Complete equipment for stainless steel pickling wastewater treatment and resource recycling and treatment process

A technology for pickling wastewater and a complete set of devices is applied in the fields of metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

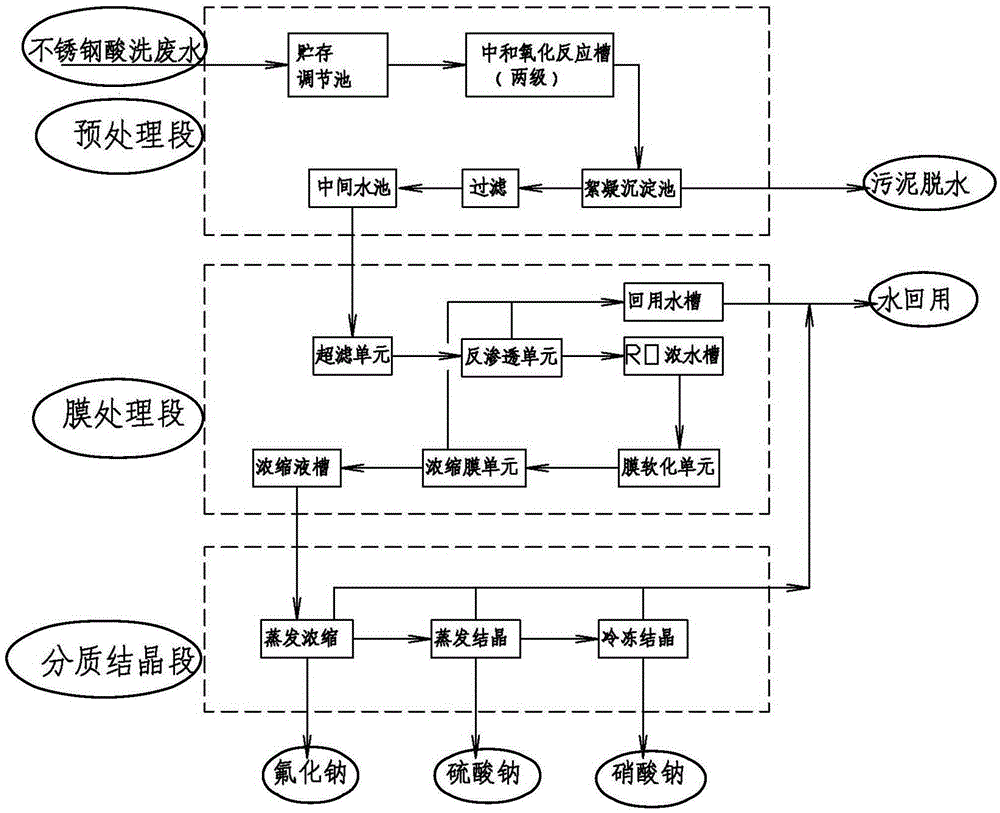

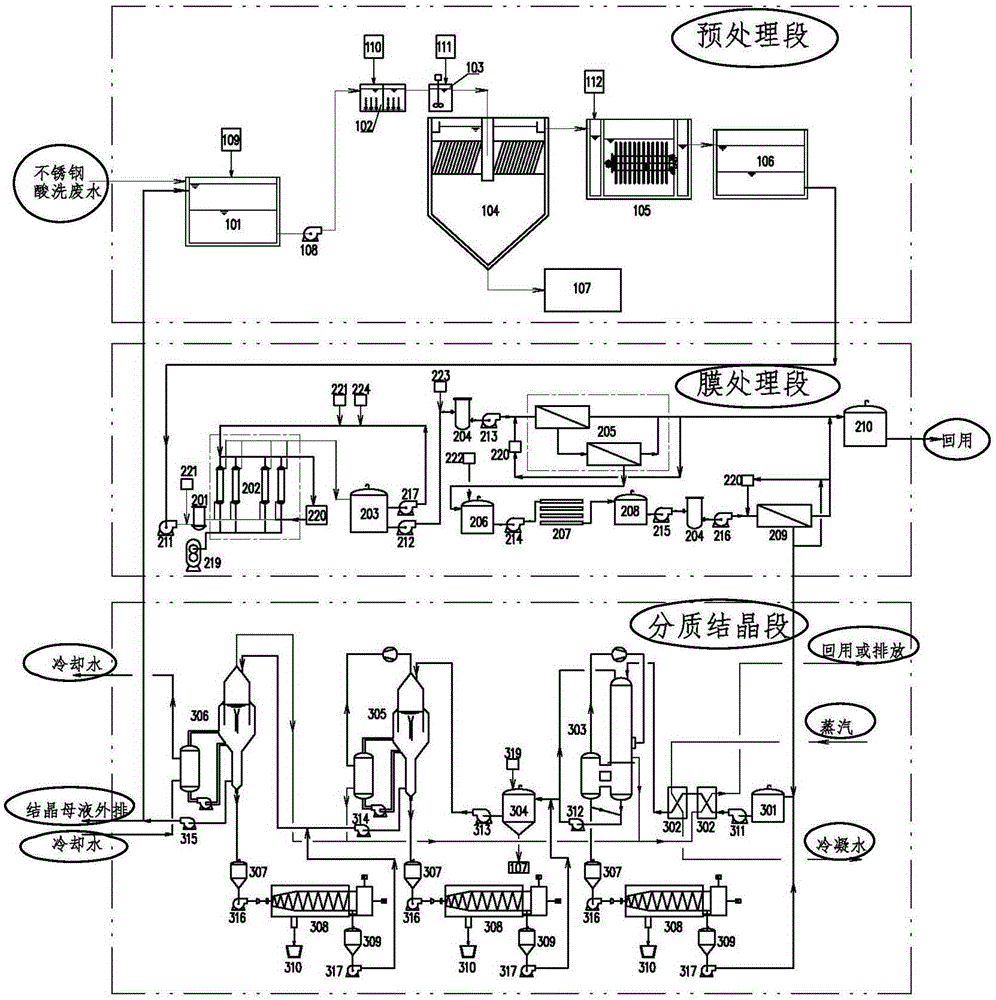

[0048] see figure 1 , figure 2 , this embodiment consists of a pretreatment section, a membrane treatment section, and a fractional crystallization section.

[0049] The pretreatment section includes: storage adjustment tank 101, neutralization oxidation reaction tank 102, flocculation reaction tank 103, sedimentation tank 104, filter 105, intermediate pool 106, sludge dehydration unit 107, adjustment tank lift pump 108, blower 109, hydrogen Sodium oxide dosing device 110 , polymer flocculant dosing device 111 , polyaluminum chloride dosing device 112 .

[0050] The membrane treatment section includes: self-cleaning filter 201, ultrafiltration device 202, ultrafiltration outlet tank 203, security filter 204, reverse osmosis device 205, reverse osmosis concentrated water tank 206, membrane softening device 207, concentration membrane water inlet tank 208, ...

Embodiment 2

[0080] The second embodiment is the same as the first embodiment, except that the filter 105 is a multimedia filter or a fiber rotary disk filter device. The concentrated membrane device 209 is a high-pressure reverse osmosis disc membrane or a vibrating membrane or a high-pressure forward osmosis membrane. The membrane softening device 207 is precipitation+ultrafiltration. The evaporative concentrator 303 is multi-effect evaporative concentration. The evaporation crystallizer 305 is a multi-effect evaporation crystallizer. The defluorination agent in the defluorination tank 304 is calcium chloride.

Embodiment 3

[0082] The present embodiment is the same as Embodiment 1, except that the sodium hydroxide dosing device 110 is a sodium hydroxide+calcium chloride (or lime) dosing device in the pretreatment, and a medicament softening agent is added after the intermediate pool 106 of the pretreatment section. Dosing device and reaction sedimentation tank, cancel the crystal separation system of sodium fluoride (sedimentation tank containing sodium fluoride crystal slurry, centrifuge feed pump, centrifuge, centrifuge mother liquor tank, crystal storage tank). A weak acid cation exchange device is added before the reverse osmosis device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com