Recycling method of lithium-rich aluminum electrolyte

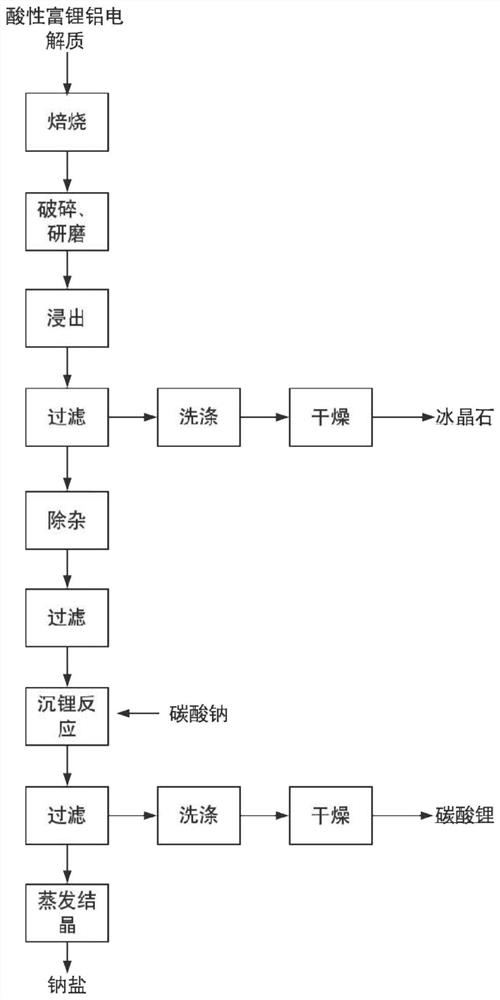

A technology of aluminum electrolyte and treatment method, which is applied in the field of recycling lithium-rich aluminum electrolytes and acidic lithium-rich aluminum electrolytes, and can solve the problems of increased energy consumption, low economic benefits, and low direct leaching efficiency of inorganic acids, etc. , to achieve the effect of reducing alkali consumption, high efficiency and promoting stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

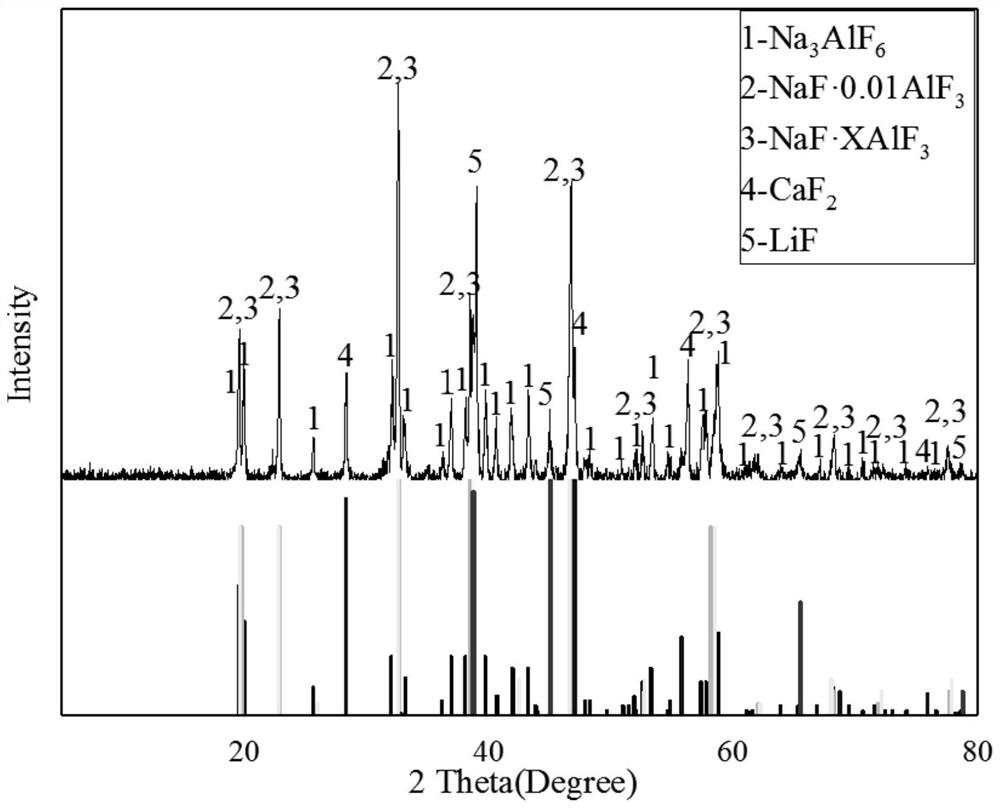

Embodiment 1

[0043] A method for reclaiming lithium from an acidic lithium-rich potassium electrolyte, the method specifically comprising the following steps:

[0044] Step 1: crush 100 g of acidic lithium-rich aluminum electrolyte, heat-treat at 960° C. for 2 hours, make the material molecular ratio 3.6, and obtain product A. Cool to room temperature, and crush product A.

