Resource treatment method for lithium-rich aluminum electrolyte

The technology of an aluminum electrolyte and a treatment method is applied in the resource treatment of acidic lithium-rich aluminum electrolyte and the resource treatment of lithium-rich aluminum electrolyte, and can solve the problem of increased energy consumption, low efficiency of direct leaching of inorganic acid, low economic benefit, etc. problems, to achieve the effect of reducing alkali consumption, promoting stable production and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

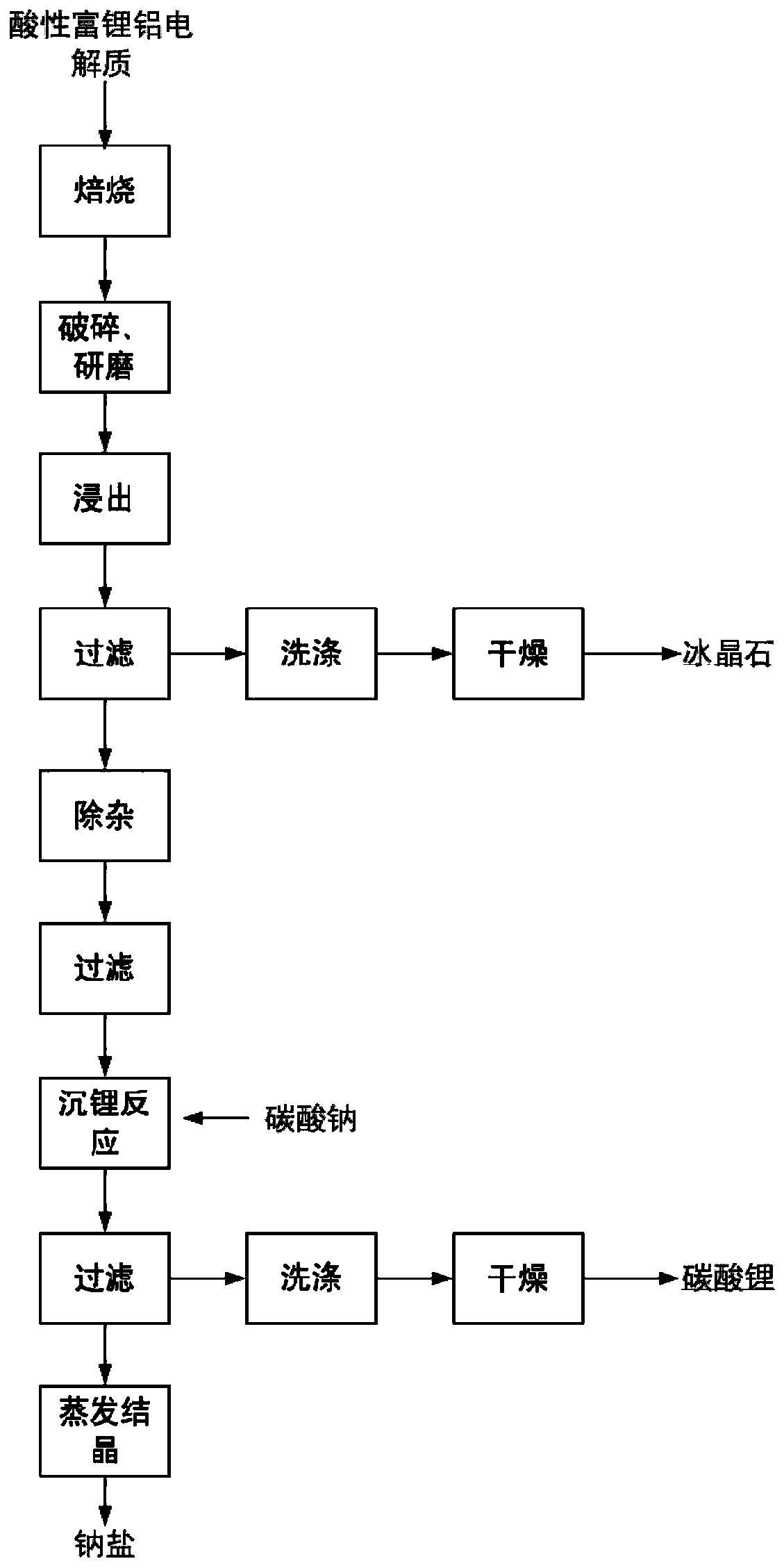

[0043] A method for reclaiming lithium from an acidic lithium-rich potassium electrolyte, the method specifically comprising the following steps:

[0044] Step 1: Broken 100g of the acidic lithium-rich aluminum electrolyte, heat-treated at 960°C for 2 hours to make the material molecular ratio 3.6, and obtained product A. Cool to room temperature, and crush the product A.

[0045] Step 2: Add the crushed product A to water to make a slurry, wherein the solid-to-liquid ratio is 1:15, add 40g of aluminum nitrate to a constant temperature magnetic stirrer at 50°C for leaching for 2 hours, and filter to obtain filtrate B and filter B.

[0046] Step 3: adding sodium hydroxide to the filtrate B to adjust the pH to 7, and filtering aluminum hydroxide after reacting for 10 minutes to obtain filtrate C.

[0047] Step 4: Add 15g of sodium carbonate to filtrate C, react for 20min, and filter to obtain 12.37g of lithium carbonate and filtrate D.

[0048] Step 5: The filtrate D is concentra...

Embodiment 2

[0050] A method for recovering lithium from an acidic lithium-rich aluminum electrolyte, the method specifically comprising the following steps:

[0051] Step 1: crush 100 g of the acidic lithium-rich aluminum electrolyte, conduct heat treatment at 960° C. for 2 hours, make the material molecular ratio 3.6, obtain product A, cool to room temperature, and crush product A.

[0052] Step 2: Add the broken roasted product A into water to make a slurry, wherein the solid-to-liquid ratio is 1:10, add 20g of sodium sulfate and 25g of aluminum sulfate octadecahydrate in a constant temperature magnetic stirrer at 50°C for leaching for 2 hours, and filter to obtain Filtrate B and filter residue B.

[0053] Step 3: Add sodium hydroxide to the filtrate B to adjust the pH to 7, filter the aluminum hydroxide after reacting for 10 minutes, and obtain the filtrate C.

[0054] Step 4: Add 17g of sodium carbonate to filtrate C, react for 20min, and filter to obtain filtrate D and 10.25g of lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com