Solar Light (Heat) Absorption Material and Heat Absorption/Accumulation Material and Solar Light (Heat) Absorption/Control Building Component Using the Same

a technology of solar energy and absorption material, which is applied in the direction of solar heat collector details, light and heating apparatus, and absorbing elements, etc. it can solve the problems of reducing the efficiency of solar energy, and reducing the need for manufacturing cost restriction, so as to improve the absorption ability of solar energy and reduce the burden on the environment. , the effect of effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Bagasse Char (1)

[0101]In this example, there was employed a squeezed waste-(bagasse) of sugarcanes produced in Miyako Island in Okinawa in the year 2008. Firstly, the bagasse was dried under nitrogen gas flow at 100° C. for 12 hours. The bagasse thus obtained was in the form of milky white fine particles of 10 mm or less. Then, this bagasse was charged into an electric furnace and then heated progressively under nitrogen gas flow from the room temperature to 500 or 700° C. at the rate of 5° C. / min. Once the predetermined temperature reached, a carbonization was carried out with keeping the temperature at the reached predetermined temperature for 5 hours. Thereafter, with continued flow of nitrogen, cooling was carried out to the room temperature by natural cooling. After this, it was found that all the bagasse had turned into black char (bagasse char). Then, this bagasse char was pulverized, for 10 minutes, at the rotation speed of 14000 by a laboratory blender made b...

example 2

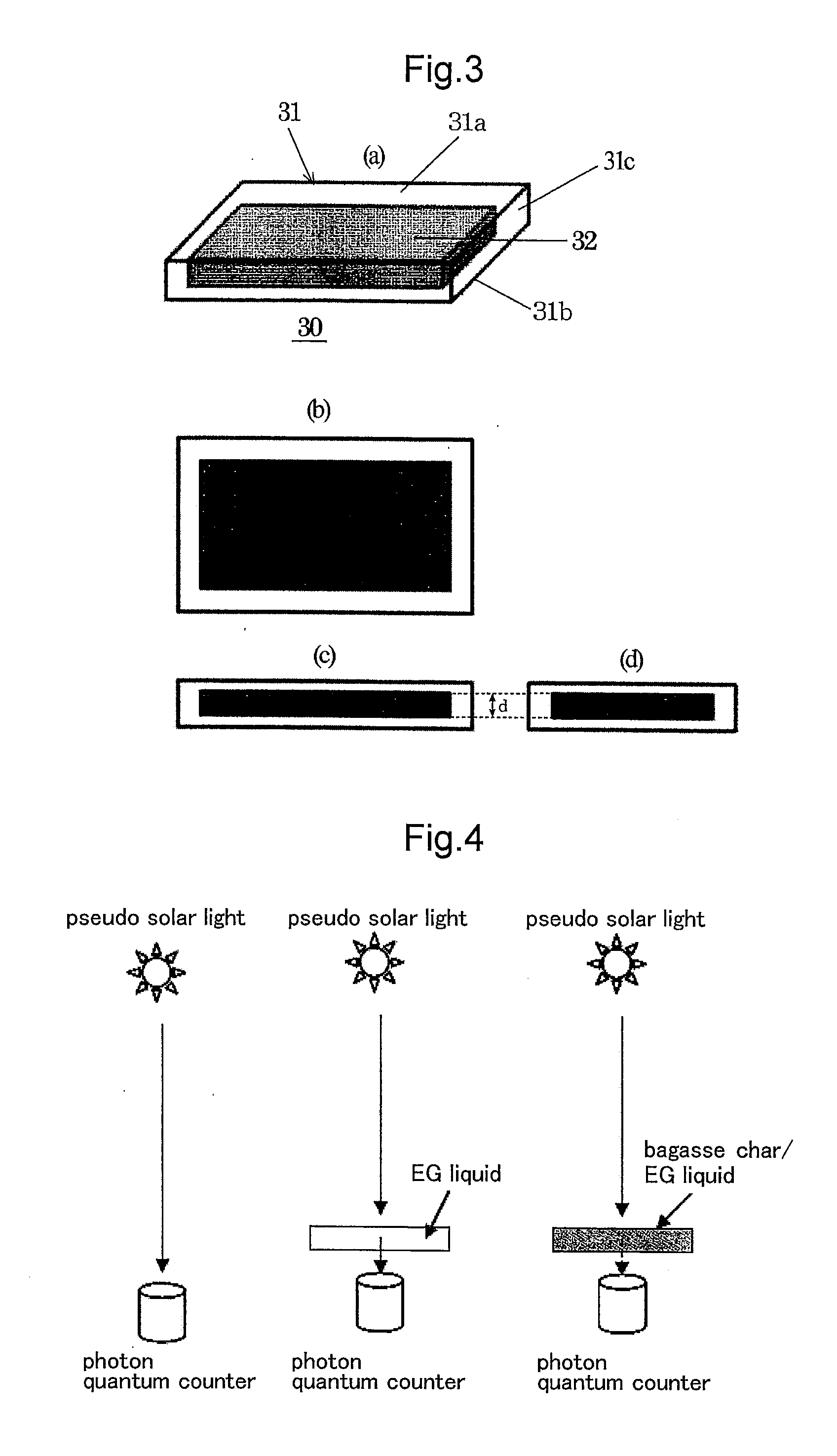

Pseudo Solar Light Absorption Experiment (1)

[0102]Into a petri dish of 10 cm in diameter, ethylene glycol (EG) liquid containing the bagasse char (500° C.) obtained in EXAMPLE 1 at the contents of 0% and 0.5% were charged to a depth of 1 cm and then subjected to irradiation by a commercially available halogen lamp (available from Toshiba Corporation) as a pseudo solar light whose output was adjusted to provide a light amount of 2800 μmol / m2 / sec (corresponding to the solar radiation amount in summer time in the city of Naha) and the amount of light past through the petri dish was determined. The light amount was determined by a commercially available photon quantum meter. From an EG liquid (Comparison Example) with no bagasse char content, photon quantum of 2660 μmol / m2 / sec was determined, thus it was found that irradiated light was hardly absorbed thereby. On the other hand, the photon past the EG liquid with 0.5% dispersion of bagasse char was 0.9 μmol / m2 / sec, indicating that 99.97...

example 3

Absorption Characteristic Experiment (1)

[0104]In order to observe in details the light absorption characteristics of the bagasse dispersion liquid, there were observed LTV-visible absorption spectra of EG (Ethylene Glycol) media whose dispersion content of the bagasse char obtained in EXAMPLE 1, carbonized at 500° C. and past the 100 mesh were varied to 0% (comparison example), 0.1%, 0.5%, respectively. As the metering cell, there was employed a quartz cell 10 mm in width and 10 mm in thickness. And, the reference in the measurement was EG liquid with no bagasse char content. The measurement was done on the transmittance spectrum of light from the 200 nm to the near infrared region of 1100 nm. The results are shown in FIG. 5.

[0105]FIG. 5 shows that with the 0.1% dispersion content, transmittance was from 30 to 35% in entire wavelength region. Whereas, with the content of 0.3% or higher, the medium shows only transmittance of less than 1% only, thus demonstrating absorption of almost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com