Solar Receivers for Use in Solar-Driven Thermochemical Processes

a solar receiver and thermochemical technology, applied in the field of solar collectors, can solve the problem of not being able to generate heat at the necessary temperature to drive high temperature processes, and achieve the effects of improving overall system efficiency, improving efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

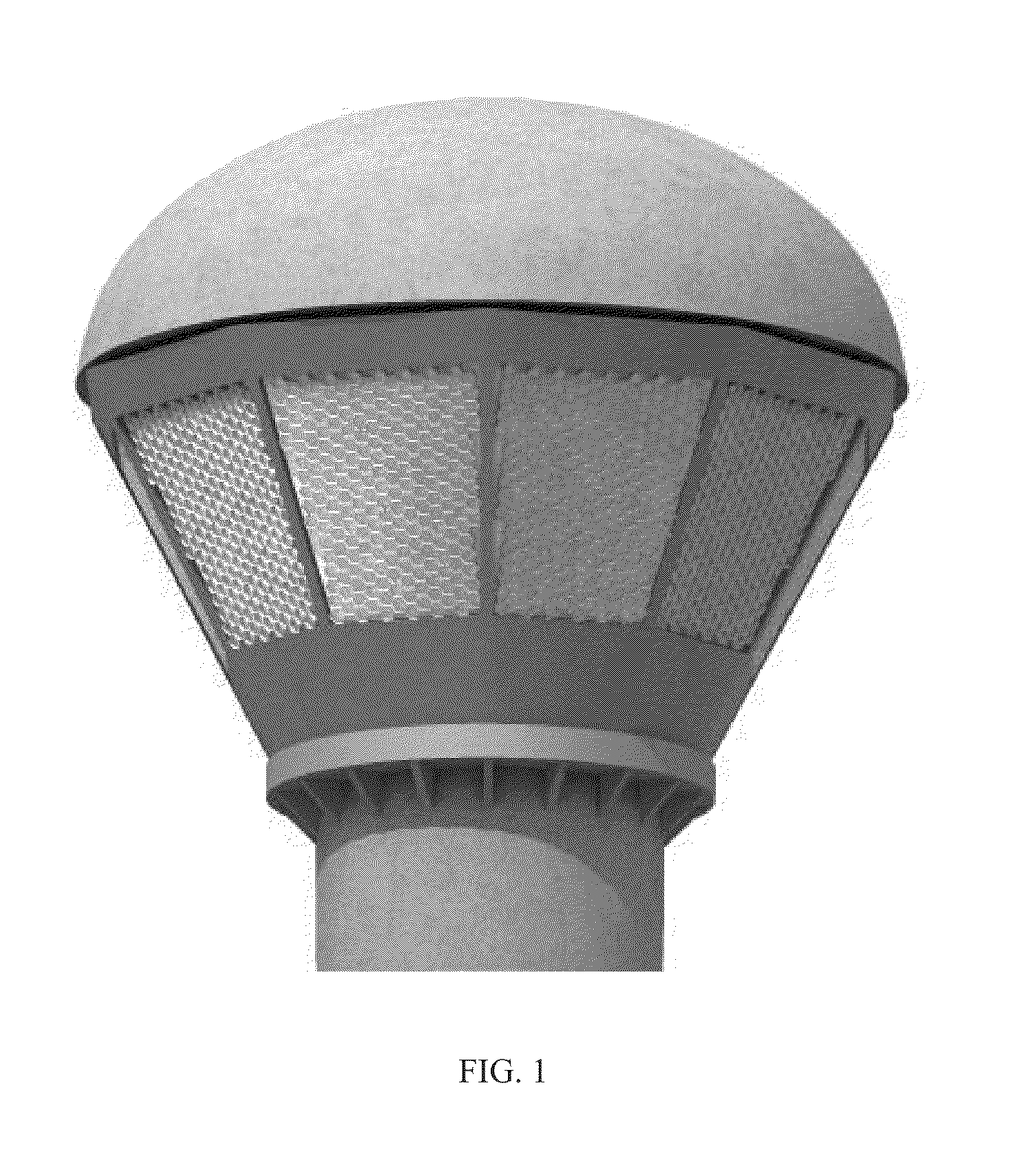

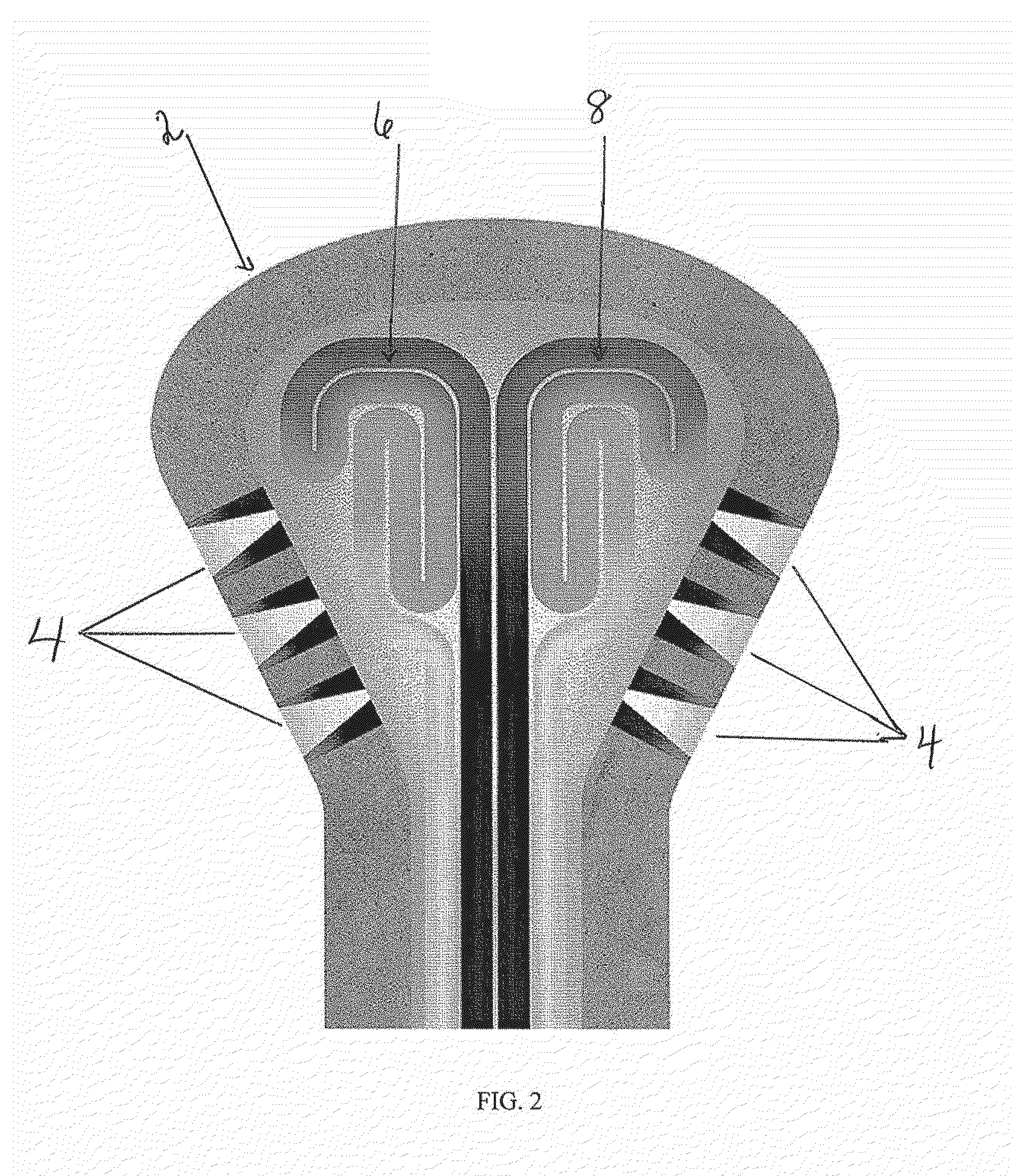

Image

Examples

Embodiment Construction

I. Definitions

