Zero-emission sewage reutilization device and method

A resource-based, zero-emission technology, applied in the field of liquid zero discharge, can solve the problems of low salt recovery ratio, high operating cost, and large amount of chemical sludge, and achieve the reduction of solid waste, lower operating costs, and high salt purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

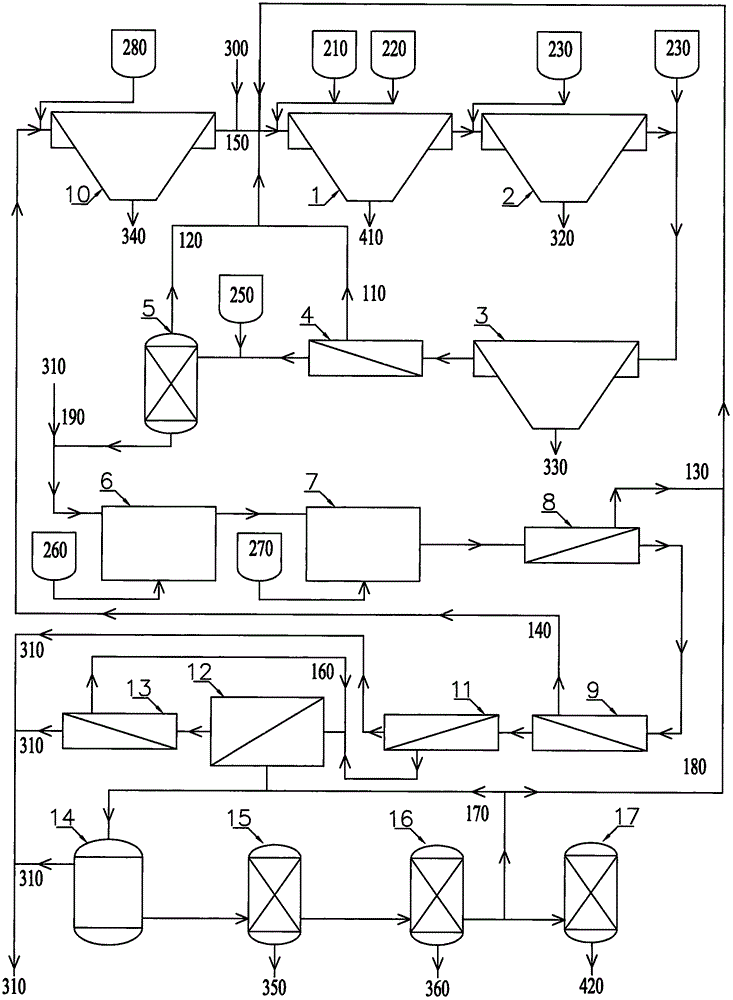

[0026] Such as figure 1 As shown, the zero-discharge treatment device for sewage recycling includes in turn a flocculant addition device (210), a coagulant addition device (220), a miscellaneous salt precipitation tank (1), a soda ash addition device (230), and a carbonic acid Calcium sedimentation tank (2), a caustic soda addition device (240), a magnesium hydroxide sedimentation tank (3), an acid addition device (250), a cation exchanger (5), an oxidant addition device (260), Oxidation contactor (6), a biofilm reactor (7) and a blower (270), a membrane filter B (8), a nanofiltration membrane separator (9), a brine concentrator (12), evaporation Crystallization device (14), heat separator (15), cold separator (16), mother liquor dryer (17); it also includes a cation exchanger (5) for returning the regeneration wastewater to the heterosalt precipitation tank (1) The cation exchanger regeneration wastewater return pipeline (120) of the cation exchanger, the membrane filter B wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com