A composite heat absorber of high temperature air and molten salt

A high-temperature air, heat sink technology, applied in indirect heat exchangers, heat exchanger types, solar collectors, etc. Stress problem, the effect of speeding up salt discharge and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

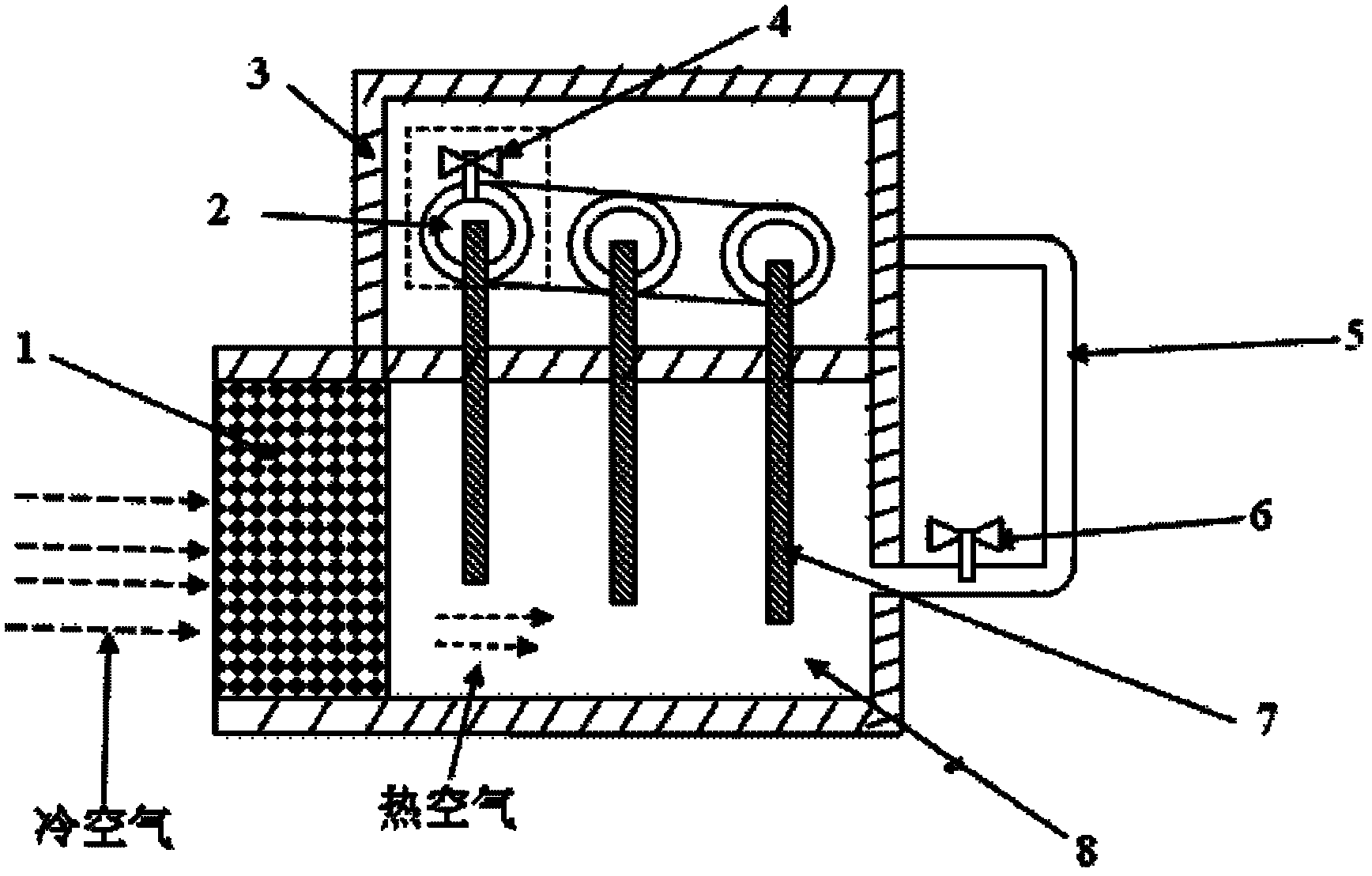

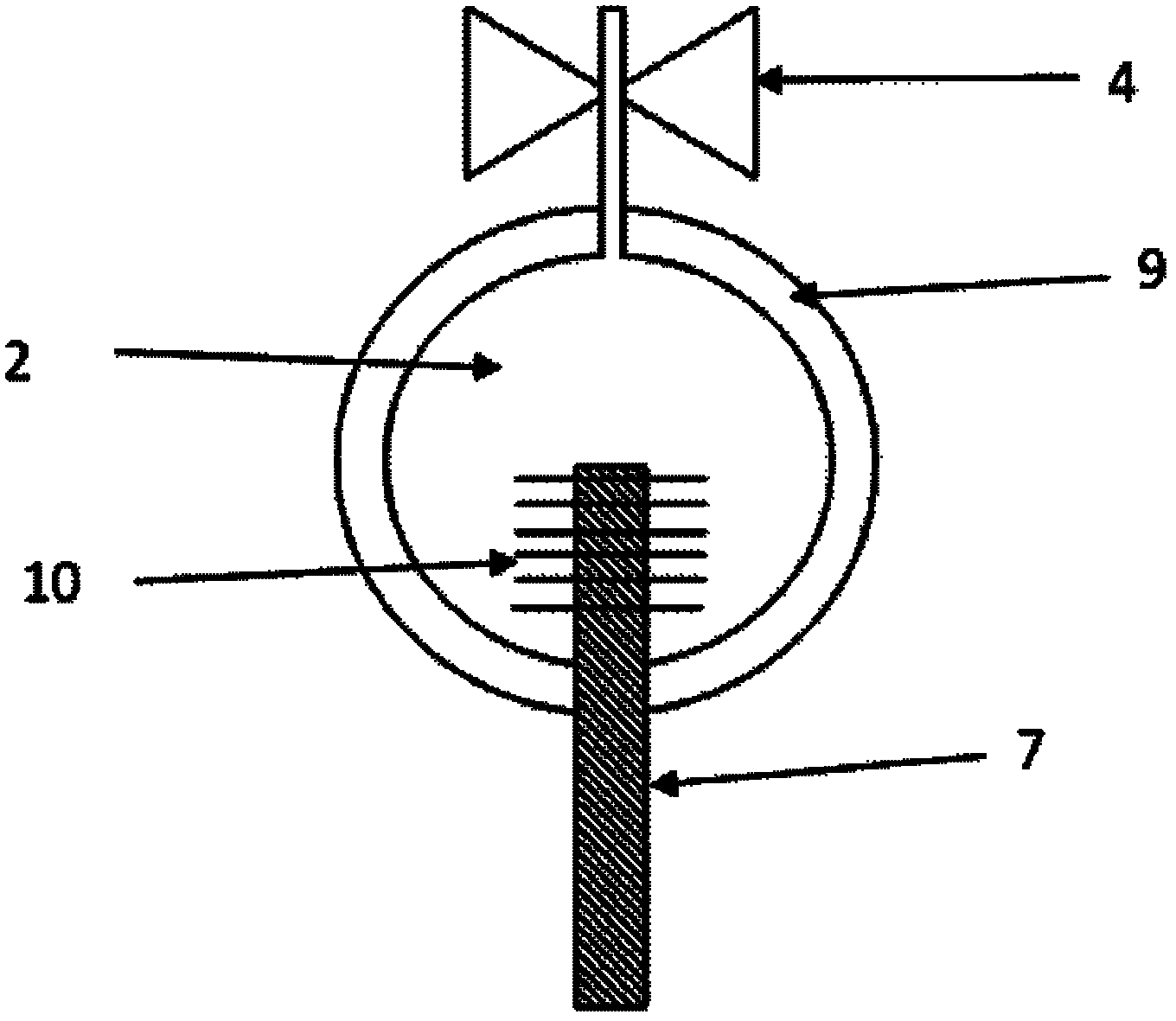

[0034] Embodiment 1: High-temperature air and molten salt composite heat absorber with heat pipe horizontal pipe structure.

[0035] In the preheating condition, the control system makes some of the heliostats in the heliostat field 19 in the working state, and the solar energy is focused by some of the heliostats to form a light spot with a low energy flux density. At the same time, the induced draft fan 15 is started, and the cold air Drawn by the fan 15, it flows through the heat absorber 1 with a porous structure. The cold air passes through the heat exchange with the heat absorber 1 of porous structure, and finally enters the heat exchange chamber 8, opens the heat tracing valve 6, and makes it in an open state, and the hot air enters the fan pipe 5 through the heat tracing valve 6. At this time, there is no molten salt working medium flowing through the molten salt heat absorbing pipe 2 and the molten salt pipeline 11 . The thermocouple in the heat exchange chamber 8 ca...