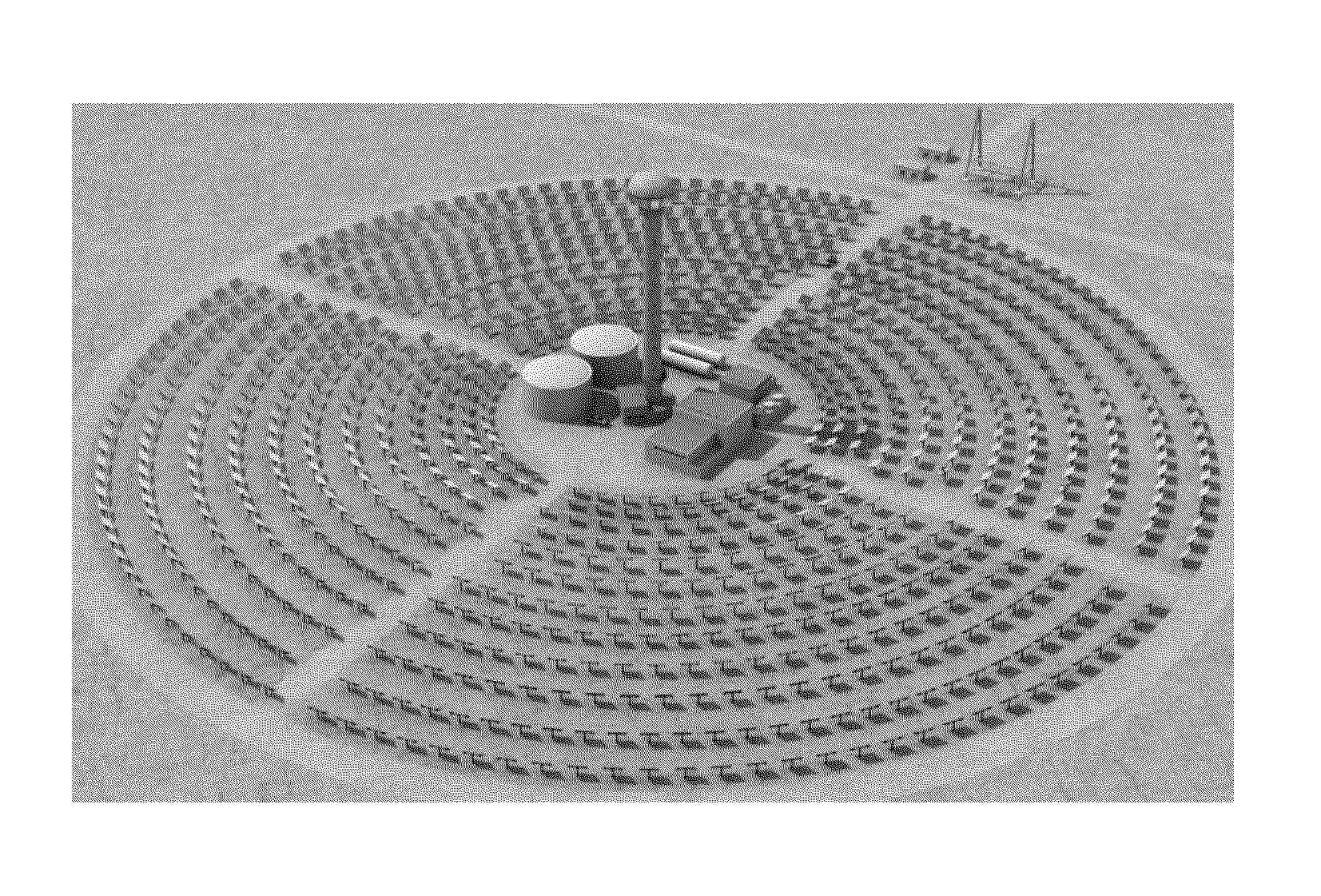

[0025]“Heliostat”, as used herein, refers to a device that includes a mirror, usually a plane mirror, which turns so as to keep reflecting sunlight toward a predetermined target, compensating for the sun's apparent motions in the sky.

[0026]“Stable”, as used herein, refers to, typically refers to the absorbing medium and means that it is chemically stable (i.e., does not react with the containment materials and / or other materials in the absorbing medium and / or degrade) and thermally stable (i.e., does not boil or chemically disassociate in an undesirable way).

[0027]“Containment materials” or “containment element”, as used herein, refers to a component of the receiver and / or reactor system that contains the heat transfer fluid, such as a pipe, valve, pump, etc. or materials that are used to form such components.

[0028]“Heat transfer fluid”, as used herein, refers to the medium which absorbs the heat collected by the receiver. The fluid can be transported to a reactor syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com