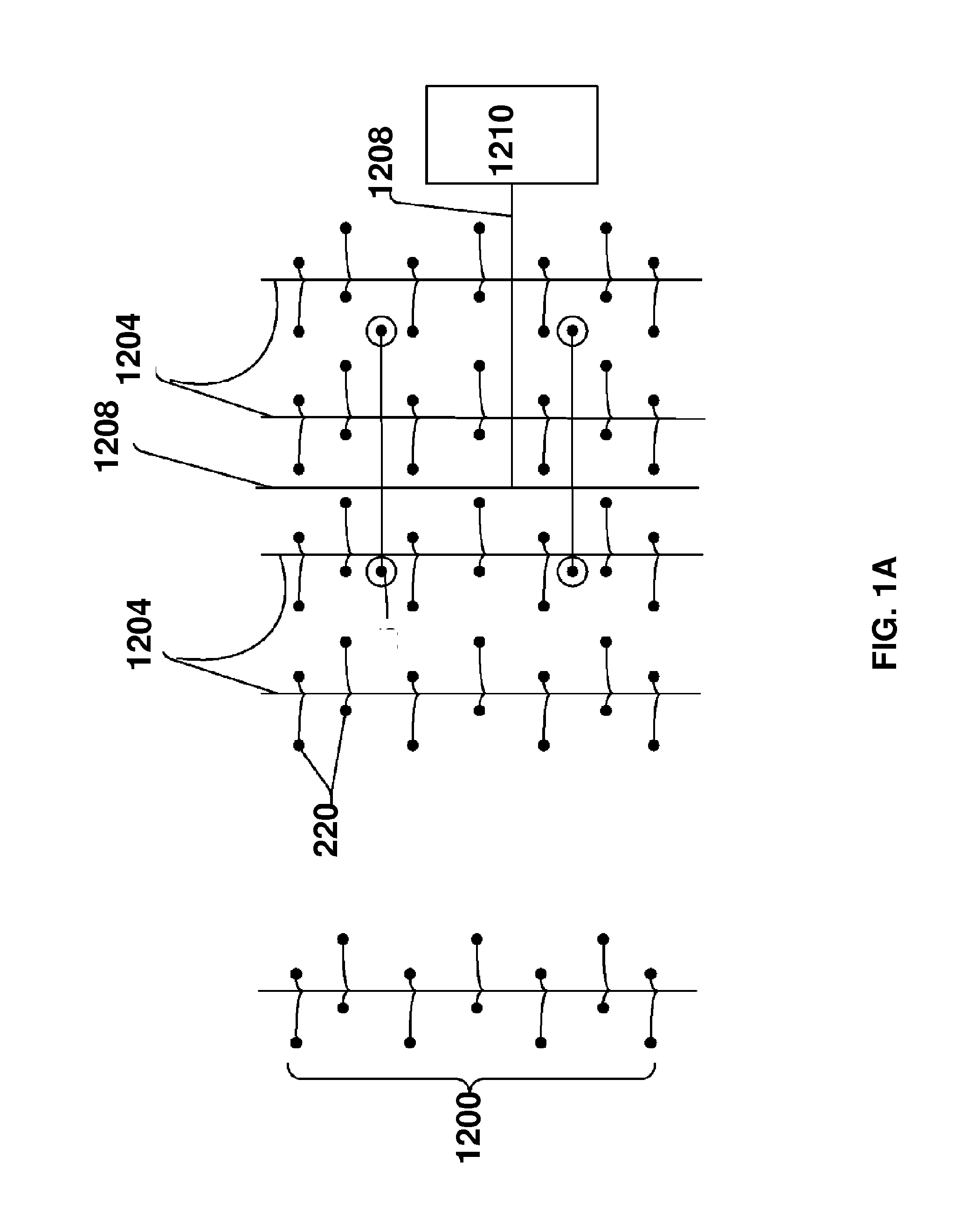

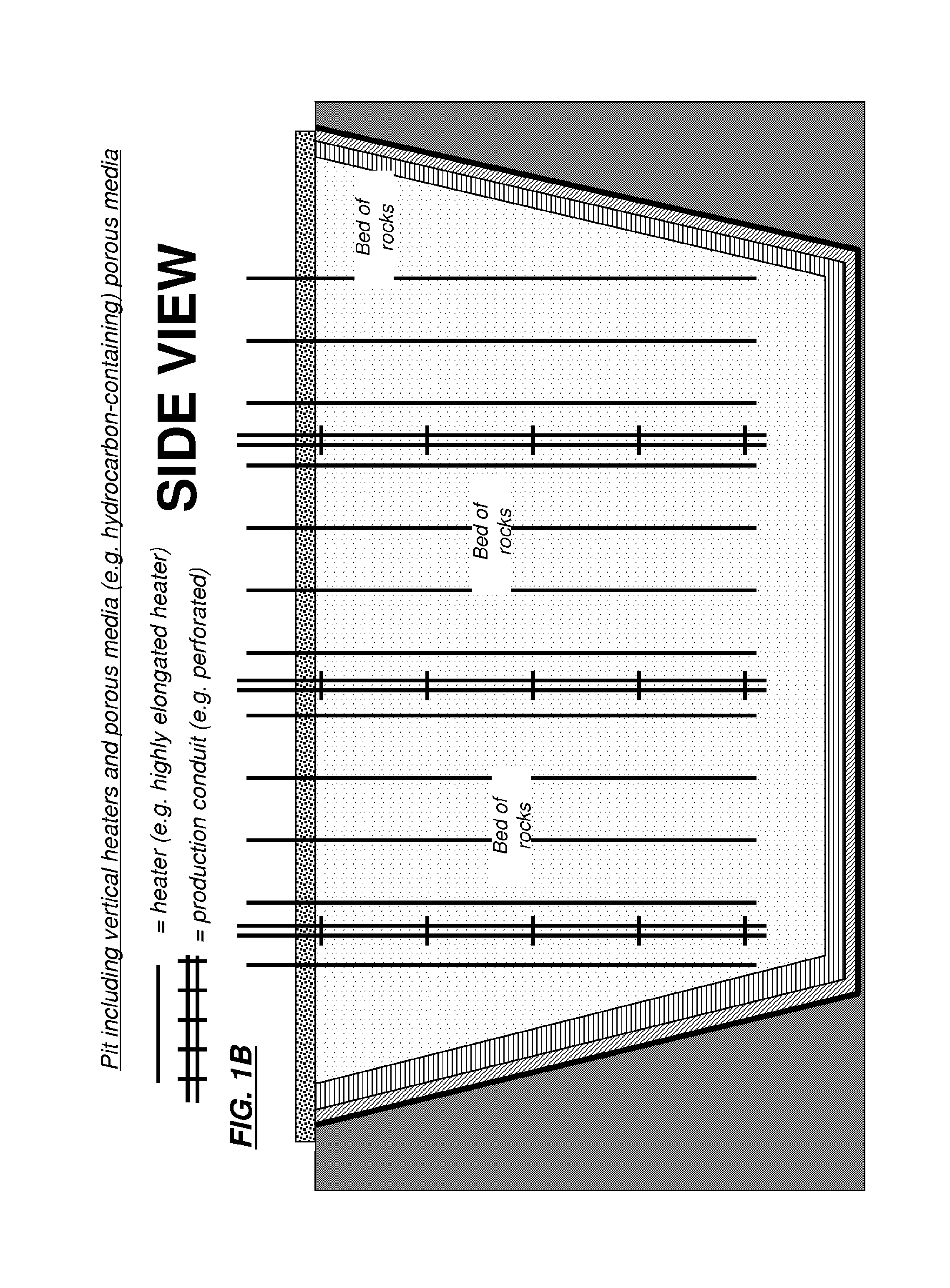

Wind-heated molten salt as a thermal buffer for producing oil from unconventional resources

InactiveUS20160047212A1Enhanced couplingLow variabilitySurveySolar heat devicesElectricityElectrical resistance and conductance

Embodiments of the present invention relate to heat transfer fluids (e.g. molten-salt) as a thermal buffer for heating, by thermal energy derived from wind-generated electricity, at least one of (i) a subsurface hydrocarbon-containing formation or (ii) a bed of hydrocarbon-containing rocks. During times when wind is plentiful, wind electricity is used to heat the heat transfer fluid—e.g. by means of an electrically resistive heater immersed in the heat transfer fluid. At any time, thermal energy from the wind electricity may be transferred to the hydrocarbon-containing rocks or subsurface formation by the heat transfer fluid. In some embodiments, the fluid is heated both by wind-generated electricity and by solar radiation. Some embodiments relate to a subsurface molten salt heater (e.g. powered by wind-generated electricity) having a non-thermally insulation portion through which molten salt flows. The heater is configured to maintain a temperature of the circulating molten salt, throughout the substantially non-thermally-insulated portion, at a temperature significantly above a melt temperature of the molten salt.

Owner:GENIE IP

Dual-cavity method and device for collecting and storing solar energy with metal oxide particles

ActiveUS20170191697A1Improve concentrationReducing endothermic reactionSolar heating energyExothermal chemical reaction heat productionOxygenAmbient air

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com