Solar heat storage and high temperature gas generating system with working medium being flowing sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

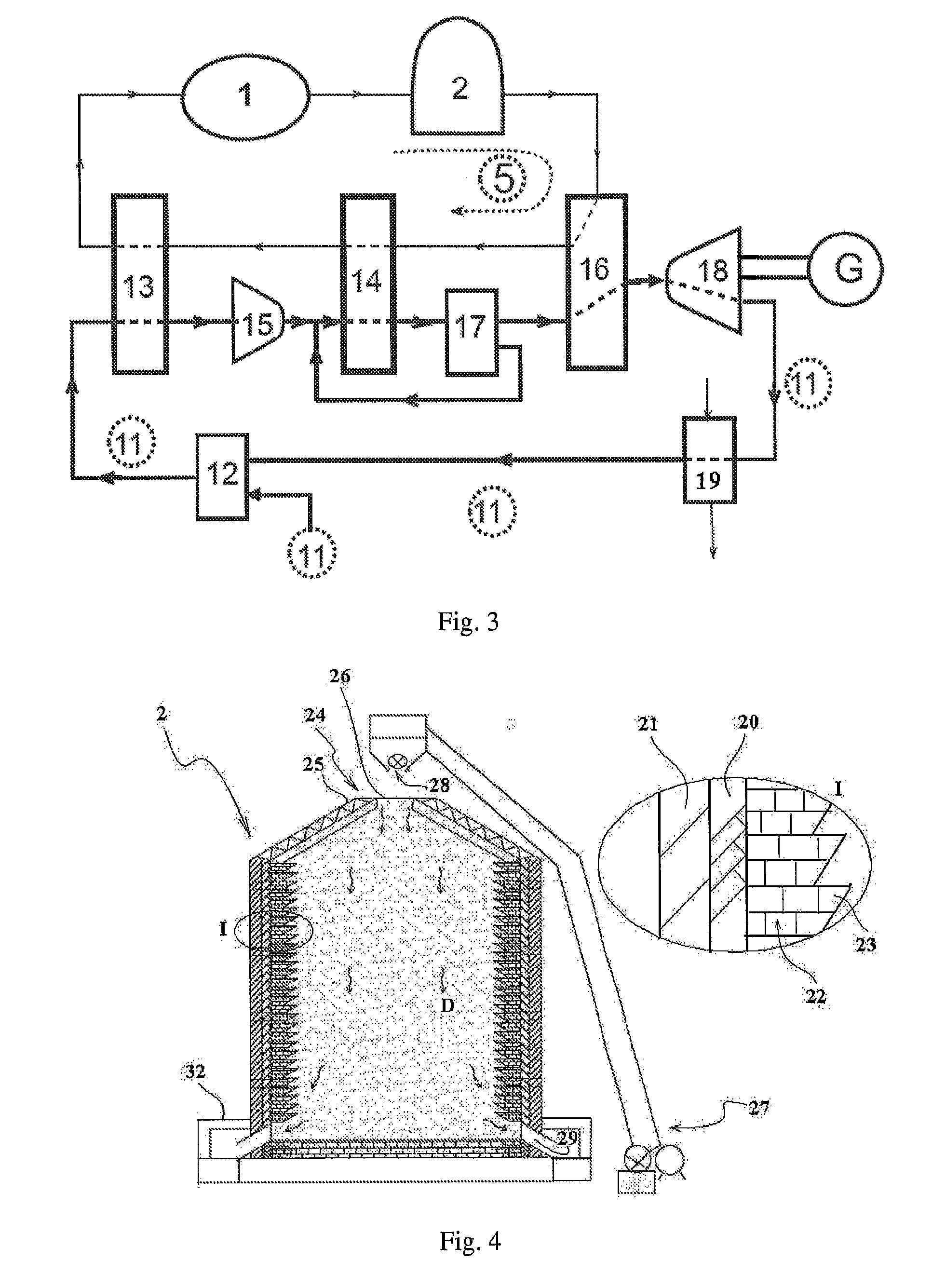

[0047]Utilizing sand's solidity, fluidity, high temperature resistance, corrosion resistance, low-cost, especially being able to be stacked, this invention provides to build solar heat energy storage tank which is of large capacity, of being able to long-term storage with flowing sand as energy storage materials and work medium. The heat storage tank allows sunlight heat sand to high temperature by intermittently input but by continuous and stable output. Addition to the sand, the invention is equally suitable for all other particulate matter and their mixtures with similar properties as flowing sand, i.e., solidity, fluidity, high temperature resistance, corrosion resistance, low-cost, especially those particulate matter and their mixtures which are able to be stacked.