Embodiment 2

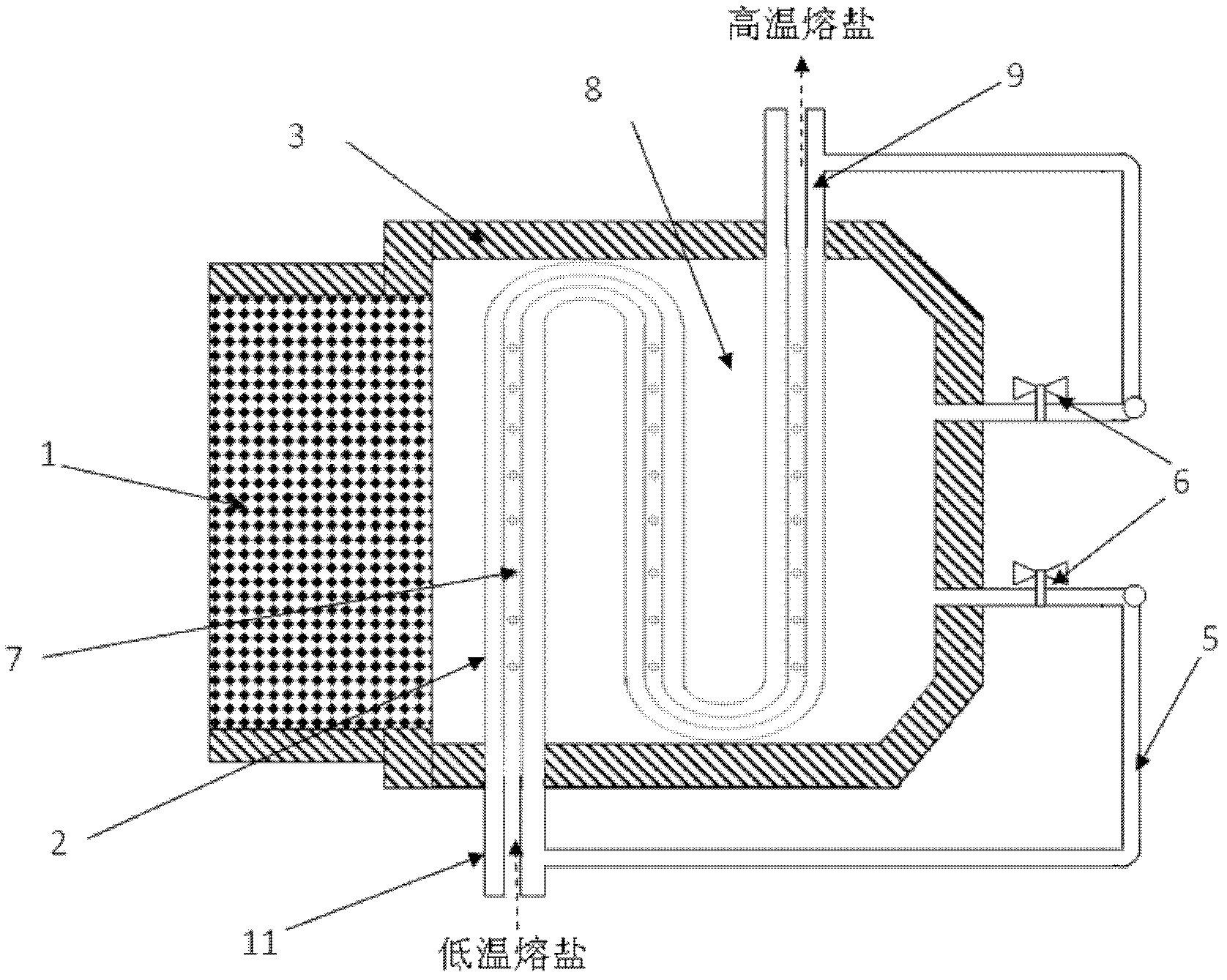

[0036] Example 2: High-temperature air and molten salt composite heat absorber with vertical structure without heat pipes

[0037] In the case of preheating, the control system makes part of the heliostats in the heliostat field 19 in the working state, the temperature of the porous structure heat absorber 1 absorbs solar energy rises, and at the same time the induced draft fan 15 is started, and the cold air passes through the porous structure heat absorber 1 1, finally enters the heat exchange chamber 8, and the air in the heat exchange chamber 8 has a relatively high temperature at this time. Then the heat tracing valve 6 is opened, and the air enters the fan duct 5 through the heat tracing valve 6 . Through feedback control, the temperature of the air in the heat exchange chamber 8 is kept stable at about 300°C. At the same time, the heat-tracing air enters the interlayer 9 of the inner and outer pipes of the molten salt heat-absorbing pipe 2 through the fan pipe 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com