Method for recycling dimethyl sulfoxide waste residue through multi-stage extraction

A technology of dimethyl sulfoxide and dimethyl sulfone, which is applied in the field of resource recovery and utilization of dimethyl sulfoxide production waste residues, can solve problems such as toxic and harmful waste residue pollution, achieve high recovery efficiency, solve production waste residue pollution problems, Effects that are easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The waste residue sample 1# used was taken from the waste residue produced by a dimethyl sulfoxide production facility in Xinjiang. The sample components were checked by laboratory tests:

[0025] component name Dimethyl sulfoxide Dimethyl sulfone total inorganic salt sodium nitrate sodium nitrite water percentage content 17% 20% 38% 28% 6% 25%

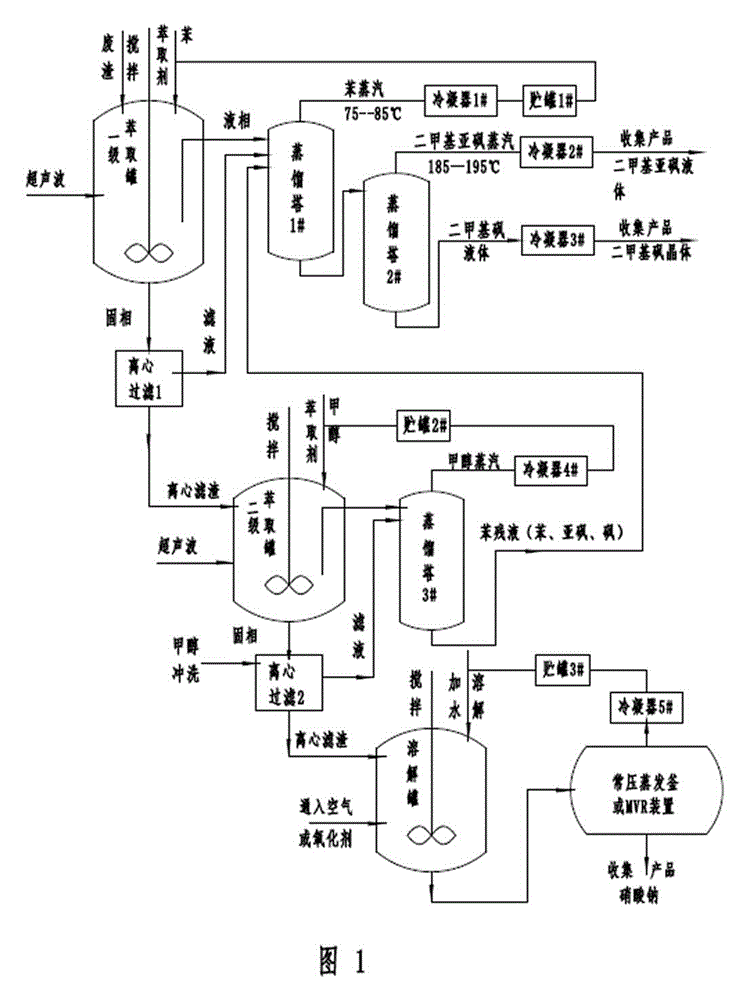

[0026] Put waste residue 1# and benzene into the primary extraction tank, operate according to the first process flow, and get benzene at the outlet of condenser 1# with a recovery rate of 95%. Dimethyl sulfoxide was obtained at the 2# outlet of the condenser, and the recovery rate was 96%. Dimethyl sulfone is obtained at the 3# outlet of the condenser, and the recovery rate is 98%. Sodium nitrate was obtained by dehydration and drying at the outlet of the atmospheric pressure evaporator, and the recovery rate was 99%. .

Embodiment 2

[0028] The waste residue sample 2# was taken from the waste residue produced by a dimethyl sulfoxide production facility in Guizhou. The sample components were checked by laboratory tests:

[0029] component name Dimethyl sulfoxide Dimethyl sulfone total inorganic salt sodium nitrate sodium nitrite water percentage content 8.4% 38.1% 45% 32% 8% 8.5%

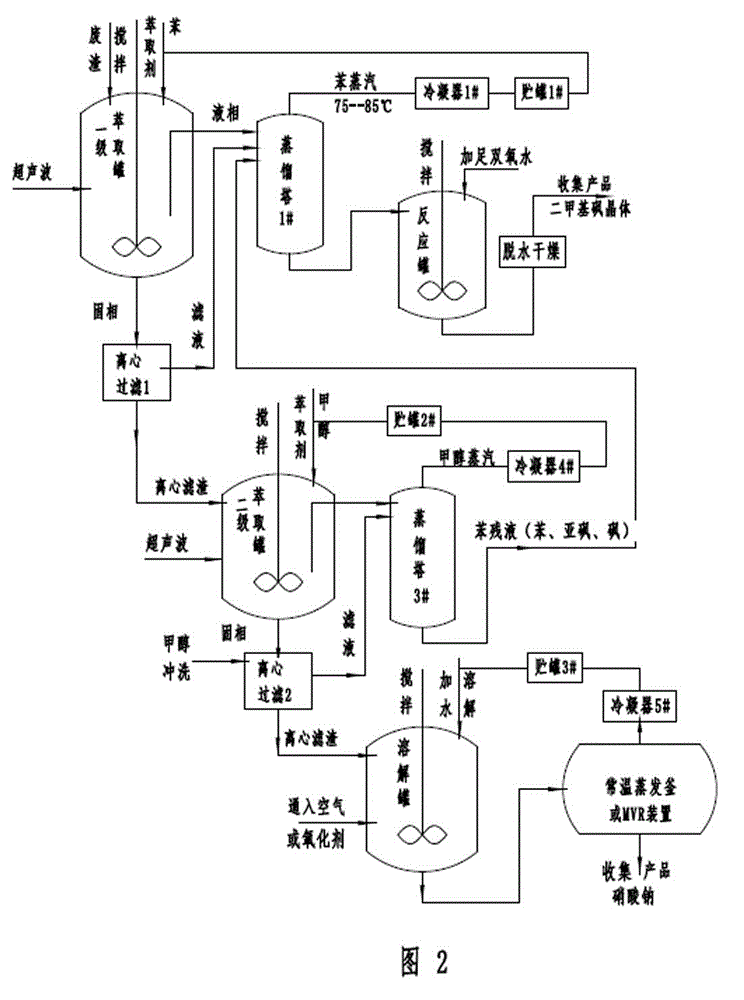

[0030] Put the waste residue 2# and benzene into the primary extraction tank, operate according to the second process flow, and the recovery rate of benzene at the outlet of condenser 1# is 95%. Dimethyl sulfone was obtained at the outlet of the drier after the reaction tank, and the recovery rate was 120% (containing the amount after the oxidation of dimethyl sulfoxide). Sodium nitrate was obtained by dehydration and drying at the outlet of the atmospheric pressure evaporator, and the recovery rate was 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com