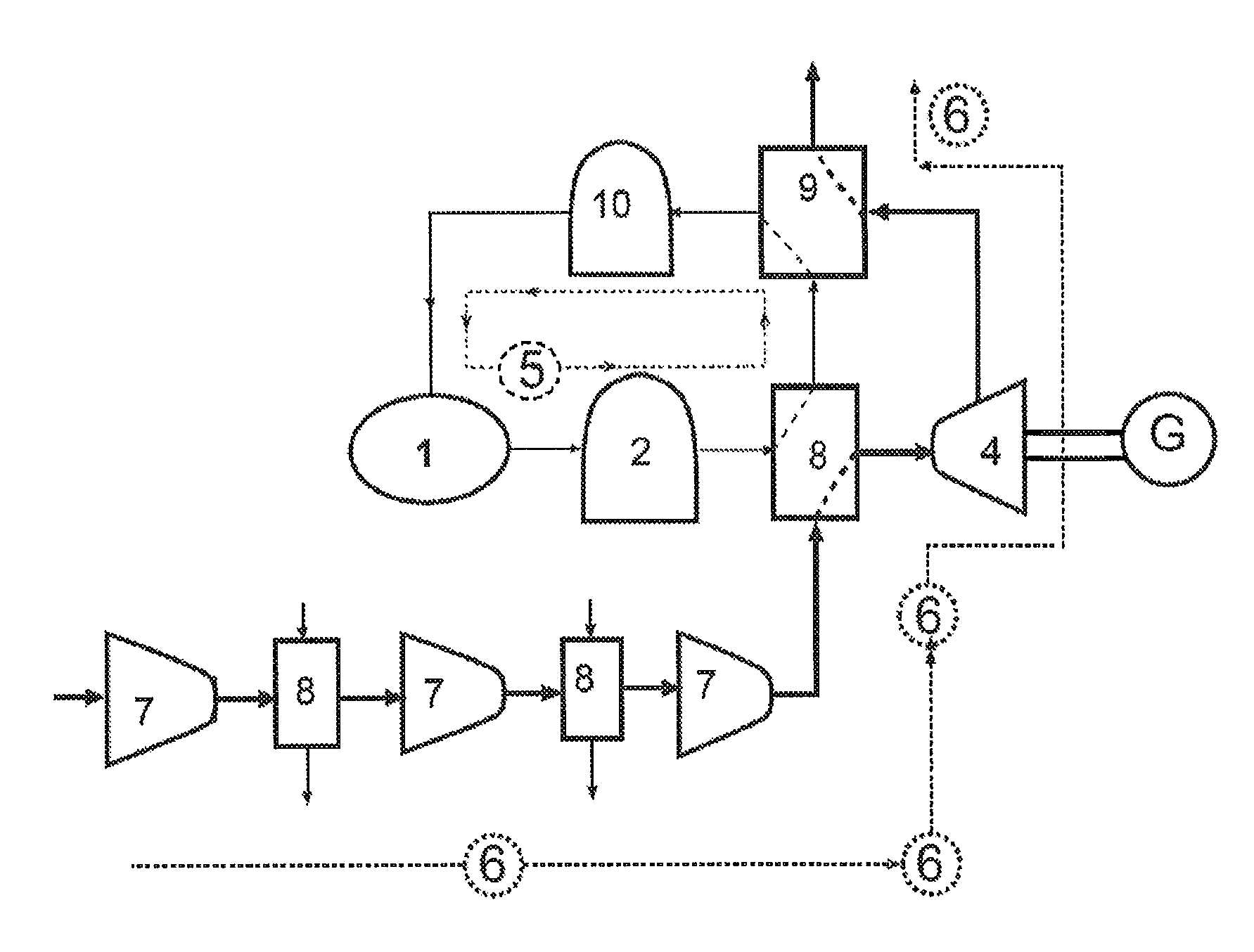

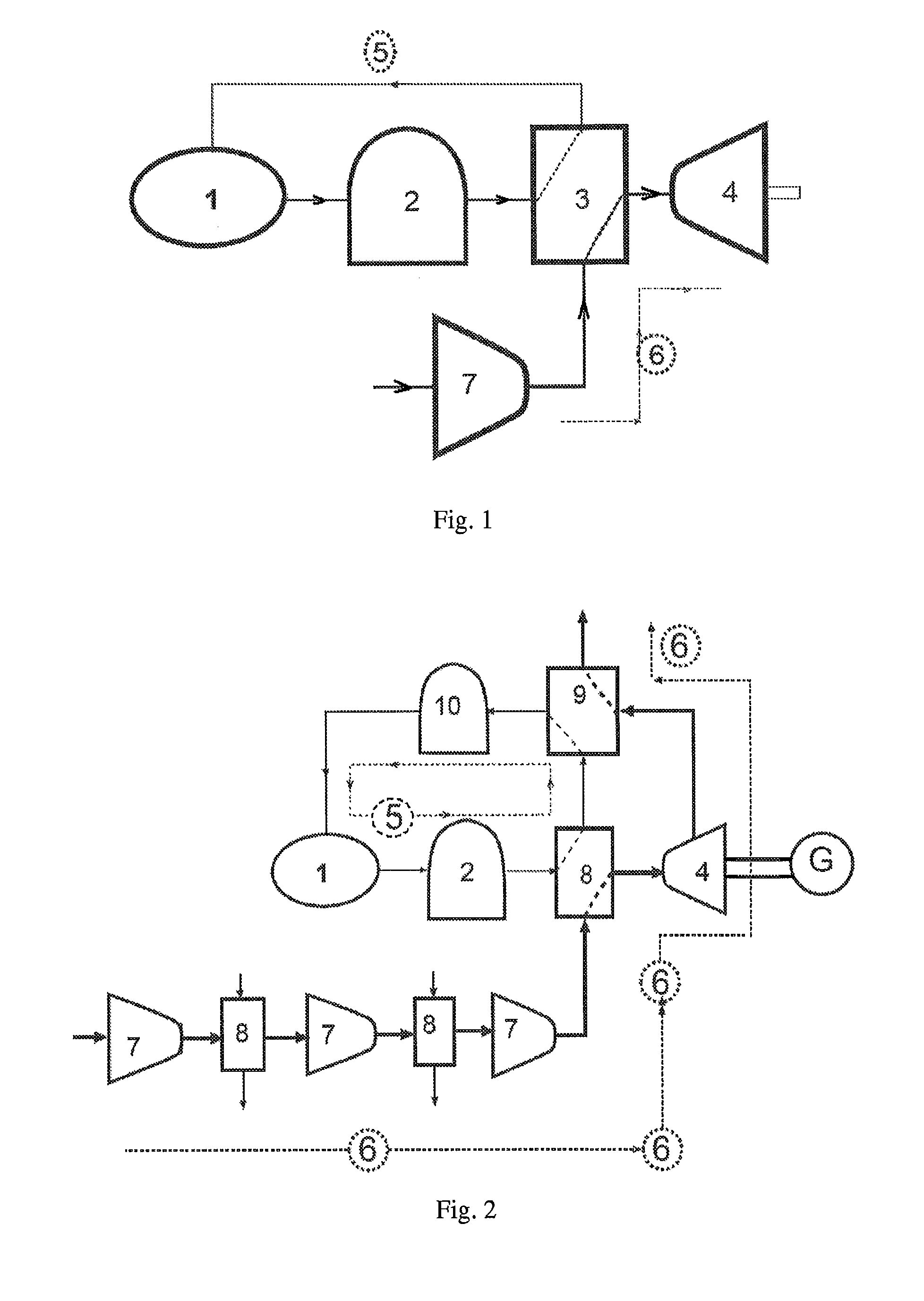

[0048]According to one aspect of the present invention, as shown in FIG. 1, it provides a method and system to generate steady, high temperature, and high pressure gas to drive turbines 4 for generating power or for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com