[0045] Step 2: Add the crushed product A to water to make a slurry, wherein the solid-to-liquid ratio is 1:15, add 40g of aluminum nitrate to a constant temperature magnetic stirrer at 50°C for leaching for 2 hours, and filter to obtain filtrate B and filter B.

[0046] Step 3: adding sodium hydroxide to the filtrate B to adjust the pH to 7, and filtering aluminum hydroxide after reacting for 10 minutes to obtain filtrate C.

[0047] Step 4: Add 15g of sodium carbonate to filtrate C, react for 20min, and filter to obtain 12.37g of lithium carbonate and filtrate D.

[0048] Step 5: The filtrate D is concentrated and enri...

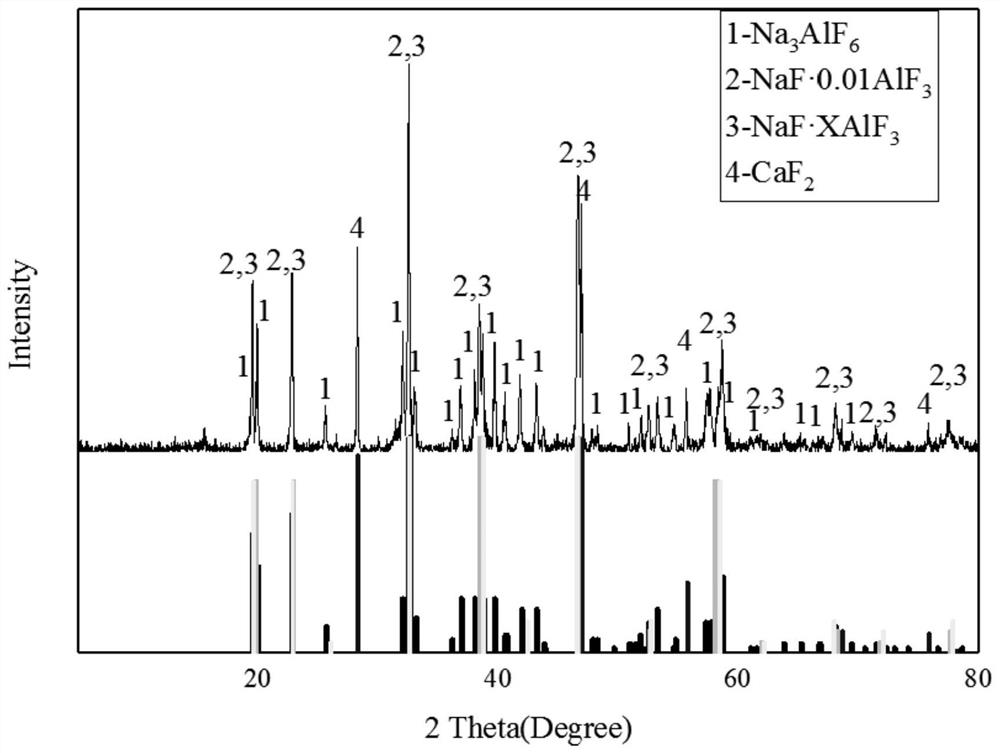

Embodiment 2

[0050] A method for recovering lithium from an acidic lithium-rich aluminum electrolyte, the method specifically comprising the following steps:

[0051] Step 1: crush 100 g of the acidic lithium-rich aluminum electrolyte, conduct heat treatment at 960° C. for 2 hours, make the material molecular ratio 3.6, obtain product A, cool to room temperature, and crush product A.

[0052] Step 2: Add the broken roasted product A into water to make a slurry, wherein the solid-to-liquid ratio is 1:10, add 20g of sodium sulfate and 25g of aluminum sulfate octadecahydrate in a constant temperature magnetic stirrer at 50°C for leaching for 2 hours, and filter to obtain Filtrate B and filter residue B.

[0053] Step 3: Add sodium hydroxide to the filtrate B to adjust the pH to 7, filter the aluminum hydroxide after reacting for 10 minutes, and obtain the filtrate C.

[0054] Step 4: Add 17g of sodium carbonate to filtrate C, react for 20min, and filter to obtain filtrate D and 10.25g of lit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com